ASTM D374-99

(Test Method)Standard Test Methods for Thickness of Solid Electrical Insulation

Standard Test Methods for Thickness of Solid Electrical Insulation

SCOPE

1.1 These test methods cover the determination of the thickness of several types of solid electrical insulating materials employing recommended techniques. Use these methods except as otherwise required by a material specification.

1.2 The values stated in inch-pound units are the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 374 – 99

Standard Test Methods for

Thickness of Solid Electrical Insulation

This standard is issued under the fixed designation D 374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

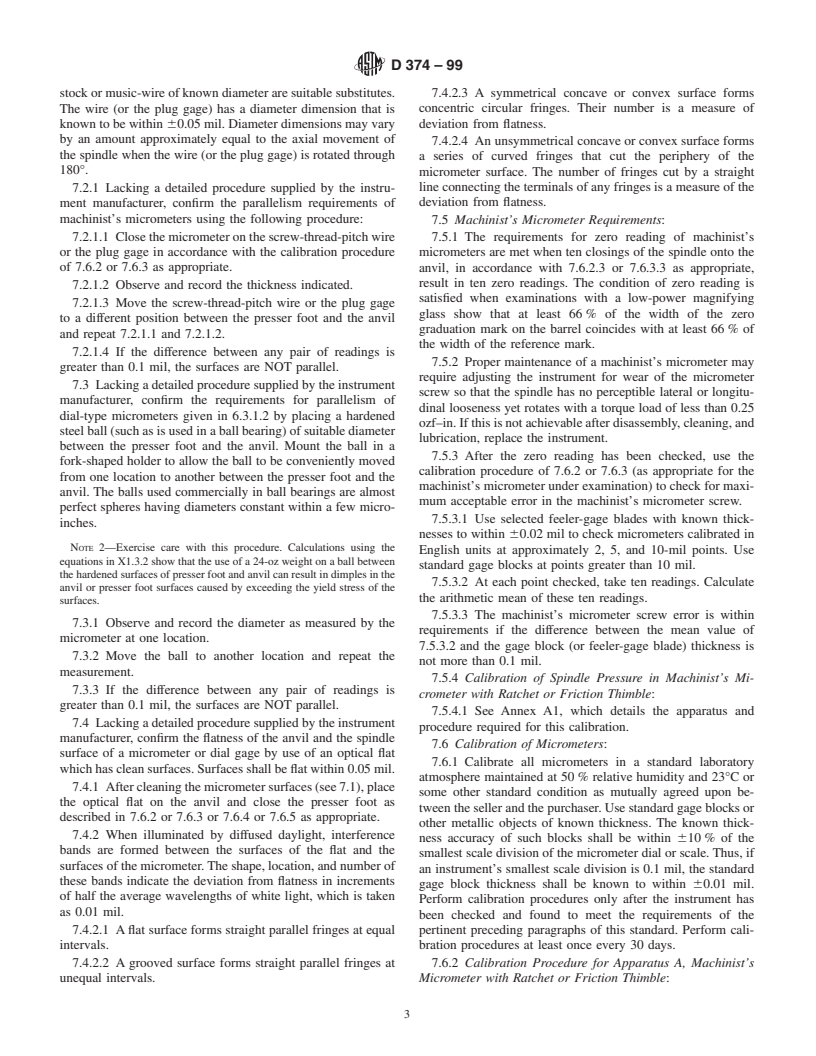

1. Scope H) employ different micrometers that exert various pressures

for varying times upon specimens of different geometries.

1.1 These test methods cover the determination of the

Table 1 and Table 2 display basic differences of each test

thickness of several types of solid electrical insulating materi-

method and identify methods applicable for use on various

als employing recommended techniques. Use these methods

categories of materials.

except as otherwise required by a material specification.

1.2 The values stated in inch-pound units are the standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 Some electrical properties, such as dielectric strength,

safety concerns, if any, associated with its use. It is the

vary with the thickness of the material. Determination of

responsibility of the user of this standard to establish appro-

certain properties, such as relative permittivity (dielectric

priate safety and health practices and determine the applica-

constant) and volume resistivity, usually require a knowledge

bility of regulatory limitations prior to use.

of the thickness. Design and construction of electrical machin-

2. Referenced Documents ery require that the thickness of insulation be known.

2.1 ASTM Standards:

6. Apparatus

D 1711 Terminology Relating to Electrical Insulation

6.1 Apparatus A— Machinist’s Micrometer Caliper with

D 6054 Practice for Conditioning Electrical Insulating Ma-

Calibrated Ratchet or Friction Thimble:

terials for Testing

6.1.1 ApparatusAis a micrometer caliper without a locking

E 252 Test Method for Thickness of Thin Foil and Film by

device but is equipped with either a calibrated ratchet or a

Weighing

friction thimble. By use of a proper manipulative procedure

3. Terminology and a calibrated spring (seeAnnexA1), the pressure exerted on

the specimen is controllable.

3.1 Refer toTerminology D 1711 for definitions pertinent to

6.1.2 Use an instrument constructed with a vernier capable

this standard.

of measurement to the nearest 0.1 mil.

3.2 Definitions of Terms Specific to This Standard:

6.1.3 Use an instrument with the diameter of the anvil and

3.2.1 1 mil, n—a dimension equivalent to 0.0010 in.

spindle surfaces (which contact the specimen) of 250 6 1 mil.

3.2.2 absolute uncertainty (of a measurement), n—the

6.1.4 Use an instrument conforming to the requirements of

smallest division that may be read directly on the instrument

7.1, 7.2, 7.5, 7.6.1, and 7.6.2.

used for measurement.

6.1.5 Periodically, test the micrometer for conformance to

3.2.3 micrometer, n—an instrument for measuring any di-

the requirements of 6.1.4.

mension with absolute uncertainty of 1 mil or smaller.

6.2 Apparatus B—Machinist’s Micrometer Without a

4. Summary of Test Methods

Ratchet:

6.2.1 Apparatus B is a micrometer caliper without a locking

4.1 This standard provides eight different test methods for

device.

the measurement of thickness of solid electrical insulation

6.2.2 Use an instrument constructed with a vernier capable

materials. The test methods (identified as Methods A through

of measurement to the nearest 0.1 mil.

6.2.3 Use an instrument with the diameter of the anvil and

spindle surfaces (which contact the specimen) 250 6 1 mil.

These test methods are under the jurisdiction of ASTM Committee D-9 on

Electrical and Electronic Insulating Materials and are the direct responsibility of 6.2.4 Use an instrument conforming to the requirements of

Subcommittee D09.12 on Electrical Tests.

7.1, 7.2, 7.5.1, 7.5.2, 7.5.3, 7.6.1, and 7.6.3.

Current edition approved March 10, 1999. Published June 1999. Originally

published as D 374 – 33T. Last previous edition D 374 – 94.

Annual Book of ASTM Standards, Vol 10.01

Annual Book of ASTM Standards, Vol 10.02.

4 5

Annual Book of ASTM Standards, Vol 02.02. Hereinafter referred to as a machinist’s micrometer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D374–99

TABLE 1 Methods Suitable for Specific Materials

6.3.2 The preferred design and construction of manually

Material Method operated dead-weight dial-type micrometers calls for a limit on

the force applied to the presser foot. The limit is related to the

Plastic sheet and film A B C or D

Paper (all thicknesses) E

compressive characteristics of the material being measured.

Paper (over 2 mils thickness) F or G

6.3.2.1 The force applied to the presser foot spindle and the

Rubber and other elastomers H

weight necessary to move the pointer upward from the zero

position shall be less than the force that will cause permanent

deformation of the specimen. The force applied to the presser

TABLE 2 Method Parameter Differences

footspindleandtheweightnecessarytojustpreventmovement

Diameter of Pressure on

Presser Foot Specimen, of the pointer from a higher to a lower reading shall be more

Method Apparatus

or Spindle, approximate,

than the minimum permissible force specified for a specimen.

mils PSI

6.4 Apparatus D—Motor-Operated Dead-Weight Dial

A Machinist micrometer with 250 not specified

Gage:

calibrated ratchet or

6.4.1 Except as additionally defined in this section, use an

thimble

B Machinist micrometer 250 unknown

instrument that conforms to the requirements of 6.3. An

without ratchet/thimble

electronic instrument having a digital readout in place of the

C Dead-weight dial type 125 to 500 0.5 to 130

dial indicator is permitted if that instrument meets the other

bench micrometer—Manual

D Dead-weight dial type 125 to 500 0.5 to 130

requirements of 6.3 and 6.4.

bench micrometer—Motor

6.4.2 Use a motor operated instrument having a presser foot

operated

spindle that is lifted and lowered by a constant speed motor

E Dead-weight dial type 250 25

bench micrometer—Motor

through a mechanical linkage such that the rate of descent (for

operated

a specified range of distances between the presser foot surface

F Dead-weight dial type 250 25

bench micrometer—Manual and the anvil) and the dwell time on the specimen are within

G Machinist micrometer with 250 25

thelimitsspecifiedforthematerialbeingmeasured.Designthe

calibrated ratchet or

mechanical linkage so that the only downward force upon the

thimble

H Dead-weight dial type 250 4 presserfootspindleisthatofgravityupontheweightedspindle

bench micrometer—Manual

assembly without any additional force exerted by the lifting/

lowering mechanism.

6.4.2.1 The preferred design and construction of motor

operated dead-weight dial-type micrometers calls for a limit on

6.2.5 Periodically, examine and test the micrometer for

the force applied to the presser foot. The limit is related to the

conformance to the requirements of 6.2.4.

compressive characteristics of the material being measured.

6.3 Apparatus C— Manually-Operated, Dead-Weight, Dial

6 6.4.2.2 The force applied to the presser foot spindle and the

Type Thickness Gage:

weight necessary to move the pointer upward from the zero

6.3.1 Use a dead-weight dial-type gage in accordance with

position shall be less than the force that will cause permanent

the requirements of 7.1, 7.3, 7.4, 7.6.1, 7.6.4, that has:

deformation of the specimen. The force applied to the presser

6.3.1.1 Apresser foot that moves in an axis perpendicular to

footspindleandtheweightnecessarytojustpreventmovement

the anvil face,

of the pointer from a higher to a lower reading must be more

6.3.1.2 The surfaces of the presser foot and the anvil (which

than the minimum permissible force specified for a specimen.

contact the specimen) parallel to within 0.1 mil (see 7.3),

6.3.1.3 A vertical dial spindle,

7. Calibration (General Considerations for Care and Use

6.3.1.4 Adial indicator essentially friction-free and capable

of Each of the Various Pieces of Apparatus for

of repeatable readings within 60.05 mil at zero setting, or on

Thickness Measurements)

a steel gage block,

7.1 Good testing practices require clean anvil and presser

6.3.1.5 A frame, housing the indicator, of such rigidity that

foot surfaces for any micrometer instrument. Prior to calibra-

a load of 3 lbf applied to the dial housing, out of contact with

tion or thickness measurements, clean such surfaces by insert-

the presser foot spindle (or any weight attached thereto) will

ing a piece of smooth, clean bond paper between the anvil and

produce a deflection of the frame not greater than the smallest

thepresserfootandslowlymovingthebondpaperbetweenthe

scale division on the indicator dial, and,

surfaces. During measurements, check the zero setting fre-

6.3.1.6 Adial diameter at least 2 in. and graduated continu-

quently. Failure to repeat the zero setting may be evidence of

ously to read directly to the nearest 0.1 mil. If necessary, equip

dirt on the surfaces.

the dial with a revolution counter that displays the number of

complete revolutions of the large hand.

NOTE 1—Avoid pulling any edge of the bond paper between the

6.3.1.7 An electronic instrument having a digital readout in

surfaces to reduce the probability of depositing any lint particles on the

place of the dial indicator is permitted if that instrument meets

surfaces.

the other requirements of 6.3.

7.2 The parallelism requirements for machinist’s microme-

ters demand that observed differences of readings on a pair of

screw-thread-pitch wires or a pair of standard 250-mil nominal

Herein referred to as a dial gage. diameter plug gages be not greater than 0.1 mil. Spring-wire

D374–99

stock or music-wire of known diameter are suitable substitutes. 7.4.2.3 A symmetrical concave or convex surface forms

The wire (or the plug gage) has a diameter dimension that is concentric circular fringes. Their number is a measure of

known to be within 60.05 mil. Diameter dimensions may vary deviation from flatness.

by an amount approximately equal to the axial movement of

7.4.2.4 An unsymmetrical concave or convex surface forms

the spindle when the wire (or the plug gage) is rotated through

a series of curved fringes that cut the periphery of the

180°.

micrometer surface. The number of fringes cut by a straight

line connecting the terminals of any fringes is a measure of the

7.2.1 Lacking a detailed procedure supplied by the instru-

deviation from flatness.

ment manufacturer, confirm the parallelism requirements of

machinist’s micrometers using the following procedure: 7.5 Machinist’s Micrometer Requirements:

7.2.1.1 Closethemicrometeronthescrew-thread-pitchwire 7.5.1 The requirements for zero reading of machinist’s

or the plug gage in accordance with the calibration procedure

micrometers are met when ten closings of the spindle onto the

of 7.6.2 or 7.6.3 as appropriate. anvil, in accordance with 7.6.2.3 or 7.6.3.3 as appropriate,

result in ten zero readings. The condition of zero reading is

7.2.1.2 Observe and record the thickness indicated.

satisfied when examinations with a low-power magnifying

7.2.1.3 Move the screw-thread-pitch wire or the plug gage

glass show that at least 66 % of the width of the zero

to a different position between the presser foot and the anvil

graduation mark on the barrel coincides with at least 66 % of

and repeat 7.2.1.1 and 7.2.1.2.

the width of the reference mark.

7.2.1.4 If the difference between any pair of readings is

7.5.2 Proper maintenance of a machinist’s micrometer may

greater than 0.1 mil, the surfaces are NOT parallel.

require adjusting the instrument for wear of the micrometer

7.3 Lacking a detailed procedure supplied by the instrument

screw so that the spindle has no perceptible lateral or longitu-

manufacturer, confirm the requirements for parallelism of

dinal looseness yet rotates with a torque load of less than 0.25

dial-type micrometers given in 6.3.1.2 by placing a hardened

ozf–in.Ifthisisnotachievableafterdisassembly,cleaning,and

steel ball (such as is used in a ball bearing) of suitable diameter

lubrication, replace the instrument.

between the presser foot and the anvil. Mount the ball in a

7.5.3 After the zero reading has been checked, use the

fork-shaped holder to allow the ball to be conveniently moved

calibration procedure of 7.6.2 or 7.6.3 (as appropriate for the

from one location to another between the presser foot and the

machinist’s micrometer under examination) to check for maxi-

anvil. The balls used commercially in ball bearings are almost

mum acceptable error in the machinist’s micrometer screw.

perfect spheres having diameters constant within a few micro-

7.5.3.1 Use selected feeler-gage blades with known thick-

inches.

nesses to within 60.02 mil to check micrometers calibrated in

NOTE 2—Exercise care with this procedure. Calculations using the

English units at approximately 2, 5, and 10-mil points. Use

equations in X1.3.2 show that the use of a 24-oz weight on a ball between

standard gage blocks at points greater than 10 mil.

the hardened surfaces of presser foot and anvil can result in dimples in the

7.5.3.2 At each point checked, take ten readings. Calculate

anvil or presser foot surfaces caused by exceeding the yield stress of the

the arithmetic mean of these ten readings.

surfaces.

7.5.3.3 The machinist’s micrometer screw error is within

7.3.1 Observe and record the diameter as measured by the

requirements if the difference between the mean value of

micrometer at one location.

7.5.3.2 and the gage block (or feeler-gage blade) thickness is

7.3.2 Move the ball to another location and repeat the

not more than 0.1 mil.

measurement.

7.5.4 Calibration of Spindle Pressure in Machinist’s Mi-

7.3.3 If the difference between any pair of readings is

crometer with Ratchet or Friction Thimble:

greater than 0.1 mil, the surfaces are NOT parallel.

7.5.4.1 See Annex A1, which details the apparatus and

7.4 Lacking a detailed procedure supplied by the instrument

procedure required for this calibration.

manufacturer, confirm the flatness of the anvil and the spindle

7.6 Calibration of Micrometers:

surface of a micrometer or dial gage by use of an optical flat

7.6.1 Calibrate all micrometers in a standard laboratory

whichhascleansurfaces.Surfacesshallbeflatwithin0.05mil.

atmosphere maintained at 50 % relative humidity and 23°C or

7.4.1 Aftercleaningthemicrometersurfaces(see7.1),place

some other sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.