ASTM D3376-14

(Test Method)Standard Test Methods of Sampling and Testing Pulps to be Used in the Manufacture of Electrical Insulation

Standard Test Methods of Sampling and Testing Pulps to be Used in the Manufacture of Electrical Insulation

SIGNIFICANCE AND USE

8.1 The conductivity of the water extract of electrical grade pulp results from electrolytic impurities in the pulp potentially present as ionizable acids, bases, salts, or a combination of these. The presence of electrolytic impurities in electrical insulation is undesirable as they tend to lower insulation resistance and have corrosion-producing tendencies under conditions of applied potential. When comparing test data, note that the extract conductivity of pulps, especially those of high purity, changes with time after manufacturing in some instances. This test is useful for routine acceptance testing, the comparison of different pulps, and research work.6

SCOPE

1.1 These test methods cover the sampling and testing of cellulosic pulps for use in the manufacture of electrical insulating papers and boards or in the direct application of pulp fibers as insulation to electrical conductors.

Note 1: The significance of any one pulp property test method, as set forth herein, should be considered with discretion depending on the product made from the pulp.

1.2 Sections on Reagents, Sampling, and Report are integral parts of each of the individual test methods that follow.

1.3 Each test method is described as being a measure of either a bulk property of the pulp or a property of a handsheet formed from the pulp.

1.3.1 Bulk characteristics determinable by these procedures appear in the following sections:

Procedure

Sections

ASTM

Method

Reference

TAPPI

Method

Reference

Aqueous Extract Conductivity

8 and 9

D202

...

Aqueous Extract pH

10 and 11

D202

...

Aqueous Extractable

Acidity-Alkalinity

12 and 13

D202

...

Analysis of Ash for Cations by Atomic Absorption Spectro-

photometry

70 – 78

D1193 and D2576

...

Ash Content

79 – 82

D202

T 413

Dirt in Pulp

40 and 41

...

T 213

Fiber Analysis

23 and 24

D202 and D1030

...

Fiber Length of Pulp

42 and 43

...

T 232, T 233

Freeness (Canadian Standard Freeness)

53 and 54

...

T 227

Kappa Number/Permanganate Number (Substances

Oxidizable by Permanga-

nate)

27 and 28

...

T 236, UM 251

Laboratory Processing of Pulp (Beater Method)

51 and 52

...

T 200

Moisture in Pulp

31 – 33

...

T 210

Neutral Aqueous Extractable Hardness in Pulp

16 – 22

D202, D1126, and D2576

...

Pentosan Content of Pulp

29 and 30

...

T 223

Resistance of Pulp to

Disintegration (Standard

RPG)

44 – 50

...

T 239, UM 252

Shive Count

34 – 39

...

...

Solvent-Soluble Matter in Pulp

25 and 26

D202

...

Tensile Properties

65 – 69

D202

...

Water-Extractable Chlorides

14 and 15

D202

...

1.3.2 Handsheet characteristics determinable by these procedures appear in the following sections:

Procedure

Section

ASTM

Method

Reference

TAPPI

Method

Reference

Air Resistance (Porosity)

57 and 58

D202

T 205

Apparent Density

63 and 64

D202

T 205

Bursting Strength

59 and 60

D202 and D774/D774M

T 205

Folding Endurance (M.I.T.)

51 and 52

D202 and D2176

T 205

Forming Handsheets for Physical Tests of Pulp

55 and 56

...

T 205

Tensile Strength

65 and 66

D202 and D828

T 205

Note 2: Methods for Ash, Silica, selected cations from Ash, Heat Stability, α, β, and γ Cellulose, Viscosity, Total Chlorine, Tear, and Dissipation Factor and Relative Permittivity, will be considered for addition as methods are developed.

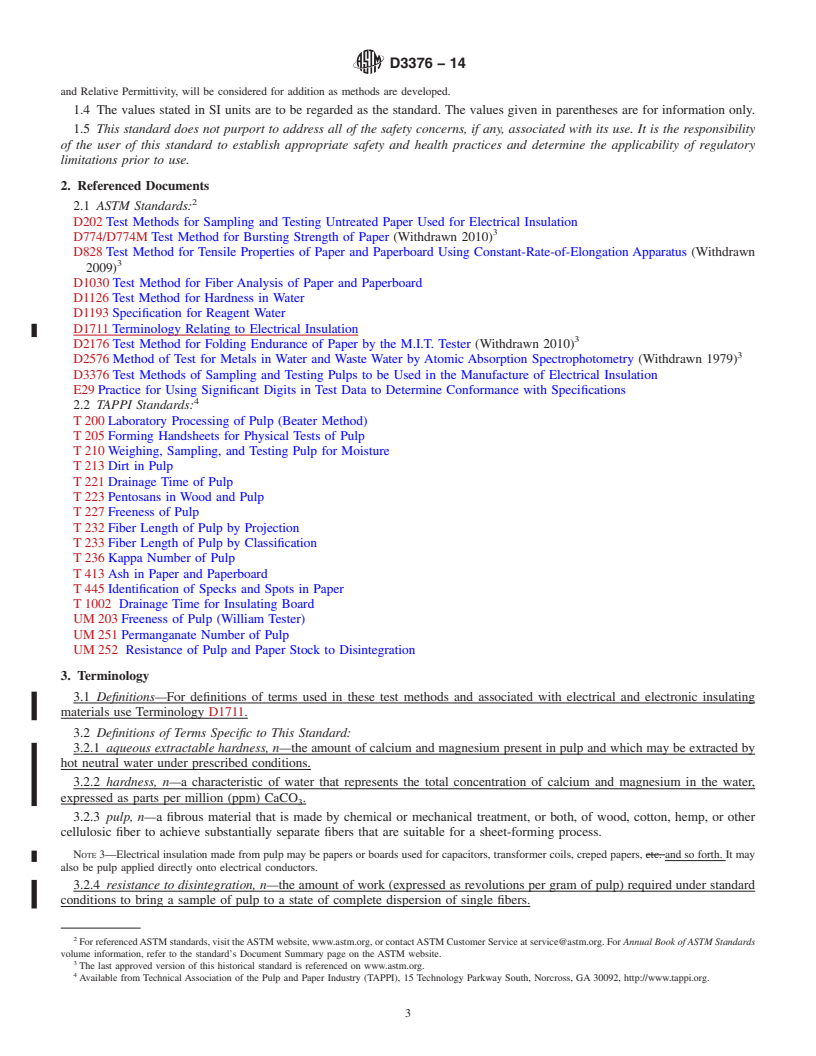

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropri...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3376 − 14

Standard Test Methods of

Sampling and Testing Pulps to be Used in the Manufacture

1

of Electrical Insulation

This standard is issued under the fixed designation D3376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

Pentosan Content of Pulp 29 and 30 . T 223

Resistance of Pulp to 44–50 . T 239, UM 252

1.1 These test methods cover the sampling and testing of

Disintegration (Standard

cellulosic pulps for use in the manufacture of electrical RPG)

Shive Count 34–39 . .

insulatingpapersandboardsorinthedirectapplicationofpulp

Solvent-Soluble Matter in Pulp 25 and 26 D202 .

fibers as insulation to electrical conductors.

Tensile Properties 65 – 69 D202 .

Water-Extractable Chlorides 14 and 15 D202 .

NOTE 1—The significance of any one pulp property test method, as set

forth herein, should be considered with discretion depending on the

1.3.2 Handsheet characteristics determinable by these pro-

product made from the pulp.

cedures appear in the following sections:

1.2 SectionsonReagents,Sampling,andReportareintegral

ASTM TAPPI

parts of each of the individual test methods that follow. Method Method

Procedure Section Reference Reference

1.3 Each test method is described as being a measure of

Air Resistance (Porosity) 57 and 58 D202 T 205

either a bulk property of the pulp or a property of a handsheet

Apparent Density 63 and 64 D202 T 205

formed from the pulp.

Bursting Strength 59 and 60 D202 and D774/ T 205

1.3.1 Bulk characteristics determinable by these procedures

D774M

Folding Endurance (M.I.T.) 51 and 52 D202 and D2176 T 205

appear in the following sections:

Forming Handsheets for 55 and 56 . T 205

ASTM TAPPI

Physical Tests of Pulp

Method Method

Tensile Strength 65 and 66 D202 and D828 T 205

Procedure Sections Reference Reference

NOTE 2—Methods for Ash, Silica, selected cations from Ash, Heat

Aqueous Extract Conductivity 8 and 9 D202 .

Stability, α, β, and γ Cellulose, Viscosity, Total Chlorine, Tear, and

Aqueous Extract pH 10 and 11 D202 .

Dissipation Factor and Relative Permittivity, will be considered for

Aqueous Extractable 12 and 13 D202 .

addition as methods are developed.

Acidity-Alkalinity

Analysis of Ash for Cations by 70 – 78 D1193 and D2576 .

1.4 The values stated in SI units are to be regarded as the

Atomic Absorption Spectro-

photometry

standard. The values given in parentheses are for information

Ash Content 79 – 82 D202 T 413

only.

Dirt in Pulp 40 and 41 . T 213

Fiber Analysis 23 and 24 D202 and D1030 .

1.5 This standard does not purport to address all of the

Fiber Length of Pulp 42 and 43 . T 232, T 233

Freeness (Canadian Standard 53 and 54 . T 227 safety concerns, if any, associated with its use. It is the

Freeness)

responsibility of the user of this standard to establish appro-

Kappa Number/Permanganate 27 and 28 . T 236, UM 251

priate safety and health practices and determine the applica-

Number (Substances

Oxidizable by Permanga-

bility of regulatory limitations prior to use.

nate)

Laboratory Processing of Pulp 51 and 52 . T 200

2. Referenced Documents

(Beater Method)

Moisture in Pulp 31–33 . T 210

2

Neutral Aqueous Extractable 16 – 22 D202, D1126, and . 2.1 ASTM Standards:

Hardness in Pulp D2576

D202Test Methods for Sampling and Testing Untreated

Paper Used for Electrical Insulation

1

These test methods are under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and are the direct responsibility of

2

Subcommittee D09.01 on Electrical Insulating Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1975. Last previous edition approved in 2009 as D3376–88(2009). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3376–14. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3376 − 14

NOTE3—Electricalinsulationmadefrompulpmaybepapersorboards

D774/D774MTest Method for Bursting Strength of Paper

3

used for capacitors, transformer coils, creped papers, and so forth. It may

(Withdrawn 2010)

also be pulp applied directly onto electrical conductors.

D828Test Method for Tensile Properties of Paper and

3.2.4 resistance to disintegration, n—the amount of work

Pape

...

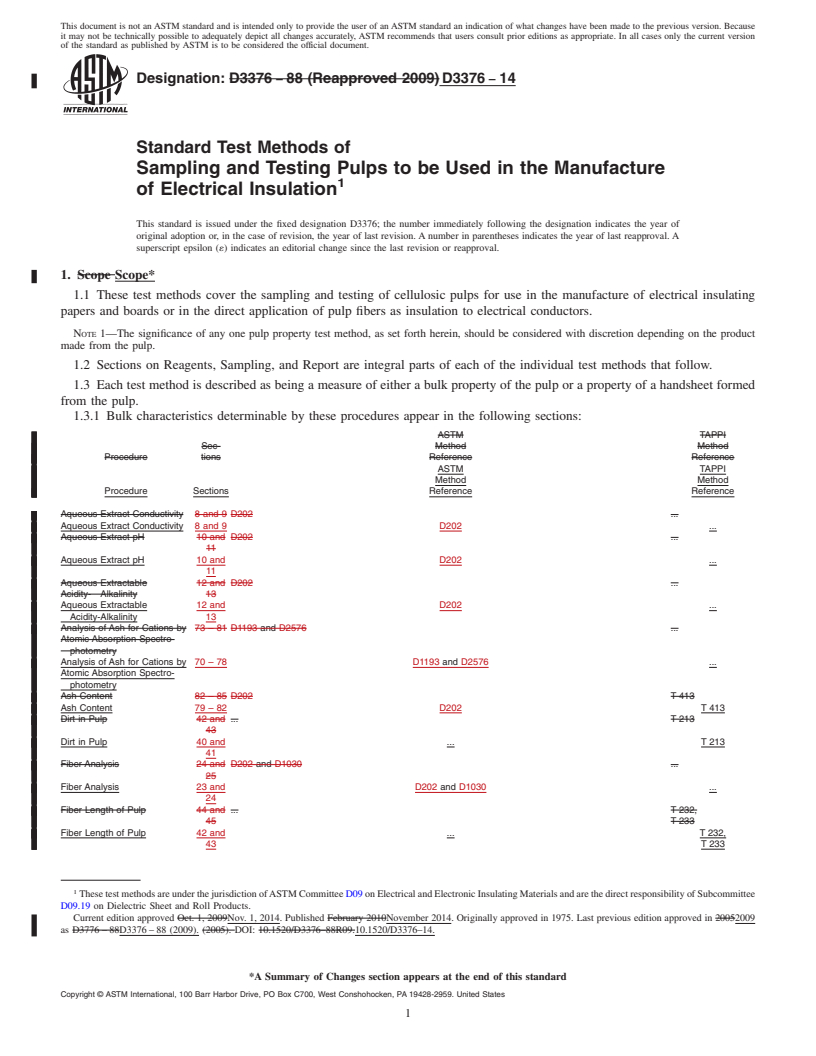

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3376 − 88 (Reapproved 2009) D3376 − 14

Standard Test Methods of

Sampling and Testing Pulps to be Used in the Manufacture

1

of Electrical Insulation

This standard is issued under the fixed designation D3376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 These test methods cover the sampling and testing of cellulosic pulps for use in the manufacture of electrical insulating

papers and boards or in the direct application of pulp fibers as insulation to electrical conductors.

NOTE 1—The significance of any one pulp property test method, as set forth herein, should be considered with discretion depending on the product

made from the pulp.

1.2 Sections on Reagents, Sampling, and Report are integral parts of each of the individual test methods that follow.

1.3 Each test method is described as being a measure of either a bulk property of the pulp or a property of a handsheet formed

from the pulp.

1.3.1 Bulk characteristics determinable by these procedures appear in the following sections:

ASTM TAPPI

Sec- Method Method

Procedure tions Reference Reference

ASTM TAPPI

Method Method

Procedure Sections Reference Reference

Aqueous Extract Conductivity 8 and 9 D202 .

Aqueous Extract Conductivity 8 and 9 D202 .

Aqueous Extract pH 10 and D202 .

11

Aqueous Extract pH 10 and D202 .

11

Aqueous Extractable 12 and D202 .

Acidity- Alkalinity 13

Aqueous Extractable 12 and D202 .

Acidity-Alkalinity 13

Analysis of Ash for Cations by 73 – 81 D1193 and D2576 .

Atomic Absorption Spectro-

photometry

Analysis of Ash for Cations by 70 – 78 D1193 and D2576 .

Atomic Absorption Spectro-

photometry

Ash Content 82 – 85 D202 T 413

Ash Content 79 – 82 D202 T 413

Dirt in Pulp 42 and . T 213

43

Dirt in Pulp 40 and . T 213

41

Fiber Analysis 24 and D202 and D1030 .

25

Fiber Analysis 23 and D202 and D1030 .

24

Fiber Length of Pulp 44 and . T 232,

45 T 233

Fiber Length of Pulp 42 and . T 232,

43 T 233

1

These test methods are under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and are the direct responsibility of Subcommittee

D09.19 on Dielectric Sheet and Roll Products.

Current edition approved Oct. 1, 2009Nov. 1, 2014. Published February 2010November 2014. Originally approved in 1975. Last previous edition approved in 20052009

as D3776 – 88D3376 – 88 (2009). (2005). DOI: 10.1520/D3376–88R09.10.1520/D3376–14.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3376 − 14

Freeness (Canadian Standard 56 and . T 227

Freeness) 57

Freeness (Canadian Standard 53 and . T 227

Freeness) 54

Kappa Number/Permanganate 28 and . T 236,

Number (Substances 29 UM 251

Oxi dizable by Permangan-

ate)

Kappa Number/Permanganate 27 and . T 236,

Number (Substances 28 UM 251

Oxidizable by Permanga-

nate)

Laboratory Processing of Pulp 54 and . T 200

(Beater Method) 55

Laboratory Processing of Pulp 51 and . T 200

(Beater Method) 52

Moisture in Pulp 32 – 34 . T 210

Moisture in Pulp 31 – 33 . T 210

Neutral Aqueous Extractable 16 – 23 D202, D1126, and .

Hardness in Pulp D2576

Neutral Aqueous Extractable 16 – 22 D202, D1126, and .

Hardness in Pulp D2576

Pentosan Content of Pulp 30 and . T 223

31

Pentosan Content of Pulp 29 and . T 223

30

Resistance of Pulp to 46 – 53 . T 239,

Disinte gration (Standard UM 252

RPG)

Resistance of Pulp to 44 – 50 . T 239,

Disintegration (Standard UM 252

RPG)

Shive Count 35 – 41 . .

Shive Count 34 – 39 . .

Solvent-Soluble Matter in Pulp 26 and D202 .

27

Solvent-Soluble Matter in Pulp 25 and D202 .

26

Tensile Properties 68 – 72 D202 .

Tensile Properties 65 – 69 D202 .

Water-Extractable Chlorides 14 and D202 .

15

Water-Extractable Chlorides 14 and D202 .

15

1.3.2 Handsheet characteristics determinable by these procedures appear in the following sections:

ASTM TAPPI

Sec- Method Method

Procedure tion Reference Reference

ASTM TAPPI

Method Method

Procedure Section Reference Reference

Air Resistance (Porosity) 60 and D202 T 205

61

Air Resistance (Porosity) 57 and D202 T 205

58

Apparent Density 66 and D202 T 205

67

Apparent Density 63 and D20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.