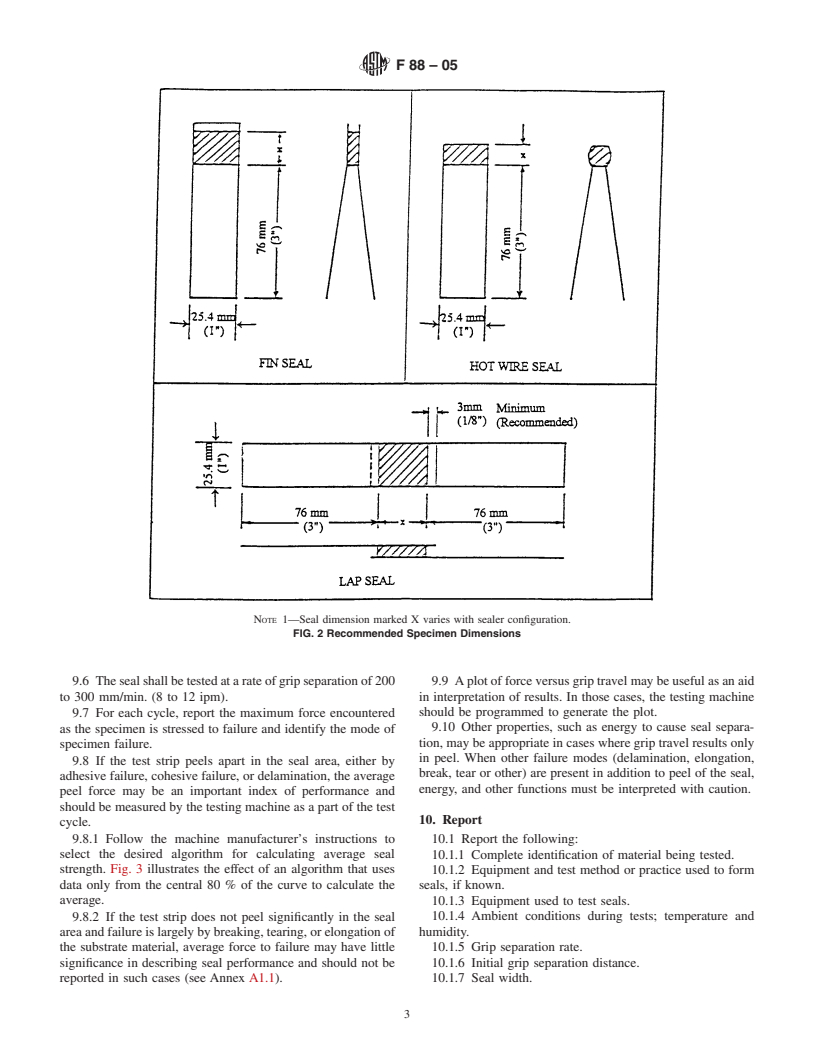

ASTM F88-05

(Test Method)Standard Test Method for Seal Strength of Flexible Barrier Materials

Standard Test Method for Seal Strength of Flexible Barrier Materials

SCOPE

1.1 This test method covers the measurement of the strength of seals in flexible barrier materials.

1.2 The test may be conducted on seals between a flexible material and a rigid material.

1.3 Seals tested in accordance with this test method may be from any source, laboratory or commercial.

1.4 This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode of specimen failure.

1.5 SI units are preferred. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 88 – 05

Standard Test Method for

1

Seal Strength of Flexible Barrier Materials

ThisstandardisissuedunderthefixeddesignationF 88;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—The average force normally is calcu-

lated by the testing machine from the digitized plot of force

1.1 Thistestmethodcoversthemeasurementofthestrength

versus grip travel. The plot starts from zero force after slack

of seals in flexible barrier materials.

has been removed from the test strip. The initial ramp-up from

1.2 The test may be conducted on seals between a flexible

zero to the force level required to peel the seal is not indicative

material and a rigid material.

of seal strength, and data from that part of the curve should not

1.3 Seals tested in accordance with this test method may be

be included in the calculation of average strength, nor should

from any source, laboratory or commercial.

the return to zero following complete failure of the specimen.

1.4 This test method measures the force required to separate

The amount of data actually discarded on each end of the

a test strip of material containing the seal. It also identifies the

measured seal-profile curve must be the same for all tests

mode of specimen failure.

within any set of comparisons of average seal strength (see

1.5 SI units are preferred. The values given in parentheses

6.1.1 and 9.8.1).

are for information only.

3.1.2 flexible, adj—indicates a material with flexural

1.6 This standard does not purport to address all of the

strengthandthicknesspermittingaturnbackatanapproximate

safety concerns, if any, associated with its use. It is the

180 degree angle.

responsibility of the user of this standard to establish appro-

3.1.3 maximum seal strength, n—maximum force per unit

priate safety and health practices and determine the applica-

width of seal required to separate progressively a flexible

bility of regulatory limitations prior to use.

material from a rigid material or another flexible material,

2. Referenced Documents

under the conditions of the test.

2

2.1 ASTM Standards:

4. Significance and Use

D 882 Test Method for Tensile Properties of Thin Plastic

4.1 Sealstrengthisaquantitativemeasureforuseinprocess

Sheeting

3

validation, process control and capability. Seal strength is not

D 1898 Practice for Sampling of Plastics

only relevant to opening force and package integrity, but to

E 171 Specification for Atmospheres for Conditioning and

measuring the packaging processes’ ability to produce consis-

Testing Flexible Barrier Materials

tent seals. Seal strength at some minimum level is a necessary

E 691 Practice for Conducting an Interlaboratory Study to

package requirement, and at times it is desirable to limit the

Determine the Precision of a Test Method

strength of the seal to facilitate opening.

3. Terminology

4.1.1 The maximum seal force is important information, but

for some applications, average force to open the seal may be

3.1 Definitions:

useful, and in those cases also should be reported.

3.1.1 average seal strength, n—averageforceperunitwidth

4.2 When a seal fails adhesively (peel seal) the value of the

of seal required to separate progressively a flexible material

bond strength measured is reported. A cohesive failure of the

from a rigid material or another flexible material, under the

bond, delamination, or failure elsewhere in the test strip

conditions of the test.

indicates that the substrate, not the seal interface, would be the

limiting factor in the strength of a package. In those cases seal

1

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

strength may be reported as “no less than” the strength

Barrier Materials and is the direct responsibility of Subcommittee F02.20 on

measured.

Physical Properties.

4.3 A portion of the force measured when testing materials

Current edition approved April 1, 2005. Published April 2005. Originally

may be a bending component and not seal strength alone. A

approved in 1968. Last previous edition approved in 2000 as F 88 – 00.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

number of fixtures and schemes have been devised to hold

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

samples at various angles to the pull direction to control this

Standards volume information, refer to the standard’s Document Summary page on

bending force. Because the effect of each of these on test

the ASTM website.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.