ASTM C835-06(2013)e1

(Test Method)Standard Test Method for Total Hemispherical Emittance of Surfaces up to 1400°C

Standard Test Method for Total Hemispherical Emittance of Surfaces up to 1400°C

SIGNIFICANCE AND USE

5.1 The emittance as measured by this test method can be used in the calculation of radiant heat transfer from surfaces that are representative of the tested specimens, and that are within the temperature range of the tested specimens.

5.2 This test method can be used to determine the effect of service conditions on the emittance of materials. In particular, the use of this test method with furnace exposure (time at temperature) of the materials commonly used in all-metallic insulations can determine the effects of oxidation on emittance.

5.3 The measurements described in this test method are conducted in a vacuum environment. Usually this condition will provide emittance values that are applicable to materials used under other conditions, such as in an air environment. However, it must be recognized that surface properties of materials used in air or other atmospheres may be different. In addition, preconditioned surfaces, as described in 5.2, may be altered in a vacuum environment because of vacuum stripping of absorbed gases and other associated vacuum effects. Thus, emittances measured under vacuum may have values that differ from those that exist in air, and the user must be aware of this situation. With these qualifications in mind, emittance obtained by this test method may be applied to predictions of thermal transference.

5.4 Several assumptions are made in the derivation of the emittance calculation as described in this test method. They are that:

5.4.1 The enclosure is a blackbody emitter at a uniform temperature,

5.4.2 The total hemispherical absorptance of the completely diffuse blackbody radiation at the temperature of the enclosure is equal to the total hemispherical emittance of the specimen at its temperature, and

5.4.3 There is no heat loss from the test section by convection or conduction. For most materials tested by the procedures as described in this test method, the effects of these assumptions are small and either neglecte...

SCOPE

1.1 This calorimetric test method covers the determination of total hemispherical emittance of metal and graphite surfaces and coated metal surfaces up to approximately 1400°C. The upper-use temperature is limited only by the characteristics (for example, melting temperature, vapor pressure) of the specimen and the design limits of the test facility. This test method has been demonstrated for use up to 1400 °C. The lower-use temperature is limited by the temperature of the bell jar.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C835 − 06 (Reapproved 2013)

Standard Test Method for

Total Hemispherical Emittance of Surfaces up to 1400°C

This standard is issued under the fixed designation C835; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Section 16 was editorially revised in April 2014.

1. Scope

e = error in the variable i, 6 %,

i

ε = total hemispherical emittance of heated specimen,

1.1 This calorimetric test method covers the determination 1

dimensionless,

oftotalhemisphericalemittanceofmetalandgraphitesurfaces

ε = total hemispherical emittance of bell jar inner surface,

and coated metal surfaces up to approximately 1400°C. The

dimensionless,

upper-usetemperatureislimitedonlybythecharacteristics(for

σ = Stefan-Boltzmann constant,

example,meltingtemperature,vaporpressure)ofthespecimen

−8 2 4

= 5.669×10 W/m ·K ,

and the design limits of the test facility. This test method has

Q = heat flow rate, W,

been demonstrated for use up to 1400°C. The lower-use

T = temperature of heated specimen, K,

temperature is limited by the temperature of the bell jar.

T = temperature of bell jar inner surface, K,

1.2 The values stated in SI units are to be regarded as A = surfaceareaofspecimenoverwhichheatgenerationis

measured, m ,

standard. No other units of measurement are included in this

A = surface area of bell jar inner surface, m ,

standard.

F = the gray body shape factor, which includes the effect

1.3 This standard does not purport to address all of the

of geometry and the departure of real surfaces from

safety concerns, if any, associated with its use. It is the

blackbody conditions, dimensionless, and

responsibility of the user of this standard to establish appro-

Pa = absolute pressure, pascal (N/m ). One pascal is

priate safety and health practices and determine the applica-

equivalent to 0.00750 mm Hg.

bility of regulatory limitations prior to use. For specific hazard

statements, see Section 7.

4. Summary of Test Method

4.1 Astrip specimen of the material, approximately 13 mm

2. Referenced Documents

wide and 250 mm long, is placed in an evacuated chamber and

2.1 ASTM Standards: is directly heated with an electric current to the temperature at

C168Terminology Relating to Thermal Insulation

which the emittance measurement is desired. The power

E230Specification and Temperature-Electromotive Force dissipated over a small central region of the specimen and the

(EMF) Tables for Standardized Thermocouples

temperature of this region are measured. Using the Stefan-

E691Practice for Conducting an Interlaboratory Study to

Boltzmannequation,thispowerisequatedtotheradiativeheat

Determine the Precision of a Test Method transfer to the surroundings and, with the measured

temperature, is used to calculate the value of the total hemi-

3. Terminology

spherical emittance of the specimen surface.

3.1 Definitions—The terms and symbols are as defined in

5. Significance and Use

Terminology C168 with exceptions included as appropriate.

5.1 The emittance as measured by this test method can be

3.2 Symbols:

used in the calculation of radiant heat transfer from surfaces

that are representative of the tested specimens, and that are

within the temperature range of the tested specimens.

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal 5.2 This test method can be used to determine the effect of

Measurement.

service conditions on the emittance of materials. In particular,

Current edition approved Sept. 1, 2013. Published April 2014. Originally

the use of this test method with furnace exposure (time at

approved in 1976. Last previous edition approved in 2006 as C835–06. DOI:

temperature) of the materials commonly used in all-metallic

10.1520/C0835-06R13E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

insulationscandeterminetheeffectsofoxidationonemittance.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 The measurements described in this test method are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. conducted in a vacuum environment. Usually this condition

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C835 − 06 (2013)

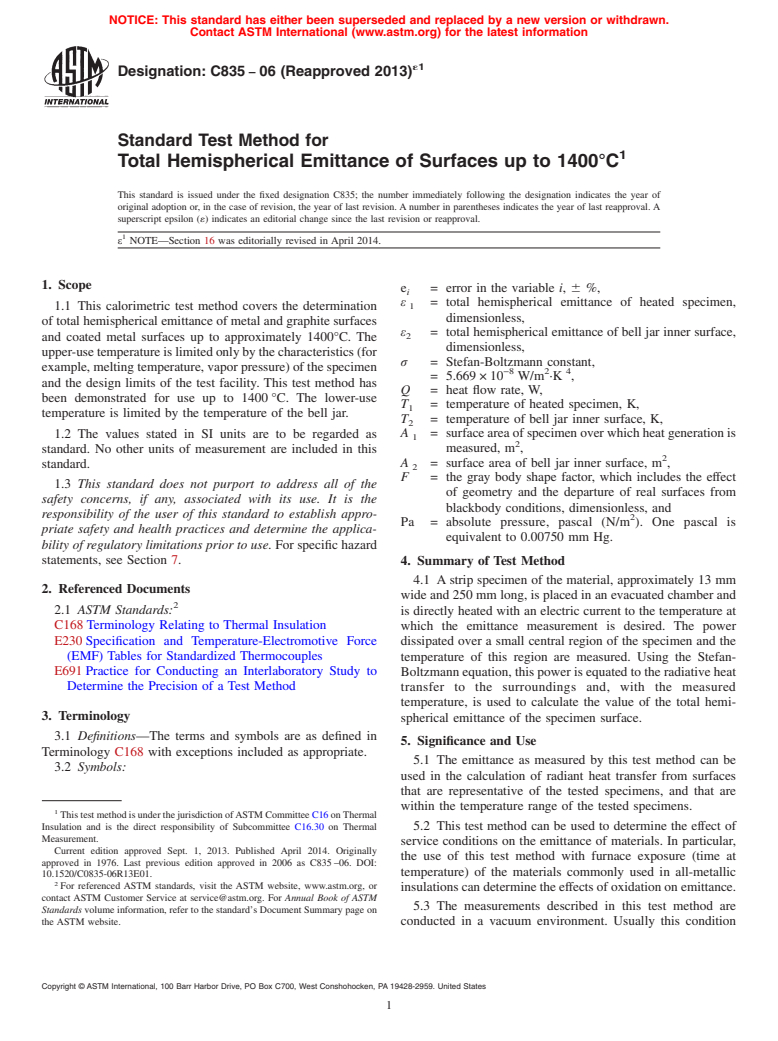

FIG. 1 System Arrangement

will provide emittance values that are applicable to materials unwise to restrict in any way the development of improved or

used under other conditions, such as in an air environment. new methods or procedures by research workers because of

However, it must be recognized that surface properties of standardization of this test method.

materials used in air or other atmospheres may be different. In

6. Apparatus

addition, preconditioned surfaces, as described in 5.2, may be

altered in a vacuum environment because of vacuum stripping

6.1 In general, the apparatus shall consist of the following

of absorbed gases and other associated vacuum effects. Thus,

equipment:abelljar,powersupplyandmulti-meterforvoltage

emittancesmeasuredundervacuummayhavevaluesthatdiffer

and current measurements, thermocouples and voltmeter or

from those that exist in air, and the user must be aware of this

other readout, vacuum system, and specimen holders. A

situation.Withthesequalificationsinmind,emittanceobtained

schematic of the test arrangement is shown in Fig. 1. Means

by this test method may be applied to predictions of thermal

must be provided for electrically heating the specimen, and

transference.

instruments are required to measure the electrical power input

to the specimen and the temperatures of the specimen and

5.4 Several assumptions are made in the derivation of the

surrounding surface.

emittancecalculationasdescribedinthistestmethod.Theyare

that:

6.2 Bell Jar:

5.4.1 The enclosure is a blackbody emitter at a uniform

6.2.1 The bell jar may be either metal or glass with an inner

temperature,

surface that presents a blackbody environment to the specimen

5.4.2 Thetotalhemisphericalabsorptanceofthecompletely

located near the center. This blackbody effect is achieved by

diffuse blackbody radiation at the temperature of the enclosure

providing a highly absorbing surface and by making the

isequaltothetotalhemisphericalemittanceofthespecimenat

surface area much larger than the specimen surface area. The

its temperature, and

relationship between bell jar size and its required surface

5.4.3 There is no heat loss from the test section by convec-

emittanceisestimatedfromthefollowingequationforthegray

tionorconduction.Formostmaterialstestedbytheprocedures

bodyshapefactorforasurfacecompletelyenclosedbyanother

as described in this test method, the effects of these assump-

surface:

tions are small and either neglected or corrections are made to

the measured emittance.

F 5 (1)

A

1 1

1 2 1

5.5 For satisfactory results in conformance with this test S D

ε A ε

1 2 2

method, the principles governing the size, construction, and

For this test method to apply, the following condition must

use of apparatus described in this test method should be

exist:

followed. If these principles are followed, any measured value

obtained by the use of this test method is expected to be

1 A 1

.. 2 1 (2)

S D

accurate to within 65%. If the results are to be reported as

ε A ε

1 2 2

having been obtained by this test method, all of the require-

This condition can be satisfied for all possible values of

ments prescribed in this test method shall be met.

specimen emittance by an apparatus design in which A /A has

1 2

5.6 It is not practical in a test method of this type to

a value less than 0.01 and ε has a value greater than 0.8. To

establish details of construction and procedure to cover all

ensure that the inner surface has an emittance greater than 0.8,

contingencies that might offer difficulties to a person without 3

metalandglassbelljarsshallbecoatedwithablackpaint (1).

technical knowledge concerning the theory of heat transfer,

temperaturemeasurements,andgeneraltestingpractices.Stan-

dardization of this test method does not reduce the need for

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

suchtechnicalknowledge.Itisrecognizedalsothatitwouldbe this standard.

´1

C835 − 06 (2013)

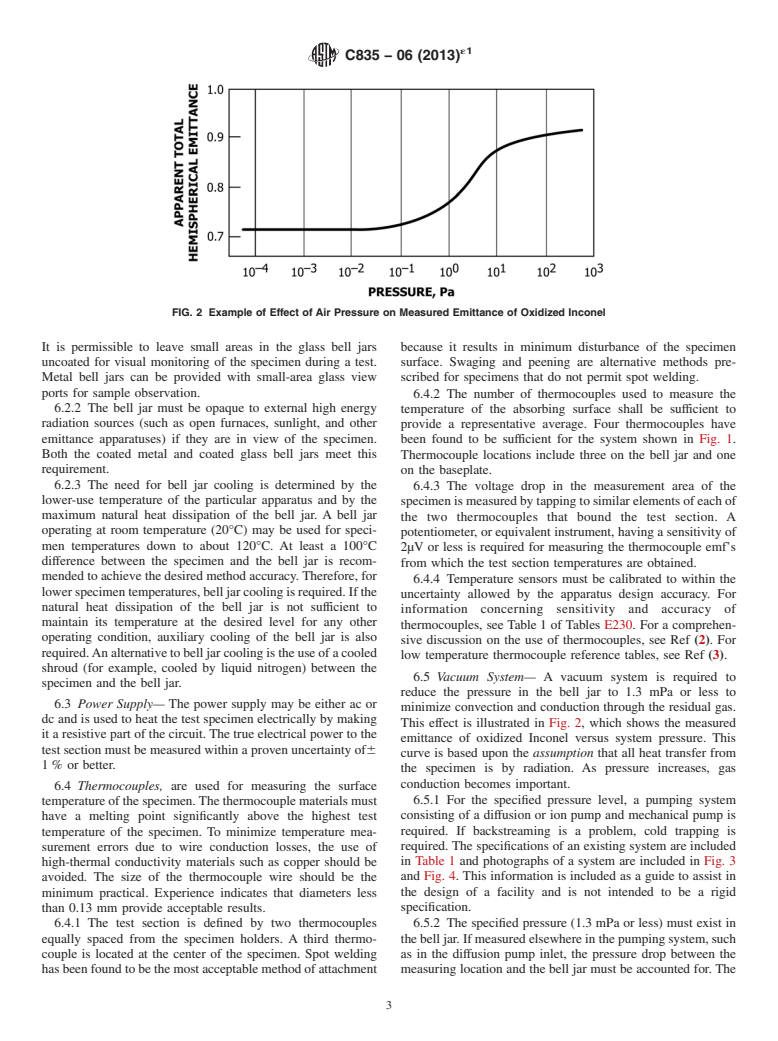

FIG. 2 Example of Effect of Air Pressure on Measured Emittance of Oxidized Inconel

It is permissible to leave small areas in the glass bell jars because it results in minimum disturbance of the specimen

uncoated for visual monitoring of the specimen during a test. surface. Swaging and peening are alternative methods pre-

Metal bell jars can be provided with small-area glass view scribed for specimens that do not permit spot welding.

ports for sample observation. 6.4.2 The number of thermocouples used to measure the

6.2.2 The bell jar must be opaque to external high energy

temperature of the absorbing surface shall be sufficient to

radiation sources (such as open furnaces, sunlight, and other

provide a representative average. Four thermocouples have

emittance apparatuses) if they are in view of the specimen.

been found to be sufficient for the system shown in Fig. 1.

Both the coated metal and coated glass bell jars meet this

Thermocouple locations include three on the bell jar and one

requirement. on the baseplate.

6.2.3 The need for bell jar cooling is determined by the

6.4.3 The voltage drop in the measurement area of the

lower-use temperature of the particular apparatus and by the

specimenismeasuredbytappingtosimilarelementsofeachof

maximum natural heat dissipation of the bell jar. A bell jar

the two thermocouples that bound the test section. A

operating at room temperature (20°C) may be used for speci-

potentiometer,orequivalentinstrument,havingasensitivityof

men temperatures down to about 120°C. At least a 100°C

2µV or less is required for measuring the thermocouple emf’s

difference between the specimen and the bell jar is recom-

from which the test section temperatures are obtained.

mendedtoachievethedesiredmethodaccuracy.Therefore,for

6.4.4 Temperature sensors must be calibrated to within the

lowerspecimentemperatures,belljarcoolingisrequired.Ifthe

uncertainty allowed by the apparatus design accuracy. For

natural heat dissipation of the bell jar is not sufficient to

information concerning sensitivity and accuracy of

maintain its temperature at the desired level for any other

thermocouples, see Table1 of Tables E230. For a comprehen-

operating condition, auxiliary cooling of the bell jar is also

sive discussion on the use of thermocouples, see Ref (2). For

required.Analternativetobelljarcoolingistheuseofacooled

low temperature thermocouple reference tables, see Ref (3).

shroud (for example, cooled by liquid nitrogen) between the

6.5 Vacuum System— A vacuum system is required to

specimen and the bell jar.

reduce the pressure in the bell jar to 1.3 mPa or less to

6.3 Power Supply— The power supply may be either ac or

minimize convection and conduction through the residual gas.

dc and is used to heat the test specimen electrically by making

This effect is illustrated in Fig. 2, which shows the measured

it a resistive part of the circuit.The true electrical power to the

emittance of oxidized Inconel versus system pressure. This

testsectionmustbemeasuredwithinaprovenuncertaintyof6

curve is based upon the assumption that all heat transfer from

1% or better.

the specimen is by radiation. As pressure increases, gas

conduction becomes important.

6.4 Thermocouples, are used for measuring the surface

6.5.1 For the specified pressure level, a pumping system

temperatureofthespecimen.Thethermocouplematerialsmust

have a melting point significantly above the highest test consisting of a diffusion or ion pump and mechanical pump is

required. If backstreaming is a problem, cold trapping is

temperature of the specimen. To minimize temperature mea-

surement errors due to wire conduction losses, the use of required. The specifications of an existing system are included

in Table 1 and photographs of a system are included in Fig. 3

high-thermal conductivity materials such as copper should be

and Fig. 4. This information is included as a guide to assist in

avoided. The size of the thermocouple wire should be the

the design of a facility and is not intended to be a rigid

minimum practical. Experience indicates that diameters less

specification.

than 0.13 mm provide acceptable results.

6.4.1 The test section is defined by two thermocouples 6.5.2 The specified pressure (1.3 mPa or less) must exist in

equally spaced from the specimen holders. A third thermo- thebelljar.Ifmeasuredelsewhereinthepumpingsystem,such

couple is located at the center of the specimen. Spot welding as in the diffusion pump inlet, the pressure drop between the

hasbeenfoundtobethemostacceptablemethodofattachment measuring location and the bell jar must be accounted for.The

´1

C835 − 06 (2013)

TABLE 1 Specifications for the Emittance Test Facility Shown in

Figs. 3 and 4

Vacuum system:

A manual vacuum coater system

Vacuum pumps consisting of an 0.8-m /s diffusion pump (100-mm inlet)

backed

by an 0.0023-m /s mechanical pump

A glass bell jar, 0.46 m in diameter by 0.91 m high with an implosion shield

Vacuum gaging, including two thermocouple-type roughing gages and an ioni-

zation gage

A specimen holder having a movable lower clamp to allow for thermal

expansion

A liquid nitrogen cold trap

Power Supply:

Output voltage—0 to 16 V

Maximum current—100 A

Sample Temperature Range:

Maximum 20 to 1400°C

Sample Size:

Nominal—0.25 by 13 by 250 mm

Maximum length—500 mm

Power Measurement:

Current is determined by measurement of voltage across a precision-

calibrated

resistor (0 to 100 A)

Voltage is measured by a digital voltmeter.

vacuum system should also be checked for gross leakage that

could allow incoming gas to sweep over the specimen.

6.6 Specimen Holders, must be designed to allow for

thermal expansion of the specimen without buckling. The

lower specimen holder shown in Fig. 4 is designed to move up

anddowninitssupporttoallowforthermalexpansion.Holders

should be positioned off-center within the bell jar to minimize

normal reflections between the specimen and bell jar inner

surface. Specimen holders require auxiliary cooling if end

conduction from the specimen causes overheating.

6.7 Micrometer Calipers, or other means are needed to

measure the dimensions (widt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.