ASTM D2872-04

(Test Method)Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

SIGNIFICANCE AND USE

This test method indicates approximate change in properties of asphalt during conventional hot-mixing at about 302°F (150°C) as indicated by viscosity and other rheological measurements. It yields a residue which approximates the asphalt condition as incorporated in the pavement. If the mixing temperature differs appreciably from the 302°F (150°C) level, more or less effect on properties will occur. This test method also can be used to determine mass change, which is a measure of asphalt volatility.

SCOPE

1.1 This test method is intended to measure the effect of heat and air on a moving film of semi-solid asphaltic materials. The effects of this treatment are determined from measurements of the selected properties of the asphalt before and after the test.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2872 − 04

StandardTest Method for

Effect of Heat and Air on a Moving Film of Asphalt (Rolling

1

Thin-Film Oven Test)

This standard is issued under the fixed designation D2872; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Precision values for this test method have been devel-

oped for viscosity at 140°F (60°C); ductility at 60°F (15.6°C);

1.1 This test method is intended to measure the effect of

and mass change.

heat and air on a moving film of semi-solid asphaltic materials.

The effects of this treatment are determined from measure-

4. Significance and Use

ments of the selected properties of the asphalt before and after

4.1 This test method indicates approximate change in prop-

the test.

erties of asphalt during conventional hot-mixing at about

1.2 The values stated in inch-pound units are to be regarded

302°F (150°C) as indicated by viscosity and other rheological

as the standard.

measurements. It yields a residue which approximates the

asphalt condition as incorporated in the pavement. If the

1.3 This standard does not purport to address all of the

mixing temperature differs appreciably from the 302°F

safety concerns, if any, associated with its use. It is the

(150°C) level, more or less effect on properties will occur.This

responsibility of the user of this standard to establish appro-

test method also can be used to determine mass change, which

priate safety and health practices and determine the applica-

is a measure of asphalt volatility.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 Oven—This shall be a double-walled electrically heated

2

2.1 ASTM Standards:

convection-type oven. Its inside dimensions shall be 15 in.

D113 Test Method for Ductility of Bituminous Materials

(381 mm) high, 19 in. (483 mm) wide (including the plenum),

1 1

D2171 Test Method for Viscosity of Asphalts by Vacuum

and 17 ⁄2 6 ⁄2 in. (445 6 13 mm) deep (with the door closed).

Capillary Viscometer

The door shall contain a symmetrically located window with

E1 Specification for ASTM Liquid-in-Glass Thermometers

dimensions of 12 to 13 in. (305 to 330 mm) wide by 8 to 9 in.

E644 Test Methods for Testing Industrial Resistance Ther-

(203 to 229 mm) high.The window shall contain two sheets of

mometers

heat-resistant glass separated by an air space. The window

E1137/E1137M Specification for Industrial Platinum Resis-

should permit an unobstructed view of the interior of the oven.

tance Thermometers 1

The top of the upper heating element shall be 1 6 ⁄8 in. (25 6

3 mm) below the oven floor.

3. Summary of Test Method

5.1.1 The oven shall be vented at the top and bottom. The

bottom vents shall be located symmetrically to supply incom-

3.1 Amoving film of asphaltic material is heated in an oven

ing air around the heating elements. They shall have an open

for 85 min at 325°F (163°C). The effects of heat and air are

2 2

area of 2.31 6 0.11 in. (15.0 6 0.7 cm ). The top vents shall

determined from changes in physical test values as measured

be symmetrically arranged in the upper part of the oven and

before and after the oven treatment. An optional procedure is

2 2

have an open area of 1.45 6 0.07 in. (9.3 6 0.45 cm ).

provided for determining the change in sample mass.

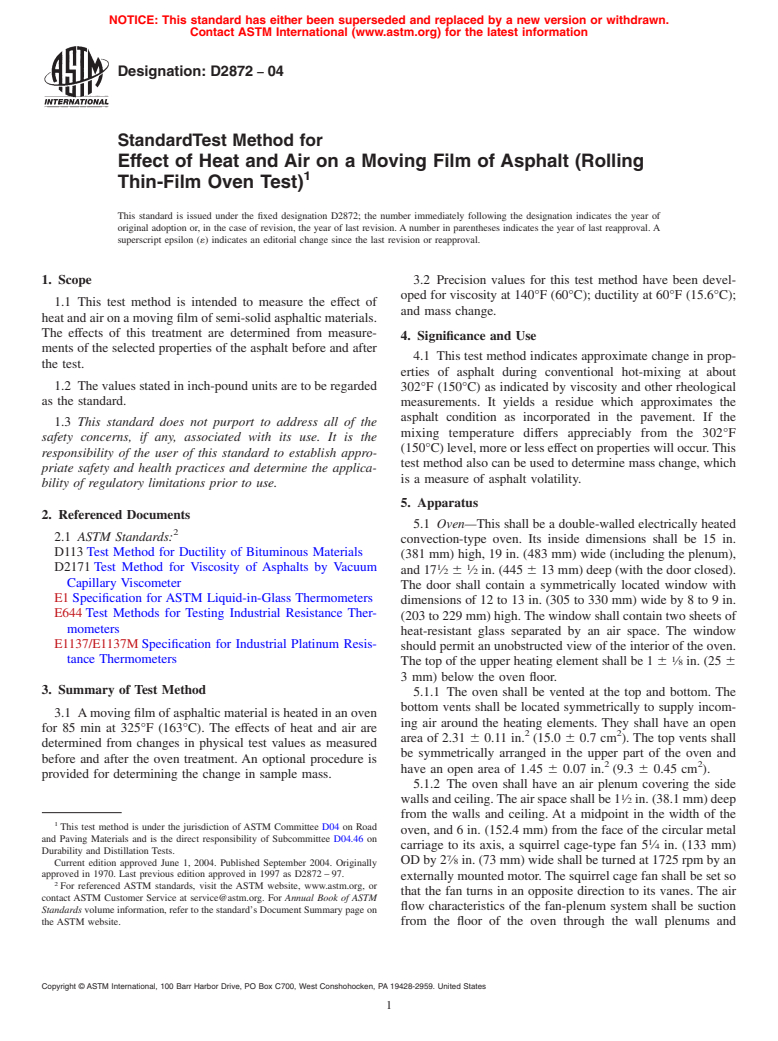

5.1.2 The oven shall have an air plenum covering the side

1

wallsandceiling.Theairspaceshallbe1 ⁄2in.(38.1mm)deep

from the walls and ceiling. At a midpoint in the width of the

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

oven, and 6 in. (152.4 mm) from the face of the circular metal

and Paving Materials and is the direct responsibility of Subcommittee D04.46 on

1

carriage to its axis, a squirrel cage-type fan 5 ⁄4 in. (133 mm)

Durability and Distillation Tests.

7

OD by 2 ⁄8 in. (73 mm) wide shall be turned at 1725 rpm by an

Current edition approved June 1, 2004. Published September 2004. Originally

approved in 1970. Last previous edition approved in 1997 as D2872 – 97.

externally mounted motor. The squirrel cage fan shall be set so

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that the fan turns in an opposite direction to its vanes. The air

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

flow characteristics of the fan-plenum system shall be suction

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. from the floor of the oven through the wall plenums and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.