ASTM E128-99(2011)

(Test Method)Standard Test Method for Maximum Pore Diameter and Permeability of Rigid Porous Filters for Laboratory Use

Standard Test Method for Maximum Pore Diameter and Permeability of Rigid Porous Filters for Laboratory Use

ABSTRACT

This test method covers the determination of maximum pore diameter and permeability of rigid porous filters used in the laboratory for filtration or diffusion. They are applicable to filters made of sintered glass, ceramic, metal, or plastic. This test method establishes a uniform designation for maximum pore diameter and also provides a means of detecting and measuring changes which occur through continued use. Maximum pore diameter is determined by immersing the filter in a suitable test liquid and applying air pressure until the first bubble of air passes through the filter. The maximum pore diameter is calculated from the surface tension of the test liquid and the applied pressure. Permeability is determined by measuring the flow of air through the filter when subjected to a pressure differential.

SCOPE

1.1 This test method covers the determination of maximum pore diameter and permeability of rigid porous filters used in the laboratory for filtration or diffusion. They are applicable to filters made of sintered glass, ceramic, metal, or plastic. This test method establishes a uniform designation for maximum pore diameter and also provides a means of detecting and measuring changes which occur through continued use.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E128 − 99 (Reapproved 2011)

Standard Test Method for

Maximum Pore Diameter and Permeability of Rigid Porous

Filters for Laboratory Use

This standard is issued under the fixed designation E128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

pore in the filter, and furthermore, that the pores are highly irregular in

1. Scope

shape. Because of this irregularity in shape and other phenomena

1.1 This test method covers the determination of maximum

characteristic of filtration, a filter may be expected to retain all particles

pore diameter and permeability of rigid porous filters used in larger than the maximum pore diameter as defined and determined by this

test method, and will generally retain particles which are much smaller

the laboratory for filtration or diffusion. They are applicable to

than the determined diameter.

filters made of sintered glass, ceramic, metal, or plastic. This

3.1.2 permeability—the flow of air, in millimetres per min-

test method establishes a uniform designation for maximum

ute per square centimetre of filter area per 1 cm of water

pore diameter and also provides a means of detecting and

pressure differential.

measuring changes which occur through continued use.

1.2 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measurement are included in this

4.1 Maximum Pore Diameter, is determined by immersing

standard.

the filter in a suitable test liquid and applying air pressure until

1.3 This standard does not purport to address all of the

the first bubble of air passes through the filter. The maximum

safety problems, if any, associated with its use. It is the

pore diameter is calculated from the surface tension of the test

responsibility of the user of this standard to establish appro-

liquid and the applied pressure.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.2 Permeability is determined by measuring the flow of air

through the filter when subjected to a pressure differential.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

D845 Specification for Five-Degree Xylene (Withdrawn

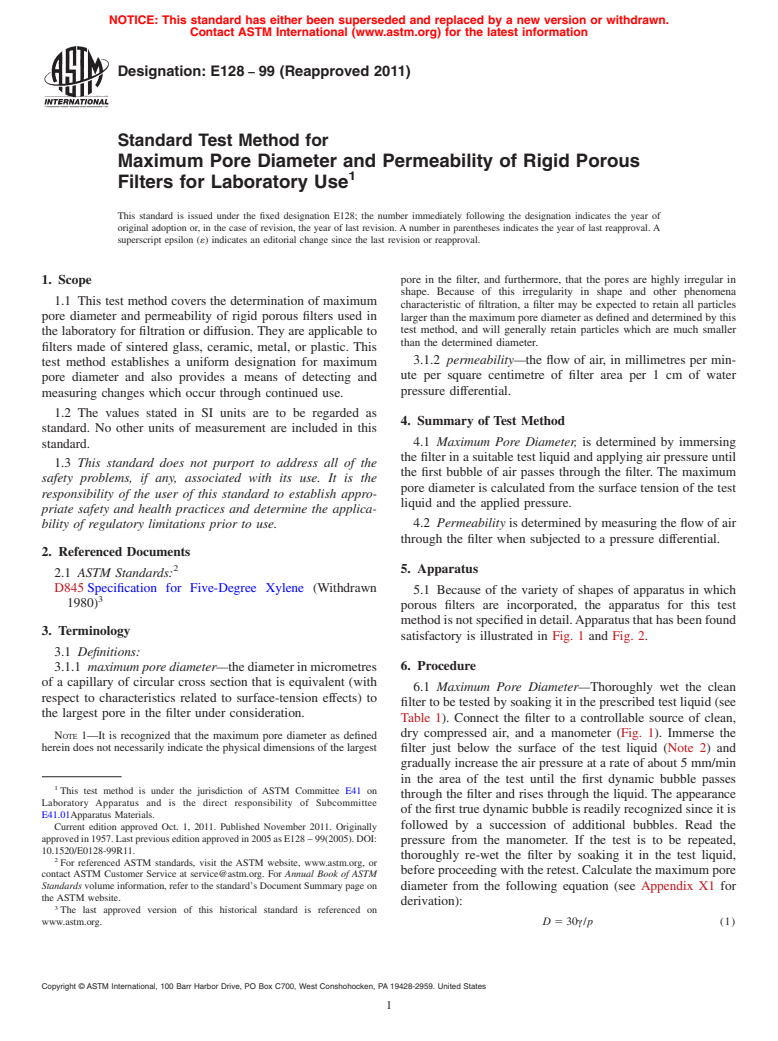

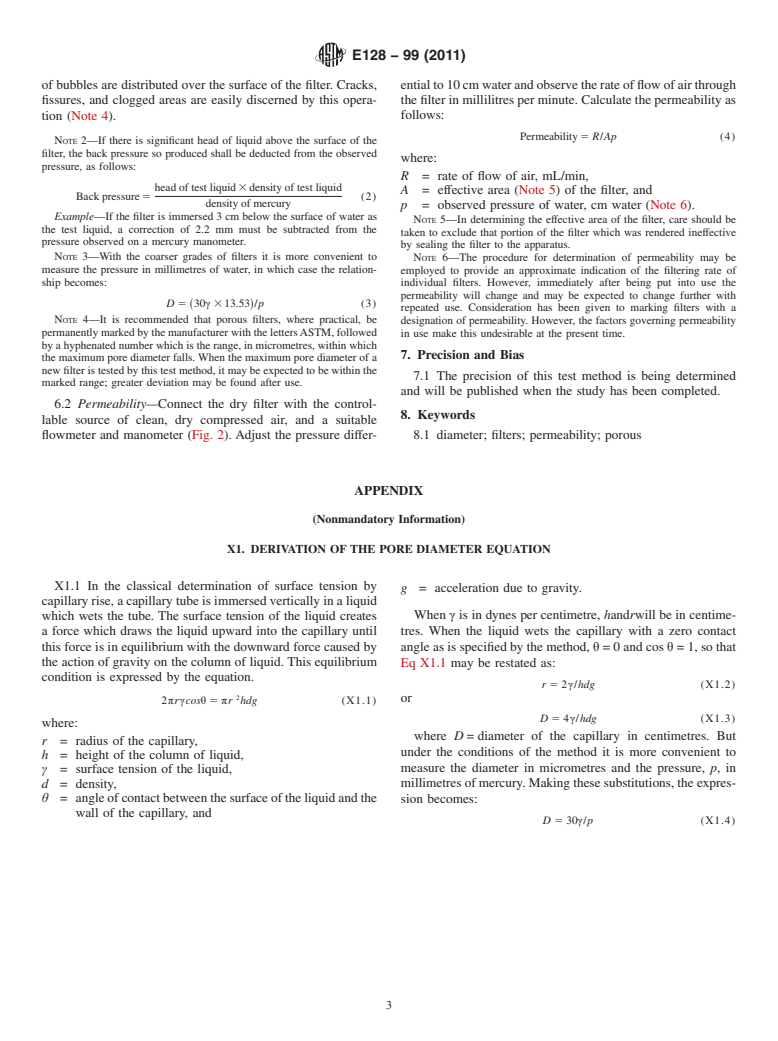

5.1 Because of the variety of shapes of apparatus in which

1980)

porous filters are incorporated, the apparatus for this test

method is not specified in detail.Apparatus that has been found

3. Terminology

satisfactory is illustrated in Fig. 1 and Fig. 2.

3.1 Definitions:

3.1.1 maximum pore diameter—thediameterinmicrometres 6. Procedure

of a capillary of circular cross section that is equivalent (with

6.1 Maximum Pore Diameter—Thoroughly wet the clean

respect to characteristics related to surface-tension effects) to

filter to be tested by soaking it in the prescribed test liquid (see

the largest pore in the filter under consideration.

Table 1). Connect the filter to a controllable source of clean,

dry compressed air, and a manometer (Fig. 1). Immerse the

NOTE 1—It is recognized that the maximum pore diameter as defined

herein does not necessarily indicate the physical dimensions of the largest filter just below the surface of the test liquid (Note 2) and

gradually increase the air pressure at a rate of about 5 mm/min

in the area of the test until the first dynamic bubble passes

This test method is under the jurisdiction of ASTM Committee E41 on

through the filter and rises through the liquid. The appearance

Laboratory Apparatus and is the direct responsibility of Subcommittee

of the first true dynamic bubble is readily recognized since it is

E41.01Apparatus Materials.

Current edition approved Oct. 1, 2011. Published November 2011. Originally followed by a succession of additional bubbles. Read the

approvedin1957.Lastpreviouseditionapprovedin2005asE128 – 99(2005).DOI:

pressure from the manometer. If the test is to be repeated,

10.1520/E0128-99R11.

thoroughly re-wet the filter by soaking it in the test liquid,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

before proceeding with the retest. Calculate the maximum pore

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on diameter from the following equation (see Appendix X1 for

the ASTM website.

derivation):

The last approved version of this historical standard is referenced on

www.astm.org. D 5 30γ/p (1)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E128 − 99 (2011)

NOTE 1—For tests on filter-type crucibles, use a standard rubber crucible adapter. For test sticks and candles a rubber stopper with a rubber tubing

attached is suitable. Clean dry compressed air shall be used.

FIG. 1 Apparatus for Determining Maximum Pore Diameter of Rigid Porous Filters

NOTE 1—For tests on filter-type crucibles, use a standard rubber crucible adapter. For test sticks and candles a rubber stopper with a rubber tubing

attached is suitable. Clean dry compressed air shall be used.

FIG. 2 Apparatus for Determination of Permeability

TABLE 1 Test Liquids Suitable for Use with Various Types of Filters

A

Filter Suitable Test Liquids

Approximate Surface

Max Pore Diameter, Tension, dynes/cm at

Material of Construction µm Liquid 20°C

Glass >4 water 72

B

<4 alcohol 22

Porcelain >3 water 72

<3 alcohol 22

Stainless steel all alcohol 22

C

xylene 29

Tetrafluoro-polyethylene all alcohol 22

Trifluoromonochloropolyethylene all alcohol 22

A

The specified liquids wet the respective filters completely. Other liquids which meet this crite

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.