ASTM D3498-99

(Specification)Standard Specification for Adhesives for Field-Gluing Plywood to Lumber Framing for Floor Systems

Standard Specification for Adhesives for Field-Gluing Plywood to Lumber Framing for Floor Systems

SCOPE

1.1 This specification covers minimum performance standards and test requirements for gap-filling construction adhesives for bonding plywood to lumber framing, particularly floor joists, at the construction site.

1.2 This specification provides a basis for ensuring the quality of the adhesives and is not intended as an application specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3498 – 99

Standard Specification for

Adhesives for Field-Gluing Plywood to Lumber Framing for

1

Floor Systems

This standard is issued under the fixed designation D 3498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers minimum performance stan- 3.1 Definitions—Many terms in this specification are de-

dards and test requirements for gap-filling construction adhe- fined in Terminology D 907.

sives for bonding plywood to lumber framing, particularly 3.1.1 gap-filling adhesive, n—an adhesive capable of form-

floor joists, at the construction site. ing and maintaining a bond between surfaces that are not

1.2 This specification provides a basis for ensuring the close-fitting.

quality of the adhesives and is not intended as an application 3.1.1.1 Discussion—Close-fitting is relative to a given ma-

specification. terial and industry; for example, standards in construction

1.3 The values stated in inch-pound units are to be regarded differ from standards in electronics. Some adhesives will bond

as the standard. The values given in parentheses are for by bridging without completely filling the gap; others by filling

information only. the gap completely.

1.4 The following precautionary caveat pertains only to the 3.1.2 open assembly time, n—the time interval between

test method portion, Section 10, of this specification: This applying adhesive on the subtrates and closing them together

standard does not purport to address all of the safety concerns, before bonding.

if any, associated with its use. It is the responsibility of the user

4. Ordering Information

of this standard to establish appropriate safety and health

4.1 The adhesive may be furnished by the manufacturer in

practices and determine the applicability of regulatory limita-

tions prior to use. any suitable form agreeable to the purchaser.

2. Referenced Documents 5. Materials

5.1 The adhesive shall be a gap-filling construction adhesive

2.1 ASTM Standards:

D 572 Test Method for Rubber—Deterioration by Heat and that sets at temperatures as low as 40°F (4.4°C).

2

5.2 The adhesive shall not support mold or bacterial growth.

Oxygen

D 905 Test Method for Strength Properties of Adhesive If the adhesive contains any materials that will support mold or

3

bacterial growth, such as amylaceous or protein fillers, the

Bonds in Shear by Compression Loading

3

D 907 Terminology of Adhesives adhesive must not only pass requirements of this specification,

but in addition, show no significant loss in strength at the 0.05

D 1174 Test Method for Effect of Bacterial Contamination

on Permanence of Adhesive Preparations and Adhesive level of probability when tested for mold and bacterial con-

4

tamination in accordance with Test Methods D 1174 and

Bonds

D 1286 Test Method for Effect of Mold Contamination on D 1286, and procedures contained in this specification. The

adhesive manufacturer shall notify in writing the agency

Permanence of Adhesive Preparations and Adhesive

4

Bonds responsible for testing, certifying, and compliance labeling of

5

the adhesive whether any such materials are present in the

D 2016 Test Method for Moisture Content of Wood

6

E 4 Practices for Tone Verification of Testing Machines adhesive.

5.3 The adhesive, when completely set, shall form a resil-

ient bond that shall be durable when protected from direct

1

This specification is under the jurisdiction of ASTM Committee D-14 on

exposure to the weather, as defined by the requirements of this

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

specification.

Adhesives.

5.4 The adhesive shall be a uniform mixture suitable for

Current edition approved May 10, 1999. Published August 1999. Originally

published as D 3498 – 76. Last previous edition D 3498 – 93. extrusion by a caulking gun or other pressurized application

2

Annual Book of ASTM Standards, Vol 09.01.

equipment.

3

Annual Book of ASTM Standards, Vol 15.06.

5.5 The adhesive shall permit an open assembly time of not

4

Discontinued; see 1983 Annual Book of ASTM Standards, Vol 15.06.

5

less than 10 min when applied to the lumber framing in

Annual Book of ASTM Standards, Vol 04.09.

6

Annual Book of ASTM Standards, Vol 03.01

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

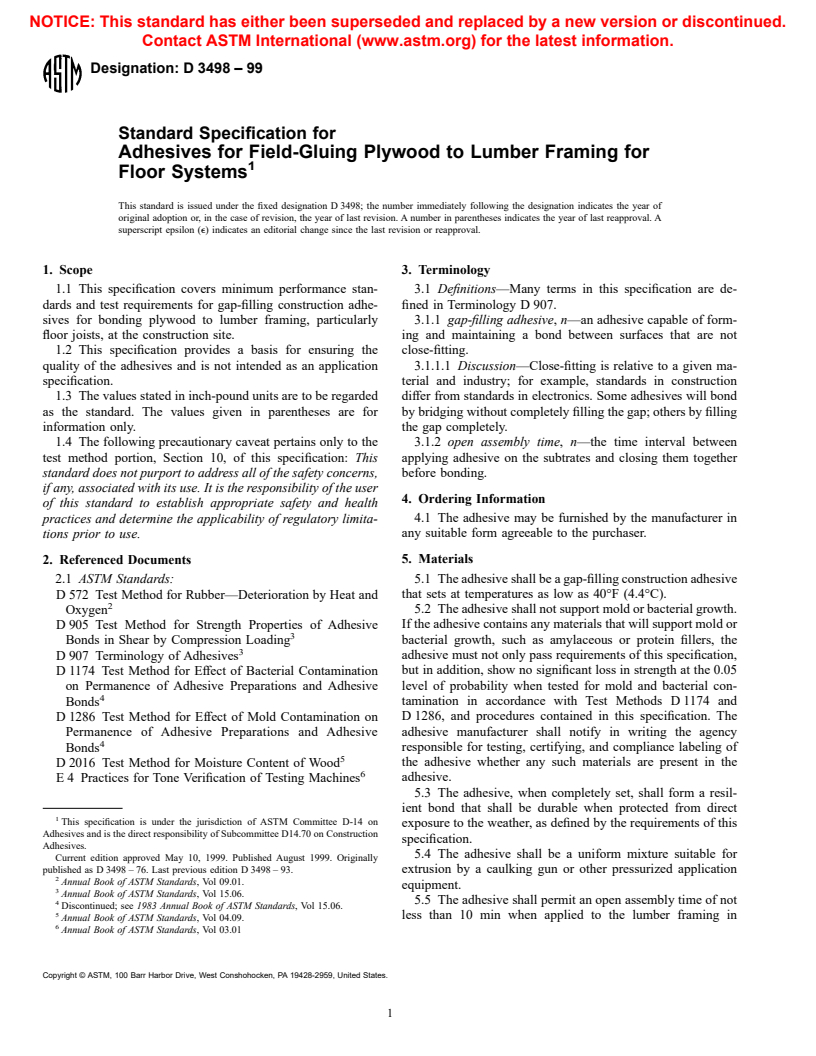

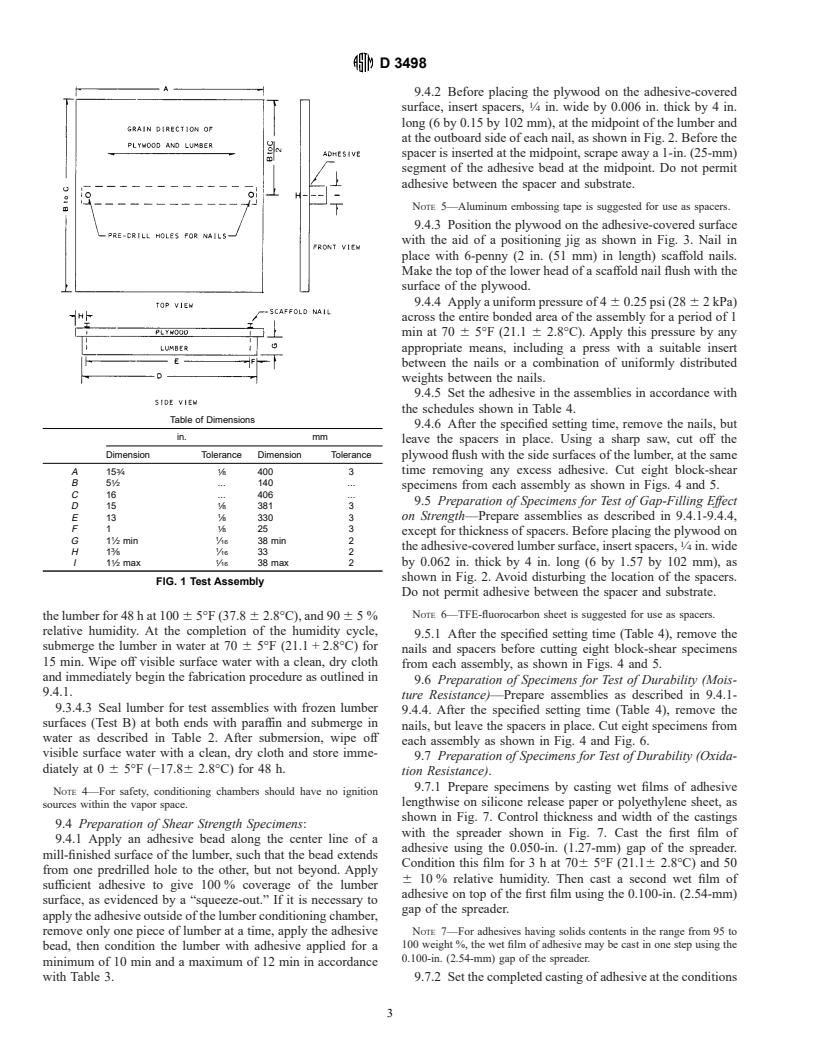

D 3498

accordance with the manufacturer’s instructions. It shall be measurement across the top surface of the plywood. Use

functional, as defined in this specification, when applied to bowed plywood only if

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.