ASTM D1388-96(2002)

(Test Method)Standard Test Method for Stiffness of Fabrics

Standard Test Method for Stiffness of Fabrics

SCOPE

1.1 This test method covers the measurement of stiffness properties of fabrics. Bending length is measured and flexural rigidity is calculated. Two procedures are provided.

1.1.1 Option A—Cantilever Test, employing the principle of cantilever bending of the fabric under its own mass.

1.1.2 Option B—Heart Loop Test, employing the principle of a loop formed in a fabric strip and hung vertically.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, pile fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated.

1.3 The values stated in SI units are to be regarded as the standard. The U.S. customary units may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1388–96 (Reapproved 2002)

Standard Test Method for

Stiffness of Fabrics

This standard is issued under the fixed designation D1388; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope TEX-PAC

1.1 This test method covers the measurement of stiffness

3. Terminology

properties of fabrics. Bending length is measured and flexural

3.1 Definitions:

rigidity is calculated. Two procedures are provided.

3.1.1 bending length, n—in textiles, a measure of the

1.1.1 OptionA—CantileverTest,employingtheprincipleof

interactionbetweenfabricweightandfabricstiffnessasshown

cantilever bending of the fabric under its own mass.

by the way in which a fabric bends under its own weight.

1.1.2 Option B—Heart Loop Test, employing the principle

3.1.1.1 Discussion—Bending length reflects the stiffness of

of a loop formed in a fabric strip and hung vertically.

a fabric when bent in one plane under the force of gravity and

1.2 This test method applies to most fabrics including

is one component of drape.

wovenfabrics,airbagfabrics,blankets,nappedfabrics,knitted

3.1.2 cross-machine direction, CD, n—the direction in the

fabrics, layered fabrics, pile fabrics. The fabrics may be

plane of the fabric perpendicular to the direction of manufac-

untreated, heavily sized, coated, resin-treated, or otherwise

ture.

treated.

3.1.2.1 Discussion—The term cross-machine direction is

1.3 The values stated in SI units are to be regarded as the

used to refer to the direction analogous to coursewise or filling

standard. The U.S. customary units may be approximate.

direction in knitted or woven fabrics, respectively.

1.4 This standard does not purport to address all of the

3.1.3 fabric, n—in textiles, a planar structure consisting of

safety concerns, if any, associated with its use. It is the

yarns or fibers.

responsibility of the user of this standard to establish appro-

3.1.4 flexural rigidity, n—a measure of stiffness, where two

priate safety and health practices and determine the applica-

equal and opposite forces are acting along parallel lines on

bility of regulatory limitations prior to use.

eitherendofastripofunitwidthbentintounitcurvatureinthe

2. Referenced Documents absence of any tension.

3.1.5 machine direction, MD, n—the direction in the plane

2.1 ASTM Standards:

2 of the fabric parallel to the direction of manufacture.

D123 Terminology Relating to Textiles

3.1.5.1 Discussion—The term machine direction is used to

D1776 Practice for Conditioning Textiles for Testing

refer to the direction analogous to walewise or warp direction

D2904 PracticeforInterlaboratoryTestingofaTextileTest

in knitted or woven fabrics, respectively.

Method That Produces Normally Distributed Data

3.1.6 stiffness, n—resistance to bending.

D2906 Practice for Statements on Precision and Bias for

3.1.7 For definitions of other textile terms used in this test

Textiles

method, refer to Terminology D123.

D3776 Test Methods for Mass Per Unit Area (Weight) of

Woven Fabric

4. Summary of Test Method Options

2.2 ASTM Adjuncts:

4.1 Option A, Cantilever Test—A specimen is slid at a

specified rate in a direction parallel to its long dimension, until

1 its leading edge projects from the edge of a horizontal surface.

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, The length of the overhang is measured when the tip of the

Specific.

Current edition approved Sept. 10, 2002. Published June 1996. Originally

published as D1388–56T. Discontinued 1995 and reinstated as D1388–96. PC programs on floppy disks for analyzing Committee D-13 interlaboratory

Annual Book of ASTM Standards, Vol 07.01. dataareavailablethroughASTM.For3 ⁄2in.disksrequestPCN:12-429040-18,for

Annual Book of ASTM Standards, Vol 07.02. 5 ⁄4 in. disk request PCN: 12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1388–96 (2002)

specimen is depressed under its own mass to the point where

the line joining the top to the edge of the platform makes a

0.924 rad (41.5°) angle with the horizontal. From this mea-

sured length, the bending length and flexural rigidity are

calculated.

4.2 Option B, Heart Loop Test—Astrip of fabric is formed

into a heart-shaped loop. The length of the loop is measured

when it is hanging vertically under its own mass. From this

measured length, the bending length and flexural rigidity are

calculated.

5. Significance and Use

5.1 Both test options in this test method are considered

satisfactory for acceptance testing of commercial shipments

since current estimates of between-laboratory precision are

acceptable and the method is used extensively in the trade for

FIG. 1 Example of a Motorized Cantilever Test Apparatus

acceptance testing.

5.1.1 In case of a dispute arising from differences in

6.1.1.1 Indicator, inclined at an angle of 0.724 6 0.01 rad

reportedtestresultswhenusingthistestmethodforacceptance

(41.5 6 0.5°) below the plane of the platform surface.

testing of commercial shipments, the purchaser and the sup-

6.1.1.2 Movable Slide, consisting of a metal bar not less

plier should conduct comparative tests to determine if there is

than25by200mm(1by8in.)byapproximately3mm( ⁄8in.)

a statistical bias between their laboratories. Competent statis-

thick and having a mass of 270 6 5 g (0.6 6 0.01 lb).

tical assistance is recommended for the investigation of bias.

6.1.1.3 Scale and Reference Point, to measure the length of

As a minimum, the two parties should take a group of test

the overhang.

specimens that are as homogeneous as possible and that are

6.1.1.4 Specimen Feed Unit, motorized (see Fig. 1) set to

from a lot of material of the type in question. Test specimens

120 mm/min (4.75 in./min) 65%, or manual equivalent.

should then be randomly assigned in equal numbers to each

6.1.2 Cutting Die—25 61mmby200 61mm(1 6 0.04

laboratory for testing. The average results from the two

in. by 8 6 0.04 in.).

laboratories should be compared using the appropriate statis-

6.2 Option B—Heart Loop Tester.

tical analysis and an acceptable probability level chosen by the

6.2.1 Clamp and Stand, for hanging the specimen.

two parties before testing is begun. If a bias is found, either its

6.2.2 Scale,suitablymountedonthestandformeasuringthe

cause must be found and corrected or the purchaser and the

length of the specimen loop and calibrated either in cm (in.) or

supplier must agree to interpret future test results with consid-

directly in bending length.

eration to the known bias.

5.2 Ingeneral,theseproceduresaremoresuitablefortesting

NOTE 1—If a constant strip length is adopted, the scale may be

woven fabrics than knit fabrics.

calibrated to read directly in units of bending length.

5.3 The Cantilever Test Option is the preferred procedure

6.2.3 Brass Bars, two, 25 3 75 3 3 6 0.1 mm

because it is simpler to perform. It is, however, not suitable for

(1 33 30.1256 0.005 in.).

very limp fabrics or those that show a marked tendency to curl

6.2.4 Pressure Sensitive Tape.

or twist at a cut edge.

6.2.5 Jig, constructed to allow positioning of the two bars

5.4 The Heart Loop Test Option is suitable for fabrics that

withtheirinneredgesparallelandatadistancefromeachother

show a tendency to curl or twist.

equal to the selected strip length.

5.5 Both options can provide a correlation with a subjective

evaluation of a given fabric type. That is, a higher number

7. Sampling and Test Specimens

represents a stiffer fabric.

7.1 Lot Sample—As a lot sample for acceptance testing,

5.6 The stiffness of a fabric may change with storage.

randomlyselectthenumberofrollsorpiecesoffabricdirected

5.7 No evidence has been found showing that bending

in an applicable material specification or other agreement

length is dependent on the width. The tendency for specimens

between the purchaser and the supplier. Consider the rolls or

to curl or twist will affect the result, because of the rigidity

pieces of fabric to be the primary sampling units. In the

providedattheedge.Consequently,thewiderthestrip,theless

absence of such an agreement, take the number of fabric rolls

important is the edge effect.

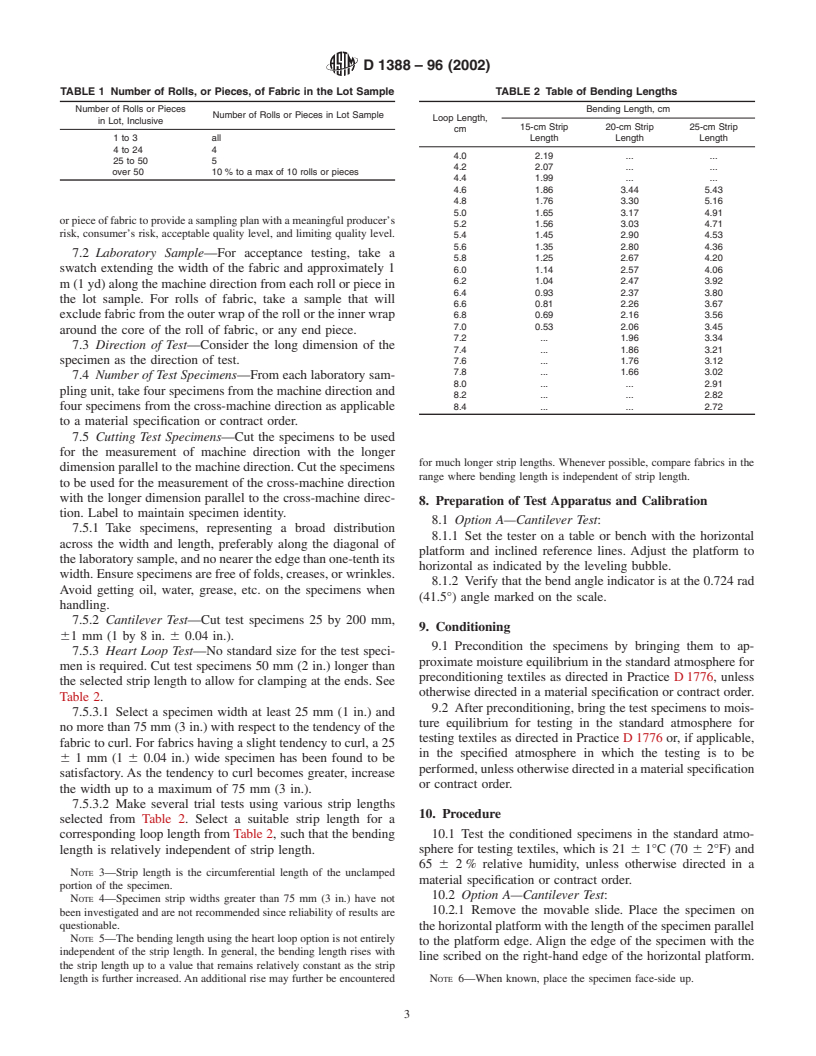

specified in Table 1.

6. Apparatus

NOTE 2—An adequate specification or other agreement between the

purchaserandsupplierrequirestakingintoaccountthevariabilitybetween

6.1 OptionA—CantileverBendingTester(Fig.1andFigs.2

rolls or pieces of fabric and between specimens from a swatch from a roll

).

6.1.1 Horizontal Platform, with a minimum area of 38 by

200 mm (1.5 by 8 in.) and having a smooth low-friction, flat

Amotorized bending tester such as described in Section 6.1 and Fig. 1 is being

surface such as polished metal or plastic. A leveling bubble

developed. Contact Instrument Marketing Services, a subsidiary of U.S. Testing

shall be incorporated in the platform. Company, Inc., 291 Fairfield Avenue, Farfield, NJ 07004.

D1388–96 (2002)

TABLE 1 Number of Rolls, or Pieces, of Fabric in the Lot Sample TABLE 2 Table of Bending Lengths

Number of Rolls or Pieces Bending Length, cm

Number of Rolls or Pieces in Lot Sample

Loop Length,

in Lot, Inclusive

15-cm Strip 20-cm Strip 25-cm Strip

cm

1to3 all Length Length Length

4to24 4

4.0 2.19 . .

25 to 50 5

4.2 2.07 . .

over 50 10 % to a max of 10 rolls or pieces

4.4 1.99 . .

4.6 1.86 3.44 5.43

4.8 1.76 3.30 5.16

5.0 1.65 3.17 4.91

orpieceoffabrictoprovideasamplingplanwithameaningfulproducer’s

5.2 1.56 3.03 4.71

risk, consumer’s risk, acceptable quality level, and limiting quality level.

5.4 1.45 2.90 4.53

5.6 1.35 2.80 4.36

7.2 Laboratory Sample—For acceptance testing, take a

5.8 1.25 2.67 4.20

swatch extending the width of the fabric and approximately 1 6.0 1.14 2.57 4.06

6.2 1.04 2.47 3.92

m(1yd)alongthemachinedirectionfromeachrollorpiecein

6.4 0.93 2.37 3.80

the lot sample. For rolls of fabric, take a sample that will

6.6 0.81 2.26 3.67

excludefabricfromtheouterwrapoftherollortheinnerwrap 6.8 0.69 2.16 3.56

7.0 0.53 2.06 3.45

around the core of the roll of fabric, or any end piece.

7.2 . 1.96 3.34

7.3 Direction of Test—Consider the long dimension of the

7.4 . 1.86 3.21

7.6 . 1.76 3.12

specimen as the direction of test.

7.8 . 1.66 3.02

7.4 Number of Test Specimens—From each laboratory sam-

8.0 . . 2.91

plingunit,takefourspecimensfromthemachinedirectionand

8.2 . . 2.82

four specimens from the cross-machine direction as applicable 8.4 . . 2.72

to a material specification or contract order.

7.5 Cutting Test Specimens—Cut the specimens to be used

for the measurement of machine direction with the longer

for much longer strip lengths. Whenever possible, compare fabrics in the

dimensionparalleltothemachinedirection.Cutthespecimens

range where bending length is independent of strip length.

to be used for the measurement of the cross-machine direction

with the longer dimension parallel to the cross-machine direc-

8. Preparation of Test Apparatus and Calibration

tion. Label to maintain specimen identity.

8.1 Option A—Cantilever Test:

7.5.1 Take specimens, representing a broad distribution

8.1.1 Set the tester on a table or bench with the horizontal

across the width and length, preferably along the diagonal of

platform and inclined reference lines. Adjust the platform to

thelaboratorysample,andnonearertheedgethanone-tenthits

horizontal as indicated by the leveling bubble.

width.Ensurespecimensarefreeoffolds,creases,orwrinkles.

8.1.2 Verify that the bend angle indicator is at the 0.724 rad

Avoid getting oil, water, grease, etc. on the specimens when

(41.5°) angle marked on the scale.

handling.

7.5.2 Cantilever Test—Cut test specimens 25 by 200 mm,

9. Conditioning

61mm(1by8in. 6 0.04 in.).

9.1 Precondition the specimens by bringing them to ap-

7.5.3 Heart Loop Test—No standard size for the test speci-

proximate moisture equilibrium in the standard atmosphere for

men is required. Cut test specimens 50 mm (2 in.) longer than

preconditioning textiles as directed in Practice D1776, unless

the selected strip length to allow for clamping at the ends. See

otherwise directed in a material specification or contract order.

Table 2.

9.2 After preconditioning, bring the test specimens to mois-

7.5.3.1 Select a specimen width at least 25 mm (1 in.) and

ture equilibrium for testing in the standard atmosphere for

no more than 75 mm (3 in.) with respect to the tendency of the

testing textiles as directed in Practice D1776 or, if applicable,

fabric to curl. For fabrics having a slight tendency to curl, a 25

in the specified atmosphere in which the testing is to be

61mm(1 6 0.04 in.) wide specimen has been found to be

performed,unlessotherwisedirectedinamaterialspecification

satisfactory.As the tendency to curl becomes greater, increase

or contract order.

the width up to a maximum of 75 mm (3 in.).

7.5.3.2 Make several trial tests using various strip lengths

10. Procedure

selected from Table 2. Select a suitable strip length for a

corresponding loop length from Table 2, such that the bending 10.1 Test the conditioned specimens in the standard atmo-

sphere for testing textiles, which is 21 6 1°C (70 6 2°F) and

length is relatively independent of strip length.

65 6 2% relative humidity, unless otherwise directed in a

NOTE 3—Strip length is the circumferential length of the unclamped

material specification or contract order.

portion of the specimen.

10.2 Option A—Cantilever Test:

NOTE 4—Specimen strip widths greater than 75 mm (3 in.) have not

10.2.1 Remove the movable slide. Place the specimen on

been investigated and are not recommended since reliability of results are

questionable.

thehorizontalplatformwiththelengthofthespecimenparallel

NOTE 5—The bending length using the heart loop option is not entirely

to the platform edge. Align the edge of the specimen with the

independent of the strip length. In general, the bending length rises with

line scribed on the right-hand edge of the horizontal platform.

the strip length up to a value that remains relatively constant as the strip

length is further increased.An additional rise may further be encountered NOTE 6—When known, place the specimen face-side up.

D1388–96 (2002)

10.2.2 Place the movable slide on the specimen, being 11. Calculation

careful not to change its initial position.

11.1 Option A, Length of Overhang, Individual

10.2.3 F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.