ASTM E2039-99

(Practice)Standard Practice for Determining and Reporting Dynamic Dielectric Properties

Standard Practice for Determining and Reporting Dynamic Dielectric Properties

SCOPE

1.1 This practice is to be used for gathering and reporting dynamic dielectric data. It incorporates laboratory practice for determining dynamic dielectric properties of specimens subjected to an oscillatory electric field using a variety of dielectric sensor/cell configurations on a variety of instruments called dielectric, microdielectric, DETA (DiElectric Thermal Analysis), or DEA (DiElectric Analysis) analyzers.

1.2 This practice determines permittivity, loss factor, ionic conductivity (or resistivity), dipole relaxation times, and transition temperatures, and is intended for materials that have a relative permittivity in the range of 1 to 105; loss factors in the range of 0 to 108; and, conductivities in the range of 1016 to 1010 siemens/cm.

1.3 The practice is primarily useful when conducted over a range of temperatures for nonreactive systems (-160°C to degradation) and over time (and temperature) for reactive systems and is valid for frequencies ranging from 1 mHz to 100 kHz.

1.4 Apparent discrepancies may arise in results obtained under differing experimental conditions. Without changing the observed data, completely reporting the conditions (as described in this practice) under which the data were obtained, in full, will enable apparent differences observed in another study to be reconciled.

1.5 Values reported in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2039 – 99

Standard Practice for

Determining and Reporting Dynamic Dielectric Properties

This standard is issued under the fixed designation E 2039; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (Dielectric Constant) of Solid Electrical Insulating Mate-

rials

1.1 This practice is to be used for gathering and reporting

E 473 Terminology Relating to Thermal Analysis

dynamic dielectric data. It incorporates laboratory practice for

E 1142 Terminology Relating to Thermophysical Proper-

determining dynamic dielectric properties of specimens sub-

ties

jected to an oscillatory electric field using a variety of dielectric

E 2038 Test Method for Temperature Calibration of Dielec-

sensor/cell configurations on a variety of instruments called

tric Analyzers

dielectric, microdielectric, DETA (DiElectric Thermal Analy-

sis), or DEA (DiElectric Analysis) analyzers.

3. Terminology

1.2 This practice determines permittivity, loss factor, ionic

3.1 Definitions:

conductivity (or resistivity), dipole relaxation times, and tran-

3.1.1 The following technical terms are applicable to this

sition temperatures, and is intended for materials that have a

document and are defined in Terminologies E 473 and E 1142:

relative permittivity in the range of 1 to 10 ; loss factors in the

8 16

dielectric thermal analysis, angular frequency, capacitance,

range of 0 to 10 ; and, conductivities in the range 10 to

conductivity, dielectric constant, dielectric dissipation factor,

10 siemens/cm.

dielectric loss angle, dipole relaxation time, dissipation factor,

1.3 The practice is primarily useful when conducted over a

frequency, loss factor, permittivity, phase angle, and tangent

range of temperatures for nonreactive systems (−160°C to

delta.

degradation) and over time (and temperature) for reactive

3.1.2 Relative permittivity and loss factor are dimensionless

systems and is valid for frequencies ranging from 1 mHz to 100

quantities and are relative to the permittivity of free space (e 5

kHz.

8.854 pF/m). Relative permittivity also is known as the

1.4 Apparent discrepancies may arise in results obtained

dielectric constant.

under differing experimental conditions. Without changing the

3.2 Definitions of Terms Specific to This Standard:

observed data, completely reporting the conditions (as de-

3.2.1 dielectric (or microdielectric) sensor, n—a set of at

scribed in this practice) under which the data were obtained, in

least two (perhaps three) contacting electrodes for measuring

full, will enable apparent differences observed in another study

the dielectric response of materials.

to be reconciled.

3.2.1.1 Discussion—The sensor generally consists of paral-

1.5 Values reported in SI units are to be regarded as the

lel, circular, conducting (metallic) plates or discs, between

standard.

which the sample is placed. The sensor also may be a set of

1.6 This standard does not purport to address all of the

interdigitated conductors on an insulating substrate. In some

safety concerns, if any, associated with its use. It is the

cases, the sensor may incorporate amplifying electronics or a

responsibility of the user of this standard to establish appro-

temperature sensing device (see Fig. 1), or both.

priate safety and health practices and determine the applica-

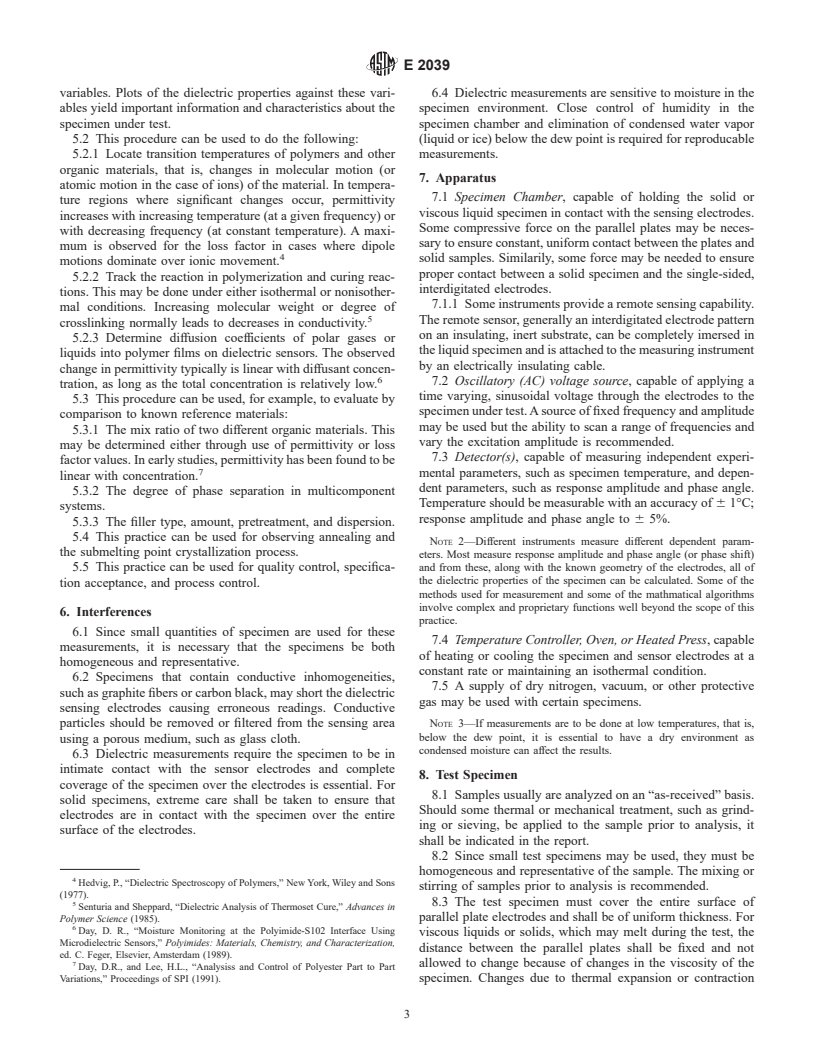

3.2.2 interdigitated electrode, n—an electrode configuration

bility of regulatory limitations prior to use. Specific precau-

consisting of two nonconnected, interpenetrating conductors

tionary statements are given in Section 10.

firmly attached to an insulating substrate and exposed to the

2. Referenced Documents specimen on top.

3.2.2.1 Discussion—Interdigitated electrodes of different

2.1 ASTM Standards:

geometry are available, such as, interpenetrating “fingers” or

D 150 Test Method for A-C Characteristics and Permittivity

“combs,” interpenetrating circular spirals, or interpenetrating

square spirals (see Fig. 1).

This practice is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

Methods and Recommended Practices. Annual Book of ASTM Standards, Vol 10.01.

Current edition approved Sept. 10, 1999. Published January 2000 . Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 2039

3.2.7.1 Discussion—This value depends only on the geom-

etry of the sensor and the material of the substrate, and not on

the specimen under test on top of the interdigitated electrodes.

3.3 Abbreviations:

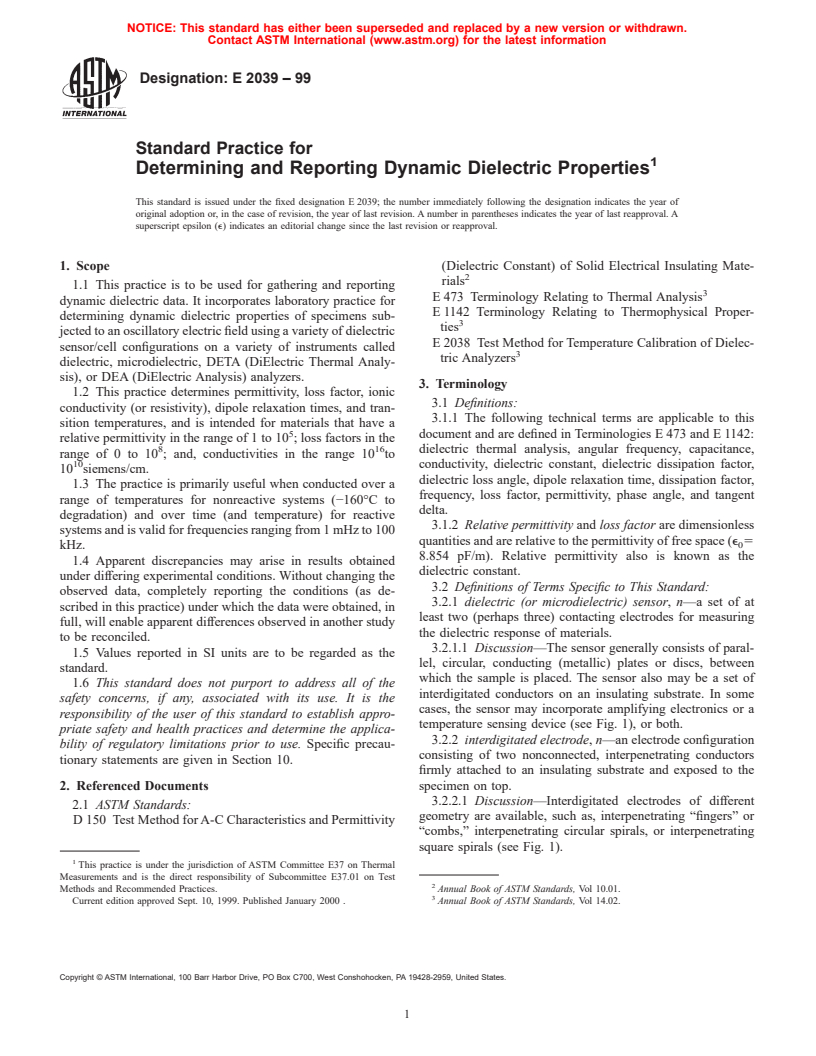

A 5 plate area (calculated as 23p3 r ) (see Fig. 1)

C 5 parallel capacitance (see Test Method D 150)

p

R 5 parallel resistance (see Test Method D 150)

p

r 5 radius of circular plate (see Fig. 1).

4. Summary of Practice

FIG. 1 Parallel Plate Electrode

4.1 An oscillatory electric potential (voltage) is applied to a

test specimen by means of an electrode of known geometry. An

electric current is measured at a sensing electrode separated

Whereas parallel plate electrodes contact a specimen on a “top” and

from the transmitting electrode by the specimen under test.

“bottom” surface, the interdigitated electrodes make contact on only

one side (single-sided contact) of the specimen.

From the amplitude and phase shift of the measured current

relative to the applied voltage and from known geometrical

3.2.3 electrode spacing (E ), n—for interdigitated elec-

S

constants, such as electrode spacing and electrode arrange-

trodes, the distance between electrodes in the electrode array

ment, desired dielectric properties of the specimen under test

(see Fig. 1).

may be obtained. Such properties include conductivity, dielec-

3.2.4 electrode width (E ), n—for interdigitated electrodes,

W

tric constant, dielectric dissipation factor, dielectric loss angle,

the width of a single electrode in the electrode array (see Fig.

dipole relaxation time, dissipation factor, relative permittivity,

1).

3.2.5 electrode height (E ), n—for interdigitated electrodes, loss factor, and tangent delta. The desired dielectric properties

h

the thickness of an electrode normal to the surface of the may be obtained as a function of frequency, temperature, or

substrate upon which it is situated (see Fig. 1).

time by varying and measuring these independent parameters

3.2.6 meander length (M ), n—for interdigitated electrodes, during the course of the experiment.

L

the length of the path between the two conductors in the

NOTE 1—The particular method for measurement of amplitude and

electrode array.

phase shift depends upon the operating principle of the instrument used.

3.2.6.1 Discussion—It is the distance a flea situated in the

space between the electrodes would have to walk, starting at

5. Significance and Use

one end of the array, to get to the other.

5.1 Dielectric measurement and testing provide a method

3.2.7 substrate capacitance (C ), n—for interdigitated

sub

electrodes, the capacitance of the sensor due to the insulating for determining the permittivity and loss factors as a function

substrate. of temperature, frequency, time, or a combination of these

FIG. 2 Interdigitated Electrodes

E 2039

variables. Plots of the dielectric properties against these vari- 6.4 Dielectric measurements are sensitive to moisture in the

ables yield important information and characteristics about the specimen environment. Close control of humidity in the

specimen under test. specimen chamber and elimination of condensed water vapor

5.2 This procedure can be used to do the following: (liquid or ice) below the dew point is required for reproducable

5.2.1 Locate transition temperatures of polymers and other measurements.

organic materials, that is, changes in molecular motion (or

7. Apparatus

atomic motion in the case of ions) of the material. In tempera-

7.1 Specimen Chamber, capable of holding the solid or

ture regions where significant changes occur, permittivity

viscous liquid specimen in contact with the sensing electrodes.

increases with increasing temperature (at a given frequency) or

Some compressive force on the parallel plates may be neces-

with decreasing frequency (at constant temperature). A maxi-

sary to ensure constant, uniform contact between the plates and

mum is observed for the loss factor in cases where dipole

solid samples. Similarily, some force may be needed to ensure

motions dominate over ionic movement.

proper contact between a solid specimen and the single-sided,

5.2.2 Track the reaction in polymerization and curing reac-

interdigitated electrodes.

tions. This may be done under either isothermal or nonisother-

7.1.1 Some instruments provide a remote sensing capability.

mal conditions. Increasing molecular weight or degree of

The remote sensor, generally an interdigitated electrode pattern

crosslinking normally leads to decreases in conductivity.

on an insulating, inert substrate, can be completely imersed in

5.2.3 Determine diffusion coefficients of polar gases or

the liquid specimen and is attached to the measuring instrument

liquids into polymer films on dielectric sensors. The observed

by an electrically insulating cable.

change in permittivity typically is linear with diffusant concen-

7.2 Oscillatory (AC) voltage source, capable of applying a

tration, as long as the total concentration is relatively low.

time varying, sinusoidal voltage through the electrodes to the

5.3 This procedure can be used, for example, to evaluate by

specimen under test. A source of fixed frequency and amplitude

comparison to known reference materials:

may be used but the ability to scan a range of frequencies and

5.3.1 The mix ratio of two different organic materials. This

vary the excitation amplitude is recommended.

may be determined either through use of permittivity or loss

7.3 Detector(s), capable of measuring independent experi-

factor values. In early studies, permittivity has been found to be

mental parameters, such as specimen temperature, and depen-

linear with concentration.

dent parameters, such as response amplitude and phase angle.

5.3.2 The degree of phase separation in multicomponent

Temperature should be measurable with an accuracy of 6 1°C;

systems.

response amplitude and phase angle to 6 5%.

5.3.3 The filler type, amount, pretreatment, and dispersion.

5.4 This practice can be used for observing annealing and

NOTE 2—Different instruments measure different dependent param-

the submelting point crystallization process.

eters. Most measure response amplitude and phase angle (or phase shift)

5.5 This practice can be used for quality control, specifica- and from these, along with the known geometry of the electrodes, all of

the dielectric properties of the specimen can be calculated. Some of the

tion acceptance, and process control.

methods used for measurement and some of the mathmatical algorithms

involve complex and proprietary functions well beyond the scope of this

6. Interferences

practice.

6.1 Since small quantities of specimen are used for these

7.4 Temperature Controller, Oven, or Heated Press, capable

measurements, it is necessary that the specimens be both

of heating or cooling the specimen and sensor electrodes at a

homogeneous and representative.

constant rate or maintaining an isothermal condition.

6.2 Specimens that contain conductive inhomogeneities,

7.5 A supply of dry nitrogen, vacuum, or other protective

such as graphite fibers or carbon black, may short the dielectric

gas may be used with certain specimens.

sensing electrodes causing erroneous readings. Conductive

particles should be removed or filtered from the sensing area NOTE 3—If measurements are to be done at low temperatures, that is,

below the dew point, it is essential to have a dry environment as

using a porous medium, such as glass cloth.

condensed moisture can affect the results.

6.3 Dielectric measurements require the specimen to be in

intimate contact with the sensor electrodes and complete

8. Test Specimen

coverage of the specimen over the electrodes is essential. For

8.1 Samples usually are analyzed on an “as-received” basis.

solid specimens, extreme care shall be taken to ensure that

Should some thermal or mechanical treatment, such as grind-

electrodes are in contact with the specimen over the entire

ing or sieving, be applied to the sample prior to analysis, it

surface of the electrodes.

shall be indicated in the report.

8.2 Since small test specimens may be used, they must be

homogeneous and representative of the sample. The mixing or

Hedvig, P., “Dielectric Spectroscopy of Polymers,” New York, Wiley and Sons

stirring of samples prior to analysis is recommended.

(1977).

5 8.3 The test specimen must cover the entire surface of

Senturia and Sheppard, “Dielectric Analysis of Thermoset Cure,” Advances in

parallel plate electrodes and shall be of uniform thickness. For

Polymer Science (1985).

Day, D. R., “Moisture Monitoring at the Polyimide-S102 Interface Using

viscous liquids or solids, which may melt during the test, the

Microdielectric Sensors,” Polyimides: Materials, Chemistry, and Characterization,

distance between the parallel plates shall be fixed and not

ed. C. Feger, Elsevier, Amsterdam (1989).

allowed to change because of changes in the viscosity of the

Day, D.R., and Lee, H.L., “Analysiss and Control of Polyester Part to Part

Variations,” Proceedings of SPI (1991). specimen. Changes due to thermal expansion or contraction

E 2039

depend upon the rate of change of dielectric properties with temperature

normally are neglected (provided the specimen does not pull

of the material being investigated. In transition regions, experience has

away from the electrodes). For parallel plate cells, the optimum

indicated that the specimen temperature should be read to the nearest °C.

test specimen thickness actually depends on the dielectric

properties of the specimen, sensor size, and choice of indepen-

11.1.3 Duplicate specimens should be examined, and the

dent variables (temperature, frequency); however, a minimum

mean results reported.

thickness of 0.1 mm is recommended.

11.2 Where frequency is to be the independent variable, do

8.4 For interdigitated electrodes, the thickness of the test

the following:

specimen, whether liquid or solid, should be at least 1.5 times

11.2.1 Fix the temperature at the desired value.

the electrode spacing and fully cover the interdigitated elec-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.