ASTM F418-77(2002)

(Practice)Standard Practice for Preparation of Samples of the Constant Composition Region of Epitaxial Gallium Arsenide Phosphide for Hall Effect Measurements (Withdrawn 2008)

Standard Practice for Preparation of Samples of the Constant Composition Region of Epitaxial Gallium Arsenide Phosphide for Hall Effect Measurements (Withdrawn 2008)

SIGNIFICANCE AND USE

The efficiency of light-emitting diodes is known to vary with the carrier density of the starting material. This procedure provides a technique to prepare specimens in which the Hall carrier density can be measured in a region typical of that in which devices are fabricated. This quantity, which is related to the carrier density, can be used directly as a quality control parameter.

Mobility is a function of a number of parameters of a semiconductor, including ionized impurity density, compensation, and lattice defects, some or all of which may be relatable to material quality as reflected in device quality. Use of this procedure makes the measurement of the mobility of the constant composition region possible.

Since in GaAs (1−x)Px with x near 0.38, as is most often used for light-emitting diodes, the direct (000 or Γ) minimum and the indirect (100 or X) minima are within a few millielectronvolts in energy of each other, both are populated with current-carrying electrons. The mobility in the two bands is significantly different, and the relative population of the two is dependent upon the precise composition (x value), doping level, and temperature. Therefore, both Hall coefficient and Hall mobility must be interpreted with care (2,3). In particular, a measurement of Hall carrier density will not agree with a carrier density measurement on the same specimen made by capacitance-voltage techniques. Nevertheless, if the intent of measuring the carrier density of purchased or grown specimens is to find those which are optimum for diode fabrication, Hall measurements can be of value because a curve of efficiency versus Hall carrier density can be derived for the device process to be used based upon data taken on specimens prepared in accordance with this procedure.

SCOPE

1.1 This practice covers a procedure to be followed to free the constant composition region of epitaxially grown gallium arsenide phosphide, GaAs(1x)Px, from the substrate and graded region on which it was grown in order to measure the electrical properties of only the constant composition region, which is typically 30 to 100 m thick. It also sets forth two alternative procedures to be followed to make electrical contact to the specimen.

1.2 It is intended that this practice be used in conjunction with Test Methods F 76.

1.3 The specific parameters set forth in this recommended practice are appropriate for GaAs0. 62P0. 38, but they can be applied, with changes in etch times, to material with other compositions.

1.4 This practice does not deal with making or interpreting the Hall measurement on a specimen prepared as described herein, other than to point out the existence and possible effects due to the distribution of the free carriers among the two conduction band minima.

1.5 This practice can also be followed in the preparation of specimens of the constant composition region for light absorption measurements or for mass or emission spectrometric analysis.

1.6 This practice becomes increasingly difficult to apply as specimens become thinner.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statement, see Section 9 and 11.9.2.4.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee F01 on Electronics, this practice was withdrawn in June 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 418–77(Reapproved2002)

Standard Practice for

Preparation of Samples of the Constant Composition

Region of Epitaxial Gallium Arsenide Phosphide for Hall

Effect Measurements

This standard is issued under the fixed designation F 418; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This practice covers a procedure to be followed to free 2.1 ASTM Standards:

the constant composition region of epitaxially grown gallium D 1125 Test Methods for Electrical Conductivity and Re-

arsenide phosphide, GaAs P , from the substrate and sistivity of Water

(1−x) x

graded region on which it was grown in order to measure the F 76 Test Methods for Measuring Resistivity and Hall

electrical properties of only the constant composition region, Coefficient and Determining Hall Mobility in Single-

which is typically 30 to 100 µm thick. It also sets forth two Crystal Semiconductors

alternativeprocedurestobefollowedtomakeelectricalcontact F 358 Test Method for Wavelength of Peak Photolumines-

to the specimen. cence and the Corresponding Composition of Gallium

1.2 It is intended that this practice be used in conjunction Arsenide Phosphide Wafers

with Test Methods F76.

3. Terminology

1.3 The specific parameters set forth in this recommended

3.1 Definitions:

practice are appropriate for GaAs P , but they can be

0.62 0.38

applied, with changes in etch times, to material with other 3.1.1 constant composition region—as applied to epitaxial

GaAs P , the layer last grown in which the composition is

compositions.

(1−x) x

1.4 This practice does not deal with making or interpreting held fixed at about the desired value of x in mole percent

phosphorus; x is typically 0.38.

the Hall measurement on a specimen prepared as described

herein,otherthantopointouttheexistenceandpossibleeffects 3.1.2 graded region—as applied to epitaxial GaAs P ,

(1−x) x

due to the distribution of the free carriers among the two thelayerfirstgrowninwhichthecompositionischangedfrom

GaAs to GaAs P during the growth of the layer. The

conduction band minima.

(1−x) x

1.5 This practice can also be followed in the preparation of purpose of this layer is to minimize the lattice mismatch

between the GaAs substrate and the GaAs P layers.

specimens of the constant composition region for light absorp-

(1−x) x

−3

tion measurements or for mass or emission spectrometric 3.1.3 Hall carrier density—1/R e[cm ]—thereciprocalof

H

the product of the Hall coefficient and the electronic charge, a

analysis.

1.6 This practice becomes increasingly difficult to apply as quantity related to the charge carrier density.

specimens become thinner.

4. Summary of Practice

1.7 This standard does not purport to address all of the

4.1 In this practice (1), a specimen is cleaved from a full

safety concerns, if any, associated with its use. It is the

wafer of GaAs P , the substrate is partially removed by

responsibility of the user of this standard to establish appro-

(1−x) x

mechanical lapping, the remainder of the substrate and the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For hazard state-

ment, see Section 9 and 11.9.2.4.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This practice is under the jurisdiction ofASTM Committee F01 on Electronics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee F01.15 on Compound Semicon- Standards volume information, refer to the standard’s Document Summary page on

ductors. the ASTM website.

Current edition approved May 27, 1977. Published July 1977. Originally The boldface numbers in parentheses refer to the list of references appended to

published as F 418-75 T. Last previous edition F 418-75 T. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 418–77 (2002)

graded region are removed by chemical lapping, and the the graded layer will add to those of the constant composition

specimen is contacted either by welding or by flip chip region in the usual multilayer fashion (4).

mounting.

6.2 Erroneous measurement of the specimen thickness will

4.2 Complete removal of substrate and graded region is lead directly to an erroneous determination of the Hall coeffi-

assured either by timed etching in an etchant with a composi-

cient, since the Hall coefficient is the product of the measured

tionallydependentetchrateorbymeasurementofcomposition Hall voltage and the thickness.

of the etched surface in accordance with Test Method F358.

6.3 Nonuniform thickness can also lead to erroneous mea-

4.3 The thickness of the final specimen is measured micro-

surements (see 6.2).

scopically on a small section cleaved out of the rest of the

6.4 GaAs P can be highly photoconductive; hence Hall

(1−x) x

thinned specimen.

measurements on this material must be made in the dark.

5. Significance and Use

7. Apparatus

5.1 The efficiency of light-emitting diodes is known to vary

7.1 Hot Stage capable of heating the lapping fixture or a

with the carrier density of the starting material.This procedure

glass microscope slide to a temperature approximately 10°C

provides a technique to prepare specimens in which the Hall

above the melting point of the mounting wax (8.6).

carrier density can be measured in a region typical of that in

7.2 Lapping Fixture capable of limiting the removal by

which devices are fabricated.This quantity, which is related to

lapping of material to a final thickness of 5 6 1 mil (0.13 6

the carrier density, can be used directly as a quality control

0.03 mm).

parameter.

7.3 Glass Plate for lapping. A sheet of plate glass ⁄4 by 8

5.2 Mobility is a function of a number of parameters of a

by 10 in. (or 7 by 200 by 250 mm) is convenient, but the exact

semiconductor, including ionized impurity density, compensa-

size is not critical.

tion, and lattice defects, some or all of which may be relatable

7.4 Chemical Laboratory Apparatus such as beakers,

to material quality as reflected in device quality. Use of this

graduates, and tweezers suitable for handling the reagents and

procedure makes the measurement of the mobility of the

solvents used in the etching and mounting steps.

constant composition region possible.

7.5 Microscope with cross hair and calibrated eyepiece

5.3 Since in GaAs P with x near 0.38, as is most often

(1−x) x

capable of measuring the specimen thickness (typically 30 to

used for light-emitting diodes, the direct (000 or G) minimum

100 µm) to 61%or 60.5 µm, whichever is greater.

and the indirect (100 or X) minima are within a few millielec-

7.5.1 Microscope Lamp or other source of intense white

tronvolts in energy of each other, both are populated with

light to illuminate the specimen by transmitted light.

current-carrying electrons. The mobility in the two bands is

7.5.2 Microscope Slides and Microscope Cover Slides.

significantly different, and the relative population of the two is

7.5.3 Diamond Scribe and Metal Straight-edge or other

dependent upon the precise composition (x value), doping

apparatus for cutting microscope cover slides.

level, and temperature. Therefore, both Hall coefficient and

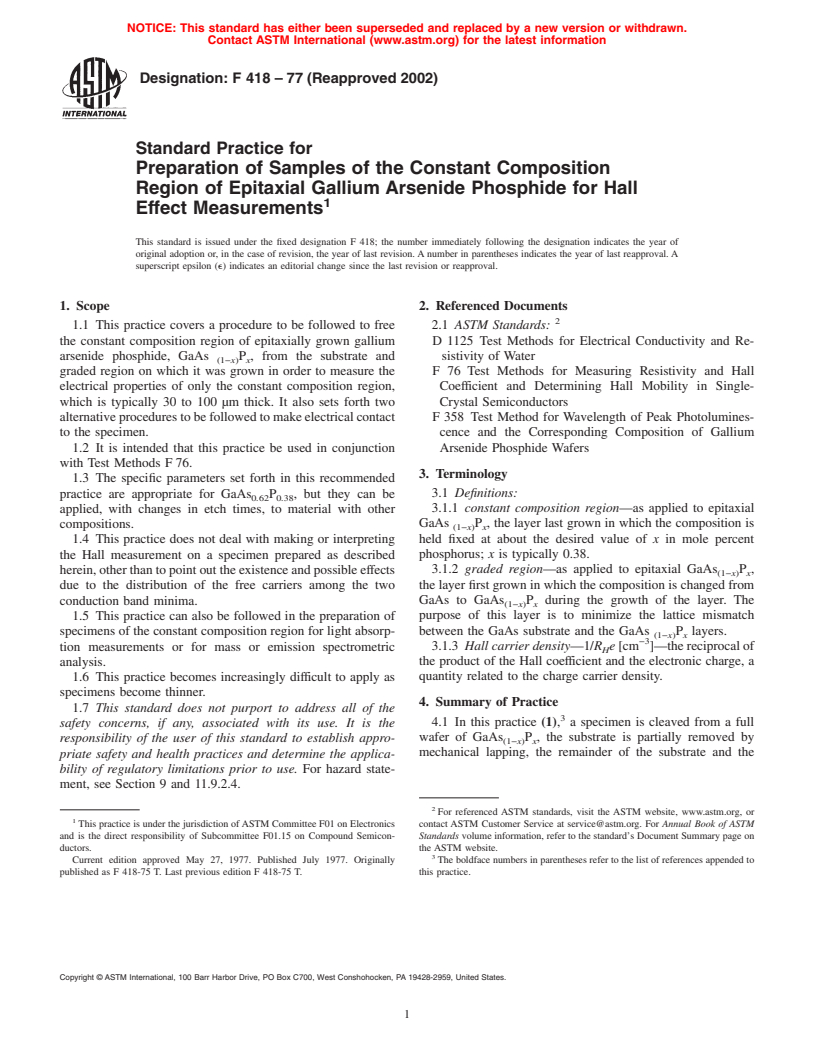

7.6 Specimen Mounts, each comprising an insulating ce-

Hall mobility must be interpreted with care (2,3). In particular,

ramic substrate composed of 96% alumina with four solder-

a measurement of Hall carrier density will not agree with a

able regions composed of fired silver palladium paste or other

carrier density measurement on the same specimen made by

solderable material (see Fig. 1).

capacitance-voltage techniques. Nevertheless, if the intent of

7.7 Contacting Apparatus as described in 7.7.1 or 7.7.2.

measuringthecarrierdensityofpurchasedorgrownspecimens

7.7.1 For Flip Chip Mounting:

is to find those which are optimum for diode fabrication, Hall

7.7.1.1 Strip Heater Apparatus capable of heating the

measurements can be of value because a curve of efficiency

versus Hall carrier density can be derived for the device specimento425 625°Cforacontrolledtimeintervalofafew

process to be used based upon data taken on specimens seconds,andthentoapproximately200°Cforacontrolledtime

prepared in accordance with this procedure. interval of up to 1 min, in a forming gas atmosphere.

7.7.1.2 Low-Power Microscope suitably positioned over

6. Interferences the strip heater to observe the specimen during the heating

cycle.

6.1 Incomplete removal of the graded region can lead to

7.7.2 For Welding:

spurious results, since the Hall coefficient and Hall mobility of

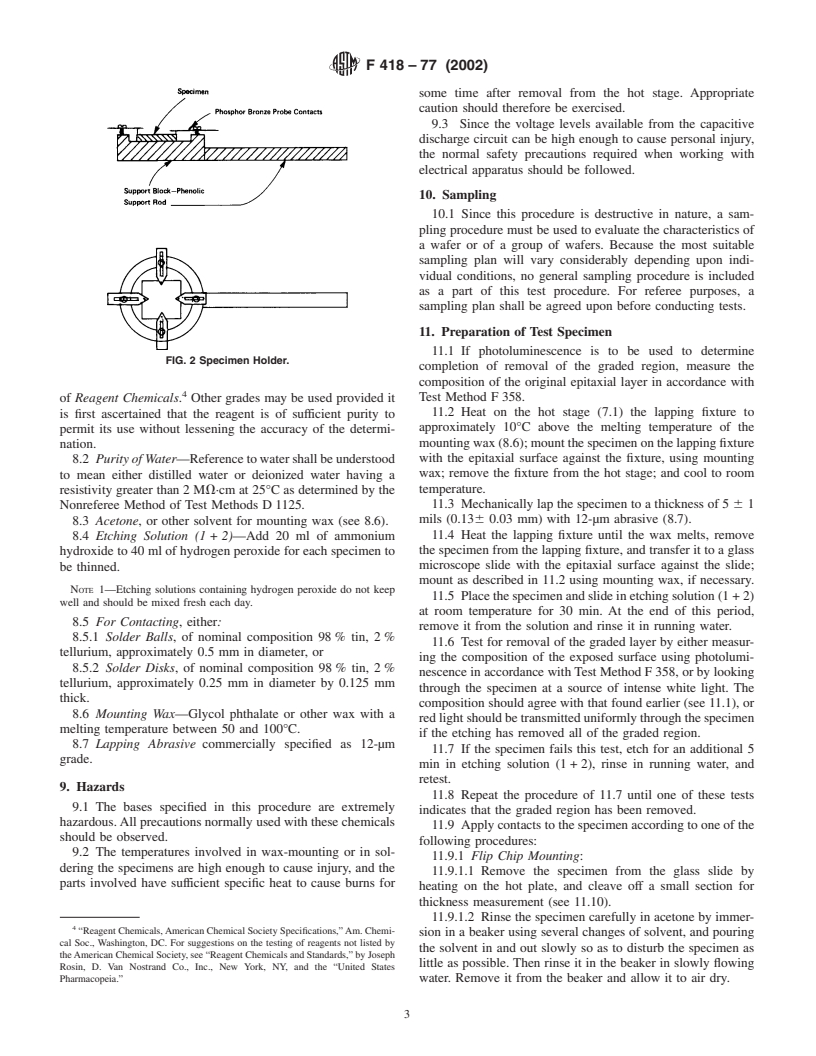

7.7.2.1 Fixture capable of supporting the specimen when

waxed onto a glass slide while making pressure contact to the

specimen at four points on its perimeter (see Fig. 2).

7.7.2.2 Electrical Apparatus capable of charging a 0.5-µF

capacitor to 100 to 200 V and of discharging that capacitor

through an arbitrary pair of the four contacts to the specimen

(see Fig. 3).

8. Reagents and Materials

8.1 Purity of Reagents—Reagent grade chemicals shall be

NOTE 1—All dimensions are approximate.

FIG. 1 Specimen Mount. usedinalltests.Allreagentsshallconformtotherequirements

F 418–77 (2002)

some time after removal from the hot stage. Appropriate

caution should therefore be exercised.

9.3 Since the voltage levels available from the capacitive

discharge circuit can be high enough to cause personal injury,

the normal safety precautions required when working with

electrical apparatus should be followed.

10. Sampling

10.1 Since this procedure is destructive in nature, a sam-

pling procedure must be used to evaluate the characteristics of

a wafer or of a group of wafers. Because the most suitable

sampling plan will vary conside

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.