ASTM C490/C490M-08

(Practice)Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

SIGNIFICANCE AND USE

This practice is intended to provide standard requirements for apparatus common to many test methods used in connection with cement and concrete and standardized procedures for its use. The detailed requirements as to materials, mixtures, specimens, conditioning of specimens, number of specimens, ages at which measurements are to be made, interpretation of results, and precision and bias are left to be dealt with in specific test methods.

SCOPE

1.1 This practice covers the requirements for the apparatus and equipment used to prepare specimens for the determination of length change in hardened cement paste, mortar, and concrete, the apparatus and equipment used for the determination of these length changes, and the procedures for its use.

1.2 Methods for the preparation and curing of test specimens, conditions of testing and curing, and detailed procedures for calculating and reporting test results are contained in applicable test methods.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C490/C490M–08

Standard Practice for

Use of Apparatus for the Determination of Length Change of

1

Hardened Cement Paste, Mortar, and Concrete

This standard is issued under the fixed designation C490/C490M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* connection with cement and concrete and standardized proce-

dures for its use. The detailed requirements as to materials,

1.1 This practice covers the requirements for the apparatus

mixtures, specimens, conditioning of specimens, number of

andequipmentusedtopreparespecimensforthedetermination

specimens, ages at which measurements are to be made,

of length change in hardened cement paste, mortar, and

interpretation of results, and precision and bias are left to be

concrete, the apparatus and equipment used for the determina-

dealt with in specific test methods.

tion of these length changes, and the procedures for its use.

1.2 Methods for the preparation and curing of test speci-

5. Apparatus

mens, conditions of testing and curing, and detailed procedures

5.1 Reference Masses and Devices for Determining Mass

for calculating and reporting test results are contained in

andVolume, shall conform to the requirements of Specification

applicable test methods.

C1005.

1.3 The values stated in either SI units or inch-pound units

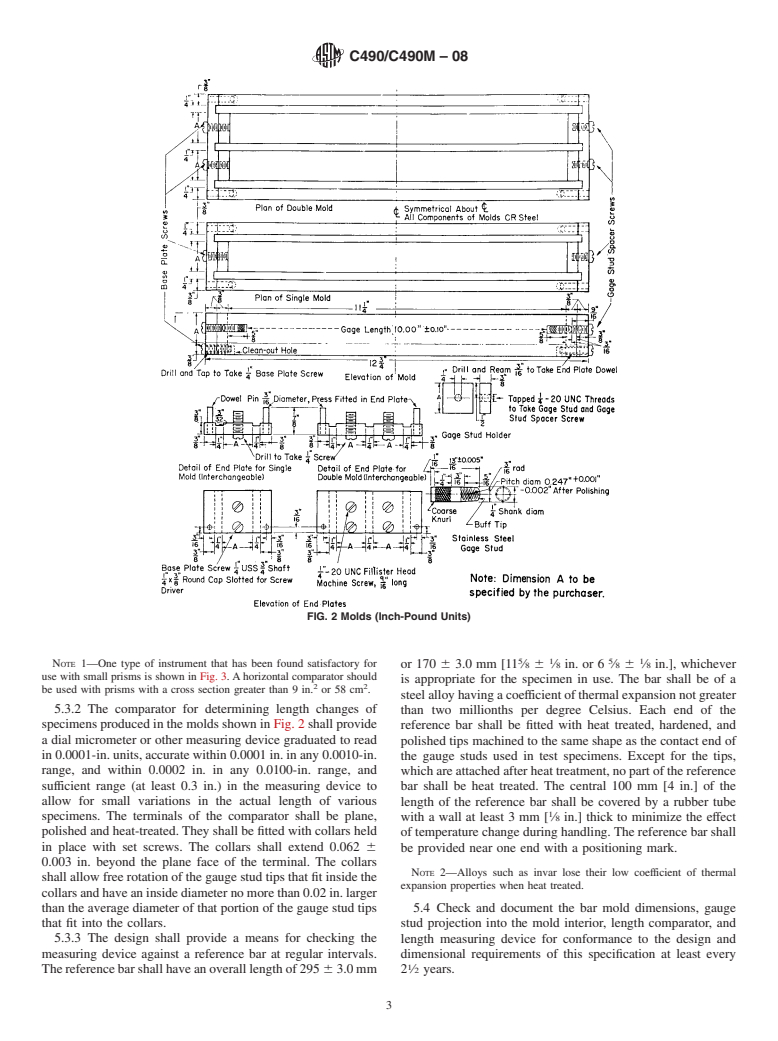

5.2 Molds, shall have either one or two compartments and

are to be regarded separately as standard. The values stated in

shall be constructed as shown in Fig. 1 or Fig. 2. Molds for test

each system may not be exact equivalents; therefore, each

specimens used in determining the length change of cement

system shall be used independently of the other. Combining

pastes and mortars shall provide for 25 by 25 by 285-mm

values from the two systems may result in non-conformance

1

prisms having a 250-mm gauge length, or for 1 by 1 by 11 ⁄4

with the standard.

–in. prisms having a 10–in. gauge length. Molds for test

2. Referenced Documents specimens used in the length change of concretes shall provide

2

for prisms of the desired cross section having a 10-in. or

2.1 ASTM Standards:

250-mm gauge length. In some routine tests, 25 by 25 by

C511 Specification for Mixing Rooms, Moist Cabinets,

160-mm specimens with a gauge length of 125 mm, or 1 by 1

Moist Rooms, and Water Storage Tanks Used in the

1

by 6 ⁄4 –in. specimens with a gauge length of 5-in. are

Testing of Hydraulic Cements and Concretes

permitted, but in case of dispute, results obtained with speci-

C1005 Specification for Reference Masses and Devices for

mens of 250-mm [10-in.] gauge length shall govern.

Determining Mass and Volume for Use in the Physical

5.2.1 The gauge length shall be considered as the nominal

Testing of Hydraulic Cements

length between the innermost ends of the gauge studs. The

3. Terminology

parts of the molds shall be tight fitting and firmly held together

when assembled, and their surfaces shall be smooth and free of

3.1 length change—an increase or decrease in the linear

pits. The molds shall be made of steel or other hard metal not

dimension of a test specimen, measured along the longitudinal

readily attacked by the cement paste, mortar, or concrete. The

axis, due to causes other than applied load.

sides of the molds shall be sufficiently rigid to prevent

4. Significance and Use

spreading or warping. For the molds shown in Fig. 1, the

tolerance on dimensionAis 60.7 mm. For the molds shown in

4.1 This practice is intended to provide standard require-

Fig. 2, the tolerance on dimension A is 60.03 in.

ments for apparatus common to many test methods used in

5.2.2 Each end plate of the mold shall be equipped to hold

properly in place, during the setting period, one of the gauge

studs shown in Fig. 1 or Fig. 2. The gauge studs shall be of

1

This practice is under the jurisdiction ofASTM Committee C01 on Cement and

3

American Iron and Steel Institute (AISI) Type 316 stainless

is the direct responsibility of Subcommittee C01.95 on Coordination of Standards.

CurrenteditionapprovedJune1,2008.PublishedJuly2008.Originallyapproved

steel or other corrosion-resistant metal of similar hardness.

in 1962. Last previous edition approved in 2007 as C490 – 07. DOI: 10.1520/

C0490_C0490M-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Details on this material are available from American Iron and Steel Institute

Standards volume information, refer to the standard’s Document Summary page on (AISI), 1140 Connecticut Ave., NW, Suite 705, Washington, DC 20036, http://

the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C490–07 Designation: C 490/C 490M – 08

Standard Practice for

Use of Apparatus for the Determination of Length Change of

1

Hardened Cement Paste, Mortar, and Concrete

This standard is issued under the fixed designation C 490/C 490M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the requirements for the apparatus and equipment used to prepare specimens for the determination of

length change in hardened cement paste, mortar, and concrete, the apparatus and equipment used for the determination of these

length changes, and the procedures for its use.

1.2 Methods for the preparation and curing of test specimens, conditions of testing and curing, and detailed procedures for

calculating and reporting test results are contained in applicable test methods.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C 511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C 1005 Specification for Reference Masses and Devices for Determining Mass and Volume for Use in the Physical Testing of

Hydraulic Cements

3. Terminology

3.1 length change—an increase or decrease in the linear dimension of a test specimen, measured along the longitudinal axis,

due to causes other than applied load.

4. Significance and Use

4.1 This practice is intended to provide standard requirements for apparatus common to many test methods used in connection

with cement and concrete and standardized procedures for its use. The detailed requirements as to materials, mixtures, specimens,

conditioning of specimens, number of specimens, ages at which measurements are to be made, interpretation of results, and

precision and bias are left to be dealt with in specific test methods.

5. Apparatus

5.1 Reference Masses and Devices for Determining Mass and Volume, shall conform to the requirements of Specification

C 1005.

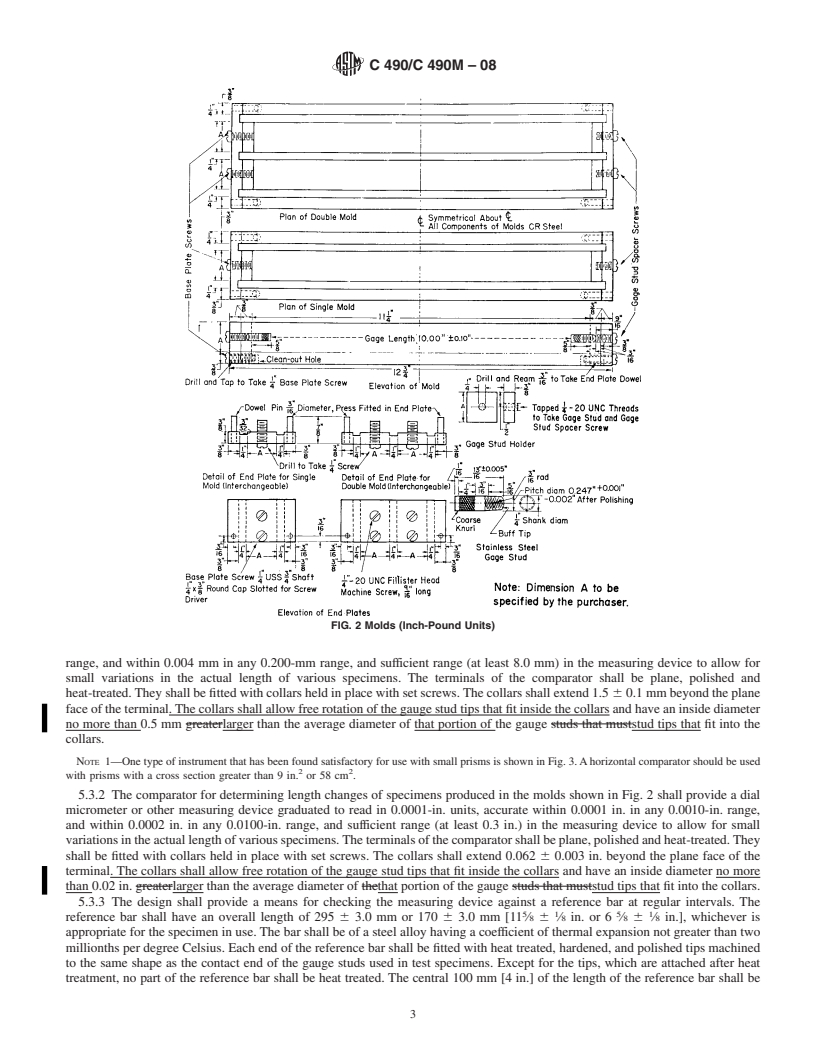

5.2 Molds, shall have either one or two compartments and shall be constructed as shown in Fig. 1 or Fig. 2. Molds for test

specimens used in determining the length change of cement pastes and mortars shall provide for 25 by 25 by 285-mm prisms

1

having a 250-mm gauge length, or for 1 by 1 by 11 ⁄4 –in. prisms having a 10–in. gauge length. Molds for test specimens used

in the length change of concretes shall provide for prisms of the desired cross section having a 10-in. or 250-mm gauge length.

1

In some routine tests, 25 by 25 by 160-mm specimens with a gauge length of 125 mm, or 1 by 1 by 6 ⁄4 –in. specimens with a

gauge length of 5-in. are permitted, but in case of dispute, results obtained with specimens of 250-mm [10-in.] gauge length shall

govern.

5.2.1 The gauge length shall be considered as the nominal length between the innermost ends of the gauge studs. The parts of

the molds shall be tight fitting and firmly held together when assembled, and their surfaces shall be smooth and free of pits. The

molds shall be made of steel or other hard metal not readily attacked by the cement paste, mortar, or concrete. The sides of the

1

This practice is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.95 on Coordination of Standards .

Current edition approved June 1, 2007.2008. Published July 2007.2008. Originally approved in 1962. Last previous edition approved in 20042007 as C 490 – 047.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 490/C 490M – 08

NOTE—Dimension A to be specified by the purchaser.

FIG. 1 Molds (SI Units)

molds shall be sufficiently

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.