ASTM D5237-14(2019)

(Guide)Standard Guide for Evaluating Fabric Softeners

Standard Guide for Evaluating Fabric Softeners

SIGNIFICANCE AND USE

5.1 The methods in this guide can be used for screening of fabric softener products or to evaluate their performance, through a single cycle or multiple accumulative cycles, relative to a designated reference product or a comparative product(s).

5.2 A single assessment of each of the product characteristics tested by these methods will not predict overall performance of the softener product. A single test run under specified fixed conditions cannot be expected to reflect the comparative performance under many other possible conditions of use.

SCOPE

1.1 This guide evaluates the performance characteristics of fabric softener products. It provides guidance for evaluating the on fabric efficacy of treatment chemicals dosed into the wash, rinse, or dryer cycle in a home laundry washer or dryer. This guide can be used for screening of fabric softener products, or to evaluate the products through multiple accumulative cycles.

1.2 The relative ranking of products assessed by these procedures may be affected by such factors as machine type and settings, fabric load composition, as well as by the washing and drying procedures used.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5237 − 14 (Reapproved 2019)

Standard Guide for

Evaluating Fabric Softeners

This standard is issued under the fixed designation D5237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2164Test Method for Directional Difference Test

2.2 AATCC Standard:

1.1 This guide evaluates the performance characteristics of

AATCC Test Method110-1994Whiteness of Textiles

fabric softener products. It provides guidance for evaluating

the on fabric efficacy of treatment chemicals dosed into the

3. Terminology

wash, rinse, or dryer cycle in a home laundry washer or dryer.

This guide can be used for screening of fabric softener 3.1 Definitions:

3.1.1 fabric softener, n—laundry auxiliary product or laun-

products, or to evaluate the products through multiple accu-

dry detergent ingredient that gives fabrics a soft feel, smooth

mulative cycles.

surface, provides fragrance, or reduces static electricity, or a

1.2 The relative ranking of products assessed by these

combination thereof.

procedures may be affected by such factors as machine type

3.1.2 front-loading high-effıciency (HE) washing machine/

andsettings,fabricloadcomposition,aswellasbythewashing

washer, n—horizontally or nearly horizontally oriented ma-

and drying procedures used.

chine used for laundry that uses varying amounts of water to

1.3 The values stated in inch-pound units are to be regarded

launder fabrics.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.1.2.1 Discussion—These washers (1) may not exhibit any

and are not considered standard. visible free water or may show significant quantities of visible

free water, (2) may lift and tumble the clothes load, (3) may

1.4 This standard does not purport to address all of the

employbothspinningandtumblinginboththewasherorrinse

safety concerns, if any, associated with its use. It is the

processes, (4) may use jet sprays of wash solution or rinse

responsibility of the user of this standard to establish appro-

solution,or (5)mayusethermalorchemicalinputs,orboth,to

priate safety, health, and environmental practices and deter-

offer sanitation or allergen claims. HE washers use consider-

mine the applicability of regulatory limitations prior to use.

ably less water and energy than traditional deep-fill washers in

1.5 This international standard was developed in accor-

the laundering process. HE washers are labeled by the appli-

dance with internationally recognized principles on standard-

ance industry and may be recognized by the U.S. Department

ization established in the Decision on Principles for the

of Energy (DOE) and U.S. Environmental Protection Agency

Development of International Standards, Guides and Recom-

(EPA) as Energy Star rated machines.

mendations issued by the World Trade Organization Technical

3.1.3 home laundering, n—cleaning or conditioning, or

Barriers to Trade (TBT) Committee.

both, of textile materials using the washing and drying equip-

ment commonly found in the home.

2. Referenced Documents

3.1.4 top-loading high-effıciency (HE) washing machine/

2.1 ASTM Standards:

washer, n—vertically oriented agitation machine that is used

E313Practice for Calculating Yellowness and Whiteness

for home laundry, with the fundamental difference from a

Indices from Instrumentally Measured Color Coordinates

traditional top-loading washer being that this washer uses

E1958Guide for Sensory Claim Substantiation

reduced water resources during the process.

3.1.4.1 Discussion—This washer may (1) deep fill once

This guide is under the jurisdiction of ASTM Committee D12 on Soaps and

(during the wash or rinse), (2) partially fill one or more times,

Other Detergents and is the direct responsibility of Subcommittee D12.15 on

Physical Testing. (3) may have a full agitator, (4) may have an impeller in place

Current edition approved Jan. 1, 2019. Published January 2019. Originally

of an agitator, (5) may use thermal or chemical inputs, or both,

approved in 1992. Last previous edition approved in 2014 as D5237-14. DOI:

to offer sanitation or allergen claims, or (6) may use spray

10.1520/D5237-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists, P.O.

the ASTM website. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5237 − 14 (2019)

washing or spray rinsing technologies, or combination thereof. a test. When running successive test loads, use fresh ballast or

HE washers use considerably less water and energy than strip the ballast prior to use.

traditional deep-fill washers in the laundering process. HE 6.2.5 Standard Reference Detergent, such as, AATCC

washers are labeled by the appliance industry and may be (American Association of Textile Chemists and Colorists),

recognizedbytheU.S.DOEandU.S.EPAasEnergyStarrated liquid or powder (suggested to use without brightener formula

machines. if testing whiteness retention), or a commercially built anionic

3.1.5 traditional deep-fill top-loading washing machine/ detergent, if desired.

washer, n—vertically oriented agitation machine that is used

6.3 Stripping Procedure—The objective of this procedure is

for home laundry.

toremovefinishesorresidues,orboth,fromtheballastandtest

fabrics.Theprocedurebelowisonesuggestedwaytomeetthis

3.1.5.1 Discussion—This washer fills to the basket top at

objective.

least two times during the wash process: once for washing and

6.3.1 Load washer with appropriate amount of fabrics. Do

once for rinsing. This type of washer may also include spray

not overload.

flushes in either the wash or rinse portions of the cycle.

6.3.2 Add appropriate dosage of built anionic detergent.

4. Summary of Guide 6.3.3 Set machine for hot wash temperature setting. Allow

washertofillwithwaterandcontinueonthroughthecomplete

4.1 Fabrics are evaluated for the impact of fabric softener

wash and rinse cycle.

products applied in the wash, rinse or dryer cycle for softness,

6.3.4 Repeat 6.3.2 and 6.3.3 four more times.

whiteness retention, rewet or water absorbency, static control,

6.3.5 Wash this load of fabric through an additional com-

or fragrance, or combination thereof, using test panels or

pletecyclethreetimeswithnodetergent.Ifthereappearstobe

instrumental methods.

residualdetergent(asevidencedbysudsingduringtheprevious

cycle)repeatthewateronlycyclesoneortwomoretimesoras

5. Significance and Use

needed to ensure removal of residual anionic detergent to a

5.1 The methods in this guide can be used for screening of

minimal level.

fabric softener products or to evaluate their performance,

6.3.6 Dry fabrics in an automatic dryer at the normal or hot

throughasinglecycleormultipleaccumulativecycles,relative

setting until the load is dry.

to a designated reference product or a comparative product(s).

6.3.7 If fabrics are stored prior to evaluation, protect from

5.2 A single assessment of each of the product characteris-

environmental influences such as odor, moisture, dust, etc.

tics tested by these methods will not predict overall perfor-

7. Fabric Treatment with Fabric Softener

manceofthesoftenerproduct.Asingletestrununderspecified

fixed conditions cannot be expected to reflect the comparative

7.1 Scope:

performance under many other possible conditions of use.

7.1.1 This section provides the procedure for application of

the test products to the textile substrates.

6. Fabric Preparation

7.2 Fixed Test Conditions—All test conditions not under

6.1 Scope:

study should be fixed within the range of normal household

6.1.1 Thissectionprovidesaprocedureforpreparingnewor

practice. The following are suggested as representative of

previously used textile specimens for further treatment and

many households.

evaluation.

7.2.1 Matched Washing Machines—All washings shall be

6.1.2 All new fabrics received directly from the mill or

performed in the same machine or in mechanically matched

purchased from vendors must be stripped of mill conditioners

units of the same model machine using a controlled experi-

and processing auxiliaries. Test fabrics are to be used for only

mental design.

a single evaluation while ballast used for load bulk may be

7.2.2 Household Automatic Washing Machine:

reused indefinitely if stripping is done between each evalua-

7.2.2.1 Conventional Deep-fill Traditional Top Loader—

tion.

Normal/casual with 10-14 min wash cycle, appropriate water

6.2 Apparatus and Materials: fill for load size, and regular spin speed.

6.2.1 Automatic Washing Machine, 7.2.2.2 Front-loading High Effıciency—Normal/casual or

6.2.2 Automatic Laundry Dryer, gas or electric. normal/colors setting, normal soil level, and high spin speed,

6.2.3 Test Fabrics, white cotton or cotton/polyester loop 7.2.2.3 Top-loading High Effıciency—Normal/casual or

terry cloth, or both, such as hand towels. Other fabrics suitable normal/colors setting, normal soil level, and high spin speed.

forfabricsoftenerproductsarealsoacceptable.Careshouldbe 7.2.3 Household Automatic Laundry Dryer, gas or electric.

taken to use matched sets of fabrics of the same brand and 7.2.4 Stripped Test Fabrics, defined in 6.2 and 6.3.

manufacturing origin, and similar construction, weight, and 7.2.5 Water Hardness—35 ppm (2 grains/gal); 100 ppm (6

fiber blend within each specific test. grains/gal); 150 ppm (9 grains/gal); and 260 ppm (15 grains/

6.2.4 Fabric Load, Minimum of 6 lb (2.7 kg) for each total gal). 120 ppm (7 grains/gal) is suggested if only one level is

load. Supplement test fabrics with ballast fabrics, such as tested.

pillow cases, terry towels, or commercially available yard 7.2.5.1 The calcium/magnesium ratio of the hardness min-

2 2 3

goods cut in pieces no larger than 1 yd (0.8 m ) per piece.All erals (expressed as CaCO ) should be adjusted to attain

ballastloadsshallbethesamecompositionforeachrunwithin different water hardness as shown in Table 1.

D5237 − 14 (2019)

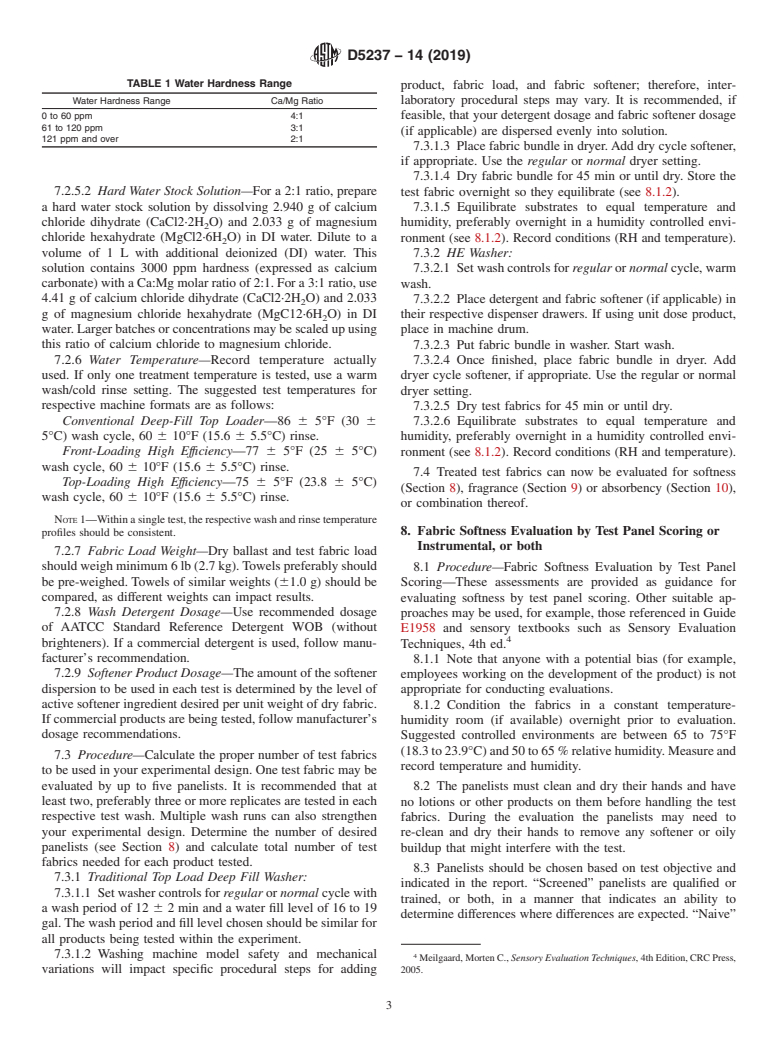

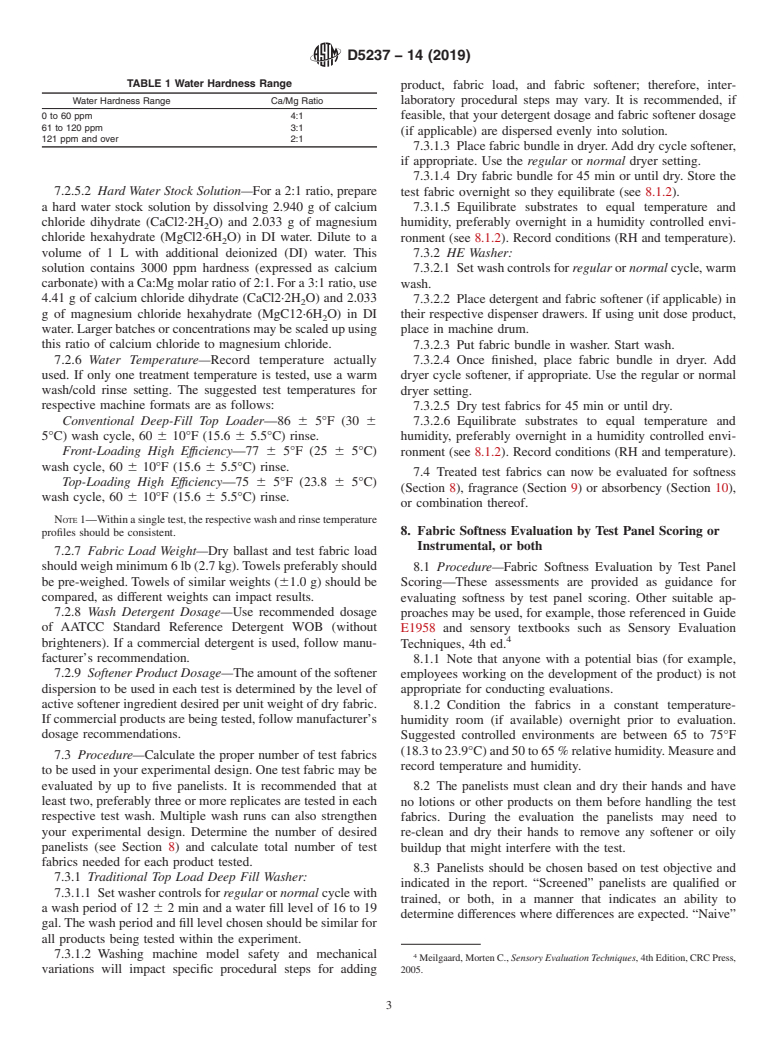

TABLE 1 Water Hardness Range

product, fabric load, and fabric softener; therefore, inter-

Water Hardness Range Ca/Mg Ratio laboratory procedural steps may vary. It is recommended, if

0to60ppm 4:1 feasible, that your detergent dosage and fabric softener dosage

61 to 120 ppm 3:1

(if applicable) are dispersed evenly into solution.

121 ppm and over 2:1

7.3.1.3 Place fabric bundle in dryer.Add dry cycle softener,

if appropriate. Use the regular or normal dryer setting.

7.3.1.4 Dry fabric bundle for 45 min or until dry. Store the

7.2.5.2 Hard Water Stock Solution—For a 2:1 ratio, prepare

test fabric overnight so they equilibrate (see 8.1.2).

a hard water stock solution by dissolving 2.940 g of calcium 7.3.1.5 Equilibrate substrates to equal temperature and

chloride dihydrate (CaCl2·2H O) and 2.033 g of magnesium

humidity, preferably overnight in a humidity controlled envi-

chloride hexahydrate (MgCl2·6H O) in DI water. Dilute to a ronment (see 8.1.2). Record conditions (RH and temperature).

volume of 1 L with additional deionized (DI) water. This

7.3.2 HE Washer:

solution contains 3000 ppm hardness (expressed as calcium 7.3.2.1 Setwashcontrolsfor regularor normalcycle,warm

carbonate)withaCa:Mgmolarratioof2:1.Fora3:1ratio,use

wash.

4.41 g of calcium chloride dihydrate (CaCl2·2H O) and 2.033 7.3.2.2 Place detergent and fabric softener (if applicable) in

g of magnesium chloride hexahydrate (MgC12·6H O) in DI their respective dispenser drawers. If using unit dose product,

water.Largerbatchesorconcentrationsmaybescaledupusing place in machine drum.

this ratio of calcium chloride to magnesium chloride. 7.3.2.3 Put fabric bundle in washer. Start wash.

7.2.6 Water Temperature—Record temperature actually 7.3.2.4 Once finished, place fabric bundle in dryer. Add

used. If only one treatment temperature is tested, use a warm dryer cycle softener, if appropriate. Use the regular or normal

wash/cold rinse setting. The suggested test temperatures for dryer setting.

respective machine formats are as follows: 7.3.2.5 Dry test fabrics for 45 min or until dry.

Conventional Deep-Fill Top Loader—86 6 5°F (30 6

7.3.2.6 Equilibrate substrates to equal temperature and

5°C) wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse. humidity, preferably overnight in a humidity controlled envi-

Front-Loading High Effıciency—77 6 5°F (25 6 5°C)

ronment (see 8.1.2). Record conditions (RH and temperature).

wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

7.4 Treated test fabrics can now be evaluated for softness

Top-Loading High Effıciency—75 6 5°F (23.8 6 5°C)

(Section 8), fragrance (Section 9) or absorbency (Section 10),

wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

or combination thereof.

NOTE1—Withinasingletest,therespectivewashandrinsetemperature

8. Fabric Softness Evaluation by Test Panel Scoring or

profiles should be consistent.

Instrumental, or both

7.2.7 Fabric Load Weight—Dry ballast and test fabric load

shouldweighminimum6lb(2.7kg).Towelspreferablyshould 8.1 Procedure—Fabric Softness Evaluation by Test Panel

be pre-weighed. Towels of similar weights (61.0 g) should be

Scoring—These assessments are provided as guidance for

compared, as different weights can impact results. evaluating softness by test panel scoring. Other suitable ap-

7.2.8 Wash Detergent Dosage—Use recommended dosage

proaches may be used, for example, those referenced in Guide

of AATCC Standard Reference Detergent WOB (without E1958 and sensory textbooks such as Sensory Evaluation

brighteners). If a commercial detergent is used, follow manu-

Techniques, 4th ed.

facturer’s recommendation. 8.1.1 Note that anyone with a potential bias (for example,

7.2.9 Softener Product Dosage—Theamountofthesoftener

employees working on the development of the product) is not

dispersion to be used in each test is determined by the level of appropriate for conducting evaluations.

active softener ingredient desired per unit weight of dry fabric.

8.1.2 Condition the fabrics in a constant temperature-

Ifcommercialproductsarebeingtested,followmanufacturer’s

humidity room (if available) overnight prior to evaluation.

dosage recommendations.

Suggested controlle

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5237 − 14 (Reapproved 2019)

Standard Guide for

Evaluating Fabric Softeners

This standard is issued under the fixed designation D5237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2164 Test Method for Directional Difference Test

2.2 AATCC Standard:

1.1 This guide evaluates the performance characteristics of

AATCC Test Method 110-1994 Whiteness of Textiles

fabric softener products. It provides guidance for evaluating

the on fabric efficacy of treatment chemicals dosed into the

3. Terminology

wash, rinse, or dryer cycle in a home laundry washer or dryer.

3.1 Definitions:

This guide can be used for screening of fabric softener

3.1.1 fabric softener, n—laundry auxiliary product or laun-

products, or to evaluate the products through multiple accu-

dry detergent ingredient that gives fabrics a soft feel, smooth

mulative cycles.

surface, provides fragrance, or reduces static electricity, or a

1.2 The relative ranking of products assessed by these

combination thereof.

procedures may be affected by such factors as machine type

3.1.2 front-loading high-effıciency (HE) washing machine/

and settings, fabric load composition, as well as by the washing

washer, n—horizontally or nearly horizontally oriented ma-

and drying procedures used.

chine used for laundry that uses varying amounts of water to

1.3 The values stated in inch-pound units are to be regarded

launder fabrics.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.1.2.1 Discussion—These washers (1) may not exhibit any

and are not considered standard. visible free water or may show significant quantities of visible

free water, (2) may lift and tumble the clothes load, (3) may

1.4 This standard does not purport to address all of the

employ both spinning and tumbling in both the washer or rinse

safety concerns, if any, associated with its use. It is the

processes, (4) may use jet sprays of wash solution or rinse

responsibility of the user of this standard to establish appro-

solution, or (5) may use thermal or chemical inputs, or both, to

priate safety, health, and environmental practices and deter-

offer sanitation or allergen claims. HE washers use consider-

mine the applicability of regulatory limitations prior to use.

ably less water and energy than traditional deep-fill washers in

1.5 This international standard was developed in accor-

the laundering process. HE washers are labeled by the appli-

dance with internationally recognized principles on standard-

ance industry and may be recognized by the U.S. Department

ization established in the Decision on Principles for the

of Energy (DOE) and U.S. Environmental Protection Agency

Development of International Standards, Guides and Recom-

(EPA) as Energy Star rated machines.

mendations issued by the World Trade Organization Technical

3.1.3 home laundering, n—cleaning or conditioning, or

Barriers to Trade (TBT) Committee.

both, of textile materials using the washing and drying equip-

ment commonly found in the home.

2. Referenced Documents

3.1.4 top-loading high-effıciency (HE) washing machine/

2.1 ASTM Standards:

washer, n—vertically oriented agitation machine that is used

E313 Practice for Calculating Yellowness and Whiteness

for home laundry, with the fundamental difference from a

Indices from Instrumentally Measured Color Coordinates

traditional top-loading washer being that this washer uses

E1958 Guide for Sensory Claim Substantiation

reduced water resources during the process.

3.1.4.1 Discussion—This washer may (1) deep fill once

This guide is under the jurisdiction of ASTM Committee D12 on Soaps and

(during the wash or rinse), (2) partially fill one or more times,

Other Detergents and is the direct responsibility of Subcommittee D12.15 on

Physical Testing. (3) may have a full agitator, (4) may have an impeller in place

Current edition approved Jan. 1, 2019. Published January 2019. Originally

of an agitator, (5) may use thermal or chemical inputs, or both,

approved in 1992. Last previous edition approved in 2014 as D5237-14. DOI:

to offer sanitation or allergen claims, or (6) may use spray

10.1520/D5237-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists, P.O.

the ASTM website. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5237 − 14 (2019)

washing or spray rinsing technologies, or combination thereof. a test. When running successive test loads, use fresh ballast or

HE washers use considerably less water and energy than strip the ballast prior to use.

traditional deep-fill washers in the laundering process. HE 6.2.5 Standard Reference Detergent, such as, AATCC

washers are labeled by the appliance industry and may be (American Association of Textile Chemists and Colorists),

recognized by the U.S. DOE and U.S. EPA as Energy Star rated liquid or powder (suggested to use without brightener formula

machines. if testing whiteness retention), or a commercially built anionic

3.1.5 traditional deep-fill top-loading washing machine/ detergent, if desired.

washer, n—vertically oriented agitation machine that is used

6.3 Stripping Procedure—The objective of this procedure is

for home laundry.

to remove finishes or residues, or both, from the ballast and test

fabrics. The procedure below is one suggested way to meet this

3.1.5.1 Discussion—This washer fills to the basket top at

objective.

least two times during the wash process: once for washing and

6.3.1 Load washer with appropriate amount of fabrics. Do

once for rinsing. This type of washer may also include spray

not overload.

flushes in either the wash or rinse portions of the cycle.

6.3.2 Add appropriate dosage of built anionic detergent.

6.3.3 Set machine for hot wash temperature setting. Allow

4. Summary of Guide

washer to fill with water and continue on through the complete

4.1 Fabrics are evaluated for the impact of fabric softener

wash and rinse cycle.

products applied in the wash, rinse or dryer cycle for softness,

6.3.4 Repeat 6.3.2 and 6.3.3 four more times.

whiteness retention, rewet or water absorbency, static control,

6.3.5 Wash this load of fabric through an additional com-

or fragrance, or combination thereof, using test panels or

plete cycle three times with no detergent. If there appears to be

instrumental methods.

residual detergent (as evidenced by sudsing during the previous

cycle) repeat the water only cycles one or two more times or as

5. Significance and Use

needed to ensure removal of residual anionic detergent to a

5.1 The methods in this guide can be used for screening of

minimal level.

fabric softener products or to evaluate their performance,

6.3.6 Dry fabrics in an automatic dryer at the normal or hot

through a single cycle or multiple accumulative cycles, relative

setting until the load is dry.

to a designated reference product or a comparative product(s).

6.3.7 If fabrics are stored prior to evaluation, protect from

5.2 A single assessment of each of the product characteris-

environmental influences such as odor, moisture, dust, etc.

tics tested by these methods will not predict overall perfor-

7. Fabric Treatment with Fabric Softener

mance of the softener product. A single test run under specified

fixed conditions cannot be expected to reflect the comparative

7.1 Scope:

performance under many other possible conditions of use.

7.1.1 This section provides the procedure for application of

the test products to the textile substrates.

6. Fabric Preparation

7.2 Fixed Test Conditions—All test conditions not under

6.1 Scope:

study should be fixed within the range of normal household

6.1.1 This section provides a procedure for preparing new or

practice. The following are suggested as representative of

previously used textile specimens for further treatment and

many households.

evaluation.

7.2.1 Matched Washing Machines—All washings shall be

6.1.2 All new fabrics received directly from the mill or

performed in the same machine or in mechanically matched

purchased from vendors must be stripped of mill conditioners

units of the same model machine using a controlled experi-

and processing auxiliaries. Test fabrics are to be used for only

mental design.

a single evaluation while ballast used for load bulk may be

7.2.2 Household Automatic Washing Machine:

reused indefinitely if stripping is done between each evalua-

7.2.2.1 Conventional Deep-fill Traditional Top Loader—

tion.

Normal/casual with 10-14 min wash cycle, appropriate water

6.2 Apparatus and Materials: fill for load size, and regular spin speed.

6.2.1 Automatic Washing Machine, 7.2.2.2 Front-loading High Effıciency—Normal/casual or

6.2.2 Automatic Laundry Dryer, gas or electric. normal/colors setting, normal soil level, and high spin speed,

6.2.3 Test Fabrics, white cotton or cotton/polyester loop 7.2.2.3 Top-loading High Effıciency—Normal/casual or

terry cloth, or both, such as hand towels. Other fabrics suitable normal/colors setting, normal soil level, and high spin speed.

for fabric softener products are also acceptable. Care should be 7.2.3 Household Automatic Laundry Dryer, gas or electric.

taken to use matched sets of fabrics of the same brand and 7.2.4 Stripped Test Fabrics, defined in 6.2 and 6.3.

manufacturing origin, and similar construction, weight, and 7.2.5 Water Hardness—35 ppm (2 grains/gal); 100 ppm (6

fiber blend within each specific test. grains/gal); 150 ppm (9 grains/gal); and 260 ppm (15 grains/

6.2.4 Fabric Load, Minimum of 6 lb (2.7 kg) for each total gal). 120 ppm (7 grains/gal) is suggested if only one level is

load. Supplement test fabrics with ballast fabrics, such as tested.

pillow cases, terry towels, or commercially available yard 7.2.5.1 The calcium/magnesium ratio of the hardness min-

2 2 3

goods cut in pieces no larger than 1 yd (0.8 m ) per piece. All erals (expressed as CaCO ) should be adjusted to attain

ballast loads shall be the same composition for each run within different water hardness as shown in Table 1.

D5237 − 14 (2019)

TABLE 1 Water Hardness Range

product, fabric load, and fabric softener; therefore, inter-

Water Hardness Range Ca/Mg Ratio laboratory procedural steps may vary. It is recommended, if

0 to 60 ppm 4:1 feasible, that your detergent dosage and fabric softener dosage

61 to 120 ppm 3:1

(if applicable) are dispersed evenly into solution.

121 ppm and over 2:1

7.3.1.3 Place fabric bundle in dryer. Add dry cycle softener,

if appropriate. Use the regular or normal dryer setting.

7.3.1.4 Dry fabric bundle for 45 min or until dry. Store the

7.2.5.2 Hard Water Stock Solution—For a 2:1 ratio, prepare test fabric overnight so they equilibrate (see 8.1.2).

a hard water stock solution by dissolving 2.940 g of calcium

7.3.1.5 Equilibrate substrates to equal temperature and

chloride dihydrate (CaCl2·2H O) and 2.033 g of magnesium humidity, preferably overnight in a humidity controlled envi-

chloride hexahydrate (MgCl2·6H O) in DI water. Dilute to a

ronment (see 8.1.2). Record conditions (RH and temperature).

volume of 1 L with additional deionized (DI) water. This 7.3.2 HE Washer:

solution contains 3000 ppm hardness (expressed as calcium

7.3.2.1 Set wash controls for regular or normal cycle, warm

carbonate) with a Ca:Mg molar ratio of 2:1. For a 3:1 ratio, use wash.

4.41 g of calcium chloride dihydrate (CaCl2·2H O) and 2.033 7.3.2.2 Place detergent and fabric softener (if applicable) in

g of magnesium chloride hexahydrate (MgC12·6H O) in DI their respective dispenser drawers. If using unit dose product,

water. Larger batches or concentrations may be scaled up using place in machine drum.

this ratio of calcium chloride to magnesium chloride. 7.3.2.3 Put fabric bundle in washer. Start wash.

7.2.6 Water Temperature—Record temperature actually 7.3.2.4 Once finished, place fabric bundle in dryer. Add

used. If only one treatment temperature is tested, use a warm dryer cycle softener, if appropriate. Use the regular or normal

wash/cold rinse setting. The suggested test temperatures for dryer setting.

respective machine formats are as follows:

7.3.2.5 Dry test fabrics for 45 min or until dry.

Conventional Deep-Fill Top Loader—86 6 5°F (30 6 7.3.2.6 Equilibrate substrates to equal temperature and

5°C) wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

humidity, preferably overnight in a humidity controlled envi-

Front-Loading High Effıciency—77 6 5°F (25 6 5°C) ronment (see 8.1.2). Record conditions (RH and temperature).

wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

7.4 Treated test fabrics can now be evaluated for softness

Top-Loading High Effıciency—75 6 5°F (23.8 6 5°C)

(Section 8), fragrance (Section 9) or absorbency (Section 10),

wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

or combination thereof.

NOTE 1—Within a single test, the respective wash and rinse temperature

profiles should be consistent. 8. Fabric Softness Evaluation by Test Panel Scoring or

Instrumental, or both

7.2.7 Fabric Load Weight—Dry ballast and test fabric load

should weigh minimum 6 lb (2.7 kg). Towels preferably should

8.1 Procedure—Fabric Softness Evaluation by Test Panel

be pre-weighed. Towels of similar weights (61.0 g) should be Scoring—These assessments are provided as guidance for

compared, as different weights can impact results.

evaluating softness by test panel scoring. Other suitable ap-

7.2.8 Wash Detergent Dosage—Use recommended dosage proaches may be used, for example, those referenced in Guide

of AATCC Standard Reference Detergent WOB (without

E1958 and sensory textbooks such as Sensory Evaluation

brighteners). If a commercial detergent is used, follow manu- Techniques, 4th ed.

facturer’s recommendation.

8.1.1 Note that anyone with a potential bias (for example,

7.2.9 Softener Product Dosage—The amount of the softener employees working on the development of the product) is not

dispersion to be used in each test is determined by the level of

appropriate for conducting evaluations.

active softener ingredient desired per unit weight of dry fabric. 8.1.2 Condition the fabrics in a constant temperature-

If commercial products are being tested, follow manufacturer’s

humidity room (i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5237 − 14 D5237 − 14 (Reapproved 2019)

Standard Guide for

Evaluating Fabric Softeners

This standard is issued under the fixed designation D5237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide evaluates the performance characteristics of fabric softener products. It provides guidance for evaluating the on

fabric efficacy of treatment chemicals dosed into the wash, rinse, or dryer cycle in a home laundry washer or dryer. This guide can

be used for screening of fabric softener products, or to evaluate the products through multiple accumulative cycles.

1.2 The relative ranking of products assessed by these procedures may be affected by such factors as machine type and settings,

fabric load composition, as well as by the washing and drying procedures used.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E313 Practice for Calculating Yellowness and Whiteness Indices from Instrumentally Measured Color Coordinates

E1958 Guide for Sensory Claim Substantiation

E2164 Test Method for Directional Difference Test

2.2 AATCC Standard:

AATCC Test Method 110-1994 Whiteness of Textiles

3. Terminology

3.1 Definitions:

3.1.1 fabric softener, n—laundry auxiliary product or laundry detergent ingredient that gives fabrics a soft feel, smooth surface,

provides fragrance, or reduces static electricity, or a combination thereof.

3.1.2 front-loading high-effıciency (HE) washing machine/washer, n—horizontally or nearly horizontally oriented machine used

for laundry that uses varying amounts of water to launder fabrics.

3.1.2.1 Discussion—

These washers (1) may not exhibit any visible free water or may show significant quantities of visible free water, (2) may lift and

tumble the clothes load, (3) may employ both spinning and tumbling in both the washer or rinse processes, (4) may use jet sprays

of wash solution or rinse solution, or (5) may use thermal or chemical inputs, or both, to offer sanitation or allergen claims. HE

washers use considerably less water and energy than traditional deep-fill washers in the laundering process. HE washers are labeled

This guide is under the jurisdiction of ASTM Committee D12 on Soaps and Other Detergents and is the direct responsibility of Subcommittee D12.15 on Physical Testing.

Current edition approved Nov. 1, 2014Jan. 1, 2019. Published December 2014January 2019. Originally approved in 1992. Last previous edition approved in 20132014

as D5237-05(2013).D5237-14. DOI: 10.1520/D5237-14.10.1520/D5237-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Association of Textile Chemists and Colorists, P.O. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5237 − 14 (2019)

by the appliance industry and may be recognized by the U.S. Department of Energy (DOE) and U.S. Environmental Protection

Agency (EPA) as Energy Star rated machines.

3.1.3 home laundering, n—cleaning or conditioning, or both, of textile materials using the washing and drying equipment

commonly found in the home.

3.1.4 top-loading high-effıciency (HE) washing machine/washer, n—vertically oriented agitation machine that is used for home

laundry, with the fundamental difference from a traditional top-loading washer being that this washer uses reduced water resources

during the process.

3.1.4.1 Discussion—

This washer may (1) deep fill once (during the wash or rinse), (2) partially fill one or more times, (3) may have a full agitator, (4)

may have an impeller in place of an agitator, (5) may use thermal or chemical inputs, or both, to offer sanitation or allergen claims,

or (6) may use spray washing or spray rinsing technologies, or combination thereof. HE washers use considerably less water and

energy than traditional deep-fill washers in the laundering process. HE washers are labeled by the appliance industry and may be

recognized by the U.S. DOE and U.S. EPA as Energy Star rated machines.

3.1.5 traditional deep-fill top-loading washing machine/washer, n—vertically oriented agitation machine that is used for home

laundry.

3.1.5.1 Discussion—

This washer fills to the basket top at least two times during the wash process: once for washing and once for rinsing. This type

of washer may also include spray flushes in either the wash or rinse portions of the cycle.

4. Summary of Guide

4.1 Fabrics are evaluated for the impact of fabric softener products applied in the wash, rinse or dryer cycle for softness,

whiteness retention, rewet or water absorbency, static control, or fragrance, or combination thereof, using test panels or

instrumental methods.

5. Significance and Use

5.1 The methods in this guide can be used for screening of fabric softener products or to evaluate their performance, through

a single cycle or multiple accumulative cycles, relative to a designated reference product or a comparative product(s).

5.2 A single assessment of each of the product characteristics tested by these methods will not predict overall performance of

the softener product. A single test run under specified fixed conditions cannot be expected to reflect the comparative performance

under many other possible conditions of use.

6. Fabric Preparation

6.1 Scope:

6.1.1 This section provides a procedure for preparing new or previously used textile specimens for further treatment and

evaluation.

6.1.2 All new fabrics received directly from the mill or purchased from vendors must be stripped of mill conditioners and

processing auxiliaries. Test fabrics are to be used for only a single evaluation while ballast used for load bulk may be reused

indefinitely if stripping is done between each evaluation.

6.2 Apparatus and Materials:

6.2.1 Automatic Washing Machine,

6.2.2 Automatic Laundry Dryer, gas or electric.

6.2.3 Test Fabrics, white cotton or cotton/polyester loop terry cloth, or both, such as hand towels. Other fabrics suitable for

fabric softener products are also acceptable. Care should be taken to use matched sets of fabrics of the same brand and

manufacturing origin, and similar construction, weight, and fiber blend within each specific test.

6.2.4 Fabric Load, Minimum of 6 lb (2.7 kg) for each total load. Supplement test fabrics with ballast fabrics, such as pillow

2 2

cases, terry towels, or commercially available yard goods cut in pieces no larger than 1 yd (0.8 m ) per piece. All ballast loads

shall be the same composition for each run within a test. When running successive test loads, use fresh ballast or strip the ballast

prior to use.

6.2.5 Standard Reference Detergent, such as, AATCC (American Association of Textile Chemists and Colorists), liquid or

powder (suggested to use without brightener formula if testing whiteness retention), or a commercially built anionic detergent, if

desired.

6.3 Stripping Procedure—The objective of this procedure is to remove finishes or residues, or both, from the ballast and test

fabrics. The procedure below is one suggested way to meet this objective.

D5237 − 14 (2019)

6.3.1 Load washer with appropriate amount of fabrics. Do not overload.

6.3.2 Add appropriate dosage of built anionic detergent.

6.3.3 Set machine for hot wash temperature setting. Allow washer to fill with water and continue on through the complete wash

and rinse cycle.

6.3.4 Repeat 6.3.2 and 6.3.3 four more times.

6.3.5 Wash this load of fabric through an additional complete cycle three times with no detergent. If there appears to be residual

detergent (as evidenced by sudsing during the previous cycle) repeat the water only cycles one or two more times or as needed

to ensure removal of residual anionic detergent to a minimal level.

6.3.6 Dry fabrics in an automatic dryer at the normal or hot setting until the load is dry.

6.3.7 If fabrics are stored prior to evaluation, protect from environmental influences such as odor, moisture, dust, etc.

7. Fabric Treatment with Fabric Softener

7.1 Scope:

7.1.1 This section provides the procedure for application of the test products to the textile substrates.

7.2 Fixed Test Conditions—All test conditions not under study should be fixed within the range of normal household practice.

The following are suggested as representative of many households.

7.2.1 Matched Washing Machines—All washings shall be performed in the same machine or in mechanically matched units of

the same model machine using a controlled experimental design.

7.2.2 Household Automatic Washing Machine:

7.2.2.1 Conventional Deep-fill Traditional Top Loader—Normal/casual with 10-14 min wash cycle, appropriate water fill for

load size, and regular spin speed.

7.2.2.2 Front-loading High Effıciency—Normal/casual or normal/colors setting, normal soil level, and high spin speed,

7.2.2.3 Top-loading High Effıciency—Normal/casual or normal/colors setting, normal soil level, and high spin speed.

7.2.3 Household Automatic Laundry Dryer, gas or electric.

7.2.4 Stripped Test Fabrics, defined in 6.2 and 6.3.

7.2.5 Water Hardness—35 ppm (2 grains/gal); 100 ppm (6 grains/gal); 150 ppm (9 grains/gal); and 260 ppm (15 grains/gal).

120 ppm (7 grains/gal) is suggested if only one level is tested.

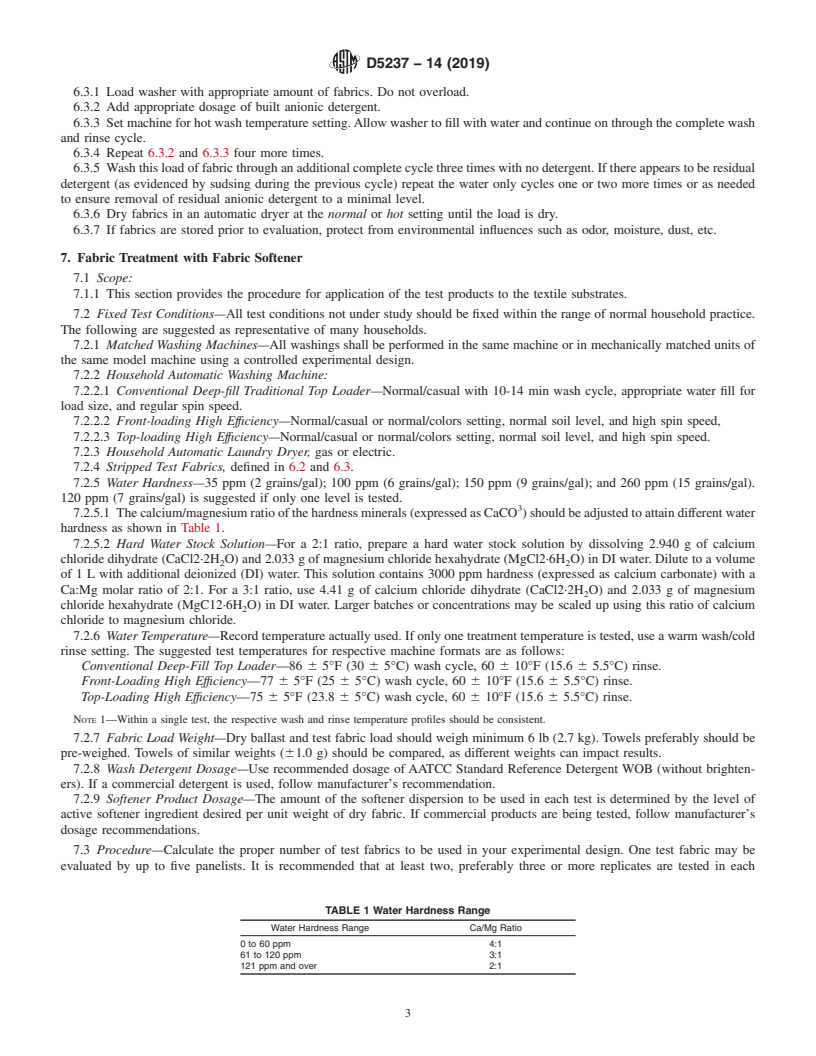

7.2.5.1 The calcium/magnesium ratio of the hardness minerals (expressed as CaCO ) should be adjusted to attain different water

hardness as shown in Table 1.

7.2.5.2 Hard Water Stock Solution—For a 2:1 ratio, prepare a hard water stock solution by dissolving 2.940 g of calcium

chloride dihydrate (CaCl2·2H O) and 2.033 g of magnesium chloride hexahydrate (MgCl2·6H O) in DI water. Dilute to a volume

2 2

of 1 L with additional deionized (DI) water. This solution contains 3000 ppm hardness (expressed as calcium carbonate) with a

Ca:Mg molar ratio of 2:1. For a 3:1 ratio, use 4.41 g of calcium chloride dihydrate (CaCl2·2H O) and 2.033 g of magnesium

chloride hexahydrate (MgC12·6H O) in DI water. Larger batches or concentrations may be scaled up using this ratio of calcium

chloride to magnesium chloride.

7.2.6 Water Temperature—Record temperature actually used. If only one treatment temperature is tested, use a warm wash/cold

rinse setting. The suggested test temperatures for respective machine formats are as follows:

Conventional Deep-Fill Top Loader—86 6 5°F (30 6 5°C) wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

Front-Loading High Effıciency—77 6 5°F (25 6 5°C) wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

Top-Loading High Effıciency—75 6 5°F (23.8 6 5°C) wash cycle, 60 6 10°F (15.6 6 5.5°C) rinse.

NOTE 1—Within a single test, the respective wash and rinse temperature profiles should be consistent.

7.2.7 Fabric Load Weight—Dry ballast and test fabric load should weigh minimum 6 lb (2.7 kg). Towels preferably should be

pre-weighed. Towels of similar weights (61.0 g) should be compared, as different weights can impact results.

7.2.8 Wash Detergent Dosage—Use recommended dosage of AATCC Standard Reference Detergent WOB (without brighten-

ers). If a commercial detergent is used, follow manufacturer’s recommendation.

7.2.9 Softener Product Dosage—The amount of the softener dispersion to be used in each test is determined by the level of

active softener ingredient desired per unit weight of dry fabric. If commercial products are being tested, follow manufacturer’s

dosage recommendations.

7.3 Procedure—Calculate the proper number of test fabrics to be used in your experimental design. One test fabric may be

evaluated by up to five panelists. It is recommended that at least two, preferably three or more replicates are tested in each

TABLE 1 Water Hardness Range

Water Hardness Range Ca/Mg Ratio

0 to 60 ppm 4:1

61 to 120 ppm 3:1

121 ppm and over 2:1

D5237 − 14 (2019)

respective test wash. Multiple wash runs can also strengthen your experimental design. Determine the number of desired panelists

(see Section 8) and calculate total number of test fabrics needed for each product tested.

7.3.1 Traditional Top Load Deep Fill Washer:

7.3.1.1 Set washer controls for regular or normal cycle with a wash period of 12 6 2 min and a water fill level of 16 to 19 gal.

The wash period and fill level chosen should be similar for all products being tested within the experiment.

7.3.1.2 Washing machine model safety and mechanical variations will impact specific procedural steps for adding product,

fabric load, and fabric softener; therefore, inter-laboratory procedural steps may vary. It is recommended, if feasible, that your

detergent dosage and fabric softener dosage (if applicable) are dispersed evenly into solution.

7.3.1.3 Place fabric bundle in dryer. Add dry cycle softener, if appropriate. Use the regular or normal dryer setting.

7.3.1.4 Dry fabric bundle for 45 min or until dry. Store the test fabric overnight so they equilibrate (see 8.1.2).

7.3.1.5 Equilibrate substrates to equal temperature and humidity, preferably overnight in a humidity controlled environment (see

8.1.2). Record conditions (RH and temperature).

7.3.2 HE Washer:

7.3.2.1 Set wash controls for regular or normal cycle, warm wash.

7.3.2.2 Place detergent and fabric softener (if applicable) in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.