ASTM C1055-03(2014)

(Guide)Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries

Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries

SIGNIFICANCE AND USE

5.1 Most heated apparatus in industrial, commercial, and residential service are insulated, unless thermal insulation would interfere with their function; for example, it is inappropriate to insulate the bottom surface of a flatiron. However, surface temperatures of insulated equipment and appliances may still be high enough to cause burns from contact exposure under certain conditions.

5.2 This guide has been developed to standardize the determination of acceptable surface operating conditions for heated systems. Current practice for this determination is widely varied. The intent of this guide is to tie together the existing practices into a consensus standard based upon scientific understanding of the thermal physics involved. Flexibility is retained within this guide for the designer, regulator, or consumer to establish specific burn hazard criteria. Most generally, the regulated criterion will be the length of time of contact exposure.

5.3 It is beyond the scope of this guide to establish appropriate contact times and acceptable levels of injury for particular situations, or determine what surface temperature is “safe.” Clearly, quite different criteria may be justified for cases as diverse as those involving infants and domestic appliances, and experienced adults and industrial equipment. In the first case, no more than first degree burns in 60 s might be desirable. In the second case, second degree burns in 5 s might be acceptable.Note 2—An overview of the medical research leading to the development of this guide was presented at the ASTM Conference on Thermal Insulation, Materials and Systems on Dec. 7, 1984 (14).

5.4 This guide is meant to serve only as an estimation of the exposure to which an average individual might be subjected. Unusual conditions of exposure, physical health variations, or nonstandard ambients all serve to modify the results.

5.5 This guide is limited to contact exposure to heated surfaces only. It should be noted that con...

SCOPE

1.1 This guide covers a process for the determination of acceptable surface operating conditions for heated systems. The human burn hazard is defined, and methods are presented for use in the design or evaluation of heated systems to prevent serious injury from contact with the exposed surfaces.

1.2 The maximum acceptable temperature for a particular surface is derived from an estimate of the possible or probable contact time, the surface system configuration, and the level of injury deemed acceptable for a particular situation.

1.3 For design purposes, the probable contact time for industrial situations has been established at 5 s. For consumer products, a longer (60-s) contact time has been proposed by Wu (1)2 and others to reflect the slower reaction times for children, the elderly, or the infirm.

1.4 The maximum level of injury recommended here is that causing first degree burns on the average subject. This type of injury is reversible and causes no permanent tissue damage. For cases where more severe conditions are mandated (by space, economic, exposure probability, or other outside considerations), this guide may be used to establish a second, less desirable injury level (second degree burns), where some permanent tissue damage can be permitted. At no time, however, are conditions that produce third degree burns recommended.

1.5 This guide addresses the skin contact temperature determination for passive heated surfaces only. The guidelines contained herein are not applicable to chemical, electrical, or other similar hazards that provide a heat generation source at the location of contact.

1.6 A bibliography of human burn evaluation studies and surface hazard measurement is provided in the list of references at the end of this guide (1-16).

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not pur...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1055 − 03 (Reapproved 2014)

Standard Guide for

Heated System Surface Conditions that Produce Contact

Burn Injuries

This standard is issued under the fixed designation C1055; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This guide covers a process for the determination of

standard.

acceptable surface operating conditions for heated systems.

1.8 This standard does not purport to address all the safety

The human burn hazard is defined, and methods are presented

concerns, if any, associated with its use. It is the responsibility

for use in the design or evaluation of heated systems to prevent

of the user of this standard to establish appropriate safety and

serious injury from contact with the exposed surfaces.

health practices and determine the applicability of regulatory

1.2 The maximum acceptable temperature for a particular

limitations prior to its use.

surface is derived from an estimate of the possible or probable

contact time, the surface system configuration, and the level of

2. Referenced Documents

injury deemed acceptable for a particular situation.

2.1 ASTM Standards:

1.3 For design purposes, the probable contact time for

C680 Practice for Estimate of the Heat Gain or Loss and the

industrial situations has been established at 5 s. For consumer

Surface Temperatures of Insulated Flat, Cylindrical, and

products, a longer (60-s) contact time has been proposed by

Spherical Systems by Use of Computer Programs

Wu (1) and others to reflect the slower reaction times for

C1057 Practice for Determination of Skin Contact Tempera-

children, the elderly, or the infirm.

ture from Heated Surfaces Using a Mathematical Model

1.4 The maximum level of injury recommended here is that

and Thermesthesiometer

causing first degree burns on the average subject. This type of

injury is reversible and causes no permanent tissue damage. 3. Terminology

For cases where more severe conditions are mandated (by

3.1 Definitions of Terms Specific to This Standard:

space, economic, exposure probability, or other outside

3.1.1 skin:

considerations), this guide may be used to establish a second,

3.1.2 epidermis—the outermost layer of skin cells. This

less desirable injury level (second degree burns), where some

layer contains no vascular or nerve cells and acts to protect the

permanent tissue damage can be permitted. At no time,

skin layers. The thickness of this layer averages 0.08 mm.

however, are conditions that produce third degree burns rec-

3.1.3 dermis—the second layer of skin tissue. This layer

ommended.

contains the blood vessels and nerve endings. The thickness of

1.5 This guide addresses the skin contact temperature de-

this layer averages 2 mm.

termination for passive heated surfaces only. The guidelines

3.1.4 necrosis—localized death of living cells. A clinical

contained herein are not applicable to chemical, electrical, or

term that defines when permanent damage to a skin layer has

other similar hazards that provide a heat generation source at

occurred.

the location of contact.

3.1.5 burns:

1.6 A bibliography of human burn evaluation studies and

3.1.6 first degree burn—the reaction to an exposure where

surface hazard measurement is provided in the list of refer-

the intensity or duration is insufficient to cause complete

ences at the end of this guide (1-16).

necrosis of the epidermis. The normal response to this level of

exposure is dilation of the superficial blood vessels (reddening

This guide is under the jurisdiction of ASTM Committee C16 on Thermal

of the skin).

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

Current edition approved Feb. 1, 2014. Published March 2014. Originally

approvedin1986.Lastpreviouseditionapprovedin2009asC1055–03(2009).DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1055-03R14. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this guide. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1055 − 03 (2014)

3.1.7 second degree burn—the reaction to an exposure 4.2 The process used in the analysis follows the outline

where the intensity and duration is sufficient to cause complete listed below:

necrosis of the epidermis but no significant damage to the

4.2.1 The user must first establish the acceptable contact

dermis. The normal response to this exposure is blistering of

exposure time and the level of acceptable injury for the

the epidermis.

particular system in question.

3.1.8 third degree burn—the reaction to an exposure where

4.2.2 Secondly, the user determines the maximum operating

significant dermal necrosis occurs. Significant dermal necrosis

surface temperature. This determination is made either by

has been defined in the literature (3) as 75% destruction of the

direct measurement (if possible) or by use of a calculation at

dermis.Thenormalresponsetothisexposureisopensoresthat

design conditions using a method conforming to Practice

leave permanent scar tissue upon healing.

C680.

3.1.9 contact exposure—the process by which the surface of

4.2.3 Next, utilizing the contact time (4.2.1), the maximum

skin makes intimate contact with a heated surface such that no

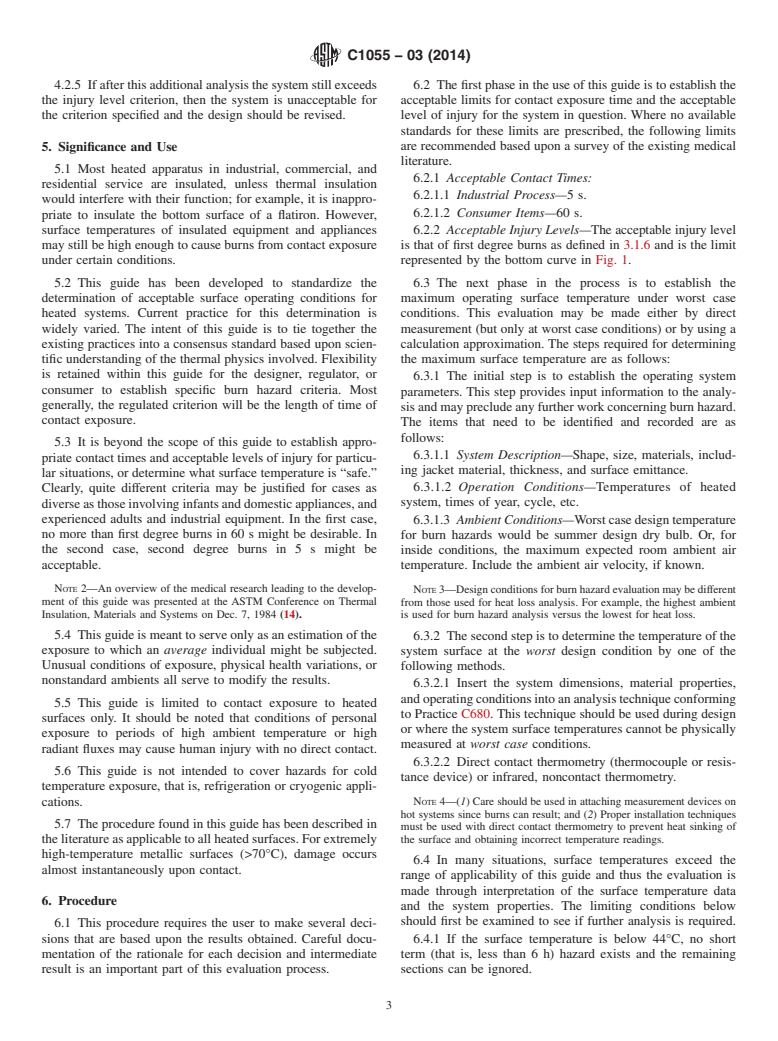

surface temperature (4.2.2), and the graph, Fig. 1, the user

insulating layer, film, moisture, etc., interferes with the rapid

determinesthepotentialinjurylevel.Iftheoperatingpointfalls

transfer of available energy.

belowtheinjurylevelspecified(4.2.1),thennofurtheranalysis

3.1.10 insulation system—the combination of an insulation is required. (See Note 1.)

material or jacket, or both that forms a barrier to the rapid loss

NOTE 1—The following equations have been developed from the

of energy from a heated surface. The insulation system may

original data used to generate Fig. 1 for easier use of this figure.

involve a broad range of types and configurations of materials.

T 5 15.00510.51907 3Ln time 31000 1352.97/ Ln time 31000

~ ! ~ ~ !!

A

3.1.11 jacket—the protective barrier placed on the exposed

(1)

sideofaninsulationtoprotecttheinsulationfromdeterioration

or abuse. The jacket material can be made of paper, plastic, T 5 39.468 2 0.41352 3Ln ~time 31000!1 190.60/~Ln ~time

B

metal, canvas cloth, or combinations of the above or similar

31000!! (2)

materials.

where:

3.1.12 thermesthesiometer—a probe device developed by

T = critical contact temperature for complete transepidermal

A

Marzetta (13) that simulates the thermal physical response of

necrosis, °C.

the human finger to contact with heated surfaces.

T = critical contact temperature for reversible epidermal injury, °C.

B

time = elapsed contact time, s.

Ln = natural logarithm.

4. Summary of Guide

4.2.4 If the injury level exceeds that specified, further

4.1 This guide establishes a means by which the engineer,

designer, or operator can determine the acceptable surface analysis of the system is required using either the thermesthe-

siometer (a direct method) or an additional calculation. Both

temperature of an existing system where skin contact may be

made with a heated surface. methods are described in Practice C1057.

FIG. 1 Temperature-Time Relationship for Burns

C1055 − 03 (2014)

4.2.5 Ifafterthisadditionalanalysisthesystemstillexceeds 6.2 The first phase in the use of this guide is to establish the

the injury level criterion, then the system is unacceptable for acceptable limits for contact exposure time and the acceptable

the criterion specified and the design should be revised. level of injury for the system in question. Where no available

standards for these limits are prescribed, the following limits

are recommended based upon a survey of the existing medical

5. Significance and Use

literature.

5.1 Most heated apparatus in industrial, commercial, and

6.2.1 Acceptable Contact Times:

residential service are insulated, unless thermal insulation

6.2.1.1 Industrial Process—5s.

would interfere with their function; for example, it is inappro-

6.2.1.2 Consumer Items—60 s.

priate to insulate the bottom surface of a flatiron. However,

surface temperatures of insulated equipment and appliances 6.2.2 Acceptable Injury Levels—The acceptable injury level

may still be high enough to cause burns from contact exposure is that of first degree burns as defined in 3.1.6 and is the limit

under certain conditions. represented by the bottom curve in Fig. 1.

5.2 This guide has been developed to standardize the 6.3 The next phase in the process is to establish the

determination of acceptable surface operating conditions for maximum operating surface temperature under worst case

heated systems. Current practice for this determination is conditions. This evaluation may be made either by direct

widely varied. The intent of this guide is to tie together the measurement (but only at worst case conditions) or by using a

existing practices into a consensus standard based upon scien- calculation approximation. The steps required for determining

tific understanding of the thermal physics involved. Flexibility the maximum surface temperature are as follows:

is retained within this guide for the designer, regulator, or

6.3.1 The initial step is to establish the operating system

consumer to establish specific burn hazard criteria. Most

parameters. This step provides input information to the analy-

generally, the regulated criterion will be the length of time of

sisandmayprecludeanyfurtherworkconcerningburnhazard.

contact exposure.

The items that need to be identified and recorded are as

follows:

5.3 It is beyond the scope of this guide to establish appro-

6.3.1.1 System Description—Shape, size, materials, includ-

priate contact times and acceptable levels of injury for particu-

ing jacket material, thickness, and surface emittance.

lar situations, or determine what surface temperature is “safe.”

6.3.1.2 Operation Conditions—Temperatures of heated

Clearly, quite different criteria may be justified for cases as

system, times of year, cycle, etc.

diverseasthoseinvolvinginfantsanddomesticappliances,and

experienced adults and industrial equipment. In the first case,

6.3.1.3 Ambient Conditions—Worstcasedesigntemperature

no more than first degree burns in 60 s might be desirable. In for burn hazards would be summer design dry bulb. Or, for

the second case, second degree burns in 5 s might be

inside conditions, the maximum expected room ambient air

acceptable. temperature. Include the ambient air velocity, if known.

NOTE 2—An overview of the medical research leading to the develop-

NOTE3—Designconditionsforburnhazardevaluationmaybedifferent

ment of this guide was presented at the ASTM Conference on Thermal from those used for heat loss analysis. For example, the highest ambient

Insulation, Materials and Systems on Dec. 7, 1984 (14).

is used for burn hazard analysis versus the lowest for heat loss.

5.4 This guide is meant to serve only as an estimation of the

6.3.2 The second step is to determine the temperature of the

exposure to which an average individual might be subjected.

system surface at the worst design condition by one of the

Unusual conditions of exposure, physical health variations, or

following methods.

nonstandard ambients all serve to modify the results.

6.3.2.1 Insert the system dimensions, material properties,

andoperatingconditionsintoananalysistechniqueconforming

5.5 This guide is limited to contact exposure to heated

to Practice C680. This technique should be used during design

surfaces only. It should be noted that conditions of personal

or where the system surface temperatures cannot be physically

exposure to periods of high ambient temperature or high

measured at worst case conditions.

radiant fluxes may cause human injury with no direct contact.

6.3.2.2 Direct contact thermometry (thermocouple or resis-

5.6 This guide is not intended to cover hazards for cold

tance device) or infrared, noncontact thermometry.

temperature exposure, that is, refrigeration or cryogenic appli-

cations. NOTE 4—(1) Care should be used in attaching measurement devices on

hot systems since burns can result; and (2) Proper installation techniques

5.7 The procedure found in this guide has been described in

must be used with direct contact thermometry to prevent heat sinking of

the surface and obtaining incorrect temperature readings.

theliteratureasapplicabletoallheatedsurfaces.Forextremely

high-temperature metallic surfaces (>70°C), damage occurs

6.4 In many situations, surface temperatures exceed the

almost instantaneously upon contact.

range of applicability of this guide and thus the evaluation is

made through interpretation of the surface temperature data

6. Procedure

and the system properties. The limiting conditions below

should first be examined to see if further analysis is required.

6.1 This procedure requires the user to make several deci-

sions that are based upon the results obtained. Careful docu- 6.4.1 If the surface temperature is below 44°C, no short

mentation of the rationale for each decision and intermediate term (that is, less than 6 h) hazard exists and the remaining

result is an important part of this evaluation process. sections can be ignored.

C1055 − 03 (2014)

6.4.2 If the surface temperature exceeds 70°C and the hazard potential is to be evaluated. Practice C1057 outlines the

surface is metallic, it may present a hazard regardless of correct procedures for use of this device for surface hazard

contact duration.Attempts should be made to lower the surface evaluation. The output from the thermesthesiometer is the

temperature below 70°C. Nonmetallic skins may be safe for maximum contact temperature of the skin that can be related to

limitedexposureattemperaturesabove70°C.Inthesecases,as Fig. 1 with no corrections for surface type needed.

with all cases between 44°C and 70°C, the analysis should be

6.8 If, after analysis using Practice C1057, the system

completed.

temperature still fails to meet the selected criterion, then

increasing insulation, changing jacketing, or other means must

6.5 With the measurement or estimation of surface tempera-

beusedtolowerthesur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.