ASTM D5397-99(2005)

(Test Method)Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test

Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test

SCOPE

1.1 This test method is used to develop test data from which the susceptibility of polyolefin geomembrane sheet material to stress cracking under a constant tensile load condition and an accelerated environmental condition can be evaluated.

1.2 This test method measures the failure time associated with a given test specimen at a specified tensile load level. Results from a series of such tests utilizing a range of load levels can be used to construct a stress-time plot on a log-log axis.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5397 – 99 (Reapproved 2005)

Standard Test Method for

Evaluation of Stress Crack Resistance of Polyolefin

Geomembranes Using Notched Constant Tensile Load Test

This standard is issued under the fixed designation D 5397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4833 Test Method for Index Puncture Resistance of

Geotextiles, Geomembranes, and Related Products

1.1 This test method is used to develop test data from which

the susceptibility of polyolefin geomembrane sheet material to

3. Terminology

stress cracking under a constant tensile load condition and an

3.1 Definitions:

accelerated environmental condition can be evaluated.

3.1.1 geomembrane, n—very low permeability synthetic

1.2 This test method measures the failure time associated

membrane liners or barriers used with any geotechnical engi-

with a given test specimen at a specified tensile load level.

neering related material so as to control fluid migration in a

Results from a series of such tests utilizing a range of load

man-made project, structure, or system (see Test Method

levels can be used to construct a stress-time plot on a log-log

D 4833).

axis.

3.1.2 stress crack, n—an external or internal crack in a

1.3 The values stated in SI units are to be regarded as the

plastic caused by tensile stresses less than its short-time

standard. The inch-pound units given in parentheses are

mechanical strength (see Definitions D 883).

provided for information only.

3.1.2.1 Discussion—The development of such cracks is

1.4 This standard does not purport to address all of the

frequently accelerated by the environment to which the plastic

safety concerns, if any, associated with its use. It is the

is exposed. The stresses that cause cracking may be present

responsibility of the user of this standard to establish appro-

internally or externally or may be combinations of these

priate safety and health practices and determine the applica-

stresses.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

2 4.1 This test method consists of subjecting a dumbbell

2.1 ASTM Standards:

shaped notched test specimen from a polyolefin sheet to a

D 638 Test Method for Tensile Properties of Plastics

constant tensile load in the presence of a surface-active agent

D 883 Terminology Relating to Plastics

and at an elevated temperature. The time to failure of the test

D 4354 Practice for Sampling of Geosynthetics for Testing

specimen is recorded. The results of a series of such tests

conducted at different stress levels are presented by plotting

stress level against failure time for each stress level on a

This test method is under the jurisdiction of ASTM Committee D35 on

log-log axis.

Geosynthetics and is the direct responsibility of Subcommittee D35.02 on Endur-

ance Properties.

5. Significance and Use

Current edition approved June 1, 2005. Published September 2005. Originally

e1

approved in 1993. Last previous edition approved in 1999 as D 5397 – 99 .

5.1 This test method does not purport to interpret the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resulting response curve. Such interpretation is left to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

parties involved in the commissioning and reporting of the test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. results.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5397 – 99 (2005)

5.2 This test method is intended as an index test and may be

used for grading polyolefin geomembrane sheets in regard to

their stress cracking sensitivity.

5.2.1 Conditions that can affect stress cracking include:

levelofloading,testtemperatureandenvironment,microstruc-

ture,polymeradditivepackage,processinghistory,andthermal

history.

6. Apparatus

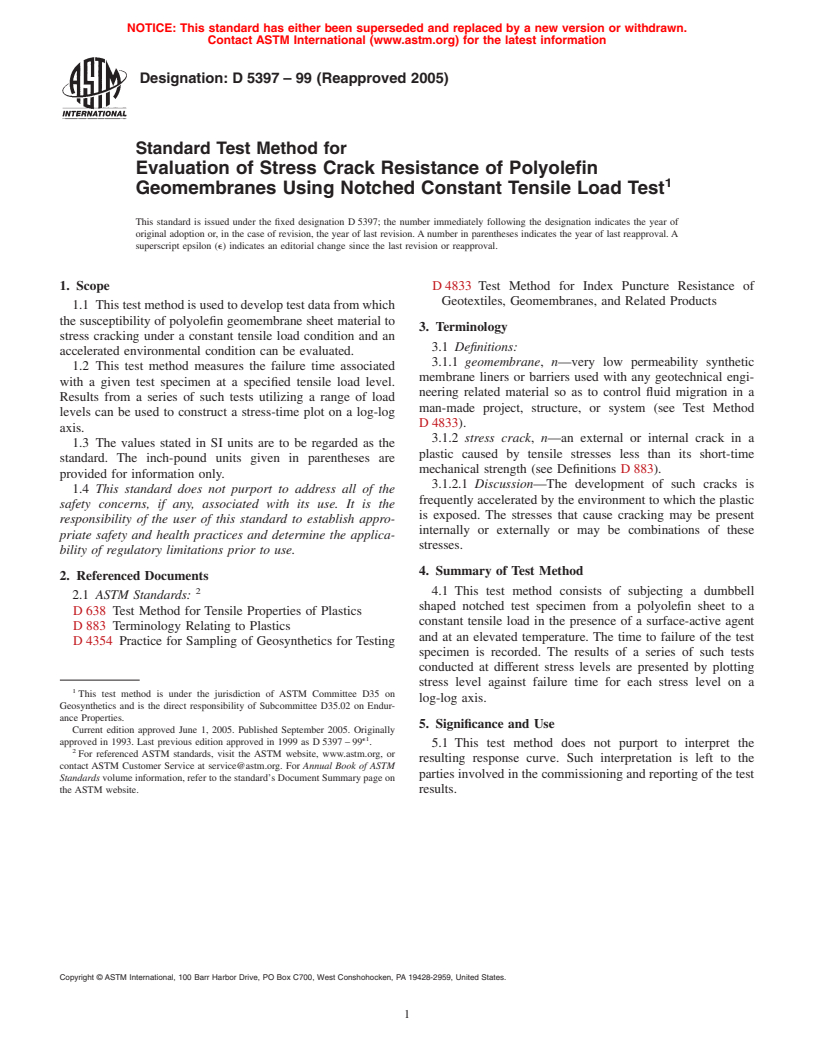

6.1 Blanking Die—Adie suitable for cutting test specimens

to the dimensions and tolerances shown in Fig. 1.

NOTE 1—The length of the specimen can be changed to suit the design

of the test apparatus. However, there should be a constant neck section

with length at least 13 mm (0.5 in.) long. The width should be 3.20 mm

NOTE 1—The number of positions in the test frame is optional.

(0.125 in.).

FIG. 2 Constant Stress Loading Apparatus Consisting of Twenty

6.2 Notching Device—A device or machine that can pro-

Specimen Test Positions

duce a consistent notch depth.

NOTE 2—An evaluation of the notching technique can be performed by

submersionheaterandcontrollerareusedtomaintainthetesttemperature.

quenching a notched specimen in liquid nitrogen and then fracturing it.

Apumpkeepstheliquidinaconstantstateofagitation.Atimingclockfor

The notch depth can readily be measured by examining the fracture

eachtestspecimenisalsoprovidedtorecordautomaticallythefailuretime

surface under a reflected light microscope

of the test specimens to the nearest 0.1 h.

6.3 Stress Cracking Apparatus—Equipment suitable for

NOTE 4—If “on/off” switches are used to control the timing clock, the

subjecting test specimens to a tensile stress of up to 13.8 MPa switch must be sensitive enough to be turned off under 200 g of the force.

(2000 lb/in. ). The specimens shall be maintained at a constant

7. Reagent

temperature of 50 6 1°C (122 6 2°F) while being totally

immersed in a surface-active agent. The solution should be 7.1 The reagent should consist of 10 % surface-active agent

constantlyagitatedtoprovideauniformconcentrationthrough- with 90 % water. The surface-active agent is Igepal CO-630

out the bath. that is nonylphenoxy poly(ethyleneoxy)ethanol. The reagent

should be stored in a closed container. The reagent in the bath

NOTE 3—The apparatus shown in Fig. 2 is one type that has been used

should be replaced every two weeks to maintain a constant

andiscapableoftestingupto20specimensatatime.Thisequipmentuses

concentration.

a lever system with a mechanical advantage (MA) of three to impose the

desired loading on each specimen. The surface-active agent in which the

NOTE 5—In case of dispute, the water should be distilled or deionized

specimens are immersed is contained in an open stainless steel tank. A

at the discretion of the parties involved.

NOTE 6—Other incubation solutions may also be used in the test,

provided that the parties involved mutually agree to the changes and state

the specific details in the final report.

Notching equipment is available through REMCO Industrial Machine Co.,

Manville, NJ 08850.

8. Sampling

This equipment is available through Custom Scientific Instruments Co., Cedar

Knolls,NJ07927,andBTTechnologyInc.,613W.ClintonSt.,Rushville,IL62681.

8.1 Lot Sample—Divide the product into lots and take the

lot sample as directed in Practice D 4354.

8.2 Laboratory Sample—As a laboratory sample for accep-

tance testing, take a full-width swatch approximately1m(40

in.) long in the machine direction from each roll in the lot

sample.Thesamplemaybetakenfromtheendportionofaroll

provided there is no evidence it is distorted or different from

other portions of the roll.

8.3 Test Specimens—At least thirty test specimens are cut

from each swatch in the laboratory sample. For each set of

tests, all specimens must be taken from one direction.

NOTE 7—Quite often the test is required to challenge the weakest

direction of the sheet material. If this is the cross machine direction, the

test specimens should be cut in this direction. Hence the notch is placed

in the machine direction so that the specimens are stressed in the desired

cross machine direction.

NOTE 1—Dimensioned in millimetres to an accuracy of 0.02 mm.

FIG. 1 Dimensions of Test Method D 1822 Type“ L” Test Igepal CO-630 may be obtained from Rhone-Poulenc, CN 7500, Prospect

Specimens Plains Road, Cranbury, NJ 08512-7500.

D 5397 – 99 (2005)

NOTE 8—Ithasbeenfoundthatinsertingagrommetoreyeletinthetwo

should range from approximately 20 to 65 % at maximum

holes at the end tabs of the test specimen helps to reduce the number of

increments of 5 %. Three specimens are tested at each stress

“grip failures” or failures occurring outside of the neck section of the

level to produce statistically significant results.

specimen.

NOTE 10—To develop the entire curve in a single direction at the

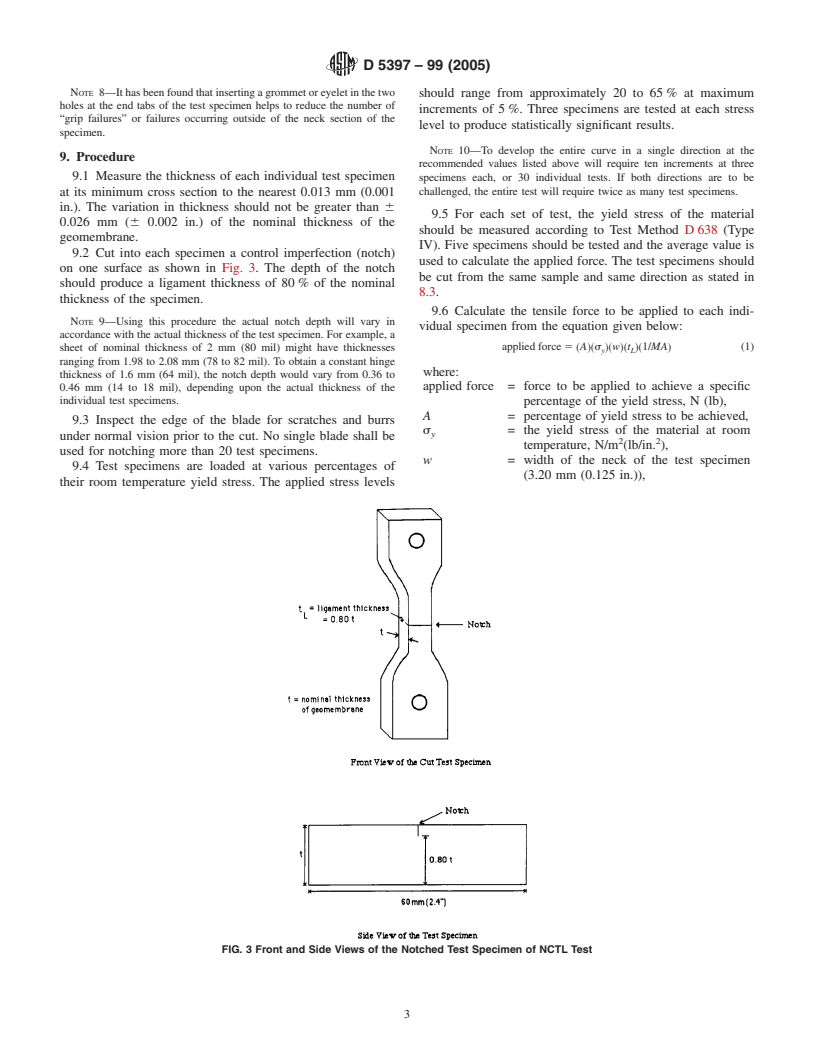

9. Procedure

recommended values listed above will require ten increments at three

9.1 Measure the thickness of each individual test specimen specimens each, or 30 individual tests. If both directions are to be

at its minimum cross section to the nearest 0.013 mm (0.001 challenged, the entire test will require twice as many test specimens.

in.). The variation in thickness should not be greater than 6

9.5 For each set of test, the yield stress of the material

0.026 mm (6 0.002 in.) of the nominal thickness of the

should be measured according to Test Method D 638 (Type

geomembrane.

IV).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.