ASTM D4870-07

(Test Method)Standard Test Method for Determination of Total Sediment in Residual Fuels

Standard Test Method for Determination of Total Sediment in Residual Fuels

SCOPE

1.1 This test method covers the determination of total sediment up to 0.40 % m/m for distillate fuel oils containing residual components and to 0.50 % m/m in residual fuel oils having a maximum viscosity of 55 cSt (mm2/s) at 100°C. Some fuels can exceed the maximum filtration time specified in this test method due to factors other than the presence of significant quantities of insoluble organic or inorganic material. This test method can be used for the assessment of total sediment after regimes of fuel pretreatment designed to accelerate the aging process.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.2, 7.3, Annex A1, and X1.6.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D4870–07a

Designation: 375/99

Standard Test Method for

1

Determination of Total Sediment in Residual Fuels

This standard is issued under the fixed designation D 4870; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* residual fuel oil by filtration through a Whatman GF/A filter

medium, and that is also insoluble in a predominantly paraf-

1.1 This test method covers the determination of total

finic solvent.

sediment up to 0.40 % m/m for distillate fuel oils containing

residual components and to 0.50 % m/m in residual fuel oils

4. Summary of Test Method

2

havingamaximumviscosityof55cSt(mm /s)at100°C.Some

4.1 A weighed quantity (10 g) of the oil sample is filtered

fuels can exceed the maximum filtration time specified in this

through the prescribed apparatus at 100°C. After solvent

testmethodduetofactorsotherthanthepresenceofsignificant

washing and drying the total sediment on the filter medium is

quantities of insoluble organic or inorganic material. This test

weighed. The test is to be carried out in duplicate.

method can be used for the assessment of total sediment after

regimes of fuel pretreatment designed to accelerate the aging

5. Significance and Use

process.

5.1 Appreciable amounts of sediment in a residual fuel oil

1.2 The values stated in SI units are to be regarded as

can cause fouling of facilities for handling, and give problems

standard. No other units of measurement are included in this

in burner mechanisms. Sediment can accumulate in storage

standard.

tanks, on filter screens, or on burner parts, resulting in

1.3 This standard does not purport to address all of the

obstruction of the flow of oil from the tank to the burner.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

6. Apparatus

priate safety and health practices and determine the applica-

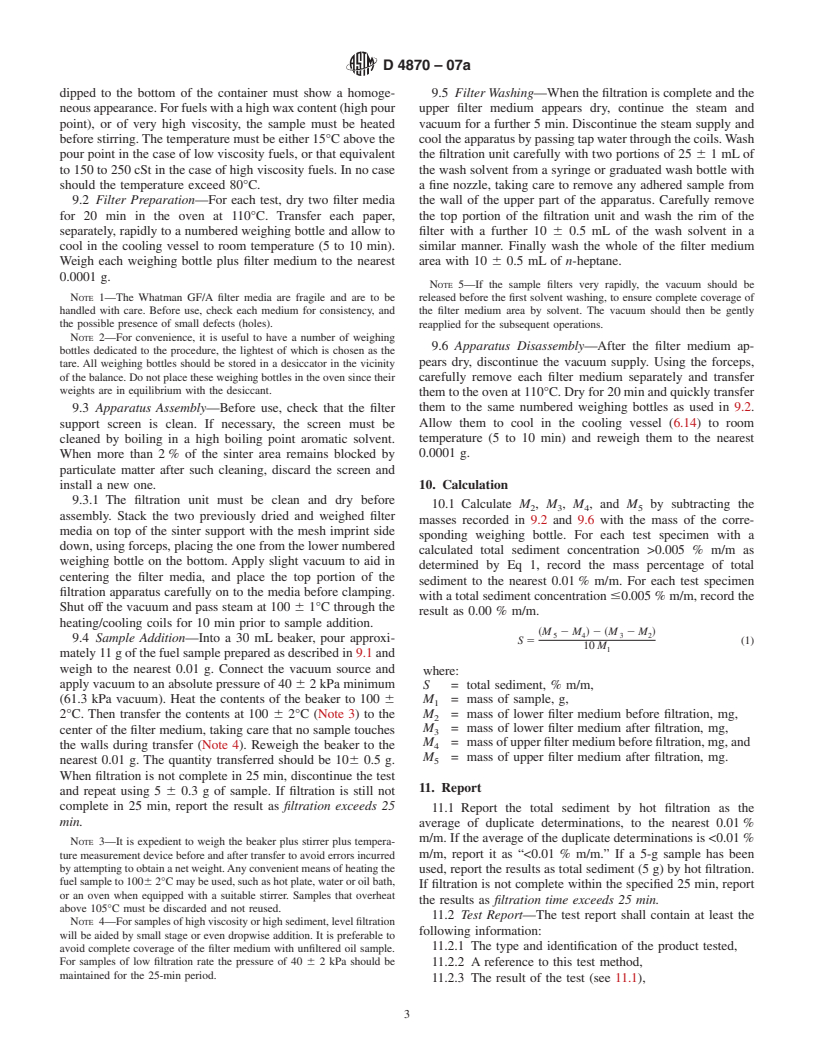

6.1 Filtration Apparatus, constructed of brass, with copper

bility of regulatory limitations prior to use. For specific

steam coils attached, suitably supported above a vacuum flask

warning statements, see 7.2, 7.3, Annex A1, and X1.6.1.

appropriately protected against the effects of implosion. See

Figs. 1 and 2.

2. Referenced Documents

2 6.2 Temperature Measuring Device, capable of measuring

2.1 ASTM Standards:

thetemperatureintherangefrom95to105°Cwithanaccuracy

D 4057 Practice for Manual Sampling of Petroleum and

of 0.5°C.

Petroleum Products

6.3 Oven, electric, capable of maintaining a temperature of

D 4177 Practice for Automatic Sampling of Petroleum and

110 6 1°C. The oven should be capable of safely evaporating

Petroleum Products

the solvent without risk of fire.

E1 Specification forASTM Liquid-in-Glass Thermometers

6.4 Stirring Rod, glass or polytetrafluoroethylene (PTFE)

3. Terminology approximately 150 mm in length and 3 mm in diameter.

6.5 Beaker,glass,30mLcapacity,eithersquatformwithlip

3.1 Definitions of Terms Specific to This Standard:

or conical.

3.1.1 total sediment—the sum of the insoluble organic and

6.6 Weighing Bottles, with ground glass stoppers, num-

inorganic material that is separated from the bulk of the

bered, 80 mm diameter by 40 mm.

6.7 Hotplate, electric.

1

This test method is under the jurisdiction of ASTM Committee D02 on

6.8 Steam Generator, to provide steam at 100 6 1°C.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

6.9 Vacuum Source, capable of providing the specified

D02.14 on Stability and Cleanliness of Liquid Fuels.

vacuum.

Current edition approved July 1, 2007. Published July 2007. Originally approved

in 1988. Last previous edition approved in 2007 as D 4870–07. 6.10 Vacuum Gauge, capable of measuring the specified

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

vacuum.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.11 Filter Medium, Whatman glass fiber filter medium,

Standards volume information, refer to the standard’s Document Summary page on

Grade GF/A, 47 mm diameter.

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4870–07a

FIG. 1 Detail of Filtration Cell

all reagents shall conform to the specifications of the commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

3

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

su

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.