ASTM D3380-90(2003)

(Test Method)Standard Test Method for Relative Permittivity (Dielectric Constant) and Dissipation Factor of Polymer-Based Microwave Circuit Substrates

Standard Test Method for Relative Permittivity (Dielectric Constant) and Dissipation Factor of Polymer-Based Microwave Circuit Substrates

SIGNIFICANCE AND USE

Permittivity and dissipation factor are fundamental design parameters for design of microwave circuitry. Permittivity plays a principal role in determining the wavelength and the impedance of transmission lines. Dissipation factor (along with copper losses) influence attenuation and power losses.

This test method is suitable for polymeric materials having permittivity in the order of two to eleven. Such materials are popular in applications of stripline and microstrip configurations used in the 1 to 18 GHz range.

This test method is suitable for design, development, acceptance specifications, and manufacturing quality control.

Note 3—See Appendix X1 for additional information regarding significance of this test method and the application of the results.

SCOPE

1.1 This test method permits the rapid measurement of apparent relative permittivity and loss tangent (dissipation factor) of metal-clad polymer-based circuit substrates in the X-band (8 to 12.4 GHz).

1.2 This test method is suitable for testing PTFE (polytetrafluorethylene) impregnated glass cloth or random-oriented fiber mats, glass fiber-reinforced polystyrene, polyphenyleneoxide, irradiated polyethylene, and similar materials having a nominal specimen thickness of 1.6 mm. The materials are applicable to service at nominal frequency of 9.6 GHz.

Note 1—See for additional information about range of permittivity, thickness other than 1.6 mm, and tests at frequencies other than 9.6 GHz.

1.3 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D3380 – 90 (Reapproved 2003)

Standard Test Method for

Relative Permittivity (Dielectric Constant) and Dissipation

Factor of Polymer-Based Microwave Circuit Substrates

This standard is issued under the fixed designation D3380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 IPC Standards:

IPC-TM-650 Test Methods Manual Method 2.5.5.5.

1.1 This test method permits the rapid measurement of

IPC-CF-150E CopperFoilforPrintedWiringApplications.

apparent relative permittivity and loss tangent (dissipation

2.3 IEEE Standards:

factor) of metal-clad polymer-based circuit substrates in the

Standard No. 488.1 Standard Digital Interface for Program-

X-band (8 to 12.4 GHz).

mable Instrumentation.

1.2 This test method is suitable for testing PTFE (polytet-

Standard No. 488.2 Standards, Codes, Formats, Protocols

rafluorethylene) impregnated glass cloth or random-oriented

and Common Commands for use with ANSI and IEEE

fiber mats, glass fiber-reinforced polystyrene, polyphenyle-

Standard488.1.

neoxide, irradiated polyethylene, and similar materials having

a nominal specimen thickness of 1.6 mm. The materials are

3. Terminology

applicable to service at nominal frequency of 9.6 GHz.

3.1 Definitions—SeeTerminologyD1711forthedefinitions

NOTE 1—See Appendix X1 for additional information about range of

of terms used in this test method. See also Test Methods

permittivity, thickness other than 1.6 mm, and tests at frequencies other

D2520, D150, and IPC TM-650 for additional information

than 9.6 GHz.

regarding the terminology.

1.3 The values stated in inch-pound units are to be regarded

3.2 Definitions of Terms Specific to This Standard:

as the standard.

3.2.1 D—a symbol used in this test method for the dissipa-

1.4 This standard does not purport to address all of the

tion factor.

safety concerns, if any, associated with its use. It is the

3.2.2 DL—a correction factor associated with length which

responsibility of the user of this standard to establish appro-

correctsforthefringingcapacitanceattheendsoftheresonator

priate safety and health practices and determine the applica-

element.

bility of regulatory limitations prior to use.

3.2.3 k8—symbolusedinthistestmethodtodenoterelative

permittivity.

2. Referenced Documents

2 NOTE 2—The preferred symbol for permittivity is Greek kappa prime

2.1 ASTM Standards:

but some persons use other symbols to denote this property such as DK,

D150 Test Methods for AC Loss Characteristics and Per-

SIC,or ´8 .

R

mittivity (Dielectric Constant) of Solid Electrical Insula-

3.2.4 microstrip line—a microwave transmission line em-

tion

ploying a flat strip conductor bonded to one surface of a

D618 Practice for Conditioning Plastics for Testing

dielectric board or sheet, the other surface of which is clad

D1711 Terminology Relating to Electrical Insulation

with,orbondedto,acontinuousconductivefoilorplatewhich

D2520 Test Methods for Complex Permittivity (Dielectric

is substantially wider than the strip. Microstrip provides easier

Constant) of Solid Electrical Insulating Materials at Mi-

accessibility than stripline for attaching components and de-

crowave Frequencies and Temperatures to 1650°C

vices to the strip circuitry.

3.2.5 microwave substrate—a board or sheet of low-loss

This test method is under the jurisdiction of ASTM Committee D09 on

dielectricmaterialwhichmaybecladwithmetalfoilonone,or

Electrical and Electronic Insulating Materials and is the direct responsibility of

both, surfaces. In this test method all metal is removed by

Subcommittee D09.12 on Electrical Tests.

etching prior to testing.

Current edition approved March 10, 2003. Published May 2003. Originally

´1

approved in 1975. Last previous edition approved in 1995 as D3380–90 (1995)

. DOI: 10.1520/D3380-90R03.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from IPC, 2215 Sanders Rd., Northbrook, IL 60062.

Standards volume information, refer to the standard’s Document Summary page on Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

the ASTM website. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3380 – 90 (2003)

3.2.6 stripline—microwave transmission line using a flat

strip conductor clamped, or bonded, between two substantially

wider dielectric boards. The outer surfaces of both boards are

bonded to, or in intimate contact with, conducting foils or

plates (ground planes). Stripline may be conceived as a

flattened version of cylindrical coaxial cable.

3.2.7 stripline resonator—a disconnected section of strip-

linelooselycoupledateachendbycapacitativegapstofeedor

probe lines.The strip becomes resonant at those frequencies at

which the strip length, increased by an increment due to the

fringing fields at the ends, is equal to an integral multiple of

half-wavelengths in the dielectric. As frequency varies gradu-

ally, the power transmitted from the input to the output feed

lines becomes maximum at resonance, and falls off sharply to

essentially zero at frequencies which are a few parts per

thousand above and below resonance.

FIG. 1 Face View of Fixture Assembly

4. Summary of Test Method

4.1 Substrate specimens, with metal cladding removed,

become the supporting dielectric spacers of a microwave

stripline resonator when properly positioned and clamped in

the test fixture. The measured values of resonant frequency of

the stripline resonator and the half-power frequencies are used

to compute the relative permittivity (dielectric constant or k8)

and the dissipation factor (D) of the test specimen. The test

specimen consists of one or more pairs of test cards.

5. Significance and Use

5.1 Permittivity and dissipation factor are fundamental de-

signparametersfordesignofmicrowavecircuitry.Permittivity

plays a principal role in determining the wavelength and the

impedanceoftransmissionlines.Dissipationfactor(alongwith

copper losses) influence attenuation and power losses.

5.2 This test method is suitable for polymeric materials FIG. 2 Exploded Side View of Assembly

having permittivity in the order of two to eleven. Such

materialsarepopularinapplicationsofstriplineandmicrostrip

configurations used in the 1 to 18 GHz range.

5.3 This test method is suitable for design, development,

acceptance specifications, and manufacturing quality control.

NOTE 3—See Appendix X1 for additional information regarding sig-

nificance of this test method and the application of the results.

6. Apparatus

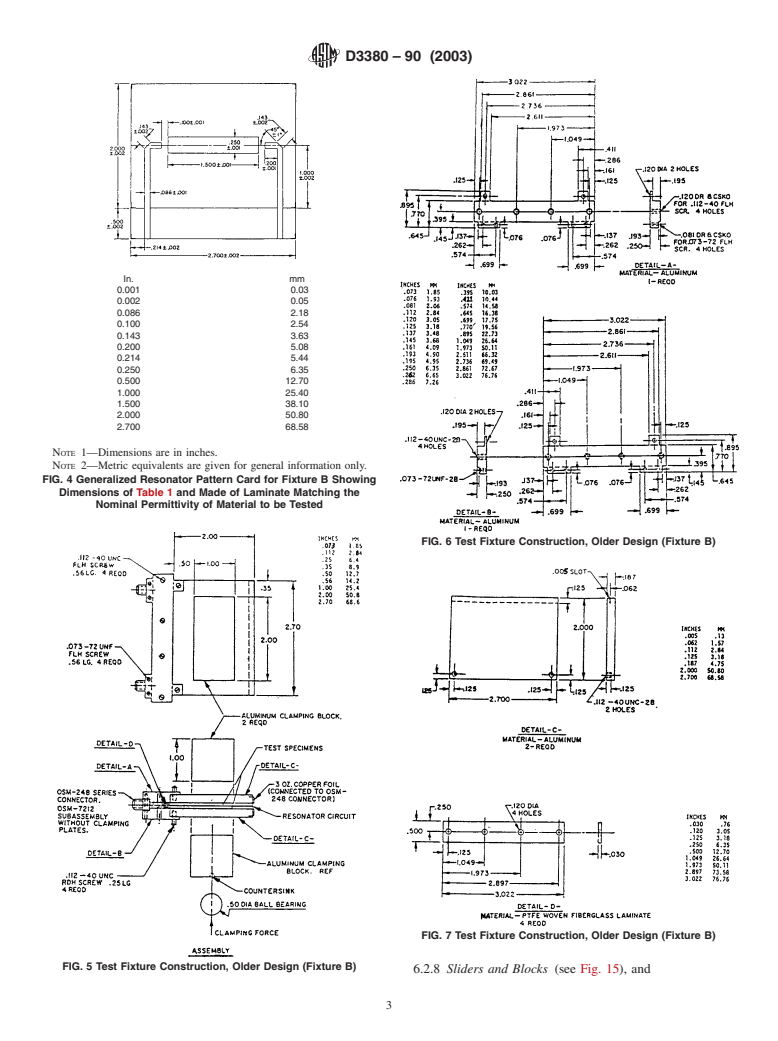

6.1 The preferred assembly fixture shown in Fig. 1, Fig. 2,

and Fig. 3 is hereby designated Fixture A. This design of test

specimen fixture provides advantages over the design of

FIG. 3 Enlarged Exploded Side View Sectioned Through a Probe

Line Showing a Lap Conductor Joint for Fixture A

Fixture B shown in Fig. 4, Fig. 5, Fig. 6, and Fig. 7.

6.1.1 The Fixture B design has been included since this

fixture has been, and still is, in service in numerous laborato- 6.2 Fixture A—The elements of the fixture include the

ries. following:

6.1.2 The Fixture B design relies upon close control of the 6.2.1 Resonator Pattern Card (see Fig. 8),

room temperature in the laboratory for control of the test 6.2.2 Base Stripline Board (see Fig. 9),

specimen temperature. 6.2.3 Base Cover Board (see Fig. 10),

6.1.3 Changing of test pattern cards in the Fixture B design 6.2.4 End-Launcher Bodies, adapted (see Fig. 11),

is less convenient than with the Fixture A design. 6.2.5 Aluminum Base Plates (see Fig. 12),

6.1.4 For Fixture A the preferred assembly for Resonator 6.2.6 Aluminum Clamping Plates (see Fig. 13),

Card and Specimen uses a Lap Conductor Joint. See Fig. 3 for 6.2.7 Aluminum Blocks, for temperature control (see Fig.

details. 14).

D3380 – 90 (2003)

In. mm

0.001 0.03

0.002 0.05

0.086 2.18

0.100 2.54

0.143 3.63

0.200 5.08

0.214 5.44

0.250 6.35

0.500 12.70

1.000 25.40

1.500 38.10

2.000 50.80

2.700 68.58

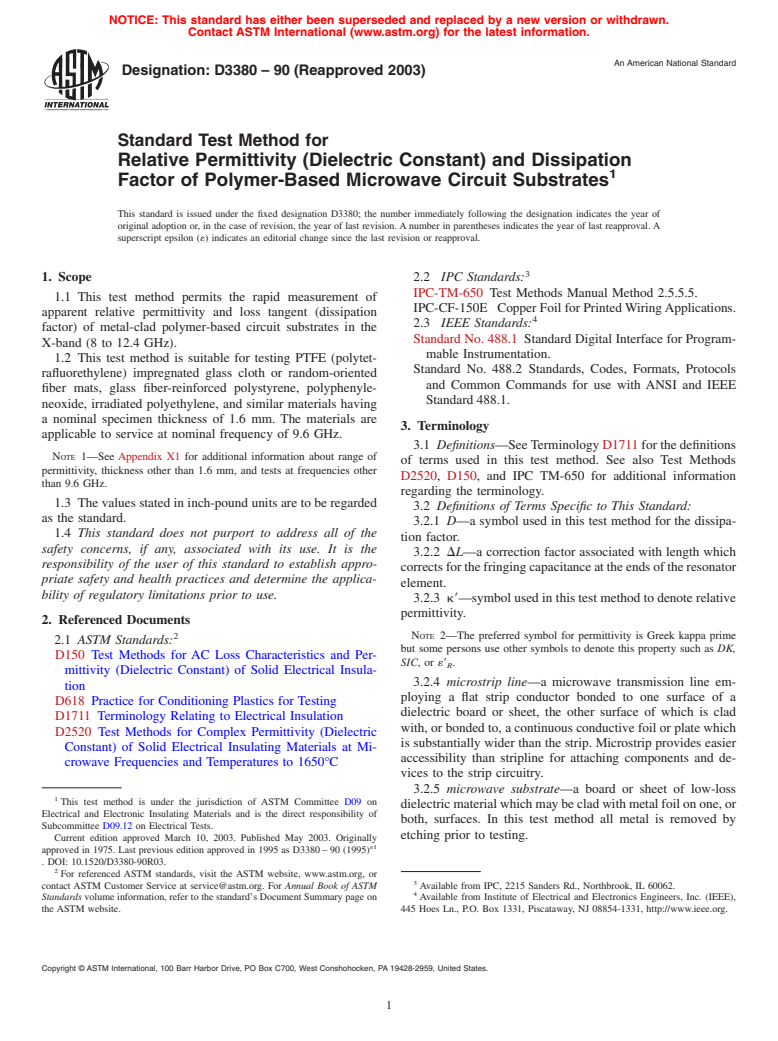

NOTE 1—Dimensions are in inches.

NOTE 2—Metric equivalents are given for general information only.

FIG. 4 Generalized Resonator Pattern Card for Fixture B Showing

Dimensions of Table 1 and Made of Laminate Matching the

Nominal Permittivity of Material to be Tested

FIG. 6 Test Fixture Construction, Older Design (Fixture B)

FIG. 7 Test Fixture Construction, Older Design (Fixture B)

FIG. 5 Test Fixture Construction, Older Design (Fixture B)

6.2.8 Sliders and Blocks (see Fig. 15), and

D3380 – 90 (2003)

FIG. 11 Detail of the Supplied End Launcher Body Adapted by

Boring Out the Tapped Holes

FIG. 8 Generalized Resonator Pattern Card for Fixture A Showing

Dimensions of and Made of Laminate Matching the Nominal

Permittivity of Materials to be Tested

FIG. 12 Aluminum Base Plate for Clamping the Base Cards and

Connecting Launcher Bodies to the Base Card

FIG. 9 Base Stripline Board with Copper Foil and Dielectric

Matching the Nominal Permittivity of the Material to be Tested

FIG. 10 Base Cover Board with Copper Foil Ground Plane

6.3 Microwave Signal Source, capable of providing an

accurate signal. An accurate signal provides a leveled power

output that falls withina0.1dBrangeduringtherequiredtime

FIG. 13 Aluminum Clamping Plate Provided with Tapped Holes

period and over the range of frequency needed to make a

for the Pressure Block and a Thermocouple Well

permittivity and loss measurement, and maintains output

within 5 MHz of the set value for the time required to make a

measurement when the signal source is set for a particular

6.6 Compression Force Gage, capable of measuring to

frequency.

5000 N (1100 lb) with an accuracy of 61% of full scale.

6.4 Frequency Measuring Device, having a resolution 5

MHz or less.

6.5 Power Level Detecting Device, having a resolution of

If you are aware of alternative suppliers, please provide this information to

0.1 dB or less and capable of comparing power levels within a

ASTM International Headquarters. Your comments will receive careful consider-

3-dB range with an accuracy of 0.1 dB. ation at a meeting of the responsible technical committee , which you may attend.

D3380 – 90 (2003)

,

6.8.1 Sweep Frequency Generator.

5,7

6.8.2 X-Band Frequency Plug-In Unit.

,

6.8.3 Frequency Meter.

5,9

6.8.4 Crystal Detector, two required.

,

6.8.5 Matched Load Resistor, for one of the crystal

detectors.

5,11

6.8.6 Standing Wave Rectified (SWR) Meter, two re-

quired.

5,12

6.8.7 Directional Coupler.

,

6.8.8 Attenuator, rated at 10 dB.

6.8.9 Semi-Rigid Coaxial Cable and Connectors.

,

6.8.10 Adapter, for waveguide to coaxial interconnec-

tion.

6.8.11 The assembly of this equipment is shown schemati-

cally in Fig. 16.

The sole source of supply of the Hewlett Packard (HP) 8350B or 8620C

generator known to the committee at this time is Hewlett Packard.

FIG. 14 Aluminum Block for Temperature Control and Transfer of

The sole source of supply of the Hewlett Packard (HP) 83545A or 86251A

Pressure to the Clamp Plates, Fitted with Tapped Holes for Slide,

plug-in unit known to the committee at this time is Hewlett Packard.

Embedded Steel Ball, and Tapped for Tubing Fittings for

The sole source of supply of the Hewlett Packard (HP) X532B meter known to

Circulating Fluid

the committee at this time is Hewlett Packard.

The sole source of supply of the Hewlett Packard 423B Neg. detector known

to the committee at this time is Hewlett Packard.

The sole source of supply of the Hewlett Packard 11523Aoption .001 resistor

known to the committee at this time is Hewlett Packard.

The sole source of supply of the Hewlett Packard 415E meter known to the

committee at this time is Hewlett Packard.

The sole source of supply of the Hewlett Packard 779D coupler known to the

committee at this time is Hewlett Packard.

The sole source of supply of the Hewlett Packard attenuator 8491B known to

the committee at this time is Hewlett Packard.

ThesolesourceofsupplyoftheHewlettPackardadapterX281Aknowntothe

committee at this time is Hewlett Packard.

FIG. 15 Slider and Block for Connecting Pressure Block and

Base Plate with Allowance for Opening the Fixture

NOTE 1—All coaxial cable connections.

NOTE 2—Equivalent makes and models of equipment may be substi-

6.7 Vise, or a press, for exerting a controlled force of 4448

tuted where it can be shown that equivalent results are obtained.

N(1000lb)onthetestfixtureandhavinganopeningofatleast

NOTE 3—Alternate test setups may be used provided that equivalent

5 in. (130 mm) to accept the force gage and test fixture.

results are obtained.

6.8 Apparatus for Manual Test Setup: FIG. 16 X-Band Permittivity Test Setup

D3380 – 90 (2003)

6.9 Apparatus for Computer Acquisition of Data—The input using an RF cable. With another RF cable, connect the

following alternative equipment or its equivalent, when prop- other output to the attenuator. Connect the attenuator to one of

erly interconnected, may be used effectively with a computer- the test fixture probe lines.

control program for automated testing: 6.9.11.2 Connect the counter and the synchronizer as speci-

,

6.9.1 Sweep Frequency Generator, see also 6.8.1. fied by the manufacturer of this equipment. Connect the FM

,

6.9.2 Radio Frequency (RF) Plug-In Unit, having a output from the synchronizer to the FM input on the sweep

range from 0.01 to 20 GHz. frequency generator using a BNC connector.

6.9.11.3 Use GPIB cables to parallel connect sweeper,

NOTE 4—Aplug-in of a narrower frequency range (in the X-band from

, synchronizer, power meter, and computer interface.

5.9 to 12.4 GHz) may be selected at significant cost savings.

6.9.11.4 Connect the power sensor to the other probe of the

,

6.9.3 Power Splitter.

test fixture and connect its special cable to the power meter.

5,19

6.9.4 Automatic Frequency Counter.

6.9.11.5 A synthesized continuous wave (CW) generator

,

6.9.5 Source Synchronizer.

may be used to replace the sweeper, plug-in, power splitter

5,21

6.9.6 Attenuator, 10 dB, see also 6.8.8.

connector, and the source synchronizer to provide the simpli-

,

6.9.7 Programmable Power Meter.

fied automated set-up shown in Fig. 18.

5,23

6.9.8 Power Sensor, having a range

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.