ASTM D3380-22

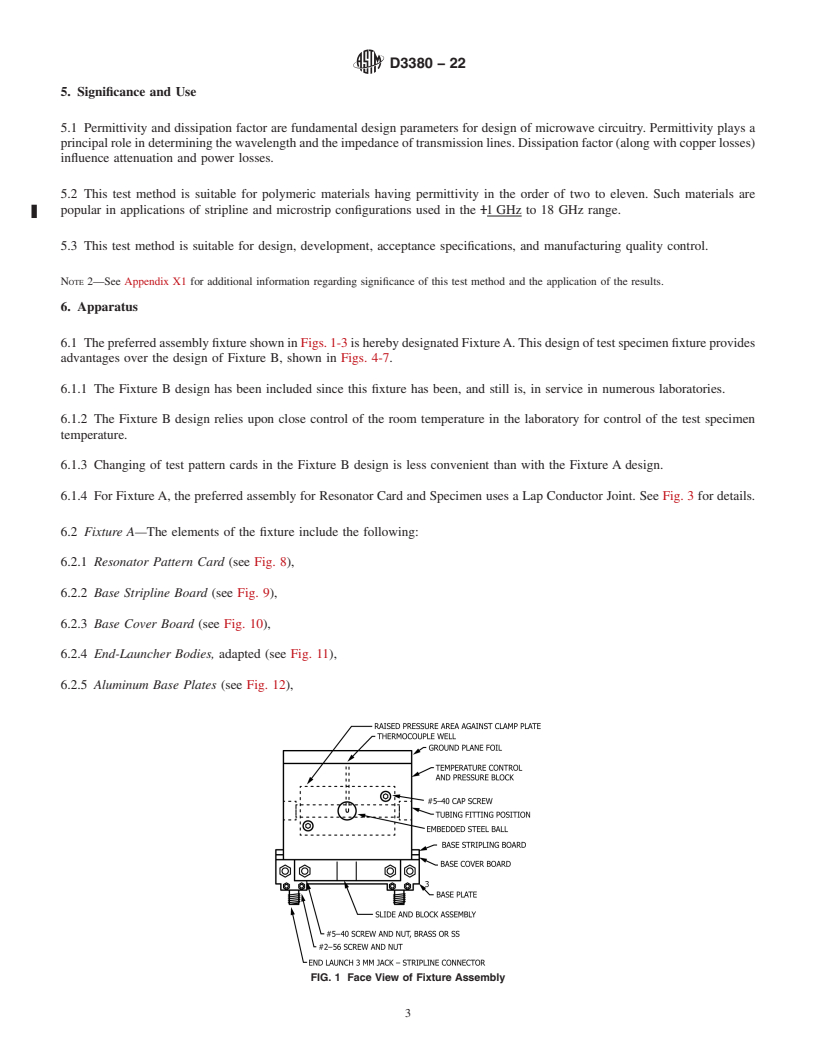

(Test Method)Standard Test Method for Relative Permittivity (Dielectric Constant) and Dissipation Factor of Polymer-Based Microwave Circuit Substrates

Standard Test Method for Relative Permittivity (Dielectric Constant) and Dissipation Factor of Polymer-Based Microwave Circuit Substrates

SIGNIFICANCE AND USE

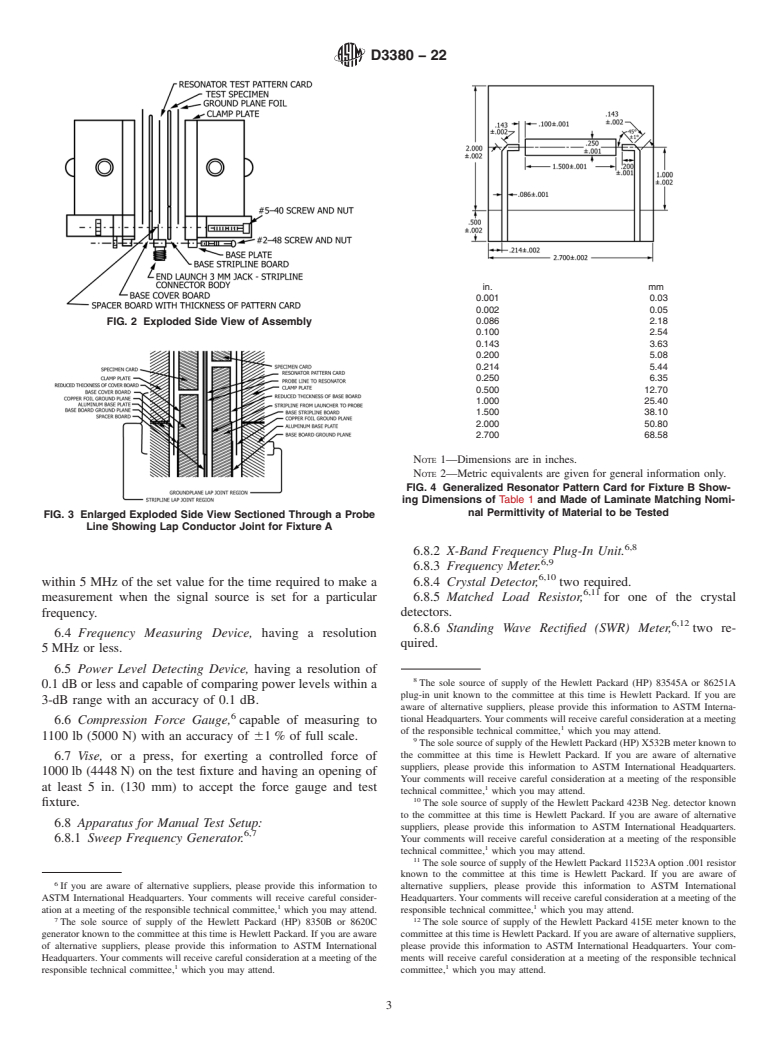

5.1 Permittivity and dissipation factor are fundamental design parameters for design of microwave circuitry. Permittivity plays a principal role in determining the wavelength and the impedance of transmission lines. Dissipation factor (along with copper losses) influence attenuation and power losses.

5.2 This test method is suitable for polymeric materials having permittivity in the order of two to eleven. Such materials are popular in applications of stripline and microstrip configurations used in the 1 GHz to 18 GHz range.

5.3 This test method is suitable for design, development, acceptance specifications, and manufacturing quality control.

Note 2: See Appendix X1 for additional information regarding significance of this test method and the application of the results.

SCOPE

1.1 This test method permits the rapid measurement of apparent relative permittivity and loss tangent (dissipation factor) of metal-clad polymer-based circuit substrates in the X-band (8 GHz to 12.4 GHz).

1.2 This test method is suitable for testing PTFE (polytetrafluorethylene) impregnated glass cloth or random-oriented fiber mats, glass fiber-reinforced polystyrene, polyphenyleneoxide, irradiated polyethylene, and similar materials having a nominal specimen thickness of 1/16 in. (1.6 mm). The materials listed in the preceding sentence have been used in commercial applications at nominal frequency of 9.6 GHz.

Note 1: See Appendix X1 for additional information about range of permittivity, thickness other than 1/16 in. (1.6 mm), and tests at frequencies other than 9.6 GHz.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3380 − 22

Standard Test Method for

Relative Permittivity (Dielectric Constant) and Dissipation

1

Factor of Polymer-Based Microwave Circuit Substrates

This standard is issued under the fixed designation D3380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method permits the rapid measurement of 2.1 ASTM Standards:

apparent relative permittivity and loss tangent (dissipation D150Test Methods forAC Loss Characteristics and Permit-

factor) of metal-clad polymer-based circuit substrates in the tivity (Dielectric Constant) of Solid Electrical Insulation

X-band (8GHz to 12.4 GHz). D1711Terminology Relating to Electrical Insulation

D2520Test Methods for Complex Permittivity (Dielectric

1.2 This test method is suitable for testing PTFE (polytet-

Constant) of Solid Electrical Insulating Materials at Mi-

rafluorethylene) impregnated glass cloth or random-oriented

crowave Frequencies and Temperatures to 1650°C

fiber mats, glass fiber-reinforced polystyrene,

D6054Practice for Conditioning Electrical Insulating Mate-

polyphenyleneoxide, irradiated polyethylene, and similar ma-

3

rials for Testing (Withdrawn 2012)

1

terials having a nominal specimen thickness of ⁄16 in.

4

2.2 IPC Standards:

(1.6mm). The materials listed in the preceding sentence have

IPC-TM-650Test Methods Manual Method 2.5.5.5.

been used in commercial applications at nominal frequency of

IPC-MF-4562Metal Foil for Printed Wiring Applications.

9.6GHz.

5

2.3 IEEE Standards:

NOTE 1—See Appendix X1 for additional information about range of

1 Standard No.488.1Standard Digital Interface for Program-

permittivity,thicknessotherthan ⁄16in.(1.6mm),andtestsatfrequencies

other than 9.6GHz. mable Instrumentation.

Standard No.488.2Standards, Codes, Formats, Protocols

1.3 The values stated in inch-pound units are to be regarded

and Common Commands for Use with ANSI and IEEE

as standard. The values given in parentheses are mathematical

Standard488.1.

conversions to SI units that are provided for information only

and are not considered standard.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions—SeeTerminology D1711 for the definitions

safety concerns, if any, associated with its use. It is the

of terms used in this test method. See also Test Methods

responsibility of the user of this standard to establish appro-

D2520, D150, and IPC TM-650 for additional information

priate safety, health, and environmental practices and deter-

regarding the terminology.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor- 3.2 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard-

3.2.1 D—a symbol used in this test method for the dissipa-

ization established in the Decision on Principles for the tion factor (loss tangent).

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

2

Barriers to Trade (TBT) Committee. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee D09 on the ASTM website.

3

Electrical and Electronic Insulating Materials and is the direct responsibility of The last approved version of this historical standard is referenced on

Subcommittee D09.12 on Electrical Tests. www.astm.org.

4

Current edition approved March 15, 2022. Published March 2022. Originally AvailablefromIPC,3000LakesideDrive,Suite309S,Bannockburn,IL60015.

5

approved in 1975. Last previous edition approved in 2014 as D3380–14. DOI: Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

10.1520/D3380-22. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3380 − 22

3.2.2 ∆L—a correction factor associated with length which materialsarepopularinapplicationsofstriplineandmicrostrip

correctsforthefringingcapacitanceattheendsoftheresonator configurations used in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3380 − 14 D3380 − 22

Standard Test Method for

Relative Permittivity (Dielectric Constant) and Dissipation

1

Factor of Polymer-Based Microwave Circuit Substrates

This standard is issued under the fixed designation D3380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method permits the rapid measurement of apparent relative permittivity and loss tangent (dissipation factor) of

metal-clad polymer-based circuit substrates in the X-band (8(8 GHz to 12.4 GHz).

1.2 This test method is suitable for testing PTFE (polytetrafluorethylene) impregnated glass cloth or random-oriented fiber mats,

glass fiber-reinforced polystyrene, polyphenyleneoxide, irradiated polyethylene, and similar materials having a nominal specimen

1

thickness of ⁄16 in. (1.6 mm). The materials listed in the preceding sentence have been used in commercial applications at nominal

frequency of 9.6 GHz.

1

NOTE 1—See Appendix X1 for additional information about range of permittivity, thickness other than ⁄161.6 mm, in. (1.6 mm), and tests at frequencies

other than 9.6 GHz.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D1711 Terminology Relating to Electrical Insulation

D2520 Test Methods for Complex Permittivity (Dielectric Constant) of Solid Electrical Insulating Materials at Microwave

Frequencies and Temperatures to 1650 °C

3

D6054 Practice for Conditioning Electrical Insulating Materials for Testing (Withdrawn 2012)

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.12 on Electrical Tests.

Current edition approved Nov. 1, 2014March 15, 2022. Published November 2014March 2022. Originally approved in 1975. Last previous edition approved in 20102014

as D3380 – 10.D3380 – 14. DOI: 10.1520/D3380-14.10.1520/D3380-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3380 − 22

4

2.2 IPC Standards:

IPC-TM-650 Test Methods Manual Method 2.5.5.5.

IPC-MF-4562 Metal Foil for Printed Wiring Applications.

5

2.3 IEEE Standards:

Standard No. 488.1 Standard Digital Interface for Programmable Instrumentation.

Standard No. 488.2 Standards, Codes, Formats, Protocols and Common Commands for Use with ANSI and IEEE Stan-

dard 488.1.

3. Terminology

3.1 Definitions—See Terminology D1711 for the definitions of terms used in this test method. See also Test Methods D2520,

D150, and IPC TM-650 for additional information regarding the terminology.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 D—a symbol used in this test method for the dissipation factor.factor (loss tangent).

3.2.2 ΔL—a correction factor associated with length which corrects for the fringing capacitance at the ends of the resonator

element.

3.2.3 κ'—symbol used in this test method to denote relati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.