ASTM D8195-18

(Specification)Standard Classification System and Basis for Specification for Polyethylene Terephthalate Film and Sheeting

Standard Classification System and Basis for Specification for Polyethylene Terephthalate Film and Sheeting

SIGNIFICANCE AND USE

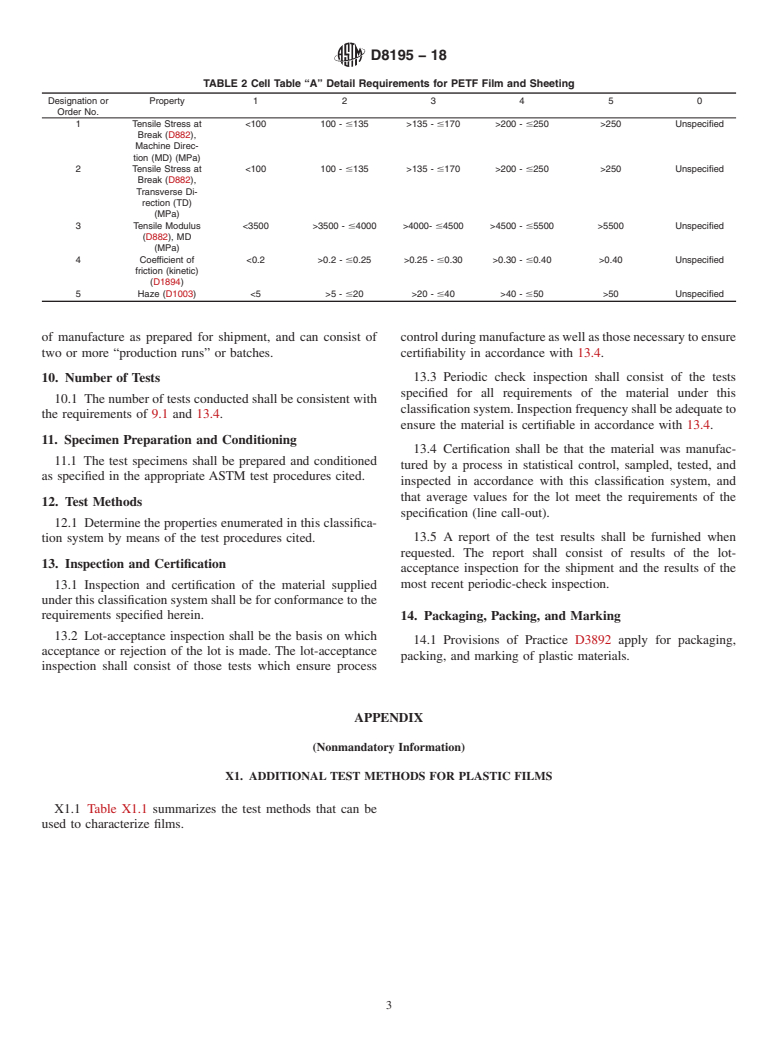

4.1 The purpose of this classification system is to provide a method of adequately identifying polyethylene terephthlate films and sheeting and to provide a means for specifying these films and sheeting by the use of a simple line call-out designation.

SCOPE

1.1 This standard provides a classification system for tabulating the properties for biaxially oriented polyethylene terephthalate film and sheeting in thicknesses from 1.5 μm to 355 μm. For this classification system, polyethylene terephthalate film and sheeting shall be defined as the material derived from terephthalic acid and ethylene glycol and shall consist of at least 90 % polyethylene terephthalate homopolymer with a typical melting temperature range of 225 °C to 250 °C. This specification does not apply to coated, coextruded, tinted, pigmented, or metallized film or sheeting. This classification (in accordance with D8065/D8065M) is intended to eventually replace Specification D5047 (ref. Note 3).

Note 1: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 250 µm.

Note 2: In order to conform to the original scope of Specification D5047, this classification also includes sheeting up to and including thicknesses of 355 µm.

Note 3: It is strongly recommended that this classification system be used for all new applications and specifications and that the specification of films referencing Specification D5047 be expeditiously withdrawn or converted to this classification system.

1.2 Polyethylene terephthalate materials, being thermoplastic, are reprocessable and recyclable. This specification allows for the use of those polyethylene terephthalate plastic materials, provided that any specific requirements as governed by the producer and end user are met.

1.3 In all cases where the provisions of this classification system would conflict with a currently referenced ASTM specification for a particular film product, the latter shall take precedence (see Note 3).

1.4 This classification system applies to commercial products and, as such, there is no control over the manufacturing parameters employed in producing the film. It shall be the responsibility of those developing the specification documents utilizing this classification system to identify the critical parameters and values to be used for the cell classifications and suffix requirements.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 4: There is no known ISO equivalent to this standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D8195 −18

Standard Classification System and Basis for Specification for

1

Polyethylene Terephthalate Film and Sheeting

This standard is issued under the fixed designation D8195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 Units—The values stated in SI units are to be regarded

as standard. No other units of measurement are included in this

1.1 This standard provides a classification system for tabu-

standard.

lating the properties for biaxially oriented polyethylene te-

1.6 This standard does not purport to address all of the

rephthalatefilmandsheetinginthicknessesfrom1.5µmto355

safety concerns, if any, associated with its use. It is the

µm. For this classification system, polyethylene terephthalate

responsibility of the user of this standard to establish appro-

film and sheeting shall be defined as the material derived from

priate safety, health, and environmental practices and deter-

terephthalic acid and ethylene glycol and shall consist of at

mine the applicability of regulatory limitations prior to use.

least 90 % polyethylene terephthalate homopolymer with a

typical melting temperature range of 225 °C to 250 °C. This

NOTE 4—There is no known ISO equivalent to this standard.

specification does not apply to coated, coextruded, tinted,

1.7 This international standard was developed in accor-

pigmented, or metallized film or sheeting. This classification

dance with internationally recognized principles on standard-

(in accordance with D8065/D8065M) is intended to eventually

ization established in the Decision on Principles for the

replace Specification D5047 (ref. Note 3).

Development of International Standards, Guides and Recom-

NOTE 1—Film is defined in Terminology D883 as an optional term for

mendations issued by the World Trade Organization Technical

sheeting having a nominal thickness no greater than 250 µm.

NOTE 2—In order to conform to the original scope of Specification Barriers to Trade (TBT) Committee.

D5047, this classification also includes sheeting up to and including

thicknesses of 355 µm.

2. Referenced Documents

NOTE 3—It is strongly recommended that this classification system be

2

2.1 ASTM Standards:

used for all new applications and specifications and that the specification

D150 Test Methods forAC Loss Characteristics and Permit-

of films referencing Specification D5047 be expeditiously withdrawn or

converted to this classification system.

tivity (Dielectric Constant) of Solid Electrical Insulation

D882 Test Method for Tensile Properties of Thin Plastic

1.2 Polyethylene terephthalate materials, being

Sheeting

thermoplastic, are reprocessable and recyclable. This specifi-

D883 Terminology Relating to Plastics

cation allows for the use of those polyethylene terephthalate

D1003 Test Method for Haze and Luminous Transmittance

plastic materials, provided that any specific requirements as

of Transparent Plastics

governed by the producer and end user are met.

D1894 Test Method for Static and Kinetic Coefficients of

1.3 In all cases where the provisions of this classification

Friction of Plastic Film and Sheeting

system would conflict with a currently referenced ASTM

D1922 Test Method for Propagation Tear Resistance of

specification for a particular film product, the latter shall take

Plastic Film and Thin Sheeting by Pendulum Method

precedence (see Note 3).

D3892 Practice for Packaging/Packing of Plastics

1.4 This classification system applies to commercial prod-

D5047 Specification for Polyethylene Terephthalate Film

ucts and, as such, there is no control over the manufacturing

and Sheeting

parameters employed in producing the film. It shall be the

D7209 Guide for Waste Reduction, Resource Recovery, and

responsibility of those developing the specification documents

Use of Recycled Polymeric Materials and Products (With-

3

utilizing this classification system to identify the critical

drawn 2015)

parametersandvaluestobeusedforthecellclassificationsand

D8065/D8065M Classification System and Basis for Speci-

suffix requirements.

fication for Specifying Plastic Films

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Standards volume information, refer to the standard’s Document Summary page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.