ASTM D6336-11

(Practice)Standard Practice for Evaluation of Flushing Vehicles for Pigment Wetting Using a Vacuum Modified Sigma Blade Mixer

Standard Practice for Evaluation of Flushing Vehicles for Pigment Wetting Using a Vacuum Modified Sigma Blade Mixer

SIGNIFICANCE AND USE

By following this practice it is possible to make reproducible flushes when using the same raw materials. Therefore, if someone wishes to evaluate the effect a different raw material has on a flush, it is possible to evaluate this effect by noting the change that occurs from a control flush to the experimental flush. This change can be, but is not limited to; such things as strength after vacuum, grind, grit, gloss etc. This practice can be used by ink companies, pigment companies or varnish companies. This practice is not meant to give absolute values but is meant to be used as a relative practice in which a control flush is made using a standard formula and the experimental flush is compared to the control flush. This practice is not meant to determine the absolute performance of a formula in production. Again it can be used to give a relative idea of how a formula will perform in production when a correlation has been established between laboratory flushing and production flushing.

SCOPE

1.1 This practice covers guidelines for the evaluations of flushing vehicles for pigment dispersion using a vacuum modified sigma blade mixer, or vacuum flusher.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6336 −11

Standard Practice for

Evaluation of Flushing Vehicles for Pigment Wetting Using a

1

Vacuum Modified Sigma Blade Mixer

This standard is issued under the fixed designation D6336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers guidelines for the evaluations of 3.1 Definitions of Terms Specific to This Standard:

flushing vehicles for pigment dispersion using a vacuum 3.1.1 additives, n—various materials that are used in rela-

modified sigma blade mixer, or vacuum flusher. tively small quantities to condition the pigment or vehicle.

3.1.2 break, n—the action that takes place when water is

1.2 The values stated in SI units are to be regarded as the

separated from the pigment in a presscake.

standard. The values given in parentheses are for information

only.

3.1.3 flushed color, n—a color base in paste form prepared

by flushing.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.4 flusher, n—a mixing device that has two sigma shaped

responsibility of the user of this standard to establish appro-

agitator blades parallel to each other, turning in opposing

priate safety and health practices and determine the applica-

directions at different speeds.

bility of regulatory limitations prior to use.

3.1.4.1 Discussion—Themixingactionofaflusheristhatof

kneading.

2. Referenced Documents

3.1.5 flushing, n—a method of transferring pigments from

2

2.1 ASTM Standards:

dispersionsinwatertodispersionsinoilbythedisplacementof

D280 Test Methods for Hygroscopic Moisture (and Other

the water by oil.

Matter Volatile Under the Test Conditions) in Pigments

3.1.5.1 Discussion—The resulting dispersions of flushing

D387 Test Method for Color and Strength of Chromatic

are known as flushed colors.

Pigments with a Mechanical Muller

3.1.6 pigment, n—the fine solid particles of colorant used to

D1316 Test Method for Fineness of Grind of Printing Inks

give color to printing inks.

By the NPIRI Grindometer

3.1.6.1 Discussion—The pigment particles are substantially

D2066 Test Methods for Relative Tinting Strength of Paste-

insoluble in the vehicle and in water.

Type Printing Ink Dispersions

3.1.7 presscake, n—a mixture of pigment and water formed

D2067 Test Method for Coarse Particles in Printing Ink

into a cake by passing through a filter press under pressure.

Dispersions

3.1.8 vacuum cycle, n—the time a flush is under vacuum to

D4017 Test Method for Water in Paints and Paint Materials

by Karl Fischer Method remove entrapped water.

D4040 Test Method for Rheological Properties of Paste

3.1.9 vehicle, n—the liquid portion of an ink that holds and

Printing and Vehicles by the Falling-Rod Viscometer

carries the pigment, provides workability and drying properties

D4361 Test Method for Apparent Tack of Printing Inks and

and binds the pigment to the substrate after the ink has dried.

Vehicles by a Three-Roller Tackmeter

4. Summary of Practice

4.1 Vehicle,pigmentpresscake,andadditivesareaddedinto

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

a sigma blade mixer and mixed until the water is displaced

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.37 on Ink Vehicles.

from the pigment presscake.

Current edition approved Nov. 1, 2011. Published November 2011. Originally

4.2 Step 4.1 is repeated two or three times until the capacity

approved in 1998. Last previous edition approved in 2004 as D6336 – 98 (2004)

which was withdrawn in 2010 and reinstated in November 2011. DOI: 10.1520/

of the flusher has been reached.

D6336-11.

2

4.3 Theflusheristhensealedandavacuumapplieduntilthe

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

dispersion (flush) is free of moisture.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 1—Lithol rubine pigment undergoes a color conversion when

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6336−11

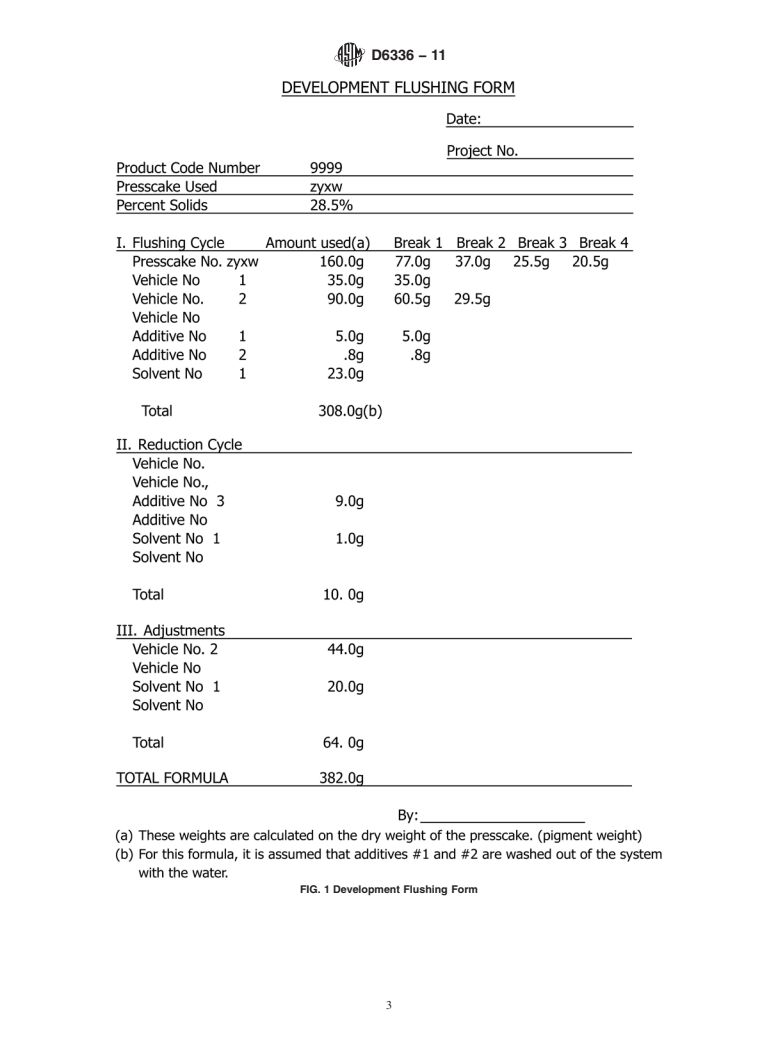

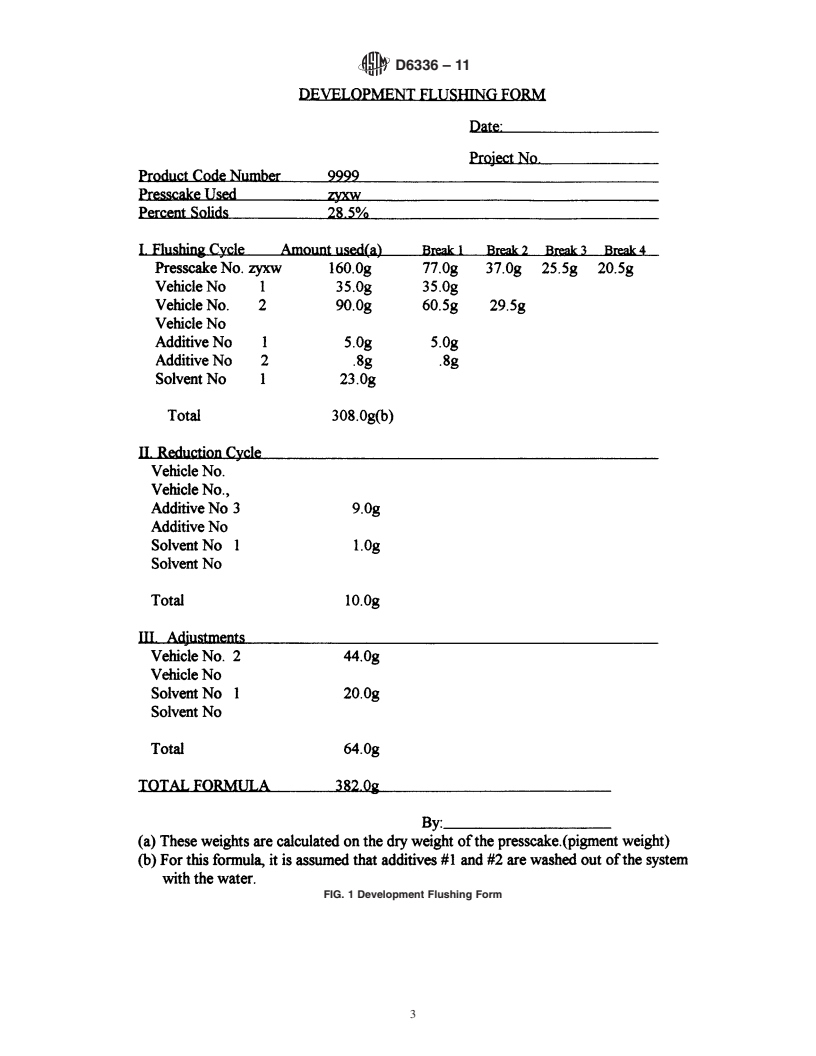

essentially all water is removed. flush the required amount of pigment in a succession of breaks (see Fig.

1).

4.4 Vehicle solvent and additives are added to adjust the

NOTE 3—Many formulas call for two or more kinds of oil or varnish or

strength, shade and body of the dispersion (flush) to that of a

resin solution etc. Directions are usually very specific

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6336–98(Reapproved2004) Designation: D6336 – 11

Standard Practice for

Evaluation of Flushing Vehicles for Pigment Wetting Using a

1

Vacuum Modified Sigma Blade Mixer

This standard is issued under the fixed designation D6336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers guidelines for the evaluations of flushing vehicles for pigment dispersion using a vacuum modified

sigma blade mixer, or vacuum flusher.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D280 Test Methods for Hygroscopic Moisture (and Other Matter Volatile Under the Test Conditions) in Pigments

D387 Test Method for Color and Strength of Chromatic Pigments with a Mechanical Muller

D1316 Test Method for Fineness of Grind of Printing Inks By the NPIRI Grindometer

D2066 Test Methods for Relative Tinting Strength of Paste-Type Printing Ink Dispersions

D2067 Test Method for Coarse Particles in Printing Ink Dispersions

D4017 Test Method for Water in Paints and Paint Materials by Karl Fischer Method

D4040 Test Method for Rheological Properties of Paste Printing and Vehicles by the Falling-Rod Viscometer

D4361 Test Method for Apparent Tack of Printing Inks and Vehicles by a Three-Roller Tackmeter

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 additives, n—various materials that are used in relatively small quantities to condition the pigment or vehicle.

3.1.2 break, n—the action that takes place when water is separated from the pigment in a presscake.

3.1.3 flushed color, n—a color base in paste form prepared by flushing.

3.1.4 flusher, n—amixingdevicethathastwosigmashapedagitatorbladesparalleltoeachother,turninginopposingdirections

at different speeds.

3.1.4.1 Discussion—The mixing action of a flusher is that of kneading.

3.1.5 flushing, n—a method of transferring pigments from dispersions in water to dispersions in oil by the displacement of the

water by oil.

3.1.5.1 Discussion—The resulting dispersions of flushing are known as flushed colors.

3.1.6 pigment, n—the fine solid particles of colorant used to give color to printing inks.

3.1.6.1 Discussion—The pigment particles are substantially insoluble in the vehicle and in water.

3.1.7 presscake, n—a mixture of pigment and water formed into a cake by passing through a filter press under pressure.

3.1.8 vacuum cycle, n—the time a flush is under vacuum to remove entrapped water.

3.1.9 vehicle, n—the liquid portion of an ink that holds and carries the pigment, provides workability and drying properties and

binds the pigment to the substrate after the ink has dried.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.37 on Ink Vehicles.

Current edition approved Nov. 1, 2004. Published November 2004. Originally approved in 1998. Last previous edition approved in 1998 as D6336–98. DOI:

10.1520/D6336-98R04.

Current edition approved Nov. 1, 2011. Published November 2011. Originally approved in 1998. Last previous edition approved in 2004 as D6336 – 98 (2004) which was

withdrawn in 2010 and reinstated in November 2011. DOI: 10.1520/D6336-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6336 – 11

4. Summary of Practice

4.1 Vehicle, pigment presscake, and additives are added into a sigma blade mixer and mixed until the water is displaced from

the pigment presscake.

4.2 Step 4.1 is repeated two or three times until the capacity of the flusher has been reached.

4.3 The flusher is the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.