ASTM D3983-98(2011)

(Test Method)Standard Test Method for Measuring Strength and Shear Modulus of Nonrigid Adhesives by the Thick-Adherend Tensile-Lap Specimen

Standard Test Method for Measuring Strength and Shear Modulus of Nonrigid Adhesives by the Thick-Adherend Tensile-Lap Specimen

SIGNIFICANCE AND USE

This test method is capable of providing shear modulus and shear strength values for adhesives with accuracy suitable for use by design engineers in predicting the characteristics of building assemblies bonded with nonrigid adhesives. Adhesive formulators will also find the method useful during the development of new adhesive systems. In general, the thick adherend lap-shear test is a useful tool in research during studies of both short- and long-term load-deformation properties of adhesives. This thick adherend lap-shear test yields a uniformity of stress distribution approaching that obtained in thin tubular butt joints subjected to torsion, which is considered to be a condition of pure shear.

The user is cautioned that pure shear strength cannot be obtained by this test method, because some tensile and compression stresses and stress concentrations are present in the joint. The estimate of shear strength by this test method will be conservative. If pure shear strength is demanded, then Test Method E229 should be used.

SCOPE

1.1 This test method describes a method of measuring the shear modulus and rupture stress in shear of adhesives in bonded joints. The method employs lap-shear specimens with wood, metal, or composite adherends, with adhesives having shear moduli ranging up to 700 MPa (100 000 psi). This test method is suitable generally for joints in which the ratio of adherend tensile modulus to adhesive shear modulus is greater than 300 to 1. It is not suitable for adhesives that have a high shear modulus in the cured state and that also require elimination of volatile constituents during cure.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3983 − 98 (Reapproved 2011)

Standard Test Method for

Measuring Strength and Shear Modulus of Nonrigid

1

Adhesives by the Thick-Adherend Tensile-Lap Specimen

This standard is issued under the fixed designation D3983; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E104Practice for Maintaining Constant Relative Humidity

by Means of Aqueous Solutions

1.1 This test method describes a method of measuring the

E229Test Method for Shear Strength and Shear Modulus of

shear modulus and rupture stress in shear of adhesives in

3

Structural Adhesives (Withdrawn 2003)

bonded joints. The method employs lap-shear specimens with

wood, metal, or composite adherends, with adhesives having

3. Terminology

shear moduli ranging up to 700 MPa (100000 psi). This test

3.1 Definitions:

method is suitable generally for joints in which the ratio of

3.1.1 For definitions of terms used in this test method, refer

adherend tensile modulus to adhesive shear modulus is greater

to Terminologies E6 and D907.

than 300 to 1. It is not suitable for adhesives that have a high

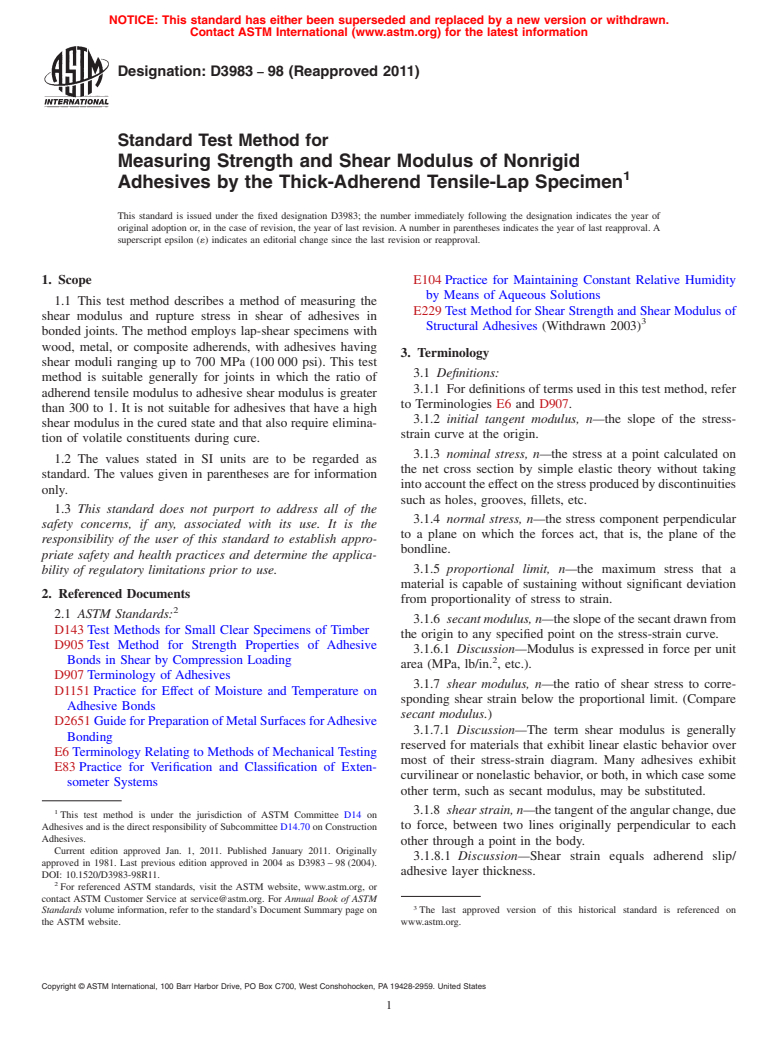

3.1.2 initial tangent modulus, n—the slope of the stress-

shear modulus in the cured state and that also require elimina-

strain curve at the origin.

tion of volatile constituents during cure.

3.1.3 nominal stress, n—the stress at a point calculated on

1.2 The values stated in SI units are to be regarded as

the net cross section by simple elastic theory without taking

standard. The values given in parentheses are for information

intoaccounttheeffectonthestressproducedbydiscontinuities

only.

such as holes, grooves, fillets, etc.

1.3 This standard does not purport to address all of the

3.1.4 normal stress, n—the stress component perpendicular

safety concerns, if any, associated with its use. It is the

to a plane on which the forces act, that is, the plane of the

responsibility of the user of this standard to establish appro-

bondline.

priate safety and health practices and determine the applica-

3.1.5 proportional limit, n—the maximum stress that a

bility of regulatory limitations prior to use.

material is capable of sustaining without significant deviation

2. Referenced Documents

from proportionality of stress to strain.

2

2.1 ASTM Standards:

3.1.6 secant modulus, n—theslopeofthesecantdrawnfrom

D143Test Methods for Small Clear Specimens of Timber

the origin to any specified point on the stress-strain curve.

D905Test Method for Strength Properties of Adhesive

3.1.6.1 Discussion—Modulus is expressed in force per unit

2

Bonds in Shear by Compression Loading

area (MPa, lb/in. , etc.).

D907Terminology of Adhesives

3.1.7 shear modulus, n—the ratio of shear stress to corre-

D1151Practice for Effect of Moisture and Temperature on

sponding shear strain below the proportional limit. (Compare

Adhesive Bonds

secant modulus.)

D2651GuideforPreparationofMetalSurfacesforAdhesive

3.1.7.1 Discussion—The term shear modulus is generally

Bonding

reserved for materials that exhibit linear elastic behavior over

E6Terminology Relating to Methods of Mechanical Testing

most of their stress-strain diagram. Many adhesives exhibit

E83Practice for Verification and Classification of Exten-

curvilinear or nonelastic behavior, or both, in which case some

someter Systems

other term, such as secant modulus, may be substituted.

1 3.1.8 shear strain, n—thetangentoftheangularchange,due

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction to force, between two lines originally perpendicular to each

Adhesives.

other through a point in the body.

Current edition approved Jan. 1, 2011. Published January 2011. Originally

3.1.8.1 Discussion—Shear strain equals adherend slip/

approved in 1981. Last previous edition approved in 2004 as D3983–98(2004).

adhesive layer thickness.

DOI: 10.1520/D3983-98R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3983 − 98 (2011)

3.1.9 shear strength, n—in an adhesive joint, the maximum

average stress when a force is applied parallel to the joint.

3.1.9.1 Discussion—In most adhesive test methods, the

shearstrengthisa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.