ASTM D2419-95

(Test Method)Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate

Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate

SCOPE

1.1 This test method is intended to serve as a rapid field-correlation test. The purpose of this test method is to indicate, under standard conditions, the relative proportions of clay-like or plastic fines and dust in granular soils and fine aggregates that pass the No. 4 (4.75-mm) sieve. The term "sand equivalent" expresses the concept that most granular soils and fine aggregates are mixtures of desirable coarse particles, sand, and generally undesirable clay or plastic fines and dust. Note 1-Some agencies perform the test on material with a top size smaller than the No. 4 (4.75-mm) sieve. This is done to avoid trapping the clay-like or plastic fines and dust below flaky shaped No. 4 to 8 (4.75 to 2.36 mm) sized particles. Testing smaller top sized material may lower the numerical results of the test.

1.2 Units of Measurement:

1.2.1 With regard to sieve sizes and the size of aggregate as determined by the use of testing sieves, the values in inch-pound units are shown for the convenience of the user; however, the standard sieve designation shown in parentheses is the standard value as stated in Specification E11.

1.2.2 With regard to mass, the values shown in SI units are to be regarded as the standard.

1.2.3 With regard to other units of measure, the values stated in inch-pound units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2419 – 95

Standard Test Method for

Sand Equivalent Value of Soils and Fine Aggregate

This standard is issued under the fixed designation D 2419; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 75 Practice for Sampling Aggregates

D 653 Terminology Relating to Soil, Rock, and Contained

1.1 This test method is intended to serve as a rapid field-

Fluids

correlation test. The purpose of this test method is to indicate,

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

under standard conditions, the relative proportions of clay-like

poses

or plastic fines and dust in granular soils and fine aggregates

2.2 AASHTO Standard:

that pass the No. 4 (4.75-mm) sieve. The term “sand equiva-

T 176 Standard Method of Test for Plastic Fines in Graded

lent” expresses the concept that most granular soils and fine

Aggregates and Soils by Use of Sand Equivalent Test

aggregates are mixtures of desirable coarse particles, sand, and

generally undesirable clay or plastic fines and dust.

3. Terminology

NOTE 1—Some agencies perform the test on material with a top size

3.1 Definitions:

smaller than the No. 4 (4.75-mm) sieve. This is done to avoid trapping the

3.1.1 fine aggregate—aggregate passing the ⁄8-in. (9.5-mm)

clay-like or plastic fines and dust below flaky shaped No. 4 to 8 (4.75 to

sieve and almost entirely passing the No. 4 (4.75-mm) sieve

2.36 mm) sized particles. Testing smaller top sized material may lower the

and predominantly retained on the No. 200 (75-μm) sieve (see

numerical results of the test.

Terminology C 125).

1.2 Units of Measurement:

3.1.2 sand equivalent—a measure of the amount of silt or

1.2.1 With regard to sieve sizes and the size of aggregate as

clay contamination in the fine aggregate (or soil) as determined

determined by the use of testing sieves, the values in inch-

by test (see Terminology D 653). (For further explanation, see

pound units are shown for the convenience of the user;

Summary of Test Method and Significance and Use.)

however, the standard sieve designation shown in parentheses

3.1.3 soil—sediments or other unconsolidated accumula-

is the standard value as stated in Specification E 11.

tions of solid particles produced by the physical and chemical

1.2.2 With regard to mass, the values shown in SI units are

disintegration of rocks which may or may not contain organic

to be regarded as the standard.

matter (see Terminology D 653).

1.2.3 With regard to other units of measure, the values

stated in inch-pound units are to be regarded as standard.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 A measured volume of soil or fine aggregate and a small

safety concerns, if any, associated with its use. It is the

quantity of flocculating solution are poured into a graduated

responsibility of the user of this standard to establish appro-

plastic cylinder and are agitated to loosen the claylike coatings

priate safety and health practices and determine the applica-

from the sand particles in the test specimen. The specimen is

bility of regulatory limitations prior to use.

then “irrigated” using additional flocculating solution forcing

the claylike material into suspension above the sand. After a

2. Referenced Documents

prescribed sedimentation period, the height of flocculated clay

2.1 ASTM Standards:

is read and the height of sand in the cylinder is determined. The

C 125 Terminology Relating to Concrete and Concrete

sand equivalent is the ratio of the height of sand to the height

Aggregates

of clay times 100.

C 670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

5. Significance and Use

C 702 Practice for Reducing Samples of Aggregate to

5.1 This test method assigns an empirical value to the

Testing Size

relative amount, fineness, and character of claylike material

This test method is under the jurisdiction of ASTM Committee D-4 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on Annual Book of ASTM Standards, Vol 04.03.

Aggregate Tests. Annual Book of ASTM Standards, Vol 04.08.

Current edition approved Sept. 10, 1995. Published November 1995. Originally Annual Book of ASTM Standards, Vol 14.02.

published as D 2419 – 65 T. Last previous edition D 2419 – 91. Available from American Association of State Highway and Transportation

Annual Book of ASTM Standards, Vol 04.02. Officials, 444 N. Capitol St. NW, Suite 225, Washington, DC 20001.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2419

present in the test specimen. stopper, irrigator tube, weighted foot assembly and siphon

5.2 A minimum sand equivalent value may be specified to assembly all conforming to the respective specifications and

limit the permissible quantity of claylike fines in an aggregate. dimensions shown in Fig. 1. See Annex A1 for alternative

5.3 This test method provides a rapid field method for apparatus.

determining changes in the quality of aggregates during 7.2 Measuring Tin— A cylindrical tin approximately 2 ⁄4-in.

production or placement. (57 mm) in diameter having a capacity of 85 6 5 mL.

7.3 No. 4 (4.75-mm) Sieve, conforming to the requirements

6. Interferences

of Specification E 11.

6.1 Maintain the temperature of the working solution at 72

7.4 Funnel, wide-mouth, for transferring test specimens into

6 5°F (22 6 3°C) during the performance of this test.

the graduated cylinder.

7.5 Bottles, two 1.0-gal (3.8-L) to store stock solution and

NOTE 2—If field conditions preclude the maintenance of the tempera-

ture range, frequent referee samples should be submitted to a laboratory

working solution.

where proper temperature control is possible. It is also possible to

7.6 Flat Pan, for mixing.

establish temperature correction curves for each material being tested

7.7 Clock or Watch, reading in minutes and seconds.

where proper temperature control is not possible. However, no general

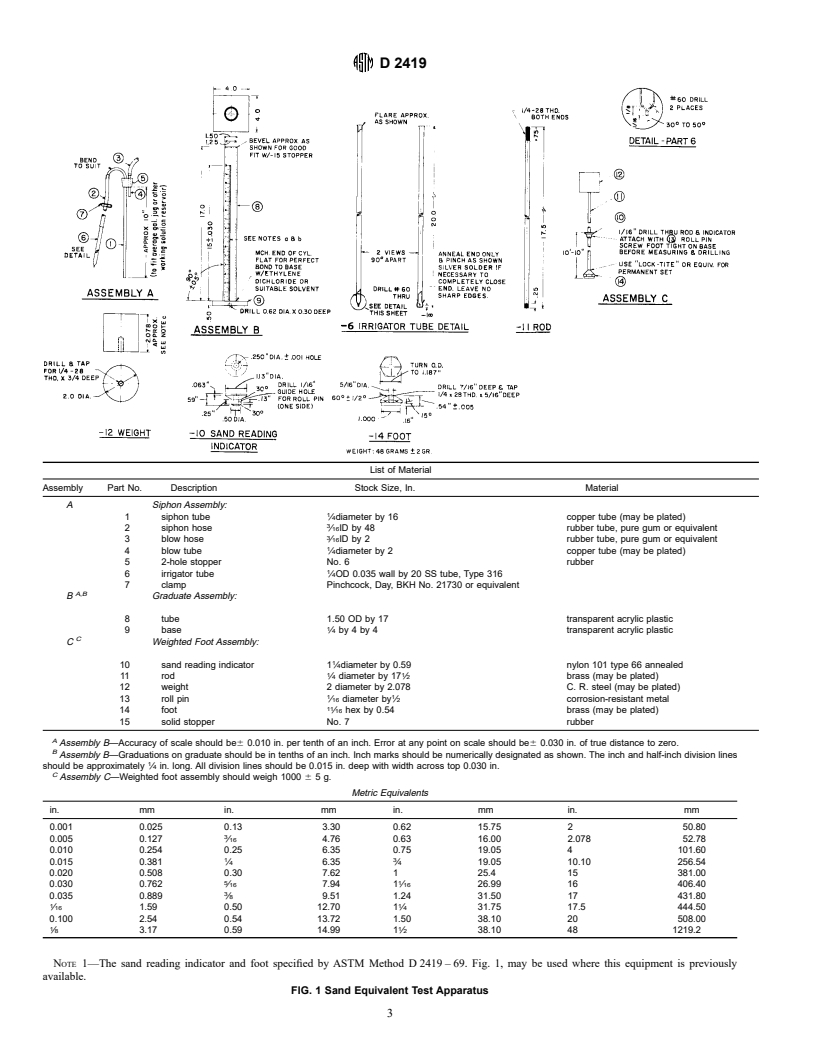

7.8 Mechanical Sand Equivalent Shaker, designed to hold

correction should be utilized for several materials even within a narrow

the required graduated plastic cylinder in a horizontal position

range of sand equivalent values. Samples that meet the minimum sand

while subjecting it to a reciprocating motion parallel to its

equivalent requirement at a working solution temperature below the

recommended range need not be subject to referee testing. length and having a throw of 8 6 0.04 in. (203.2 6 1.0 mm)

and operating at 175 6 2 cpm. A typical apparatus is shown in

6.2 Perform the test at a location free from vibration.

Fig. 2. The shaker shall be securely fastened to a firm and level

Excessive vibration may cause the suspended material to settle

mount.

at a greater rate than normal.

6.3 Do not expose the plastic cylinders to direct sunlight any

NOTE 3—Moving parts of the mechanical shaker should be provided

more than is necessary. with a safety guard for protection of the operator.

6.4 Occasionally it may be necessary to remove a fungus

7.9 Manually Operated Sand Equivalent Shaker—

growth from the working calcium chloride solution container

(optional), as shown in Fig. 3, or equivalent, capable of

and from the inside of the flexible tubing and irrigator tube.

producing an oscillating motion at a rate of 100 complete

This fungus can easily be seen as a slimy substance in the

cycles in 45 6 5 s, with a hand-assisted half stroke length of 5

solution, or as a mold growing on the inside of the container.

6 0.2 in. (127 6 5 mm). The device shall be designed to hold

6.4.1 To remove this growth, prepare a cleaning solvent by

the required graduated cylinder in a horizontal position while

diluting sodium hypochlorite solution (household chlorine

subjecting it to a reciprocating motion parallel to its length.

bleach) with an equal quantity of water.

The shaker shall be fastened securely to a firm and level mount.

6.4.2 After discarding the contaminated solution, fill the

If only a few tests are to be run the shaker may be held by hand

solution container with the prepared cleaning solvent: allow

on a firm level mount.

about 1 L of the cleaning solvent to flow through the siphon

7.10 Oven, of sufficient size, and capable of maintaining a

assembly and irrigator tube, then place the pinch clamp on the

temperature of 230 6 9°F (1106 5°C).

end of the tubing to cut off the flow of solvent and to hold the

7.11 Filter Paper, Watman No. 2V or equivalent.

solvent in the tube. Refill the container and allow to stand

overnight.

8. Reagents and Materials

6.4.3 After soaking, allow the cleaning solvent to flow out

8.1 Stock Solution— The materials listed in 8.1.1, 8.1.2 or

through the siphon assembly and irrigator tube.

8.1.3 may be used to prepare the stock solution. If the use of

6.4.4 Remove the siphon assembly from the solution con-

formaldehyde as the biocide is of concern, the materials in

tainer and rinse both with clear water. The irrigator tube and

8.1.2 or 8.1.3 should be used. A fourth alternative is not to use

siphon assembly can be rinsed easily by attaching a hose

any biocide provided the time of storage of stock solution is not

between the tip of the irrigator tube and water faucet and

sufficient to promote the growth of fungi.

backwashing fresh water through the tube.

8.1.1 Stock solution with formaldehyde.

6.5 Occasionally the holes in the tip of the irrigator tube

8.1.1.1 Anhydrous Calcium Chloride, 454 g (1.0 lb) of

may become clogged by a particle of sand. If the obstruction

technical grade.

cannot be freed by any other method, use a pin or other sharp

8.1.1.2 USP Glycerin, 2050 g (1640 mL).

object to force it out using extreme care not to enlarge the size

8.1.1.3 Formaldehyde, (40 volume % solution) 47 g (45

of the opening.

mL).

6.6 Working solution which is more than two weeks old

8.1.1.4 Dissolve the 454 g (1.0 lb) of calcium chloride in

shall be discarded.

1.89 L ( ⁄2 gal) of distilled water. Cool and filter through ready

6.7 Mixing and storage container(s) for solutions shall be

pleated rapid filtering paper. Add the 2050 g of glycerin and the

thoroughly rinsed prior to mixing a fresh batch of solution.

47 g of formaldehyde to the filtered solution, mix well, and

6.8 Fresh solution shall not be added to old solution

dilute to 3.78 L (1 gal).

regardless of age.

8.1.2 Stock solution with glutaraldehyde.

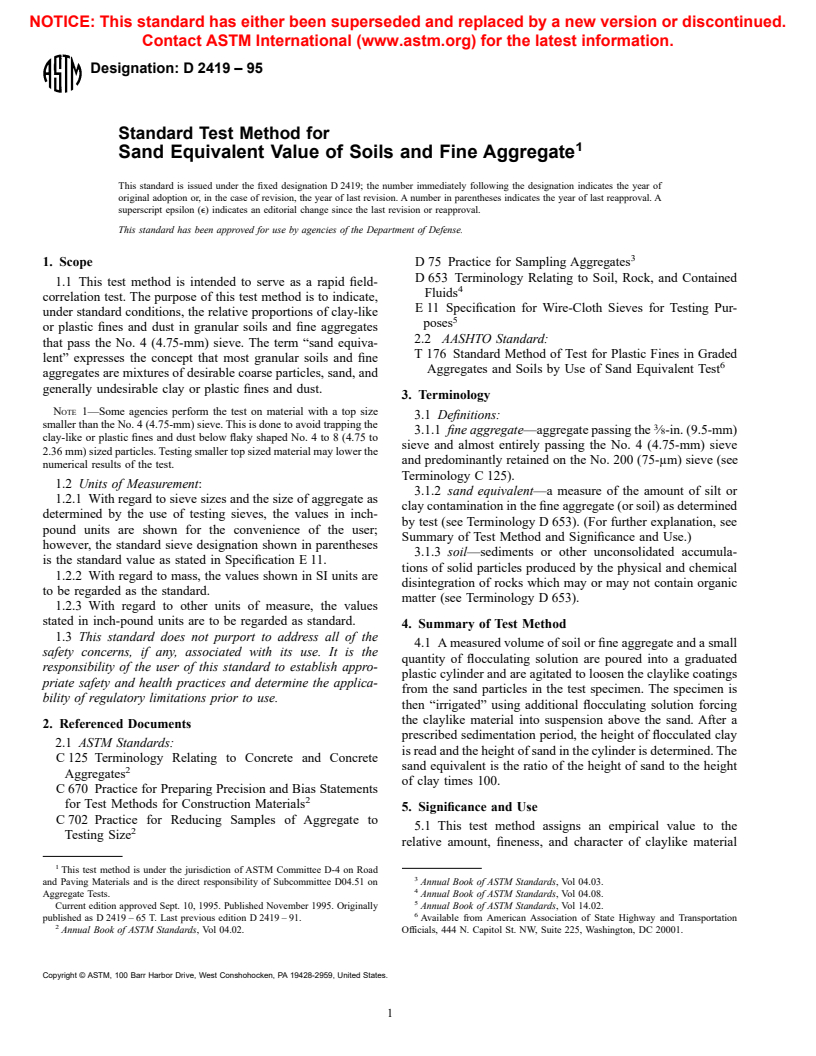

7. Apparatus

8.1.2.1 Calcium Chloride Dihydrate, 577 g (1.27 lb) of A.

7.1 A graduated transparent acrylic plastic cylinder, rubber C. S. grade.

D 2419

List of Material

Assembly Part No. Description Stock Size, In. Material

A Siphon Assembly:

1 siphon tube ⁄4diameter by 16 copper tube (may be plated)

2 siphon hose ⁄16ID by 48 rubber tube, pure gum or equivalent

3 blow hose ⁄16ID by 2 rubber tube, pure gum or equivalent

4 blow tube ⁄4diameter by 2 copper tube (may be plated)

5 2-hole stopper No. 6 rubber

6 irrigator tube ⁄4OD 0.035 wall by 20 SS tube, Type 316

7 clamp Pinchcock, Day, BKH No. 21730 or equivalent

A,B

B Graduate Assembly:

8 tube 1.50 OD by 17 transparent acrylic plastic

9 base ⁄4 by4by4 transparent acrylic plastic

C

C Weighted Foot Assembly:

10 sand reading indicator 1 ⁄4diameter by 0.59 nylon 101 type 66 annealed

1 1

11 rod ⁄4 diameter by 17 ⁄2 brass (may be plated)

12 weight 2 diameter by 2.078 C. R. steel (may be plated)

1 1

13 roll pin ⁄16 diameter by ⁄2 corrosion-resistant metal

14 foot ⁄16 hex by 0.54 brass (may be plated)

15 solid stopper No. 7 rubber

A

Assembly B—Accuracy of scale should be6 0.010 in. per tenth of an inch. Error at any point on scale should be6 0.030 in. of true distance to zero.

B

Assembly B—Graduations on graduate should be in tenths of an inch. Inch marks should be numerically designated as shown. The inch and half-inch division lines

should be approximately ⁄4 in. long. All division lines should be 0.015 in. deep with width across top 0.030 in.

C

Assembly C—Weighted foot assembly should weigh 1000 6 5g.

Metric Equivalents

in. mm in. mm in. mm in. mm

0.001 0.025 0.13 3.30 0.62 15.75 2 50.80

0.005 0.127 ⁄16 4.76 0.63 16.00 2.078 52.78

0.010 0.254 0.25 6.35 0.75 19.05 4 101.60

1 3

0.015 0.381 ⁄4 6.35 ⁄4 19.05 10.10 256.54

0.020 0.508 0.30 7.62 1 25.4 15 381.00

5 1

0.030 0.762 ⁄16 7.94 1 ⁄16 26.99 16 406.40

0.035 0.889 ⁄8 9.51 1.24 31.50 17 431.80

1 1

⁄16 1.59 0.50 12.70 1 ⁄4 31.75 17.5 444.50

0.100 2.54 0.54 13.72 1.50 38.10 20 508.00

1 1

⁄8 3.17 0.59 14.99 1 ⁄2 38.10 48 1219.2

NOTE 1—The sand reading indicator and foot specified by ASTM Method D 2419 – 69. Fig. 1, may be used where this equipment is previously

available.

FIG. 1 Sand Equivalent Test Apparatus

D 2419

not affect the test results, it is permissible to use it instead of

distilled or demineralized water except in the event of dispute.

NOTE 6—The effect of local tap water on sand equivalent test results

may be determined by comparing the results of three sand equivalent tests

using distilled water with the results of three sand equivalent tests using

the local tap water. The six test specimens required for this comparison

shall be prepared from the sample of material and oven-dried as prescribed

in this test method.

9. Sample Preparation

9.1 Sample the material to be tested in accordance with

Practice D 75.

9.2 Thoroughly mix the sample and reduce it as necessary

using the applicable procedures in Practice C 702.

9.3 Obtain at least 1500 g of material passing the No. 4

(4.75-mm) sieve in the following manner:

9.3.1 Separate the sample on the No. 4 (4.75-mm) sieve by

means of a lateral and vertical motion of the sieve, accompa-

nied by a jarring action so as to keep the sample moving

continuously over the surface of the sieve. Continue the sieving

until not more than 1 weight % of the residue passes the sieve

during 1 min. The sieving operation may be performed either

by hand or by a mechanical apparatus. When thoroughness of

FIG. 2 Mechanized Shaker

mechanical sieving is being determined, test by the hand

method described above using a single layer of material on the

NOTE 4—ACS grade calcium chloride dihydrate is specified for the

sieve.

stock solution prepared with glutaraldehyde because tests indicate that

9.3.2 Break down any lumps of material in the coarse

impurities in the technical grade anhydrous calcium chloride may react

fraction to pass the No. 4 (4.75-mm) sieve. A mortar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.