ASTM E1852-19

(Test Method)Standard Test Method for Determination of Low Levels of Antimony in Carbon and Low-Alloy Steel by Graphite Furnace Atomic Absorption Spectrometry

Standard Test Method for Determination of Low Levels of Antimony in Carbon and Low-Alloy Steel by Graphite Furnace Atomic Absorption Spectrometry

SIGNIFICANCE AND USE

5.1 This test method is utilized for the determination of trace levels of antimony in carbon and low-alloy steel. It is assumed that the procedure will be performed by trained analysts capable of performing common laboratory practices skillfully and safely. It is expected that the work will be performed in a properly equipped laboratory and proper waste disposal procedures will be followed.

SCOPE

1.1 This test method covers the determination of antimony in carbon and low-alloy steel in the 0.0005 % through 0.010 % range.

1.2 If this test method is used to test materials having contents less than 0.001 % antimony, users of different laboratories will experience more than the usual 5 % risk that their results will differ by more than 50 % relative error.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1852 − 19

Standard Test Method for

Determination of Low Levels of Antimony in Carbon and

Low-Alloy Steel by Graphite Furnace Atomic Absorption

1

Spectrometry

This standard is issued under the fixed designation E1852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1601Practice for Conducting an Interlaboratory Study to

Evaluate the Performance of an Analytical Method

1.1 This test method covers the determination of antimony

E1770Practice for Optimization of Instrumentation for

incarbonandlow-alloysteelinthe0.0005%through0.010%

Graphite Furnace Atomic Absorption Spectrometry

range.

E1806Practice for Sampling Steel and Iron for Determina-

1.2 If this test method is used to test materials having

tion of Chemical Composition

contents less than 0.001% antimony, users of different labo- 3

2.2 ISO Standards:

ratories will experience more than the usual 5% risk that their

ISO 5725Precision of Test Methods—Determination of

results will differ by more than 50% relative error.

Repeatability and Reproducibility for a Standard Test

1.3 This standard does not purport to address all of the

Method by Inter-Laboratory Tests

safety concerns, if any, associated with its use. It is the

ISO 10698Steel—Determination of Antimony Content—

responsibility of the user of this standard to establish appro-

ElectrothermalAtomicAbsorption Spectrometric Method

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

dance with internationally recognized principles on standard-

Terminology E135.

ization established in the Decision on Principles for the

4. Summary of Test Method

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 ThesampleisdissolvedinHClandHNO anddilutedto

3

Barriers to Trade (TBT) Committee.

volume. An appropriate aliquot is injected into the graphite

furnace atomizer of an atomic absorption spectrometer, which

2. Referenced Documents

isequippedwithabackgroundcorrection.Thesampleisdried,

2

2.1 ASTM Standards:

pyrolized, and atomized.The absorbance of the radiation from

E29Practice for Using Significant Digits in Test Data to

the external light source is measured and compared to the

Determine Conformance with Specifications

absorbance of samples of known composition.

E50Practices for Apparatus, Reagents, and Safety Consid-

NOTE 1—In general, the deuterium correction system should be able to

erations for Chemical Analysis of Metals, Ores, and

correct for the broad-band background absorbance up to 0.5 to 0.6

Related Materials

absorbance units. Zeeman systems should compensate for background

E135Terminology Relating to Analytical Chemistry for

levels as high as 1.0 to 1.5 absorbance units.

Metals, Ores, and Related Materials

5. Significance and Use

E1184Practice for Determination of Elements by Graphite

Furnace Atomic Absorption Spectrometry

5.1 This test method is utilized for the determination of

trace levels of antimony in carbon and low-alloy steel. It is

assumed that the procedure will be performed by trained

1

This test method is under the jurisdiction of ASTM Committee E01 on

analysts capable of performing common laboratory practices

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

skillfully and safely. It is expected that the work will be

Current edition approved June 15, 2019. Published August 2019. Originally

performed in a properly equipped laboratory and proper waste

approved in 1996. Last previous edition approved in 2013 as E1852–13. DOI:

disposal procedures will be followed.

10.1520/E1852-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

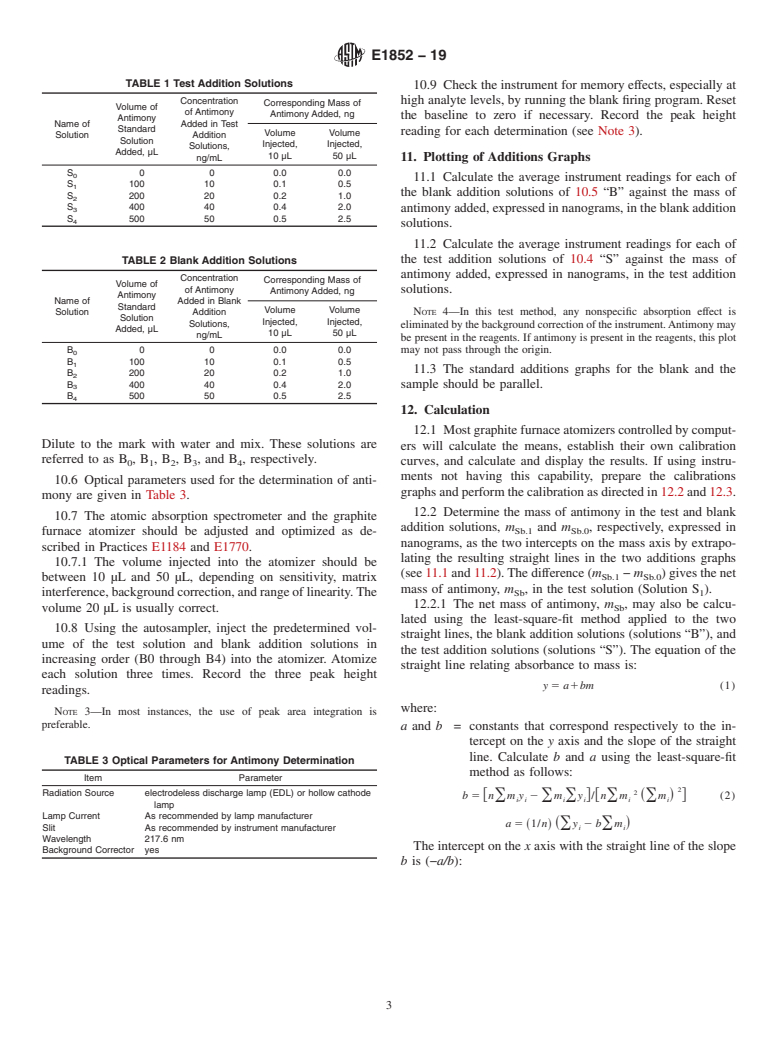

E1852 − 19

6. Hazards 9. Sampling and Sa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1852 − 13 E1852 − 19

Standard Test Method for

Determination of Low Levels of Antimony in Carbon and

Low-Alloy Steel by Graphite Furnace Atomic Absorption

1

Spectrometry

This standard is issued under the fixed designation E1852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of antimony in carbon and low-alloy steel in the 0.0005 %% through 0.010 %

range.

1.2 If this test method is used to test materials having contents less than 0.001 % antimony, users of different laboratories will

experience more than the usual 5 % risk that their results will differ by more than 50 % relative error.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E1184 Practice for Determination of Elements by Graphite Furnace Atomic Absorption Spectrometry

E1601 Practice for Conducting an Interlaboratory Study to Evaluate the Performance of an Analytical Method

E1770 Practice for Optimization of Instrumentation for Graphite Furnace Atomic Absorption Spectrometry

E1806 Practice for Sampling Steel and Iron for Determination of Chemical Composition

3

2.2 ISO Standards:

ISO 5725 Precision of Test Methods—Determination of Repeatability and Reproducibility for a Standard Test Method by

Inter-Laboratory Tests

ISO 10698 Steel—Determination of Antimony Content—Electrothermal Atomic Absorption Spectrometric Method

3. Terminology

3.1 For definitions of terms used in this test method, refer to Terminology E135.

4. Summary of Test Method

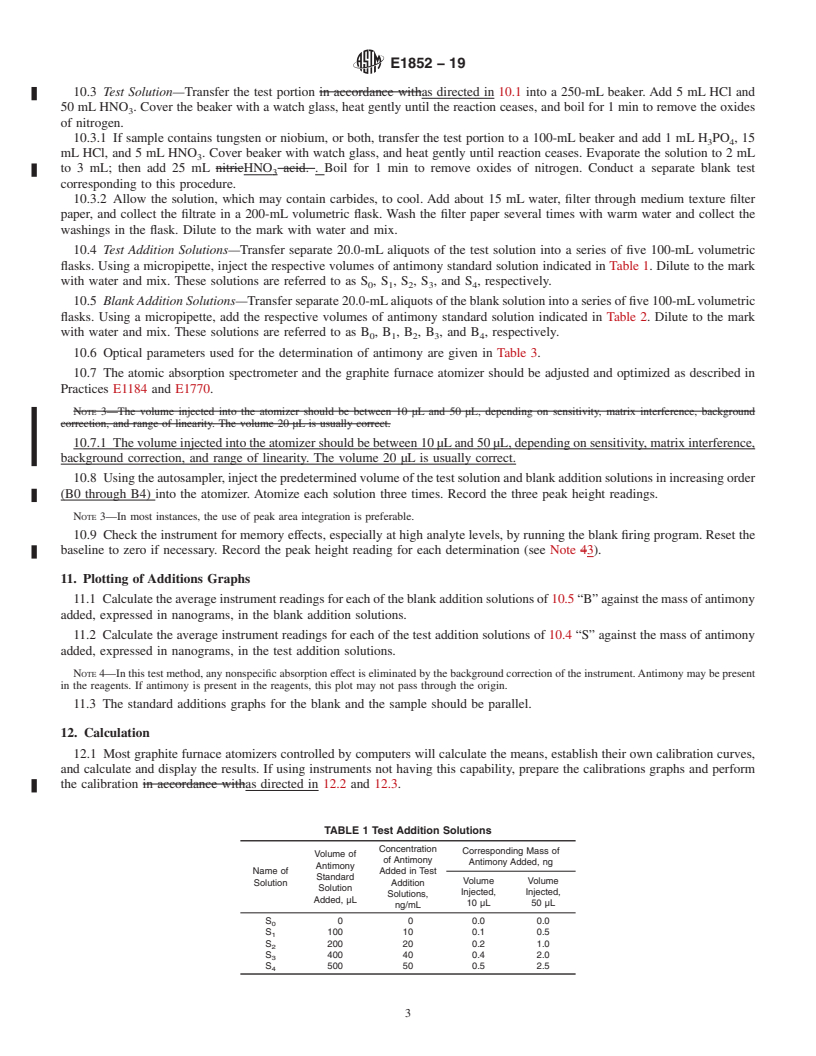

4.1 The sample is dissolved in hydrochloricHCl and nitricHNO acids and diluted to volume. An appropriate aliquot is injected

3

into the graphite furnace atomizer of an atomic absorption spectrometer, which is equipped with a background correction. The

sample is dried, pyrolized, and atomized. The absorbance of the radiation from the external light source is measured and compared

to the absorbance of samples of known composition.

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved Nov. 15, 2013June 15, 2019. Published January 2014August 2019. Originally approved in 1996. Last previous edition approved in 20082013

as E1852 – 08.E1852 – 13. DOI: 10.1520/E1852-13.10.1520/E1852-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1852 − 19

NOTE 1—In general, the deuterium correction system should be able to correct for the broad-band background absorbance up to 0.5 to 0.6 absorbance

units. Zeeman systems should compensate for background levels as high as 1.0 to 1.5 absorbance units.

5. Significance and Use

5.1 This test method is utilized for the determination of trace levels of antimony in carbon and low-alloy steel. It is assumed

that the procedure will

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.