ASTM E1730-04

(Specification)Standard Specification for Rigid Foam for Use in Structural Sandwich Panel Cores

Standard Specification for Rigid Foam for Use in Structural Sandwich Panel Cores

ABSTRACT

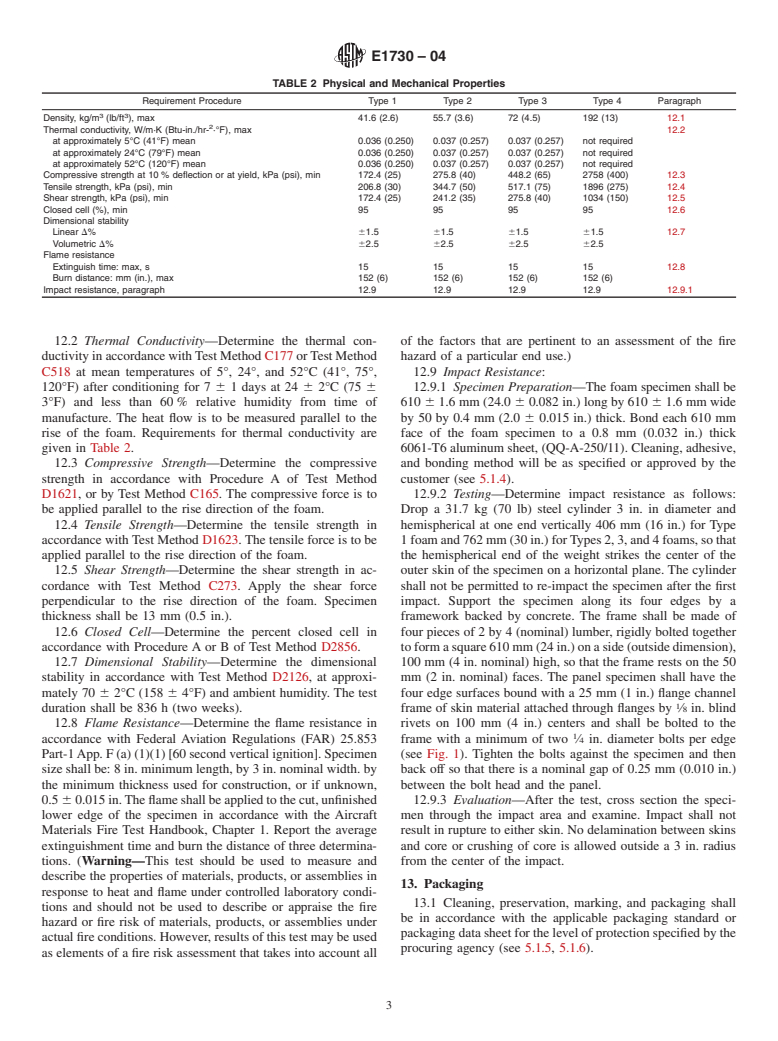

This specification covers rigid closed-cell polyurethane and polyisocyanurate thermal insulation foams for application in sandwich structural panel cores used in shelter construction for exposure to specified ambient temperatures. The unfaced foam thermal insulation boards are classified into three types (Types 1, 2, 3, and 4) according to increasing nominal density. The morphology of the insulation shall consist of a multitude of individual cells of uniform size and dimension, essentially closed off from each other, homogeneous throughout, free of voids, accumulations of unexpanded material, foreign inclusions, or seams. Upon undergoing appropriate acceptance tests, sampled specimens should adhere accordingly to the limiting values set for the following physical and mechanical properties: density; thermal conductivity; compressive strength; shear strength; percent closed cell; linear and volumetric dimensional stability; flame resistance (extinguish time and burn distance); and impact resistance.

SCOPE

1.1 This specification covers rigid, closed cell, polyurethane and polyisocyanurate thermal insulation for sandwich panels used in shelter construction for exposure to ambient temperatures of - 25 to 160°F (- 32 to 71°C). Painted surfaces of shelters in actual field use reach temperatures of 200°F (93°C). The materials in this specification must be capable of withstanding processing, (laminating) temperatures of 110°C (230°F).

1.2 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E1730 – 04

Standard Specification for

1

Rigid Foam for Use in Structural Sandwich Panel Cores

This standard is issued under the fixed designation E1730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C518 Test Method for Steady-State Thermal Transmission

Properties by Means of the Heat Flow Meter Apparatus

1.1 Thisspecificationcoversrigid,closedcell,polyurethane

C550 Test Method for Measuring Trueness and Squareness

and polyisocyanurate thermal insulation for sandwich panels

of Rigid Block and Board Thermal Insulation

used in shelter construction for exposure to ambient tempera-

D883 Terminology Relating to Plastics

tures of−25° to 160°F (−32° to 71°C). Painted surfaces of

D1621 Test Method for Compressive Properties Of Rigid

sheltersinactualfieldusereachtemperaturesof200°F(93°C).

Cellular Plastics

The materials in this specification must be capable of with-

D1622 Test Method forApparent Density of Rigid Cellular

standing processing, (laminating) temperatures of 110°C

Plastics

(230°F).

D1623 Test Method forTensile andTensileAdhesion Prop-

1.2 The values stated in either inch-pound or SI units are to

erties of Rigid Cellular Plastics

be regarded separately as the standard. The values given in

D2126 Test Method for Response of Rigid Cellular Plastics

parentheses are for information only.

to Thermal and Humid Aging

1.3 The following precautionary caveat pertains only to the

D2856 Test Method for Open-Cell Content of Rigid Cellu-

test method portion, Section 12, of this specification: This

3

lar Plastics by the Air Pycnometer

standard does not purport to address all of the safety concerns,

2.2 Code of Federal Regulations Aeronautics and Space:

if any, associated with its use. It is the responsibility of the user

14 CFR25.853 (Federal Air Regulation 25.853) Compart-

of this standard to establish appropriate safety and health

4

ment Interior (Amend. 25-72)

practices and determine the applicability of regulatory limita-

2.3 Federal Standard:

tions prior to use.

5

QQ-A-25011 Aluminum Alloy 6061-T6 Plate and Sheet

5

2. Referenced Documents

QQ-A-260/11 Aluminum Alloy 6081, Plate and Sheet

2

2.4 Military Standards:

2.1 ASTM Standards:

MIL STD 105 Sampling Procedures and Tables for Inspec-

C165 Test Method for Measuring Compressive Properties

5

tion by Attributes

of Thermal Insulations

6

2.5 Other Documents:

C168 Terminology Relating to Thermal Insulation

Aircraft Materials Fire Test Handbook, DOT/FAA/AR-

C177 Test Method for Steady-State Heat Flux Measure-

00/12

ments and Thermal Transmission Properties by Means of

Federal Aviation Regulation (FAR) 25.853

the Guarded-Hot-Plate Apparatus

C273 Test Method for Shear Properties of Sandwich Core

3. Terminology

Materials

3.1 Definitions—The terms used in this specification are

C366/C366M Test Methods for Measurement of Thickness

defined in Terminologies C168 and D883.

of Sandwich Cores

C390 Practice for Sampling and Acceptance of Thermal

4. Classification

Insulation Lots

4.1 The unfaced foam thermal insulation boards covered by

this specification are classified as follows:

1

This specification is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is under the direct responsibility of Subcommittee

3

E06.53 on Materials and Processes for Durable Rigidwall Relocatable Structures. Withdrawn. The last approved version of this historical standard is referenced

Current edition approved Nov 1, 2004. Published November 2004. Originally on www.astm.org.

4

approved in 1995. Last previous edition approved in 2002 as E1730–02. DOI: AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

10.1520/E1730-04. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Robbins Ave., Philadelphia, PA 19111-5098.

6

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1730 – 04

3 3

4.1.1 Type 1—Nominal density: 32 kg/m (2.0 lb/ft ). 9.2 Acceptance Testing (Physical Properties)—A represen-

3 3

4.1.2 Type

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.