ASTM D29-98

(Test Method)Standard Test Methods for Sampling and Testing Lac Resins (Withdrawn 2005)

Standard Test Methods for Sampling and Testing Lac Resins (Withdrawn 2005)

SCOPE

1.1 These test methods cover procedures for sampling and testing orange shellac, button lac, garnet lac, and bleached lac.

1.2 The sampling procedures and test methods appear in the following order: Sections Sampling: Orange Shellac, Button Lac, and Garnet Lac 3 Bleached Lac 4 Identification of Samples 5 General Requirements for Test Methods: Reagents 6 Source and Preparation of Portions of Sample for Tests 7 Insoluble Matter 8 to 9.5 Iodine Value 10 to 10.3 Purity 11 to 13.2 Volatile Matter (Moisture) 14 to 15.2 Wax 16 to 16.4 Matter Soluble in Water 17 to 17.2 Ash 18 to 18.2 Color 19 to 19.4.3 Color of Orange Shellac 20 to 20.4.4 Acid Value 21 to 21.4 Orpiment 22 to 22.4 Saponification Value 23 to 23.4

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> Specific hazard statements are given in Note 1.

WITHDRAWN RATIONALE

These test methods cover procedures for sampling and testing orange shellac, button lac, garnet lac, and bleached lac.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in May 2005. This standard is being withdrawn without replacement because of its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D29–98

Standard Test Methods for

Sampling and Testing Lac Resins

ThisstandardisissuedunderthefixeddesignationD 29;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope (Gardner Color Scale)

D 1545 Test Method for Viscosity of Transparent Liquids

1.1 These test methods cover procedures for sampling and

by Bubble Time Method

testing orange shellac, button lac, garnet lac, and bleached lac.

D 1959 Test Method for Iodine Value of Drying Oils and

1.2 The sampling procedures and test methods appear in the

Fatty Acids

following order:

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

Sections

poses

Sampling:

Orange Shellac, Button Lac, and Garnet Lac 3

Bleached Lac 4

SAMPLING

Identification of Samples 5

General Requirements for Test Methods:

3. Orange Shellac, Button Lac, and Garnet Lac

Reagents 6

Source and Preparation of Portions of Sample for

3.1 Lot Size—For the purpose of sampling, the quantity of a

Tests 7

lot of any one of these types of lac resin shall not exceed 500

Insoluble Matter 8 to 9.5

Iodine Value 10 to 10.3 bags or packages. The net weight of lac resin in each bag or

Purity 11 to 13.2

package shall not exceed 75 kg.

Volatile Matter (Moisture) 14 to 15.2

3.2 Source and Number of Samples—Only original un-

Wax 16to16.4

Matter Soluble in Water 17 to 17.2

opened bags or packages shall be sampled. Ten percent of the

Ash 18 to 18.2

containersineverylotoflacresinshallbetakenatrandom,but

Color 19 to 19.4.3

not less than 5 nor more than 25 containers shall be taken.

Color of Orange Shellac 20 to 20.4.4

Acid Value 21 to 21.4

3.3 Free-Flowing Lac Resins—In sampling free-flowing lac

Orpiment 22 to 22.4

resins, samples shall be drawn from different places in each

Saponification Value 23 to 23.4

container in double handfuls or by means of a suitable sampler

1.3 This standard does not purport to address all of the

such as a grain sampler. A total of approximately 2.7 kg shall

safety concerns, if any, associated with its use. It is the

be taken.

responsibility of the user of this standard to establish appro-

3.4 Blocked or Matted Lac Resin—Pieces of blocked or

priate safety and health practices and determine the applica-

matted lac resin shall be chipped with an axe, pick, or other

bility of regulatory limitations prior to use. Specific hazard

suitable instrument from each container taken for sampling.

statements are given in Note 1.

Approximately the same amount shall be taken from each

container and the total amount taken shall be about 2.7 kg. The

2. Referenced Documents

pieces of lac resin shall then be ground to pass a No. 4

2.1 ASTM Standards:

(4.75-mm) sieve. All sieves referenced must conform to the

D 304 Specification for n-Butyl Alcohol (Butanol)

requirements of Specification E 11 .

D 331 Specification for 2-Ethoxyethanol

3.5 Preparation of Samples for Observation or Analysis—

D 1193 Specification for Reagent Water

Whether free-flowing or rough ground, as in the case of

D 1544 Test Method for Color of Transparent Liquids

blocked lac resin, the entire sample representing any lot shall

be thoroughly mixed and divided into halves. The use of a

mechanical mixer is recommended for mixing the resin and a

1 riffle sampler for dividing it into quarters. When these devices

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-1onPaint

are not available for use, the entire sample shall be mixed,

and Related Coatings, Materials, and Applications and are the direct responsibility

of Subcommittee D 01.33 on Polymers and Resins.

Current edition approved June 10, 1998. Published October 1998. Originally

{1

published as D 29 – 14 T. Last previous edition D 29 – 81(l993) .

2 4

Annual Book of ASTM Standards, Vol 06.04. Annual Book of ASTM Standards, Vol 06.01.

3 5

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 06.03.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D29–98

heaped, and quartered along two diameters that intersect at 5. Identification of Samples

right angles and the opposite quarters combined. One half the

5.1 The following information shall be legibly placed on the

sample, thus obtained, shall then be mixed and divided into

label, which shall be securely attached to each sample con-

quarters as before. Each quarter shall be placed in an airtight

tainer: date of the sampling, number of bags, barrels or

container, sealed, labeled (Section 5), and sent to the interested

packages sampled, total number of containers in the lot,

parties as the “original observation sample.” When agreed

condition of the containers and their contents, manufacturer’s

upon between the seller and the purchaser, the “original

name, lot and code numbers of the containers, and the purpose

observation sample” shall be used for the determination of

identification, namely “original observation sample” or

volatile matter (moisture) (Sections 14 to 15, as applicable).

“sample for determination of volatile matter (moisture)”,

The other half of the sample shall be ground to pass a No. 10

“reserve sample” or “prepared sample” as may apply.

(2.00-mm)sieve,mixedthoroughly,anddividedintotwoequal

portions A and B. Portion A shall be labeled the “reserve TEST METHODS

sample.” Portion B shall then be ground to pass a No. 25

6. Reagents

(710-µm) sieve, mixed thoroughly, and quartered as described

above. Each quarter shall be packaged in an airtight container, 6.1 Purity of Reagents—Reagent grade chemicals shall be

sealed, labeled “prepared sample,” and sent to the testing

used in all tests. Unless otherwise indicated, it is intended that

laboratory for analysis. allreagentsshallconformtotheSpecificationsoftheAmerican

Chemical Society, where such specifications are available.

4. Bleached Lac Other grades may be used, provided it is first ascertained that

the reagent is of sufficiently high purity to permit its use

4.1 Lot Size—For the purpose of sampling, the quantity of a

without lessening the accuracy of the determination.

lot shall not exceed 200 packages.

6.2 Purity of Water—Unless otherwise indicated, references

4.2 Source and Number of Samples—Only original un-

to water shall be understood to mean reagent water conforming

opened packages shall be sampled. Twenty percent of the

to Type II of Specification D 1193.

containers in every lot shall be taken at random, but not less

than two containers in any lot shall be taken, except in the case

7. Source and Preparation of Specimens for Tests

where the entire lot is packaged in a single container.

7.1 Each portion of sample for use in a given test shall be

4.3 Dry Bleached Lac (Free-Flowing)—Samples shall be

taken from the sample of lac resin only after it has been mixed,

drawn with a scoop or suitable sampler from different parts of

either by rolling on paper or by rolling and tumbling in its

each container directly after the packages are opened or bored.

airtight container, as the condition of the sample requires, a

Approximately 450 g shall be drawn from each container. The

sufficientnumberoftimestoensureuniformityofthespecimen

samples shall be combined, mixed thoroughly, and where

taken. The test specimens shall be taken from the“ prepared

larger than 1.4 kg, shall be reduced by quartering as prescribed

sample”(3.5or4.6),asreceived,exceptinthefollowingcases:

in 3.5 to a sample of this size.

7.1.1 When it has been previously agreed upon between the

4.4 Dry Bleached Lac (Blocked or Matted)—Samples ag-

seller and the purchaser that the “original observation sample”

gregating at least 450 g shall be chopped or chiseled from

shall be used for the determination of volatile matter (mois-

different parts of each container. The composite sample from

ture). In this case, the “original observation sample” shall be

all the containers shall be quickly crushed to lumps about 25

mixed, quartered, ground, and sieved in accordance with the

mm square or smaller. The crushed lac resin shall be well

procedure described in 3.5 for obtaining the “prepared

mixed and where the amount is larger than 1.4 kg, it shall be

sample.” All operations shall be done as expeditiously as

reduced by quartering, as prescribed in 3.5, to a sample of

possible and the test specimen taken immediately after the

approximately this size.

sieved sample has been thoroughly mixed, to avoid any

4.5 Hanks, Bars, or Crushed Free-Ground Bleached Lac—

possible loss by evaporation.

This material, which generally contains approximately 25 %

7.1.2 When the “prepared sample” is known to have a high

moisture, shall be sampled by the procedures described in 4.3

moisturecontent,asinthecaseofcertainformsofbleachedlac

or 4.4, as applicable.

(4.5), it shall be dried to a moisture content of 6 % before the

4.6 Preparation of Samples for Analysis—The composite

testspecimensaretaken.Thelacresinshallbedriedbyplacing

sample obtained as described in 4.3 or 4.4 shall be mixed

it in a thin layer in a flat-bottom dish (loosely covered to

thoroughly and divided into two equal portions A and B as

prevent dust contamination) and exposing it to the atmosphere

prescribed in 3.5. Each portion shall be placed in a clean, dry

at room temperature for 24 h and then desiccating it over

glass jar provided with a rubber-sealed cap or an airtight

anhydrous calcium chloride. The partially dried lac resin shall

friction-top tin can. Portion A shall be labeled “reserve

be kept in a clean, dry, airtight container, and shall be

sample.” Portion B obtained in accordance with 4.3 or 4.4 shall

be further ground to pass a No. 20 (850-µm) sieve, thoroughly

mixed and replaced in the jar, sealed and labeled “prepared

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

sample.” Portion B obtained in accordance with 4.5 shall be

listed by the American Chemical Society, see Analar Standards for Laboratory

further ground to pass a No. 10 (2.00-mm) sieve, thoroughly

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

mixed, replaced in the jar, sealed, labeled “prepared sample,”

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

and sent to the laboratory for analysis. MD.

D29–98

thoroughly mixed by rolling and tumbling in the container

before the specimens are taken for analysis.

INSOLUBLE MATTER

8. Test Method A—For Orange Shellac, Button Lac,

Garnet Lac, and Regular Bleached

8.1 Apparatus:

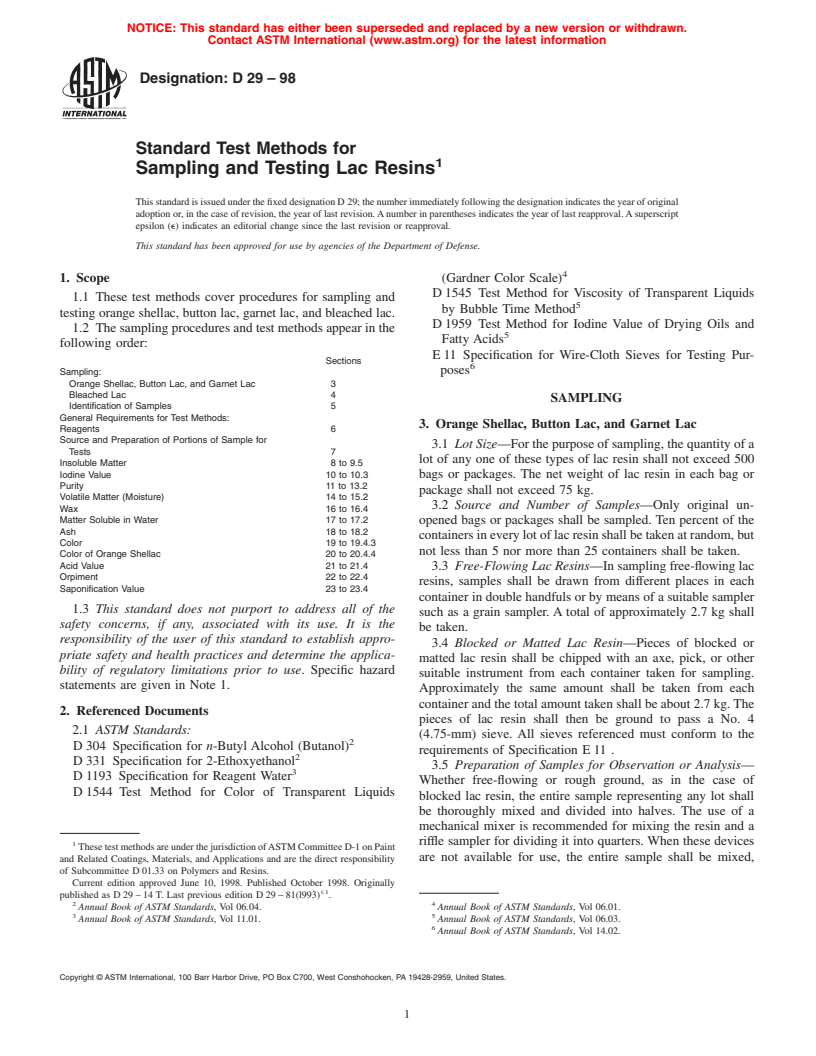

8.1.1 Condenser—A four-bulb Allihn condenser of the di-

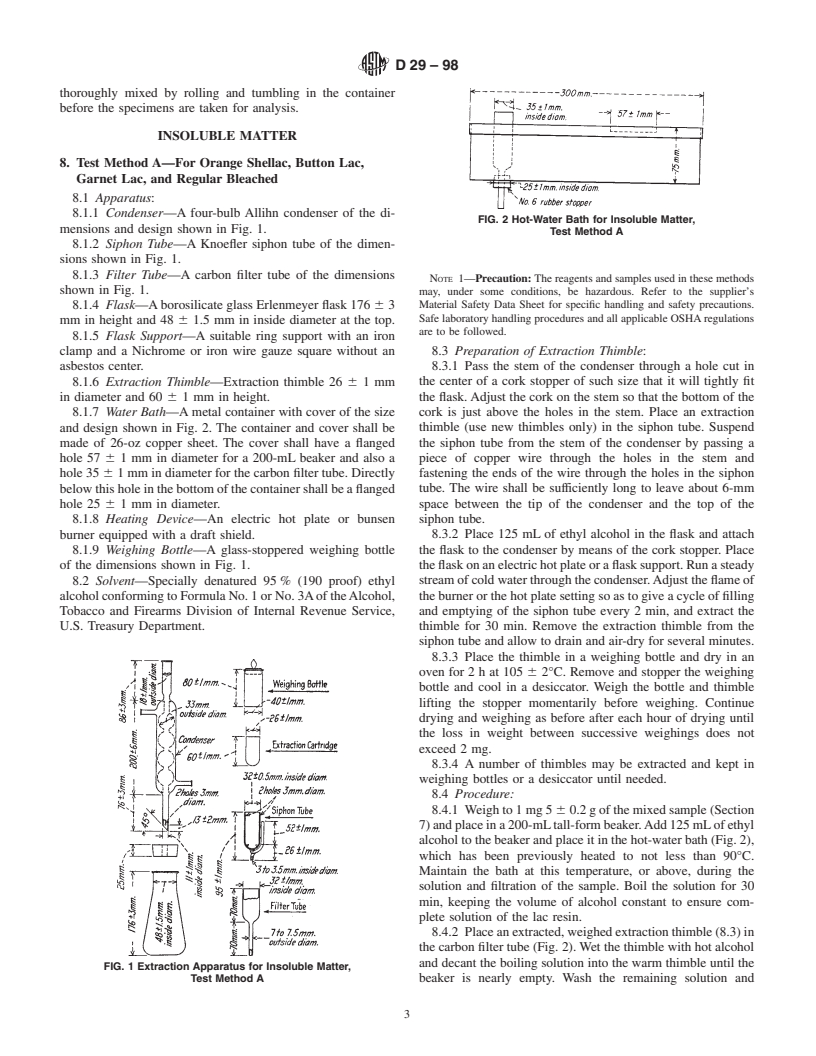

FIG. 2 Hot-Water Bath for Insoluble Matter,

mensions and design shown in Fig. 1.

Test Method A

8.1.2 Siphon Tube—A Knoefler siphon tube of the dimen-

sions shown in Fig. 1.

8.1.3 Filter Tube—A carbon filter tube of the dimensions

NOTE 1—Precaution: The reagents and samples used in these methods

shown in Fig. 1.

may, under some conditions, be hazardous. Refer to the supplier’s

8.1.4 Flask—Aborosilicate glass Erlenmeyer flask 176 6 3 Material Safety Data Sheet for specific handling and safety precautions.

Safe laboratory handling procedures and all applicable OSHAregulations

mm in height and 48 6 1.5 mm in inside diameter at the top.

are to be followed.

8.1.5 Flask Support—A suitable ring support with an iron

clamp and a Nichrome or iron wire gauze square without an 8.3 Preparation of Extraction Thimble:

asbestos center. 8.3.1 Pass the stem of the condenser through a hole cut in

8.1.6 Extraction Thimble—Extraction thimble 26 61mm the center of a cork stopper of such size that it will tightly fit

in diameter and 60 6 1 mm in height. the flask.Adjust the cork on the stem so that the bottom of the

cork is just above the holes in the stem. Place an extraction

8.1.7 Water Bath—Ametal container with cover of the size

and design shown in Fig. 2. The container and cover shall be thimble (use new thimbles only) in the siphon tube. Suspend

the siphon tube from the stem of the condenser by passing a

made of 26-oz copper sheet. The cover shall have a flanged

hole 57 6 1 mm in diameter for a 200-mL beaker and also a piece of copper wire through the holes in the stem and

fastening the ends of the wire through the holes in the siphon

hole 35 6 1 mm in diameter for the carbon filter tube. Directly

belowthisholeinthebottomofthecontainershallbeaflanged tube. The wire shall be sufficiently long to leave about 6-mm

space between the tip of the condenser and the top of the

hole 25 6 1 mm in diameter.

8.1.8 Heating Device—An electric hot plate or bunsen siphon tube.

burner equipped with a draft shield. 8.3.2 Place 125 mL of ethyl alcohol in the flask and attach

8.1.9 Weighing Bottle—A glass-stoppered weighing bottle the flask to the condenser by means of the cork stopper. Place

of the dimensions shown in Fig. 1. theflaskonanelectrichotplateoraflasksupport.Runasteady

8.2 Solvent—Specially denatured 95 % (190 proof) ethyl streamofcoldwaterthroughthecondenser.Adjusttheflameof

alcoholconformingtoFormulaNo.1orNo.3AoftheAlcohol, the burner or the hot plate setting so as to give a cycle of filling

Tobacco and Firearms Division of Internal Revenue Service, and emptying of the siphon tube every 2 min, and extract the

U.S. Treasury Department. thimble for 30 min. Remove the extraction thimble from the

siphon tube and allow to drain and air-dry for several minutes.

8.3.3 Place the thimble in a weighing bottle and dry in an

oven for2hat105 6 2°C. Remove and stopper the weighing

bottle and cool in a desiccator. Weigh the bottle and thimble

lifting the stopper momentarily before weighing. Continue

drying and weighing as before after each hour of drying until

the loss in weight between successive weighings does not

exceed 2 mg.

8.3.4 A number of thimbles may be extracted and kept in

weighing bottles or a desiccator until needed.

8.4 Procedure:

8.4.1 Weighto1mg5 60.2gofthemixedsample(Section

7)andplaceina200-mLtall-formbeaker.Add125mLofethyl

alcohol to the beaker and place it in the hot-water bath (Fig. 2),

which has been previously heated to not less than 90°C.

Maintain the bath at this temperature, or above, during the

solution and filtration of the sample. Boil the solution for 30

min, keeping the volume of alcohol constant to ensure com-

plete solution of the lac resin.

8.4.2 Placeanextracted,weighedextractionthimble(8.3)in

the carbon filter tube (Fig. 2). Wet the thimble with hot alcohol

and decant the bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.