ASTM E2113-00

(Test Method)Standard Test Method for Length Change Calibration of Thermomechanical Analyzers

Standard Test Method for Length Change Calibration of Thermomechanical Analyzers

SCOPE

1.1 This method describes calibration of the length change (deflection) measurement or thermal expansion of thermomechanical analyzers (TMA) over the temperature range from -100 to 600C using the thermal expansion of a suitable reference material.

1.2 Computer or electronic based instruments, techniques or data treatment equivalent to this method may be used.

Note 1--Users are advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine necessary equivalency prior to use.

1.3 SI values are the standard.

1.4 This method differs from ISO standard 11359-1 by providing an alternative calibration procedure.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 2113 – 00

Standard Test Method for

Length Change Calibration of Thermomechanical Analyzers

This standard is issued under the fixed designation E 2113; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This method describes calibration of the length change 4.1 Thermomechanical analyzers (TMAs) or related devices

(deflection) measurement or thermal expansion of thermome- are commonly used to determine coefficient of linear thermal

chanical analyzers (TMA) over the temperature range from expansion of solid materials (e.g., method E 831). The test

-100 to 600°C using the thermal expansion of a suitable specimen is heated at a linear rate over the temperature range

reference material. of interest and the change in length (dimension) is electroni-

1.2 Computer or electronic based instruments, techniques or cally recorded.

data treatment equivalent to this method may be used. 4.2 Performance verification or calibration of the length

change measurement is needed to obtain accurate coefficient of

NOTE 1—Users are advised that all such instruments or techniques may

thermal expansion data.

not be equivalent. It is the responsibility of the user to determine necessary

4.3 The thermal expansion of a reference material is re-

equivalency prior to use.

corded using a thermomechanical analyzer. The recorded

1.3 SI values are the standard.

thermal expansion is compared to the known value of the

1.4 This method differs from ISO standard 11359-1 by

reference material. The resultant ratio, a calibration coefficient,

providing an alternative calibration procedure.

may then be applied to the determination of unknown speci-

1.5 This standard does not purport to address all of the

mens to obtain accurate results.

safety concerns, if any, associated with its use. It is the

responsibility of whoever uses this standard to consult and

5. Significance and Use

establish appropriate safety and health practices and deter-

5.1 Performance verification or calibration is essential to the

mine the applicability of regulatory limitations prior to use.

accurate determination of quantitative dimension change mea-

surements.

2. Referenced Documents

5.2 This method may be used for instrument performance

2.1 ASTM Standards:

validation, regulatory compliance, research, and development

E 473 Terminology Relating to Thermal Analysis

and quality assurance purposes.

E 831 Test Method for Linear Thermal Expansion of Solid

Materials by Thermomechanical Analysis

6. Apparatus

E 1142 Terminology Relating to Thermophysical Proper-

6.1 Thermomechanical Analyzer (TMA)— The essential

ties

instrumentation required to provide the minimum thermome-

E 1363 Test Method for Temperature Calibration of Ther-

chanical analytical or thermodilametric capability for this

momechanical Analyzers

method includes:

2.2 Other Standards:

6.1.1 A rigid specimen holder of inert, low expansivity

ISO 11359-1 Plastics—Thermomechanical analysis

material [<0.5 μm / (m · K)] to center the specimen in the

(TMA)—Part 1: General principles

furnace and to fix the specimen to mechanical ground.

6.1.2 A rigid expansion probe of inert, low expansivity

3. Terminology

material [<0.5 μm/(m · K)] which contacts the specimen with

3.1 Specific technical terms used in this method are de-

an applicable compressive or tensile force.

scribed in Terminologies E 473 and E 1142.

6.1.3 A sensing element, linear over a minimum of 2 mm, to

measure the displacement of the rigid probe to within 6 10 nm

resulting from changes in length/height of the specimen.

This test method is under the jurisdiction of ASTM Committee E37 on Thermal

6.1.4 A weight or force transducer to generate a constant

Measurements and is the direct responsibility of Subcommittee E37.01 on Thermal.

Current edition approved Nov. 10, 2000. Published April 2001. force between 1 and 100 mN (0.1 and 10 g) applied through the

Annual Book of ASTM Standards, Vol 14.02.

rigid probe to the specimen.

Available from American National Standards Institute, 11 W 42nd Street, 13th

6.1.5 A furnace capable of providing uniform controlled

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E2113

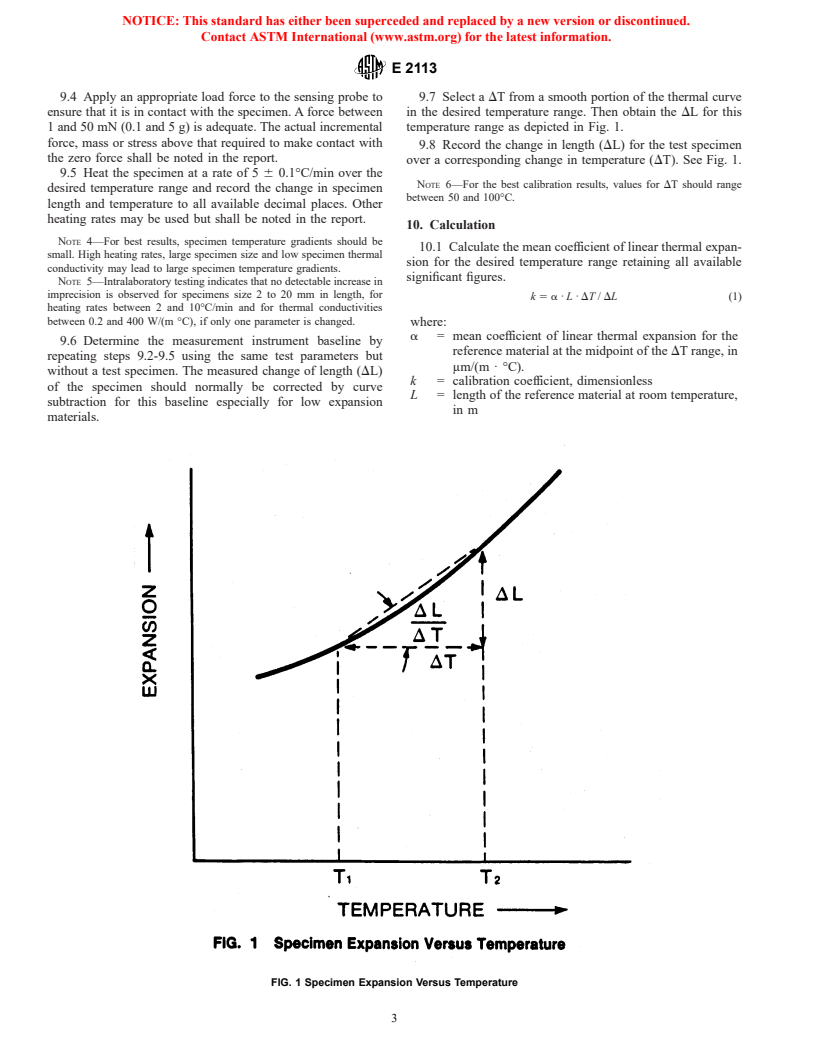

heating (cooling) of a specimen to a constant temperature or at suppliers. Contact ASTM Headquarters for list of such poten-

a constant rate within the applicable temperature range of this tial suppliers.

method. 6.4.2 In the absence of primary or secondary reference

6.1.6 A temperature controller capable of executing a spe- materials, high purity aluminum or platinum may be used

cific temperature program by operating the furnace between along with the values for coefficient of thermal expansion

-100 and 600°C at a rate of temperature change of 5 K/min presented in Table 1.

constant to within 6 0.1 K/min.

NOTE 3—The linear expansion of high purity aluminum, commonly

6.1.7 A temperature sensor that can be attached to, in

supplied by instrument manufactures, is useful as a working reference

contact with, or reproducibly positioned in close proximity to

material. Coefficient of thermal expansion values for pure aluminum are

the specimen to provide an indication of the specimen/furnace

presented in Table 1 along with those for platinum.

temperature to within within 6 0.1 K.

7. Test Specimen

6.1.8 A means of sustaining an environment around the

7.1 Specimens shall be between 6 and 10 mm in length and

specimen of an inert purge gas at a rate of 10 to 50 6 5

mL/min. have flat and parallel ends to within 6 25 μm. Lateral

dimensions shall be between 3 and 9 mm. Other lengths and

NOTE 2—Typically, 99.9+% pure nitrogen, helium or argon is em-

widths may be used but shall be noted in the report.

ployed, when oxidation in air is a concern. Unless effects of moisture are

to be studied, use of dry purge gas is recommended and is essential for

8. Calibration

operation at subambient temperatures.

8.1 Perform any calibration procedures described in the

6.1.9 A recording device, either digital or analog, capable of

manufacturer’s operations manual.

recording and displaying any fraction of the specimen dimen-

8.2 Calibrate the temperature sensor using Method E 1363.

sion change signal (TMA curve) including the signal noise.

9. Procedure

6.2 Micrometer, calipers or other length measurement de-

vice capable of measuring linear dimensions up to 10 mm with 9.1 Measure the initial specimen length in the direction of

readability of 6 25 μm. the expansion test to within 6 25 μm at 23 6 2°C.

6.3 While not required, the user may find useful software 9.2 Place the specimen on the specimen holder under the

that performs the calculations described in this method. probe. Place the specimen temperature sensor within 2 mm but

6.4 Thermal expansion reference material of 8 6 2mm not touching the test specimen.

length, the linear coefficient of expansion of which is known to 9.3 Move the furnace to enclose the specimen holder. If

6 0.1 μm / (m · K). The thermal coefficient of expansion measurements at subambient temperatures are to be made, cool

should be between 9 and 40 μm / (m · K). the test specimen to at least 20°C below the lowest temperature

6.4.1 Reference materials of known value traceable to a of interest. The refrigerant used for cooling shall not come into

National Reference laboratory are available from a number of direct contact with the specimen.

A

TABLE 1 Expansion Coefficients

BCDEF GHI

Aluminum Platinum

Mean Coefficient of Linear Linear Thermal Expansion, Mean Coefficient of Linear Linear Thermal Expansion,

Temperature, °C

Thermal Expansion, μm/(m · °C) μm/m Thermal Expansion, μm/(m · °C) μm/m

800 7770

700 10.75 6680

600 16760 10.42 5620

550 35.3 14930

500 33.2 13230 10.15 4595

450 31.8 11610

400 30.5 10050 9.92 3590

350 29.2 8560

300 27.8 7130 9.68 2610

250 26.8 5780

200 26.2 4450 9.42 1655

150 25.5 3160

100 24.5 1900 9.17 725

50 23.6 710 9.05 270

0 22.6 –460 8.85 –180

–50 20.9 –1550 8.53 –615

–100 18.8 –2550 8.10 –1035

–150 –3430 –1425

A

Mean coefficient of linear thermal expansion values a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.