ASTM F978-90(1996)e1

(Test Method)Standard Test Method for Characterizing Semiconductor Deep Levels by Transient Capacitance Techniques

Standard Test Method for Characterizing Semiconductor Deep Levels by Transient Capacitance Techniques

SCOPE

1.1 This test method covers three procedures for determining the density, activation energy, and prefactor of the exponential expression for the emission rate of deep-level defect centers in semiconductor depletion regions by transient-capacitance techniques. Procedure A is the conventional, constant voltage, deep-level transient spectroscopy (DLTS) technique in which the temperature is slowly scanned and an exponential capacitance transient is assumed. Procedure B is the conventional DLTS (Procedure A) with corrections for nonexponential transients due to heavy trap doping and incomplete charging of the depletion region. Procedure C is a more precise referee technique that uses a series of isothermal transient measurements and corrects for the same sources of error as Procedure B.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 978 – 90 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Characterizing Semiconductor Deep Levels by Transient

Capacitance Techniques

This standard is issued under the fixed designation F 978; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in January 1996.

1. Scope 3. Summary of Test Method

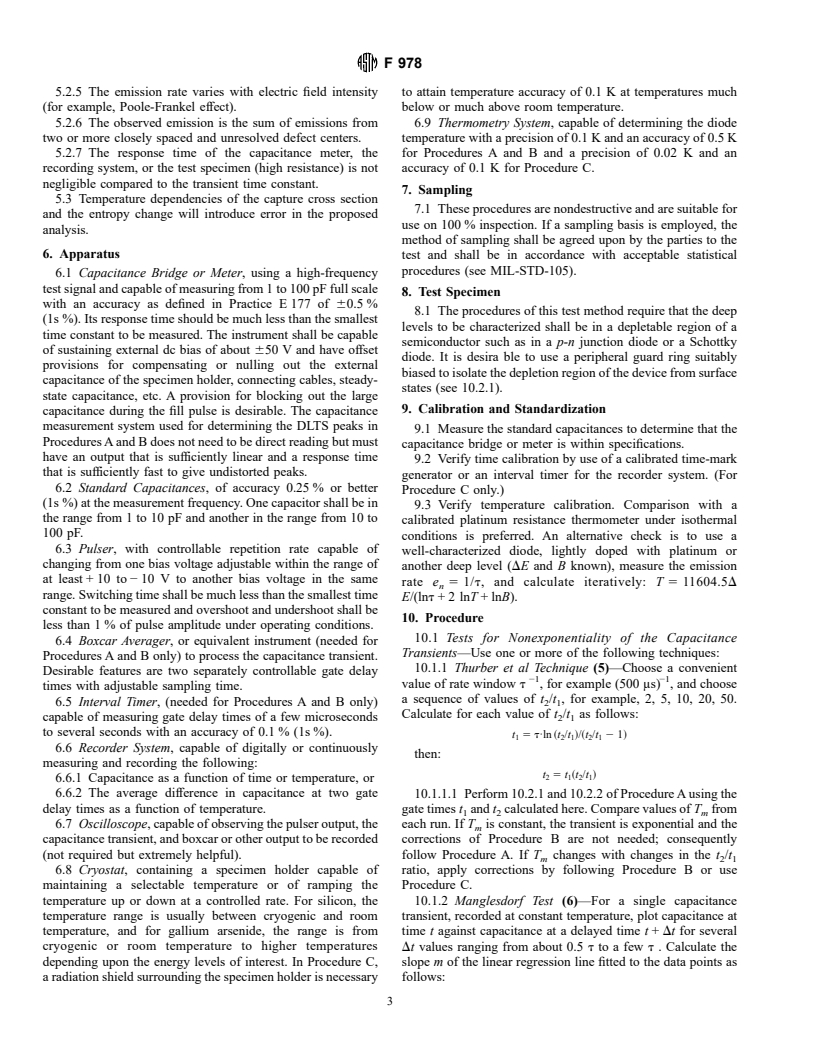

1.1 This test method covers three procedures for determin- 3.1 In this method procedures are given for determining the

ing the density, activation energy, and prefactor of the expo- density, activation energy, and the prefactor of the exponential

nential expression for the emission rate of deep-level defect expression for the emission rate of deep-level defect centers. In

Procedure A (see Fig. 1), the temperature of the diode is slowly

centers in semiconductor depletion regions by transient-

capacitance techniques. Procedure A is the conventional, con- scanned while the bias voltage is repetitively changed. The

stant voltage, deep-level transient spectroscopy (DLTS) tech- high-frequency capacitance transient due to trap emission is

sampled at two successively delayed gate times. The average

nique in which the temperature is slowly scanned and an

difference between these sampled values constitutes the signal

exponential capacitance transient is assumed. Procedure B is

that has a maximum or peak at a temperature that is a function

the conventional DLTS (Procedure A) with corrections for

of the gate times. The time constant associated with the peak

nonexponential transients due to heavy trap doping and incom-

response is fixed by the rate window of the boxcar averager

plete charging of the depletion region. Procedure C is a more

used to sample the transient or by computer simulation of such

precise referee technique that uses a series of isothermal

an instrument. For nonexponential transients, Procedure B adds

transient measurements and corrects for the same sources of

a correction to the calculation of the time constant at the

error as Procedure B.

temperature of the response peak. In Procedure C, the tempera-

1.2 This standard does not purport to address all of the

ture is held constant at each of a series of temperatures and the

safety concerns, if any, associated with its use. It is the

observed capacitance transient is analyzed for its corrected

responsibility of the user of this standard to establish appro-

time constant. An Arrhenius-type semilogarithmic plot of

priate safety and health practices and determine the applica-

normalized emission rate versus reciprocal temperature is

bility of regulatory limitations prior to use.

made in each procedure, and the activation energy and prefac-

tor are calculated from the slope and intercept, respectively.

2. Referenced Documents

The density of the defects is determined from the magnitude of

2.1 ASTM Standards:

the capacitance changes.

E 177 Practice for Use of the Terms Precision and Bias in

3.2 The use of a boxcar averager is assumed in the discus-

ASTM Test Methods

sion of Procedures A and B. However, a lock-in amplifier may

E 178 Practice for Dealing with Outlying Observations

also be used for these procedures, provided that factors which

F 419 Test Method for Determining Carrier Density in

may degrade the results are taken into account. Constant-

Silicon Epitaxial Layers by Capacitance Voltage Measure-

capacitance versions of these procedures are not discussed but

ments on Fabricated Junction or Schottky Diodes

are, of course, suitable for the purposes considered here. The

2.2 Other Standard:

nonexponential corrections covered in this test method are in

MIL-STD-105 Sampling Procedures and Tables for Inspec- general not needed for constant-capacitance measurements as

tion by Attributes the method itself eliminates most of the nonexponentiality.

4. Significance and Use

This test method is under the jurisdiction of ASTM Committee F-1 on

Electronics and is the direct responsibility of Subcommittee F01.06 on Electrical 4.1 Deep-level defect measurement techniques such as iso-

and Optical Measurement.

thermal transient capacitance (ITCAP) (1, 2) and DLTS (3)

Current edition approved June 29, 1990. Published August 1990. Originally

utilize the ability of electrically active defects to trap free

published as F 978 – 86. Last previous edition F 978 – 86.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 10.05.

4 5

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 The boldface numbers in parentheses refer to the list of references at the end of

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. this test method.

F 978

+

FIG. 1 Schematic of Biased n p Diode and Waveforms Associated with Repetitively Changing the Bias and Analyzing the Resulting

Capacitance Transient

carriers and to re-emit them by thermal emission. related to the densities of the defects present. The interest in

Theoretically, the emission rate e for electrons is given by the measurement of deep levels in semiconductors stems from the

n

following equation: following two related aspects:

4.3.1 Detection, identification, and control of unwanted

e 5s v N exp ~2DG/kT!

n n t c

native or process-induced impurities or defects; and

where:

4.3.2 Characterization and control of impurities specifically

s 5 capture cross section of the defect for an

n introduced for lifetime or other parameter control.

electron,

v 5 thermal velocity of the electron,

t 5. Interferences

N 5 density-of-states in the conduction band,

c

5.1 Temperature errors will significantly reduce the

DG 5 Gibbs free energy (a function of temperature) of

accuracy of emission-rate measurements and, therefore, reduce

the defect,

the accuracy of the energy determination. Temperature

k 5 Boltzmann constant, and

inaccuracies that vary in magnitude with temperature are even

T 5 absolute temperature.

more significant.

4.2 A form commonly used for emission rate,

5.2 Nonexponentiality of the capacitance transient interferes

e 5 BT exp(−DE/kT), where B is assumed to be independent

n

with the characterization technique. Tests for

of temperature, is obtained by using DG5DE − TDS, where

nonexponentiality are given in 10.1. Causes of

DE is the activation energy (the enthalpy to be more exact

nonexponentiality are as follows:

which is the energy of the trap below the conduction band) and

5.2.1 The density of the deep-level defects is not small

DS is the change in entropy (4). For the equivalence of BT to

compared to the net shallow dopant density. Procedures B and

s v N exp(DS/k), one assumes s and DS to have no

n t c n

1/2

C correct for this interference.

dependence on temperature, a T dependence for v , and a

t

3/2

5.2.2 Trap charging does not take place throughout the

T dependence for N . For DG to equal DE, DS 5 0 (that is,

c

depletion region at moderate (or higher) levels of trap density

no change between the initial and final state degeneracy or

relative to net shallow dopant density. Procedures B and C

lattice relaxation associated with the transition).

correct for this interference.

4.3 An analogous expression can be written for the whole

emission rate. Analysis of the measured thermal emission rate 5.2.3 The junction is not sufficiently abrupt.

in the depletion layer of a test device as a function of 5.2.4 The onset of free carriers at the edge of the depletion

temperature leads to activation energies and effective capture region is not sufficiently abrupt (that is, the approximation of

cross sections of the defects present. The magnitude of the complete depletion is not valid). Procedures B and C help

capacitance changes associated with the emission can be correct for this.

F 978

5.2.5 The emission rate varies with electric field intensity to attain temperature accuracy of 0.1 K at temperatures much

(for example, Poole-Frankel effect). below or much above room temperature.

5.2.6 The observed emission is the sum of emissions from 6.9 Thermometry System, capable of determining the diode

two or more closely spaced and unresolved defect centers. temperature with a precision of 0.1 K and an accuracy of 0.5 K

5.2.7 The response time of the capacitance meter, the for Procedures A and B and a precision of 0.02 K and an

recording system, or the test specimen (high resistance) is not accuracy of 0.1 K for Procedure C.

negligible compared to the transient time constant.

7. Sampling

5.3 Temperature dependencies of the capture cross section

7.1 These procedures are nondestructive and are suitable for

and the entropy change will introduce error in the proposed

use on 100 % inspection. If a sampling basis is employed, the

analysis.

method of sampling shall be agreed upon by the parties to the

6. Apparatus

test and shall be in accordance with acceptable statistical

procedures (see MIL-STD-105).

6.1 Capacitance Bridge or Meter, using a high-frequency

test signal and capable of measuring from 1 to 100 pF full scale

8. Test Specimen

with an accuracy as defined in Practice E 177 of 60.5 %

8.1 The procedures of this test method require that the deep

(1s %). Its response time should be much less than the smallest

levels to be characterized shall be in a depletable region of a

time constant to be measured. The instrument shall be capable

semiconductor such as in a p-n junction diode or a Schottky

of sustaining external dc bias of about 650 V and have offset

diode. It is desira ble to use a peripheral guard ring suitably

provisions for compensating or nulling out the external

biased to isolate the depletion region of the device from surface

capacitance of the specimen holder, connecting cables, steady-

states (see 10.2.1).

state capacitance, etc. A provision for blocking out the large

9. Calibration and Standardization

capacitance during the fill pulse is desirable. The capacitance

measurement system used for determining the DLTS peaks in

9.1 Measure the standard capacitances to determine that the

Procedures A and B does not need to be direct reading but must

capacitance bridge or meter is within specifications.

have an output that is sufficiently linear and a response time

9.2 Verify time calibration by use of a calibrated time-mark

that is sufficiently fast to give undistorted peaks.

generator or an interval timer for the recorder system. (For

6.2 Standard Capacitances, of accuracy 0.25 % or better

Procedure C only.)

(1s %) at the measurement frequency. One capacitor shall be in

9.3 Verify temperature calibration. Comparison with a

the range from 1 to 10 pF and another in the range from 10 to

calibrated platinum resistance thermometer under isothermal

100 pF.

conditions is preferred. An alternative check is to use a

6.3 Pulser, with controllable repetition rate capable of

well-characterized diode, lightly doped with platinum or

changing from one bias voltage adjustable within the range of

another deep level (DE and B known), measure the emission

at least + 10 to − 10 V to another bias voltage in the same

rate e 5 1/t, and calculate iteratively: T 5 11604.5D

n

range. Switching time shall be much less than the smallest time

E/(lnt+2 lnT+lnB).

constant to be measured and overshoot and undershoot shall be

10. Procedure

less than 1 % of pulse amplitude under operating conditions.

10.1 Tests for Nonexponentiality of the Capacitance

6.4 Boxcar Averager, or equivalent instrument (needed for

Transients—Use one or more of the following techniques:

Procedures A and B only) to process the capacitance transient.

10.1.1 Thurber et al Technique (5)—Choose a convenient

Desirable features are two separately controllable gate delay

−1 −1

value of rate window t , for example (500 μs) , and choose

times with adjustable sampling time.

a sequence of values of t /t , for example, 2, 5, 10, 20, 50.

6.5 Interval Timer, (needed for Procedures A and B only) 2 1

Calculate for each value of t /t as follows:

capable of measuring gate delay times of a few microseconds 2 1

to several seconds with an accuracy of 0.1 % (1s %).

t 5t·ln ~t /t !/~t /t 2 1!

1 2 1 2 1

6.6 Recorder System, capable of digitally or continuously

then:

measuring and recording the following:

t 5 t ~t /t !

2 1 2 1

6.6.1 Capacitance as a function of time or temperature, or

6.6.2 The average difference in capacitance at two gate 10.1.1.1 Perform 10.2.1 and 10.2.2 of Procedure A using the

delay times as a function of temperature. gate times t and t calculated here. Compare values of T from

1 2 m

6.7 Oscilloscope, capable of observing the pulser output, the each run. If T is constant, the transient is exponential and the

m

capacitance transient, and boxcar or other output to be recorded corrections of Procedure B are not needed; consequently

(not required but extremely helpful). follow Procedure A. If T changes with changes in the t /t

m 2 1

6.8 Cryostat, containing a specimen holder capable of ratio, apply corrections by following Procedure B or use

maintaining a selectable temperature or of ramping the

Procedure C.

temperature up or down at a controlled rate. For silicon, the 10.1.2 Manglesdorf Test (6)—For a single capacitance

temperature range is usually between cryogenic and room transient, recorded at constant temperature, plot capacitance at

temperature, and for gallium arsenide, the range is from time t against capacitance at a delayed time t + Dt for several

cryogenic or room temperature to higher temperatures Dt values ranging from about 0.5 t to a few t . Calculate the

depending upon the energy levels of interest. In Procedure C, slope m of the linear regression line fitted to the data points as

a radiation shield surrounding the specimen holder is necessary follows:

F 978

10.2.4 Make Arrhenius plot (see 11.6.1).

m 5 nZ 2 X ·Y !/ nX 2 X !

~ ~

1 1 1 2 1

10.2.5 Calculate and record activation energy of the defect

where:

level and its standard deviation, DE 6 s (see 11.6.2 to

DE

n 5 number of points,

11.6.4).

X 5(C (t),

10.2.6 Calculate and record prefactor of the exponential and

X 5([C (t)] ,

its standard deviation, B 6 s (see 11.6.5).

B

Y 5(C (t + Dt), and

10.2.7 To the extent possible, allow specimen to reach

Z 5([C(t)·C (t + Dt)].

equilibrium at a temperature that will permit the recording of a

10.1.2.1 Calculatet5 −Dt/ln(m). If t does not change as Dt

capacitance transie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.