ASTM D5196-91(1999)

(Guide)Standard Guide for Biomedical Grade Water

Standard Guide for Biomedical Grade Water

SCOPE

1.1 This guide is intended to describe the physical and chemical characteristics of water to be used whenever critical purity is essential to the use intended in clinical, pharmaceutical, biophysical, biomedical, chemical, physical research applications, or a combination of these. This guide is not intended for use in preparing water for injectables. Generally, the appropriate use of this guide may include experiments involving tissue culture, chromatography, mass spectroscopy, or analysis where molecular quantities of impurities may be important.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D 5196–91 (Reapproved 1999)

Standard Guide for

Biomedical Grade Water

This standard is issued under the fixed designation D 5196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 1094 Test Methods for Microbiological Monitoring of

Water Used for Processing Electron and Microelectronic

1.1 This guide is intended to describe the physical and

Devices by Direct-PressureTap SamplingValve and by the

chemical characteristics of water to be used whenever critical

Pre-Sterilized Plastic Bag Method

purity is essential to the use intended in clinical, pharmaceu-

tical, biophysical, biomedical, chemical, physical research

3. Terminology

applications, or a combination of these. This guide is not

3.1 Definitions—For definitions of terms used in this guide,

intended for use in preparing water for injectables. Generally,

refer to Terminology D 1129.

the appropriate use of this guide may include experiments

3.2 Definitions of Terms Specific to This Standard:

involving tissue culture, chromatography, mass spectroscopy,

3.2.1 endotoxins—substances or by-products usually pro-

or analysis where molecular quantities of impurities may be

ducedbygramnegativemicro-organismswhichgiveapositive

important.

test for endotoxin in accordance with 8.24.

1.2 This standard does not purport to address all of the

3.2.2 heterotropic bacterial counts/1000 mL—total number

safety problems, if any, associated with its use. It is the

of viable micro-organisms present in the 1000-mL sample,

responsibility of the user of this standard to establish appro-

excluding anaerobic and microaerophilic bacteria.

priate safety and health practices and determine the applica-

3.2.3 total organic carbon—carbon measured after inor-

bility of regulatory limitations prior to use.

ganic carbon response has been eliminated by one of the

2. Referenced Documents prescribed ASTM methods.

3.2.4 water—water prepared in accordance with this guide.

2.1 ASTM Standards:

D 1125 Test Methods for Electrical Conductivity and Re-

4. Significance and Use

sistivity of Water

2 4.1 The purity of water is only relative and is usually

D 1129 Terminology Relating to Water

defined by the limits of impurities found in the water as well as

D 1426 Test Methods for Ammonia Nitrogen in Water

bythemethodsusedtoprepareandhandlethewater.Appendix

D 1428 Test Methods for Sodium and Potassium in Water

3 X1 describes a method of preparation of moderate volumes of

and Water-Formed Deposits by Flame Photometry

water with the highest purity practical using available equip-

D 3919 Practice for Measuring Trace Elements in Water by

2 ment and techniques.

Graphite FurnaceAtomicAbsorption Spectrophotometry

4.2 The method of preparation of water described inAppen-

D 3973 Test Method for Low Molecular Weight Haloge-

4 dix X1 is designed to remove organic, inorganic, volatile,

nated Hydrocarbons in Water

particulate, and biological impurities to provide water that

D 4453 Practice for Handling of Ultra-Pure Water

2 should meet the concentration limits in Table 1. These are

Samples

suggested limits, since the actual maxima of the individual

D 4517 Test Method for Low-Level Total Silica in High

impurities will depend upon the required end use of the water.

Purity Water by Flameless Atomic Absorption Spectros-

4 The limits in the guide in most cases are dictated not by the

copy

desired maximum concentration of the impurities, but by the

D 4779 Test Method for Total, Organic, and Inorganic

methodsofanalysis.Morerestrictivelimitsmayberequiredby

Carbon in High Purity Water by Ultraviolet (UV), or

4 mutual consent of the parties concerned, provided a suitable

Persulfate Oxidation, or Both, and Infrared Detection

test method is agreed upon.

4.3 The guide for the storage of high purity water is very

1 important because impurities are added to the water in propor-

This guide is under the jurisdiction ofASTM Committee D-19 on Water and is

tion to the solubility, area of contact, and time of contact

the direct responsibility of Subcommittee D19.02 on General Specifications,

Technical Resources, and Statistical Methods.

between the water and the materials of containment. It is

Current edition approved Oct. 15, 1991. Published February 1992.

Annual Book of ASTM Standards, Vol 11.01.

Discontinued 1990—See 1989 Annual Book of ASTM Standards, Vol 11.01.

4 5

Annual Book of ASTM Standards, Vol 11.02. Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5196–91 (1999)

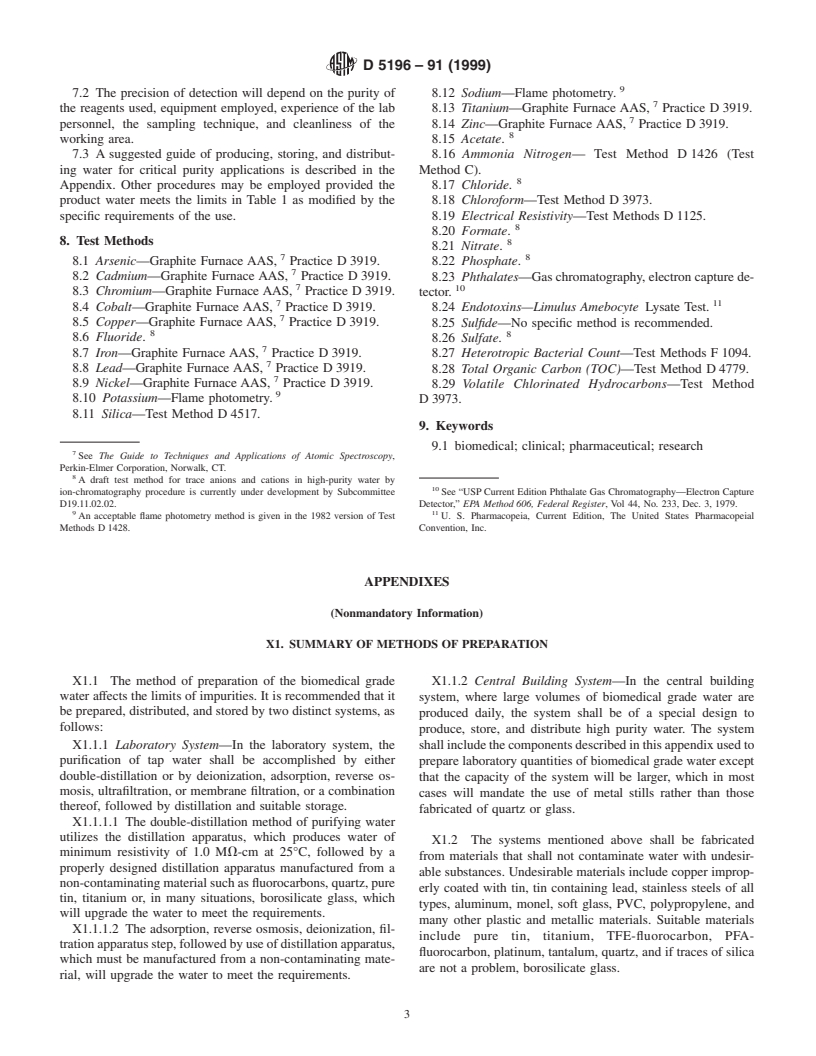

TABLE 1 Suggested Maximum Analyte Concentrations

where such specifications are available. Other grades may be

Maximum Concentration, used, provided it is first ascertained that the reagent is of

Analyte

µg/L

sufficiently high purity to permit its use without lessening the

Arsenic 0.1

accuracy of the determination.

Cadmium 0.1

5.2 Purity of Water— Unless indicated otherwise, refer-

Chromium 1.0

Cobalt 1.0 ences to water shall be understood to mean water as defined in

Copper 1.0

this guide.

Fluoride 1.0

Iron 1.0

Lead 1.0

6. Sampling

Nickel 0.1

Potassium 2.0 6.1 The test methods specified in Section 8 assume that

Silica (total) 5.0

great care and skill will be employed in obtaining the water

Sodium 0.5

samples to be tested. It is assumed that the operators will

Titanium 1.0

prevent container and airborne contamination to the best of

Zinc 0.5

Acetate 3.0

their ability, making note of possible sources of contamination

Ammonia 1.0

due to the sampling procedure. It is recommended that the

Chloride 1.0

Chloroform 5.0 samples be handled in accordance with Practice D 4453.

Formate 2.0

6.2 Extreme care must be exercised in handling samples

Nitrate 1.0

when making analyses. Experimental laboratory-ware should

Phosphate 1.0

Phthalates 0.1

be made of PFA- or TFE-fluorocarbon, and less desirably from

Sulfide 1.0

quartz or borosilicate glass, to minimize the contamination of

Sulfate 1.0

the water. Borosilicate glassware may leach ions at picogram-

Total organic carbon (TOC) 20.0

Volatile chlorinated hydrocarbon 5.0

per-litrelevels.Themajorcontaminantsfromborosilicateglass

Endotoxins (Endotoxin Unit) <0.03 EU/mL

are sodium (Na), potassium (K), boron (B), and silica (SiO ).

Heterotropic bacterial counts <10/1000 mL

A

No detectable ions leach out of PFA- or TFE-fluorocarbon that

Electrical resistivity, min, MV-cm at 25°C:

–measured at the production point not in contact 10.0

has been properly cleaned.

with air

6.2.1 Containers should be cleaned with HNO (1+4) or

–measured from storage or distribution system in 1.0

contact with air HCl (1 + 4), or both, by filling the container and allowing it to

A

stand for a minimum of 1 h.

Electrical resistivity can be expressed in microsiemens per centimetre conduc-

tivity at 25°C. The conductivity is reciprocal of the resistivity, ⁄R .

6.2.2 The containers should be rinsed with three container

volumes of a sampled water and then allowed to stand for 24

h with the same sampled water.

importanttominimizethecontacttimeofstorageandtorealize

6.2.3 The containers should be rinsed again twice with the

that the containment materials will determine the type of

sampled water before filling.

contaminants. Particular emphasis must be placed upon pos-

6.2.4 The containers should be filled by flushing at least five

sible contamination from the atmosphere above the water

volumes of the sampled water into the vessel before sealing.

which may add biological as well as gaseous and particulate

The seal must be of a non-contaminating material.

impurities.

6.2.5 Storage of the sample may be required for the detec-

4.4 The distribution systems present a large area of contact

tion of metals, in which case 1 mLof redistilled HNO (1 + 99)

between the water and the pipe or tubing and, therefore, must

or HCl (1 + 99) should be added per litre to reduce the pH and

be of a very pure insoluble substance. Organic impurities, such

to preserve solubility of the metals within the sample.

as plasticizers, micro-organisms and their by-products, etc., are

6.2.6 The water sample should remain in storage a minimal

often more important considerations than inorganic impurities.

length of time since some impurities have a tendency to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.