ASTM A717/A717M-12

(Test Method)Standard Test Method for Surface Insulation Resistivity of Single-Strip Specimens

Standard Test Method for Surface Insulation Resistivity of Single-Strip Specimens

SIGNIFICANCE AND USE

5.1 This test method is particularly suitable for quality control in the application of insulating coatings.

5.2 Surface insulation resistivity is evaluated from a dc current that can range from 0 (perfect insulator) to 1 A (perfect conductor).

5.3 Single readings should not be considered significant since the nature of the test device and specimen are such that successive measurements of a specimen often yield different values.

SCOPE

1.1 This test method covers a means of testing the surface insulation resistivity of single strips or punchings of flat-rolled electrical steel under predetermined conditions of voltage, pressure, and temperature.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A717/A717M − 12

Standard Test Method for

1

Surface Insulation Resistivity of Single-Strip Specimens

This standard is issued under the fixed designationA717/A717M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

4.1 Ten metallic contacts of fixed area are applied to one of

1.1 This test method covers a means of testing the surface

thesurfacesofthespecimenandelectricalcontactismadewith

insulation resistivity of single strips or punchings of flat-rolled

the base metal by two drills. The effectiveness of the surface

electrical steel under predetermined conditions of voltage,

insulation is then indicated by a measurement of average

pressure, and temperature.

electrical current flowing between the contacts and the base

1.2 The values stated in either SI units or inch-pound units

metal under specified applied voltage. This measurement can

are to be regarded separately as standard. The values stated in

be used directly as an indicator of insulation quality or may be

each system may not be exact equivalents; therefore, each

converted to an apparent surface insulation resistivity value.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

5. Significance and Use

with the standard.

5.1 This test method is particularly suitable for quality

1.3 This standard does not purport to address all of the

control in the application of insulating coatings.

safety concerns, if any, associated with its use. It is the

5.2 Surface insulation resistivity is evaluated from a dc

responsibility of the user of this standard to establish appro-

current that can range from 0 (perfect insulator) to 1A(perfect

priate safety and health practices and determine the applica-

conductor).

bility of regulatory limitations prior to use.

5.3 Single readings should not be considered significant

since the nature of the test device and specimen are such that

2. Referenced Documents

successive measurements of a specimen often yield different

2

2.1 ASTM Standards:

values.

A34/A34M Practice for Sampling and Procurement Testing

of Magnetic Materials

6. Apparatus

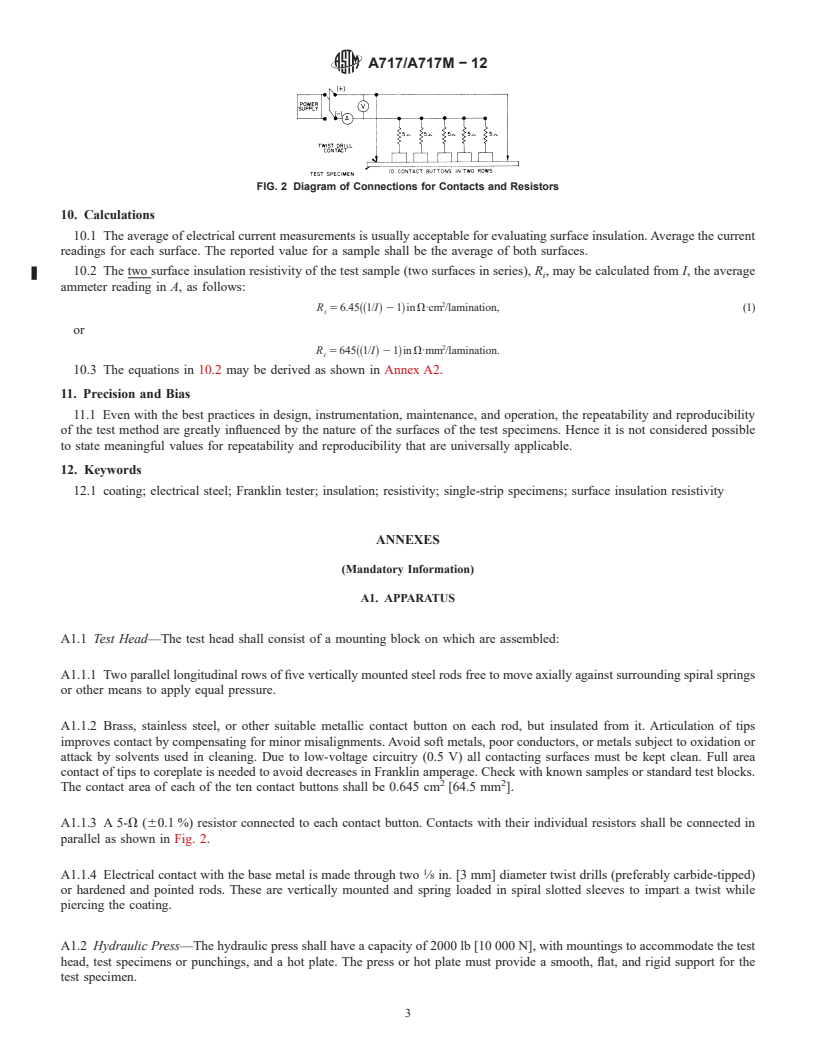

6.1 The apparatus, as shown in Fig. 1 and Fig. 2, shall

3. Terminology

consist of a contact unit or test head which is attached to the

3.1 Definitions of Terms Specific to This Standard:

head of a hydraulic press. Its associated measuring equipment,

3.1.1 surface insulation resistivity—refers to the effective

which may be remotely located, includes an ammeter,

resistivity of a single insulative layer tested between applied

voltmeter, and voltage regulated dc power supply. When

bare metal contacts and the base metal of the insulated test

measurements are to be made at elevated temperatures, the

specimen.Itisnotthesameasthetermsinterlaminarresistivity

platen beneath the specimen is heated and controlled. Detailed

and stack resistivity, which refer to the average resistivity of

descriptions of the various components are given in AnnexA1.

two adjacent insulative surfaces in contact with each other.

7. Sampling

3.1.2 The apparatus is popularly known as a Franklin tester.

7.1 Samples shall be representative of the steel and shall be

cut in a manner to assure representative sampling as described

in Practice A34/A34M.

1

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

8. Test Specimen

Methods.

CurrenteditionapprovedMay1,2012.PublishedJuly2012.Originallyapproved

8.1 Thewidthandlengthofaspecimenstripshallbegreater

in 1975. Last previous edition approved in 2006 as A717/A717M –06. DOI:

than the width and length respectively of the assembly of

10.1520/A0717_A0717M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contacts. The suggested minimum specimen size is 2 by 5 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

[50 by 130 mm].

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 8.2 A minimum of five specimen strips is recommended.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A717/A717M − 12

FIG. 1 Apparatus of Surface Insulation Resistivity Measurement

9.6 When the insulation may be hygroscopic, a conditioning

procedure immediately prior to testing should be mutually

agreed upon by the producer and the user.

9.7 Place the specimen on the platen beneath the test head

and positio

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A717/A717M − 06 A717/A717M − 12

Standard Test Method for

1

Surface Insulation Resistivity of Single-Strip Specimens

This standard is issued under the fixed designation A717/A717M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a means of testing the surface insulation resistivity of single strips or punchings of flat-rolled

electrical steel under predetermined conditions of voltage, pressure, and temperature.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 surface insulation resistivity—refers to the effective resistivity of a single insulative layer tested between applied bare

metal contacts and the base metal of the insulated test specimen. It is not the same as the terms interlaminar resistivity and stack

resistivity, which refer to the average resistivity of two adjacent insulative surfaces in contact with each other.

3.1.2 The termapparatus surface insulation resistivity used in this method refers to the effective resistivity of a single insulative

layer tested between applied bare metal contacts and the base metal of the insulated test specimen. It is not the same as the terms

interlaminar resistivity and stack resistivity, which refer to the average resistivity of two adjacent insulative surfaces in contact with

each other.is popularly known as a Franklin tester.

3.2 The apparatus is popularly known as a Franklin tester.

4. Summary of Test Method

4.1 Ten metallic contacts of fixed area are applied to one of the surfaces of the specimen and electrical contact is made with

the base metal by two drills. The effectiveness of the surface insulation is then indicated by a measurement of average electrical

current flowing between the contacts and the base metal under specified applied voltage. This measurement can be used directly

as an indicator of insulation quality or may be converted to an apparent surface insulation resistivity value.

5. Significance and Use

5.1 This test method is particularly suitable for quality control in the application of insulating coatings.

5.2 Surface insulation resistivity is evaluated from a dc current that can range from 0 (perfect insulator) to 1 A (perfect

conductor).

5.3 Single readings should not be considered significant since the nature of the test device and specimen are such that successive

measurements of a specimen often yield different values.

1

This test method is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.01 on Test Methods.

Current edition approved May 1, 2006May 1, 2012. Published May 2006July 2012. Originally approved in 1975. Last previous edition approved in 20012006 as

A717/A717M – 01.A717/A717M –06. DOI: 10.1520/A0717_A0717M-06.10.1520/A0717_A0717M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A717/A717M − 12

6. Apparatus

6.1 The apparatus, as shown in Fig. 1 and Fig. 2, shall consist of a contact unit or test head which is attached to the head of

a hydraulic press. Its associated measuring equipment, which may be remotely located, includes an ammeter, voltmeter, and

voltage regulated dc power supply. When measurements are to be made at eleva

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.