ASTM D2357-74(1995)e1

(Classification)Standard for Qualitative Classification of Surfactants by Infrared Absorption

Standard for Qualitative Classification of Surfactants by Infrared Absorption

SCOPE

1.1 This standard covers the qualitative classification of synthetic detergent products or mixtures of synthetic detergents. It is applicable to built detergent formulations as well as individual surfactant compositions. Note 1-The organic active ingredient must be isolated from built syndet compositions in accordance with Test Method D2358.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 2357 – 74 (Reapproved 1995)

Standard for

Qualitative Classification of Surfactants by Infrared

Absorption

This standard is issued under the fixed designation D 2357; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in February 1995.

1. Scope 4.2 Dies and Press, for preparation of KBr disks.

4.3 Detergent Reference Spectra.

1.1 This standard covers the qualitative classification of

synthetic detergent products or mixtures of synthetic deter-

5. Reagents

gents. It is applicable to built detergent formulations as well as

5.1 Mineral Oil, USP.

individual surfactant compositions.

5.2 Potassium Bromide (KBr), infrared quality, powdered.

NOTE 1—The organic active ingredient must be isolated from built

5.3 Additional Reagents, as specified in Test Method

syndet compositions in accordance with Test Method D 2358.

D 2358.

1.2 This standard does not purport to address all of the

6. Preparation of Sample

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 6.1 Sample in Pure Form—If the sample is in pure form or

priate safety and health practices and determine the applica-

contains only volatile solvents, dry the sample in accordance

bility of regulatory limitations prior to use. with 5.8 of Test Method D 2358, and obtain the infrared

spectrum of the dried sample.

2. Referenced Documents

6.2 For Built Surfactants and Synthetic Detergent

2.1 ASTM Standards:

Compositions—Obtain the infrared spectrum of the active

D 2358 Test Method for Separation of Active Ingredient

ingredient(s) separated in accordance with Test Method

from Surfactant and Syndet Compositions

D 2358.

3. Summary of Classification

7. Procedure

3.1 A portion of the active ingredient is scanned in the

7.1 Whenever possible, the infrared spectrum should be

infrared region of the spectrum from at least 2 to 15 μm.

obtained directly from the organic material, by formation of a

Qualitative identification of surfactant type is based on the

film between salt blocks, and by recording the spectrum

presence of infrared absorption bands attributable to specific

between 2 and 15 μm. The film is satisfactory if the spectrum

functional groups.

shows 10 to 30 % transmittance in the strongest absorption

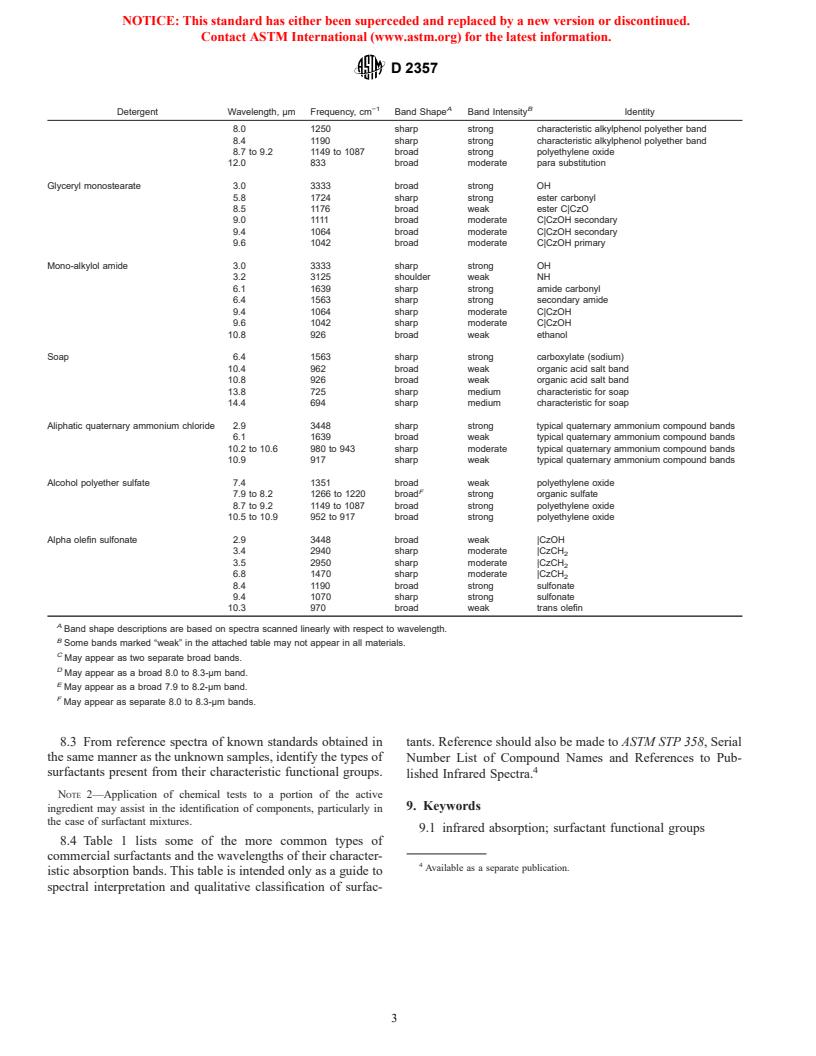

3.2 A listing of absorption bands corresponding to the

region.

characteristic functional groups of some of the more common

7.2 If the physical properties of the sample prevent use of

types of commercial surfactants is included in this method. Use

the film technique, the spectrum may be made from a mineral

of available detergent reference spectra may provide additional

oil mull. Form the mull by adding 2 to 3 drops of mineral oil

information.

to a small quantity of sample contained in a polished grinding

surface (agate) mortar, and grinding for a minimum of 5 min.

4. Apparatus

This should produce a very fine syrupy dispersion. Use the

4.1 Spectrophotometer, recording, infrared.

mull as a film between salt blocks and obtain the spectrum as

in 7.1.

7.3 If the sample can be obtained in dry, powdered form, the

This classification is under the jurisdiction of ASTM Committee D-12 on Soaps

KBr pressed-disk method may be used. Grind the sample

and Other Detergents, and is the direct responsibility of Subcommittee D12.12 on

sufficiently fine to prevent radiation scatter, and add approxi-

Analysis of Soaps and Synthetic Detergents.

Current edition approved April 29, 1974. Published June 1974. Originally

mately 1 part sample to 19 parts of dry powdered KBr. Using

published as D 2357 – 65 T. Last previous edition D 2357 – 69.

suitable equipment, form the disk at room temperature in

Annual Book of ASTM Standards, Vol 15.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2357

spectrum of the disk, sample between 2 and 15 μm as in 7.1.

vacuum, under pressure of 10 to 30 tons/in. Obtain the

8. Identification of Components

8.1 Note the wavelength position of each specific absorption

band.

8.2 Identify the absorption bands in terms of functional

groups by the use of data in Table 1 or other appropriate

reference source.

For details of infrared experimental techniques, see Jones, R. N. and Sandorfy,

C., “The Application of Infrared and Raman Spectrometry to the Elucidation of

Molecular Structure.” Technique of Organic Chemistry, Vol IX, 1956. Interscience

Publishers, Inc., New York, NY.

TABLE 1 Infrared Absorption Bands of Typical Commercial Detergents

−1 A B

Detergent Wavelength, μm Frequency, cm Band Shape Band Intensity Identity

Alkylbenzene sulfonate 6.7 1493 shoulder weak aromatic bands

C

8.1 to 8.5 1235 to 1176 broad strong sulfonate group

8.8 1136 sharp moderate sulfonate group

9.6 1042 sharp strong ABS bands

9.9 1010 sharp strong ABS bands

12.0 833 broad moderate para substitution

D

Fatty alcohol sulfate 8.0 1250 sharp strong organic sulfate group

D

8.3 1205 sharp strong organic sulfate group

9.2 1087 sharp moderate most characteristic alcohol sulfate band

10.3 971 broad weak characteristic alcohol sulfate bands

10.8 926 broad weak characteristic alcohol sulfate bands

Sulfonated amide (taurate) 6.1 1639 sharp strong amide carbonyl

6.4 1563 shoulder weak secondary amide

8.1 to 8.5 1235 to 1176 broad strong sulfonate group

9.4 1064 sharp strong C|CzN or alkyl sulfonate

Sulfonated ester (isethionate) 5.8 1724 sharp strong ester carbonyl

6.4 1563 broad weak soap

8.1 to 8.5 1235 to 1176 broad strong sulfonate group

8.5 1176 broad strong ester C|C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.