ASTM E1644-04(2016)e1

(Practice)Standard Practice for Hot Plate Digestion of Dust Wipe Samples for the Determination of Lead

Standard Practice for Hot Plate Digestion of Dust Wipe Samples for the Determination of Lead

SIGNIFICANCE AND USE

5.1 This practice is intended for the digestion of lead in dust wipe samples collected during various lead hazard activities performed in and around buildings and related structures.

5.2 This practice is also intended for the digestion of lead in dust wipe samples collected during and after building renovations.

5.3 This practice is applicable to the digestion of dust wipe samples that have or have not been collected in accordance with Practice E1728 using wipes that may or may not conform to Specification E1792.

5.4 This practice is applicable to the digestion of dust wipe samples that were placed in either hard-walled, rigid containers such as 50-mL centrifuge tubes or flexible plastic bags.

Note 2: Due to the difficulty in performing quantitative transfers of some samples from plastic bags, hard-walled rigid containers such as 50-mL plastic centrifuge tubes are recommended for sample collection.

5.5 Digestates prepared according to this practice are intended to be analyzed for lead concentration using spectrometric techniques such as Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES) and Flame Atomic Absorption Spectrometry (FAAS) (see Test Method E1613), or using electrochemical techniques such as anodic stripping voltammetry (see Practice E2051).

5.6 This practice is not capable of determining lead bound within matrices, such as silica, that are not soluble in nitric acid.

5.7 This practice is capable of determining lead bound within paint.

SCOPE

1.1 This practice covers the acid digestion of surface dust samples (collected using wipe sampling practices) and associated quality control (QC) samples for the determination of lead.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—Informational inch-pound units are provided in Note 3.)

1.3 This practice contains notes which are explanatory and not part of mandatory requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1644 − 04 (Reapproved 2016)

Standard Practice for

Hot Plate Digestion of Dust Wipe Samples for the

Determination of Lead

This standard is issued under the fixed designation E1644; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Caution statement changed to a warning in 8.1.4 and editorial changes made throughout in November 2016.

1. Scope Wipe Sampling Methods for Subsequent Lead Determi-

nation

1.1 This practice covers the acid digestion of surface dust

E1792 Specification for Wipe Sampling Materials for Lead

samples (collected using wipe sampling practices) and associ-

in Surface Dust

ated quality control (QC) samples for the determination of

E2051 Practice for the Determination of Lead in Paint,

lead.

Settled Dust, Soil and Air Particulate by Field-Portable

1.2 The values stated in SI units are to be regarded as

Electroanalysis (Withdrawn 2010)

standard. No other units of measurement are included in this

E2239 PracticeforRecordKeepingandRecordPreservation

standard.

for Lead Hazard Activities

1.2.1 Exception—Informational inch-pound units are pro-

2.2 Other Documents:

vided in Note 3.)

EPA SW 846, Method 3050, “Acid Digestion of Sediments,

1.3 This practice contains notes which are explanatory and

Sludges, and Soils.”This method is found in Test Methods

not part of mandatory requirements of the standard.

for Evaluating Solid Waste, Physical/Chemical Methods,

1.4 This standard does not purport to address all of the U.S. EPA SW 846, 3rd Edition, Revision 1, 1987

NIOSH Manual of Analytical Methods, NIOSH 7082 and

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 7105, Eller, P.M., Ed., 3rd ed., 1984

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3. Terminology

3.1 Definitions—Fordefinitionsoftermsnotappearinghere,

2. Referenced Documents

refer to Terminologies D1129 and E1605.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D1129 Terminology Relating to Water

3.2.1 blank wipe—an unused, unspiked dust wipe that is

D1193 Specification for Reagent Water

only removed from its packaging immediately before use.

E1605 Terminology Relating to Lead in Buildings

3.2.1.1 Discussion—Blank wipes are used to prepare non-

E1613 Test Method for Determination of Lead by Induc-

spiked,spiked,andspikedduplicatequalityassurancesamples.

tively Coupled Plasma Atomic Emission Spectrometry

3.2.2 dust wipe sample—surface dust collected on a wipe.

(ICP-AES), Flame Atomic Absorption Spectrometry

3.2.3 method blank—a digestate that reflects the maximum

(FAAS), or Graphite Furnace Atomic Absorption Spec-

treatment given any one sample within a sample batch except

trometry (GFAAS) Techniques

that only the sampling medium (such as a blank wipe) is

E1728 PracticeforCollectionofSettledDustSamplesUsing

initially placed into the digestion vessel. (The same reagents

and processing conditions that are applied to field samples

within a batch are also applied to the method blanks.)

This practice is under the jurisdiction of ASTM Committee E06 on Perfor-

3.2.3.1 Discussion—Analysis results from method blanks

manceofBuildingsandisthedirectresponsibilityofSubcommitteeE06.23onLead

provide information on the level of potential contamination

Hazards Associated with Buildings.

Current edition approved Oct. 1, 2016. Published November 2016. Originally

ɛ1

approved in 1994. Last previous edition approved in 2012 as E1644–04(2012) .

DOI: 10.1520/E1644-04R16E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Technical Information Service (NTIS), 5301 Shawnee

the ASTM website. Rd., Alexandria, VA 22312, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1644 − 04 (2016)

resulting from the laboratory and sampling medium sources 5.6 This practice is not capable of determining lead bound

that are experienced by samples processed within the batch. within matrices, such as silica, that are not soluble in nitric

acid.

3.2.4 non-spiked sample—a portion of a homogenized

sample that was targeted for the addition of analyte but is not

5.7 This practice is capable of determining lead bound

fortified with the target analytes before sample preparation.

within paint.

3.2.4.1 Discussion—Forwipesamples,anon-spikedsample

is equivalent to a method blank. Analysis results for this

6. Apparatus and Materials

sample are used to correct for background levels in the blank

6.1 Borosilicate Glassware:

wipes used for spiked and spiked duplicate samples.

6.1.1 Class A Volumetric Flasks with Stoppers, 100 mL and

3.2.5 reagent blank—a digestate that reflects the maximum

other sizes needed to make serial dilutions,

treatment given any one sample within a sample batch except

6.1.2 Griffın Beakers, 150 mL or 250 mL,

that it has no sample placed into the digestion vessel. (The

6.1.3 Watch Glasses, sized to cover Griffin beakers,

same reagents and processing conditions that are applied to

6.1.4 Class A Pipets, as needed to make serial dilutions, and

field samples within a batch are also applied to the reagent

6.1.5 Glass Rods.

blank.)

6.2 Funnels—Plastic or porcelain or borosilicate funnels

3.2.5.1 Discussion—Analysis results from reagent blanks

sized to fit into a 100-mL volumetric flask.

provide information on the level of potential contamination

6.3 Filter Paper—Fast filtering, suitable for metals analysis.

resulting from only laboratory sources that are experienced by

samples processed within the batch.

6.4 Thermometers—Red alcohol or thermocouple, that cov-

3.2.6 spiked sample and spiked duplicate sample—a blank ers a range of 0 to 150°C.

wipe that is spiked with a known amount of analyte (that is,

6.5 Electric Hot Plate—Suitable for operation at tempera-

lead) before hot plate digestion and subsequent lead analysis.

tures up to at least 100°C (see Note 3).

3.2.6.1 Discussion—Analysis results for these samples are

NOTE 3—Provided that the hot plate is capable of handling the extra

used to provide information on accuracy and precision of the

heating required, use of a 12- to 25-mm (0.5- to 1-in.) thick aluminum

overall analysis process.

plate placed on the burner head can help reduce the presence of hot spots

common to electric hot plates.

4. Summary of Practice

6.6 Vinyl Gloves—Powderless.

4.1 A dust wipe sample is digested using hot plate type

6.7 Micropipettors with Disposable Plastic Tips—Sizes

heating with nitric acid and hydrogen peroxide. The digestate

needed to make reagent additions, and spike standards. In

is diluted to final volume prior to lead measurement.

general, the following sizes should be readily available: 1 to

NOTE 1—The procedure in this practice is based on U.S. EPA SW846

5 mL adjustable, 100 µL, 500 µL, 250 µL, and 1000 µL.

Method 3050, NIOSH 7082, and NIOSH 7105.

7. Reagents

5. Significance and Use

7.1 Purity of Reagents—Reagent grade chemicals shall be

5.1 This practice is intended for the digestion of lead in dust

used in this practice. Unless otherwise indicated, it is intended

wipe samples collected during various lead hazard activities

thatallreagentsconformtothespecificationsoftheCommittee

performed in and around buildings and related structures.

on Analytical Reagents of the American Chemical Society,

5.2 This practice is also intended for the digestion of lead in

where such specifications are available. Other grades may be

dust wipe samples collected during and after building renova-

used, provided it is first ascertained that the reagent is of

tions.

sufficiently high purity to permit its use without lessening

5.3 This practice is applicable to the digestion of dust wipe

accuracy of the determination.

samples that have or have not been collected in accordance

7.2 Nitric Acid—Concentrated, suitable for atomic spec-

with Practice E1728 using wipes that may or may not conform

trometry analysis such as spectroscopic grade.

to Specification E1792.

7.3 Hydrogen Peroxide—30 % (w/w), suitable for atomic

5.4 This practice is applicable to the digestion of dust wipe

spectrometry analysis such as spectroscopic grade.

samplesthatwereplacedineitherhard-walled,rigidcontainers

7.4 Purity of Water—Unless otherwise indicated, references

such as 50-mL centrifuge tubes or flexible plastic bags.

NOTE 2—Due to the difficulty in performing quantitative transfers of to water shall be understood to mean reagent water as defined

some samples from plastic bags, hard-walled rigid containers such as

by Type 1 of Specification D1193.

50-mL plastic centrifuge tubes are recommended for sample collection.

5.5 Digestates prepared according to this practice are in-

tended to be analyzed for lead concentration using spectromet- 5

Reagent Chemicals, American Chemical Society Specifications, American

ric techniques such as Inductively Coupled Plasma Atomic

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Emission Spectrometry (ICP-AES) and FlameAtomicAbsorp-

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

tion Spectrometry (FAAS) (see Test Method E1613), or using

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USP), Rockville,

electrochemica

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1 ´1

Designation: E1644 − 04 (Reapproval 2012) E1644 − 04 (Reapproved 2016)

Standard Practice for

Hot Plate Digestion of Dust Wipe Samples for the

Determination of Lead

This standard is issued under the fixed designation E1644; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial corrections made to Section Caution statement changed to a warning in 28.1.4 in April 2012.and edito-

rial changes made throughout in November 2016.

1. Scope

1.1 This practice covers the acid digestion of surface dust samples (collected using wipe sampling practices) and associated

quality control (QC) samples for the determination of lead.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—Informational inch-pound units are provided in Note 3.)

1.3 This practice contains notes which are explanatory and not part of mandatory requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water

E1605 Terminology Relating to Lead in Buildings

E1613 Test Method for Determination of Lead by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES),

Flame Atomic Absorption Spectrometry (FAAS), or Graphite Furnace Atomic Absorption Spectrometry (GFAAS) Techniques

E1728 Practice for Collection of Settled Dust Samples Using Wipe Sampling Methods for Subsequent Lead Determination

E1792 Specification for Wipe Sampling Materials for Lead in Surface Dust

E2051 Practice for the Determination of Lead in Paint, Settled Dust, Soil and Air Particulate by Field-Portable Electroanalysis

(Withdrawn 2010)

E2239 Practice for Record Keeping and Record Preservation for Lead Hazard Activities

2.2 Other Documents:

EPA SW 846, Method 3050, “Acid Digestion of Sediments, Sludges, and Soils.” This method is found in Test Methods for

Evaluating Solid Waste, Physical/Chemical Methods, U.S. EPA SW 846, 3rd Edition, Revision 1, 1987

NIOSH Manual of Analytical Methods, NIOSH 7082 and 7105, Eller, P.M., Ed., 3rd ed., 1984

3. Terminology

3.1 Definitions—For definitions of terms not appearing here, refer to Terminologies D1129 and E1605.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 blank wipe—an unused, unspiked dust wipe that is only removed from its packaging immediately before use.

This practice is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.23 on Lead Hazards

Associated with Buildings.

Current edition approved April 1, 2012Oct. 1, 2016. Published May 2012November 2016. Originally approved in 1994. Last previous edition approved in 20042012 as

ɛ1

E1644 – 04.E1644–04(2012) . DOI: 10.1520/E1644-04R12.10.1520/E1644-04R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from National Technical Information Service (NTIS), 5301 Shawnee Rd., Alexandria, VA 22312, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1644 − 04 (2016)

3.2.1.1 Discussion—

Blank wipes are used to prepare non-spiked, spiked, and spiked duplicate quality assurance samples.

3.2.2 dust wipe sample—surface dust collected on a wipe.

3.2.3 method blank—a digestate that reflects the maximum treatment given any one sample within a sample batch except that

only the sampling medium (such as a blank wipe) is initially placed into the digestion vessel. (The same reagents and processing

conditions that are applied to field samples within a batch are also applied to the method blanks.)

3.2.3.1 Discussion—

Analysis results from method blanks provide information on the level of potential contamination resulting from the laboratory and

sampling medium sources that are experienced by samples processed within the batch.

3.2.4 non-spiked sample—a portion of a homogenized sample that was targeted for the addition of analyte but is not fortified

with the target analytes before sample preparation.

3.2.4.1 Discussion—

For wipe samples, a non-spiked sample is equivalent to a method blank. Analysis results for this sample are used to correct for

background levels in the blank wipes used for spiked and spiked duplicate samples.

3.2.5 reagent blank—a digestate that reflects the maximum treatment given any one sample within a sample batch except that

it has no sample placed into the digestion vessel. (The same reagents and processing conditions that are applied to field samples

within a batch are also applied to the reagent blank.)

3.2.5.1 Discussion—

Analysis results from reagent blanks provide information on the level of potential contamination resulting from only laboratory

sources that are experienced by samples processed within the batch.

3.2.6 spiked sample and spiked duplicate sample—a blank wipe that is spiked with a known amount of analyte (that is, lead)

before hot plate digestion and subsequent lead analysis.

3.2.6.1 Discussion—

Analysis results for these samples are used to provide information on accuracy and precision of the overall analysis process.

4. Summary of Practice

4.1 A dust wipe sample is digested using hot plate type heating with nitric acid and hydrogen peroxide. The digestate is diluted

to final volume prior to lead measurement.

NOTE 1—The procedure in this practice is based on U.S. EPA SW846 Method 3050, NIOSH 7082, and NIOSH 7105.

5. Significance and Use

5.1 This practice is intended for the digestion of lead in dust wipe samples collected during various lead hazard activities

performed in and around buildings and related structures.

5.2 This practice is also intended for the digestion of lead in dust wipe samples collected during and after building renovations.

5.3 This practice is applicable to the digestion of dust wipe samples that have or have not been collected in accordance with

Practice E1728 using wipes that may or may not conform to Specification E1792.

5.4 This practice is applicable to the digestion of dust wipe samples that were placed in either hard-walled, rigid containers such

as 50-mL centrifuge tubes or flexible plastic bags.

NOTE 2—Due to the difficulty in performing quantitative transfers of some samples from plastic bags, hard-walled rigid containers such as 50-mL

plastic centrifuge tubes are recommended for sample collection.

5.5 Digestates prepared according to this practice are intended to be analyzed for lead concentration using spectrometric

techniques such as Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES) and Flame Atomic Absorption

Spectrometry (FAAS) (see Test Method E1613), or using electrochemical techniques such as anodic stripping voltammetry (see

Practice E2051).

5.6 This practice is not capable of determining lead bound within matrices, such as silica, that are not soluble in nitric acid.

´1

E1644 − 04 (2016)

5.7 This practice is capable of determining lead bound within paint.

6. Apparatus and Materials

6.1 Borosilicate Glassware:

6.1.1 Class A Volumetric Flasks with Stoppers, 100 mL and other sizes needed to make serial dilutions,

6.1.2 Griffın Beakers, 150 mL or 250 mL,

6.1.3 Watch Glasses, sized to cover Griffin beakers,

6.1.4 Class A Pipets, as needed to make serial dilutions, and

6.1.5 Glass Rods. Glass Rods.

6.2 Funnels—Plastic or porcelain or borosilicate funnels sized to fit into a 100-mL volumetric flask.

6.3 Filter Paper—Fast filtering, suitable for metals analysis.

6.4 Thermometers—Red alcohol or thermocouple, that covers a range of 0 to 150°C.

6.5 Electric Hot Plate—Suitable for operation at temperatures up to at least 100°C (see Note 3).

NOTE 3—Provided that the hot plate is capable of handling the extra heating required, use of a 1212- to 25-mm (0.5(0.5- to 1-in.) thick aluminum plate

placed on the burner head can help reduce the presence of hot spots common to electric hot plates.

6.6 Vinyl Gloves—Powderless.

6.7 Micropipettors with Disposable Plastic Tips—Sizes needed to make reagent additions, and spike standards. In general, the

following sizes should be readily available: 1 to 5 mL 5 mL adjustable, 100 μL, 500 μL, 250 μL, and 1000 μL.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in this practice. Unless otherwise indicated, it is intended that

all reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening accuracy of the determination.

7.2 Nitric Acid—Concentrated, suitable for atomic spectrometry analysis such as spectroscopic grade.

7.3 Hydrogen Peroxide—30 % (w/w), suitable for atomic spectrometry analysis such as spectroscopic grade.

7.4 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type 1 of Specification D1193.

7.5 Calibration Stock Solution—100 μg/mL of Pb in dilute nitric acid.

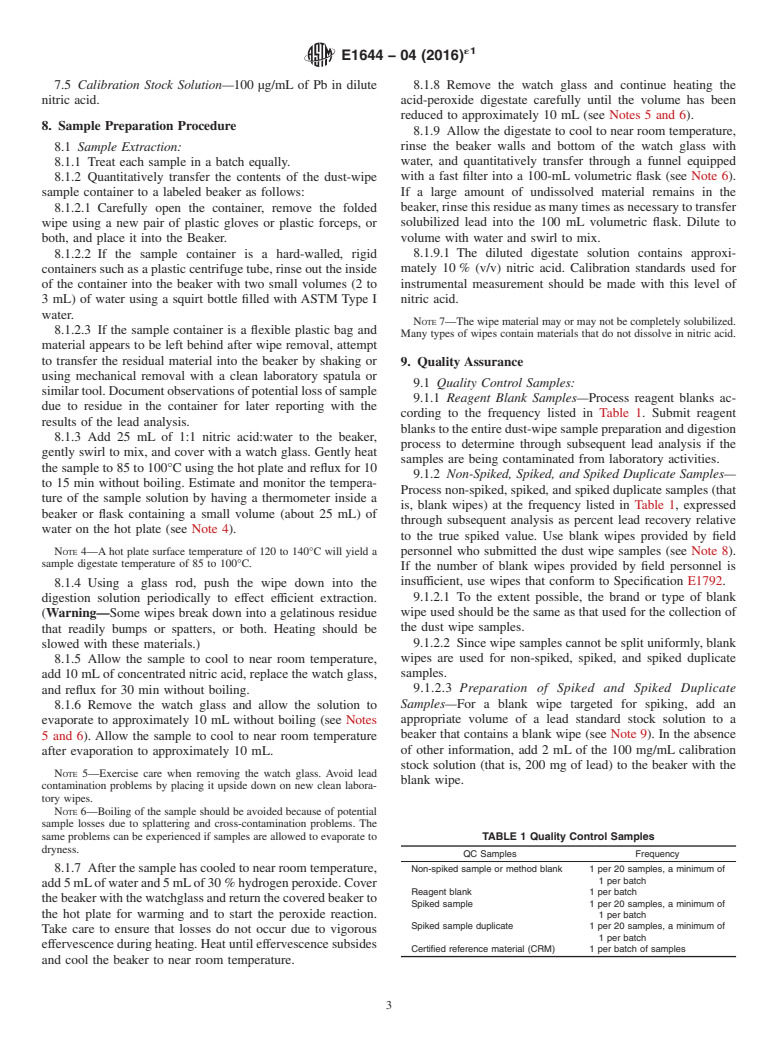

8. Sample Preparation Procedure

8.1 Sample Extraction:

8.1.1 Treat each

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.