ASTM D7672-11a

(Specification)Standard Specification for Evaluating Structural Capacities of Rim Board Products and Assemblies

Standard Specification for Evaluating Structural Capacities of Rim Board Products and Assemblies

SCOPE

1.1 This specification provides procedures for testing and establishing the structural capacities of proprietary rim board products and assemblies for use in light-frame wood construction using I-joist or structural composite lumber joist framing. It does not apply to rim board products manufactured to a commodity rim board standard.

1.2 This specification was developed in light of currently manufactured panel, structural composite lumber, and pre-fabricated I-joist rim board products as defined in 3.2. Materials that do not conform to the definitions of 3.2 are beyond the scope of this specification.

1.3 Fire safety, sound transmission, building envelope performance, and cutting/notching attributes of rim board products and assemblies are all items that may need to be considered in an end-use application. These items fall outside the scope of this specification.

1.4 This specification primarily considers end use in dry service conditions, such as most protected framing members, where the equilibrium moisture content for solid-sawn lumber is less than 16 %.

1.5 This specification provides methods to establish “allowable stress” design resistances for use with the National Design Specification for Wood Construction (NDS). Derivation of design resistances from the test data in accordance with “load and resistance factor design” or “limit states design” are beyond the scope of this specification.

1.6 Quality control requirements are outside the scope of this Specification.

1.7 The performance of a rim board product will be affected by the constituent wood species, geometry, adhesive, and production parameters. Therefore, rim board products produced by each individual manufacturer shall be evaluated to determine their product properties, regardless of the similarity in characteristics to products produced by other manufacturers.

1.8 Where a manufacturer produces product in more than one facility, each production facility shall be evaluated independently. For additional production facilities, any revisions to the full qualification program in accordance with this specification shall be approved by an accredited, independent qualifying agency.

1.9 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7672 – 11a

Standard Specification for

Evaluating Structural Capacities of Rim Board Products and

1

Assemblies

This standard is issued under the fixed designation D7672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

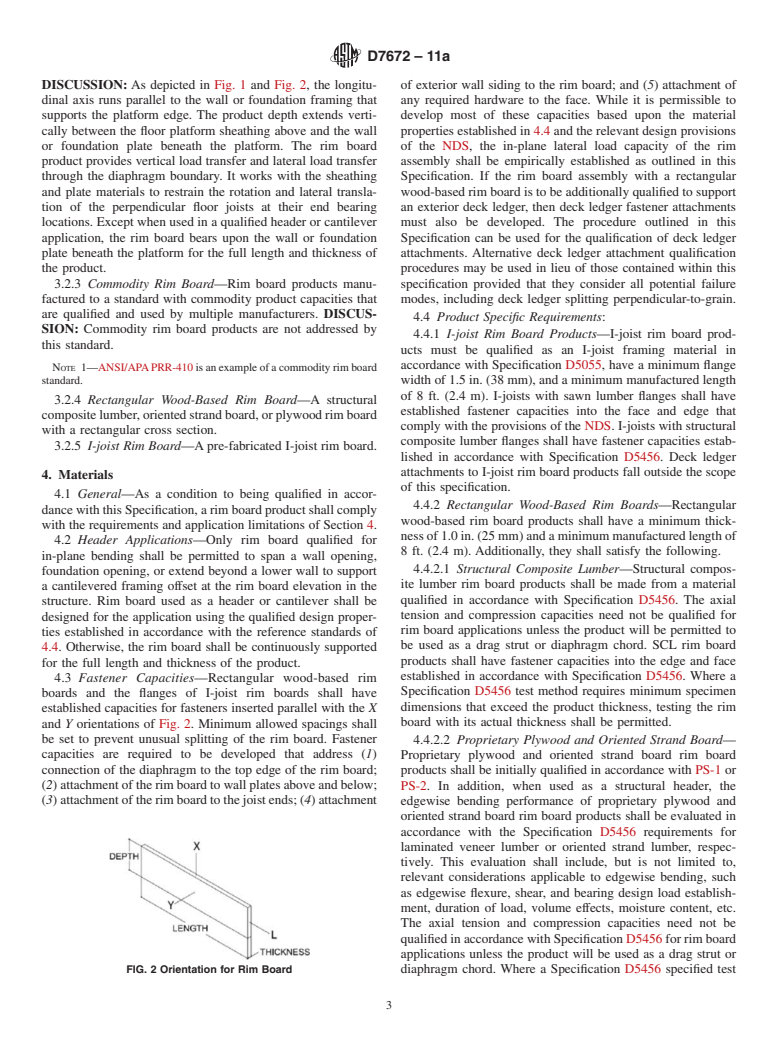

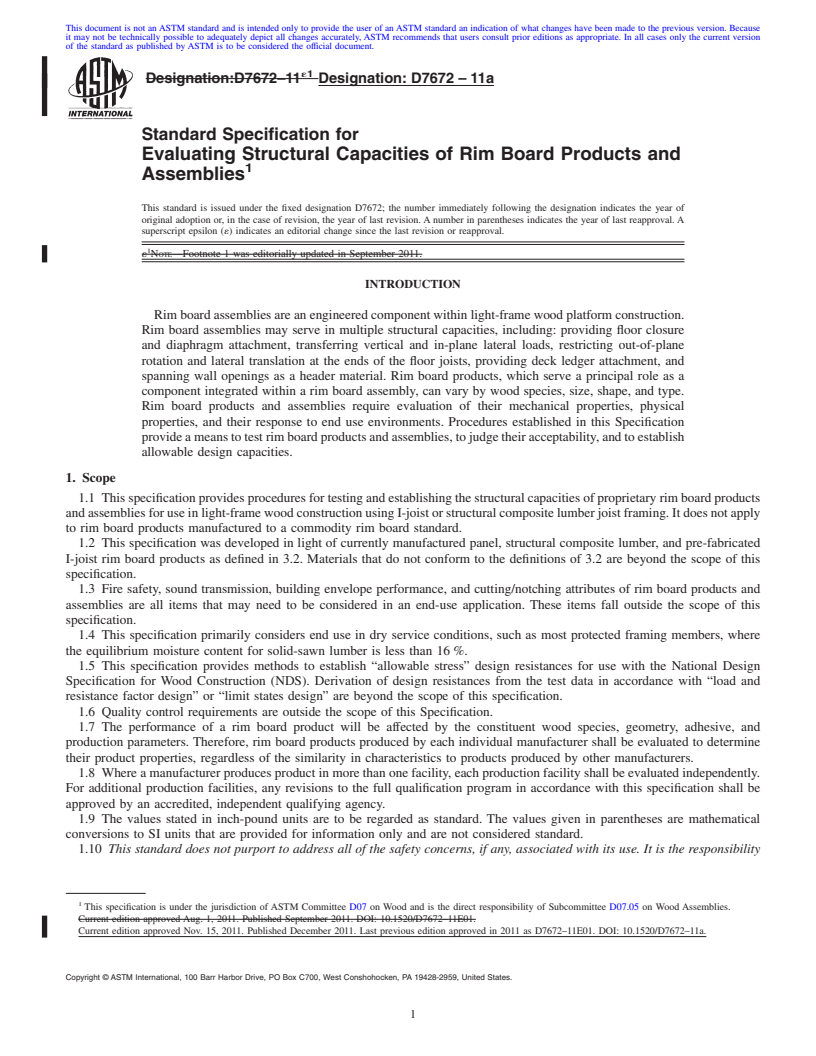

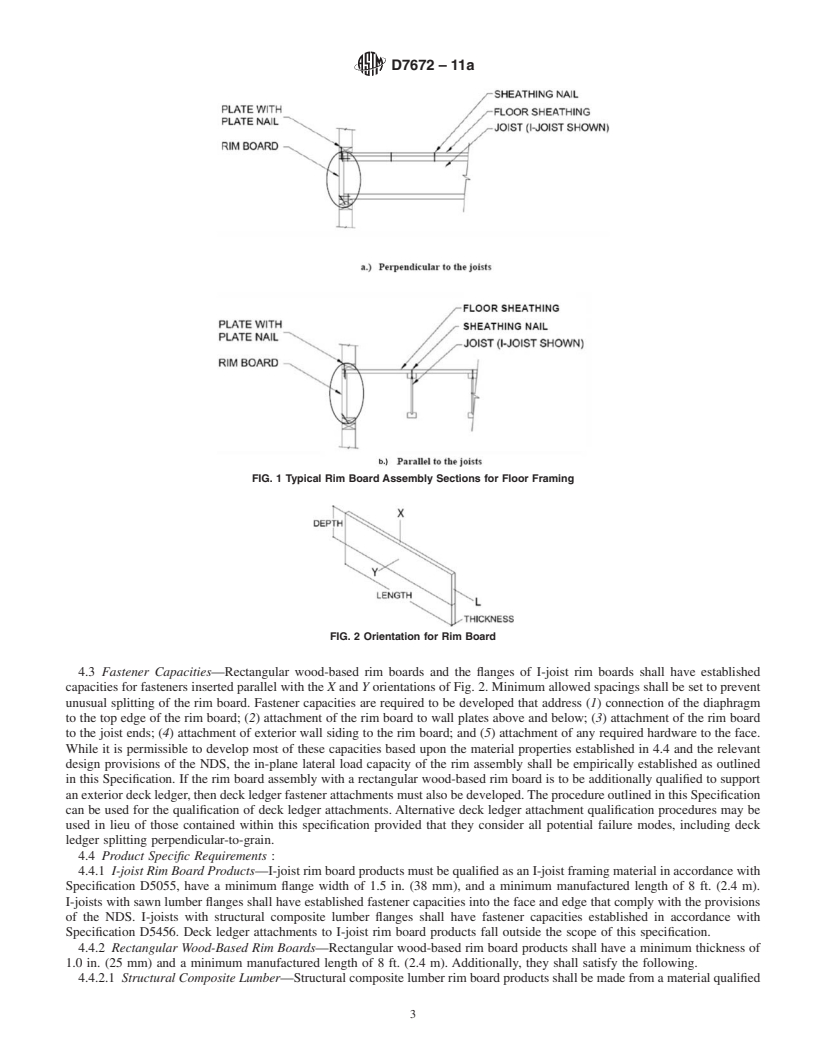

Rimboardassembliesareanengineeredcomponentwithinlight-framewoodplatformconstruction.

Rim board assemblies may serve in multiple structural capacities, including: providing floor closure

and diaphragm attachment, transferring vertical and in-plane lateral loads, restricting out-of-plane

rotation and lateral translation at the ends of the floor joists, providing deck ledger attachment, and

spanning wall openings as a header material. Rim board products, which serve a principal role as a

component integrated within a rim board assembly, can vary by wood species, size, shape, and type.

Rim board products and assemblies require evaluation of their mechanical properties, physical

properties, and their response to end use environments. Procedures established in this Specification

provideameanstotestrimboardproductsandassemblies,tojudgetheiracceptability,andtoestablish

allowable design capacities.

1. Scope 1.5 This specification provides methods to establish “allow-

ablestress”designresistancesforusewiththeNationalDesign

1.1 This specification provides procedures for testing and

Specification for Wood Construction (NDS). Derivation of

establishing the structural capacities of proprietary rim board

design resistances from the test data in accordance with “load

products and assemblies for use in light-frame wood construc-

and resistance factor design” or “limit states design” are

tion using I-joist or structural composite lumber joist framing.

beyond the scope of this specification.

It does not apply to rim board products manufactured to a

1.6 Quality control requirements are outside the scope of

commodity rim board standard.

this Specification.

1.2 This specification was developed in light of currently

1.7 The performance of a rim board product will be affected

manufactured panel, structural composite lumber, and pre-

by the constituent wood species, geometry, adhesive, and

fabricated I-joist rim board products as defined in 3.2. Mate-

production parameters. Therefore, rim board products pro-

rials that do not conform to the definitions of 3.2 are beyond

duced by each individual manufacturer shall be evaluated to

the scope of this specification.

determine their product properties, regardless of the similarity

1.3 Fire safety, sound transmission, building envelope per-

in characteristics to products produced by other manufacturers.

formance, and cutting/notching attributes of rim board prod-

1.8 Where a manufacturer produces product in more than

ucts and assemblies are all items that may need to be

one facility, each production facility shall be evaluated inde-

considered in an end-use application. These items fall outside

pendently. For additional production facilities, any revisions to

the scope of this specification.

the full qualification program in accordance with this specifi-

1.4 This specification primarily considers end use in dry

cation shall be approved by an accredited, independent quali-

service conditions, such as most protected framing members,

fying agency.

where the equilibrium moisture content for solid-sawn lumber

1.9 The values stated in inch-pound units are to be regarded

is less than 16 %.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

1

This specification is under the jurisdiction ofASTM Committee D07 on Wood

and are not considered standard.

and is the direct responsibility of Subcommittee D07.05 on Wood Assemblies.

Current edition approved Nov. 15, 2011. Published December 2011. Last

previous edition approved in 2011 as D7672–11E01. DOI: 10.1520/D7672–11a.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7672 – 11a

1.10 This standard does not purport to address all of the D7033 Practice for Establishing Design Capacities for Ori-

safety concerns, if any, associated with its use. It is the ented Strand Board (OSB) Wood-Based Structural-Use

responsibility of the user of this standard to establish appro- Panels

priate safety and health practices and determine the applica- F1667 Specification for Driven Fasteners: Nails, Spikes,

bility of regulatory limitations prior to use. and Staples

2.2 Other Standards:

2. Referenced Documents

NDS ANSI/AF&PA National Design Spe

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D7672–11 Designation: D7672 – 11a

Standard Specification for

Evaluating Structural Capacities of Rim Board Products and

1

Assemblies

This standard is issued under the fixed designation D7672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Footnote 1 was editorially updated in September 2011.

INTRODUCTION

Rimboardassembliesareanengineeredcomponentwithinlight-framewoodplatformconstruction.

Rim board assemblies may serve in multiple structural capacities, including: providing floor closure

and diaphragm attachment, transferring vertical and in-plane lateral loads, restricting out-of-plane

rotation and lateral translation at the ends of the floor joists, providing deck ledger attachment, and

spanning wall openings as a header material. Rim board products, which serve a principal role as a

component integrated within a rim board assembly, can vary by wood species, size, shape, and type.

Rim board products and assemblies require evaluation of their mechanical properties, physical

properties, and their response to end use environments. Procedures established in this Specification

provideameanstotestrimboardproductsandassemblies,tojudgetheiracceptability,andtoestablish

allowable design capacities.

1. Scope

1.1 Thisspecificationprovidesproceduresfortestingandestablishingthestructuralcapacitiesofproprietaryrimboardproducts

andassembliesforuseinlight-framewoodconstructionusingI-joistorstructuralcompositelumberjoistframing.Itdoesnotapply

to rim board products manufactured to a commodity rim board standard.

1.2 This specification was developed in light of currently manufactured panel, structural composite lumber, and pre-fabricated

I-joist rim board products as defined in 3.2. Materials that do not conform to the definitions of 3.2 are beyond the scope of this

specification.

1.3 Fire safety, sound transmission, building envelope performance, and cutting/notching attributes of rim board products and

assemblies are all items that may need to be considered in an end-use application. These items fall outside the scope of this

specification.

1.4 This specification primarily considers end use in dry service conditions, such as most protected framing members, where

the equilibrium moisture content for solid-sawn lumber is less than 16 %.

1.5 This specification provides methods to establish “allowable stress” design resistances for use with the National Design

Specification for Wood Construction (NDS). Derivation of design resistances from the test data in accordance with “load and

resistance factor design” or “limit states design” are beyond the scope of this specification.

1.6 Quality control requirements are outside the scope of this Specification.

1.7 The performance of a rim board product will be affected by the constituent wood species, geometry, adhesive, and

production parameters. Therefore, rim board products produced by each individual manufacturer shall be evaluated to determine

their product properties, regardless of the similarity in characteristics to products produced by other manufacturers.

1.8 Where a manufacturer produces product in more than one facility, each production facility shall be evaluated independently.

For additional production facilities, any revisions to the full qualification program in accordance with this specification shall be

approved by an accredited, independent qualifying agency.

1.9 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

1

This specification is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.05 on Wood Assemblies.

Current edition approved Aug. 1, 2011. Published September 2011. DOI: 10.1520/D7672–11E01.

Current edition approved Nov. 15, 2011. Published December 2011. Last previous edition approved in 2011 as D7672–11E01. DOI: 10.1520/D7672–11a.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7672 – 11a

of the use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.