ASTM C704-01

(Test Method)Standard Test Method for Abrasion Resistance of Refractory Materials at Room Temperature

Standard Test Method for Abrasion Resistance of Refractory Materials at Room Temperature

SCOPE

1.1 This test method covers the determination of relative abrasion resistance of refractory brick at room temperature. This test method can also be applied to castable refractories (see Metric Dimensions C861 and Practice C865) and plastic refractories (see Practice C1054).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 704 – 01

Standard Test Method for

Abrasion Resistance of Refractory Materials at Room

1

Temperature

This standard is issued under the fixed designation C 704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of relative 4.1 This test method measures the relative abrasion resis-

abrasion resistance of refractory brick at room temperature. tance of various refractory samples under standard conditions

This test method can also be applied to castable refractories at room temperature.

(see Metric Dimensions C 861 and Practice C 865) and plastic 4.2 The abrasion resistance of a refractory material provides

refractories (see Practice C 1054). an indication of its suitability for service in abrasion or erosive

1.2 The values stated in SI units are to be regarded as the environments.

standard. The values given in parentheses are provided for 4.3 The results obtained by this test method could be

information only. different than those obtained in service because of the different

1.3 This standard does not purport to address all of the conditions encountered.

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

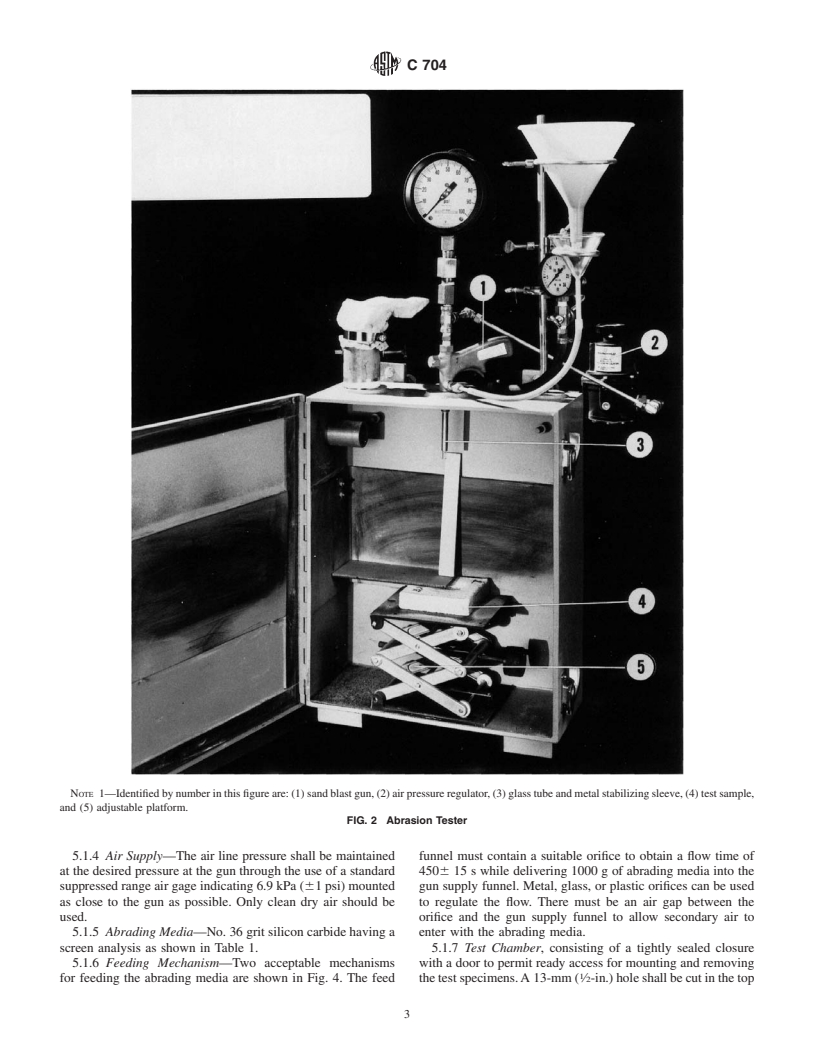

5.1 Abrasion Tester, used for measuring the abrasion resis-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. tance of refractory specimens, consisting of the following (Fig.

1 and Fig. 2):

3

2. Referenced Documents

5.1.1 Blast Gun , modified for this equipment as shown in

2.1 ASTM Standards: Fig. 3.

C 134 Test Methods for Size, Dimensional Measurements, 5.1.2 Nozzle—Apiece of glass tubing is used to replace the

and Bulk Density of Refractory Brick and Insulating steel nozzle supplied with the sand-blast gun to permit control

2

Firebrick of nozzle size through nozzle replacement after each determi-

1 1

C 179 Test Method for Drying and Firing Linear Change of nation. Flint-glass tubing, 115 mm (4 ⁄2in.) long, 7 mm ( ⁄4in.)

2

1

Refractory Plastic and Ramming Mix Specimens in outside diameter, with a nominal 1.1 mm ( ⁄16in.) wall, is

C 861 Practice for Determining Metric Dimensions of Stan- used. This piece of glass tubing is held in place by a 70 mm

2

3

dard Series Refractory Brick and Shapes (2 ⁄4 in.) long piece of stainless steel tubing. The I.D. (inside

C 862 Practice for Preparing Refractory Concrete Speci- diameter) of this tubing, which should be flared at one end to

2

3

mens by Casting sit snugly inside a 9.53 mm ( ⁄8in.) tubing nut, should be 7.15

2

9

C 865 Practice for Firing Refractory Concrete Specimens mm ( ⁄32in.). The O.D. (outside diameter) should be 9.53 mm

3

C 1054 Practice for Pressing and Drying Refractory Plastic ( ⁄8 in.). This sleeve is glued in place along with a rubber

2

3

and Ramming Mix Specimens grommet of proper size, inside the 9.53 mm ( ⁄8 in.) tubing nut,

and is used primarily to hold the glass tubing perpendicular to

3. Summary of Test Method

the test sample, assuring a proper vacuum within the gun. The

3.1 This test method measures the volume of material in end of the glass tube, through which the abrading media enters

cubic centimetres abraded from a flat surface at a right angle to

the nozzle in the venturi chamber, is placed at a distance of 2

a nozzle through which 1000 g of size-graded silicon carbide mm (0.08 in.) from the air-generator nozzle. This is done by

grain is blasted by air at 448 kPa (65 psi).

placing the glass tubing on a brass rod, 4.5 mm (0.175 in.) in

5

diameter with a shoulder 7.9 mm ( ⁄16 in.) in diameter, 117 mm

(4.68 in.) from the tip. This will allow the operator to push the

1

This test method is under the jurisdiction of ASTM Committee C08 on

glass tubing up through the rubber grommet until the rod

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

Tests and Properties.

Current edition approved Dec. 10, 2001. Published January 2002. Originally

3

published as C 704 – 72. Last previous edition C 704 – 99. The sand blast gun shown in Fig. 3, available from Leitch and Company, 971

2

Annual Book of ASTM Standards, Vol 15.01. Howard St., San Francisco, CA, has been found suitable for use in this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 704

NOTE 1—Identified by number in this figure are: (1) cabinet pressure manometer, (2) dust collector vent, (3) t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.