ASTM E2402-11

(Test Method)Standard Test Method for Mass Loss and Residue Measurement Validation of Thermogravimetric Analyzers

Standard Test Method for Mass Loss and Residue Measurement Validation of Thermogravimetric Analyzers

SIGNIFICANCE AND USE

This method may be used to validate the performance of a specific TGA apparatus.

This method may be used to validate the performance of a specific method based upon a TGA mass loss or residue measurement.

This method may be used to determine the repeatability of a specific apparatus, operator or laboratory.

This method may be used for specification and regulatory compliance purposes.

SCOPE

1.1 This method provides procedures for validating mass loss and residue measurements by thermogravimetric analyzers (TGA) and analytical methods based upon the measurement of mass loss or residue content. Performance parameters determined include mass loss and residue repeatability (precision), detection limit, quantitation limit, linearity and bias.

1.2 Validation of apparatus performance and analytical methods is requested or required for quality initiatives or where results may be used for legal purposes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 There is no ISO standard equivalent to this method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2402 − 11

Standard Test Method for

Mass Loss and Residue Measurement Validation of

1

Thermogravimetric Analyzers

This standard is issued under the fixed designation E2402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2040 Test Method for Mass Scale Calibration of Thermo-

gravimetric Analyzers

1.1 This method provides procedures for validating mass

E2161 Terminology Relating to Performance Validation in

lossandresiduemeasurementsbythermogravimetricanalyzers

Thermal Analysis

(TGA) and analytical methods based upon the measurement of

2.2 Other Standard:

mass loss or residue content. Performance parameters deter-

mined include mass loss and residue repeatability (precision), United States Food and Drug Administration, Q2B Valida-

tion of Analytical Procedures: Methodology, 62 FR

detection limit, quantitation limit, linearity and bias.

3

27464, May 19, 1997

1.2 Validation of apparatus performance and analytical

methodsisrequestedorrequiredforqualityinitiativesorwhere

3. Terminology

results may be used for legal purposes.

3.1 Technical terms used in this standard are defined in

1.3 The values stated in SI units are to be regarded as

Practice E177 and in Terminologies E473, E1142, and E2161.

standard. No other units of measurement are included in this

3.2 Definitions of Terms Specific to This Standard:

standard.

3.2.1 highly volatile matter—materials (such as moisture,

1.4 There is no ISO standard equivalent to this method.

plasticizer, residual solvent, etc.) that boil at temperatures

1.5 This standard does not purport to address all of the

below 200 °C.

safety concerns, if any, associated with its use. It is the

3.2.2 medium volatile matter—materials (such as oil and

responsibility of the user of this standard to establish appro-

polymer degradation products) that boil in the temperature

priate safety and health practices and determine the applica-

range between 200 and 400 °C.

bility of regulatory limitations prior to use.

3.2.3 residue—material remaining (such as metal

2. Referenced Documents components, filler content or inert reinforcing materials) after

2 more volatile components are vaporized.

2.1 ASTM Standards:

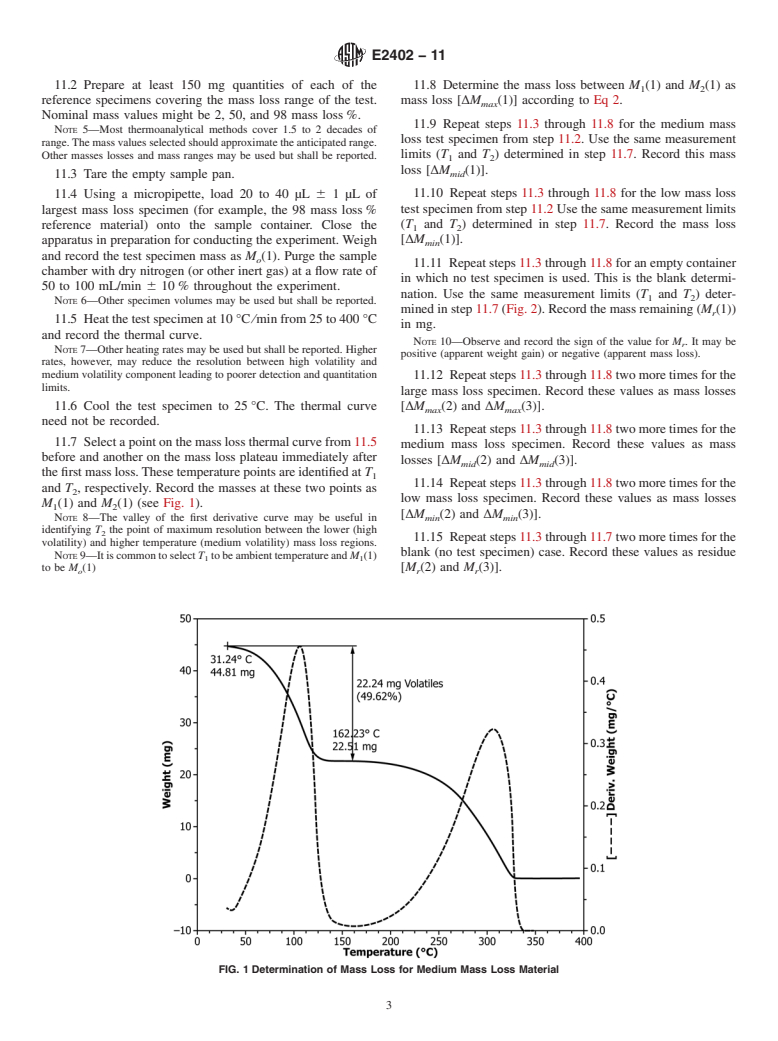

3.2.4 mass loss plateau—a region of a thermogravimetric

E177 Practice for Use of the Terms Precision and Bias in

curve with a relatively constant mass (that is, accompanied by

ASTM Test Methods

a minima in the first derivative of mass with respect to time).

E473 Terminology Relating to Thermal Analysis and Rhe-

ology

4. Summary of Test Method

E1142 Terminology Relating to Thermophysical Properties

E1582 Practice for Calibration of Temperature Scale for

4.1 Mass is the primary dependent parameter and tempera-

Thermogravimetry

ture is the primary independent parameter measured by TGA.

E1970 PracticeforStatisticalTreatmentofThermoanalytical

4.2 Mass loss and residue measurements are validated by

Data

their direct measurement using thermogravimetric apparatus

over a specified temperature range using reference materials of

known volatiles content as an analyte.

1

This test method is under the jurisdiction ofASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.10 on

4.3 Alternatively, validation of a TGA method based upon

Fundamental, Statistical and Mechanical Properties.

mass loss and residue measurements may be performed using

Current edition approved April 1, 2011. Published May 2011. Originally

a specific test specimen as the analyte.

approved in 2005. Last previous edition approved in 2005 as E2402 – 05. DOI:

10.1520/E2402-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Food and Drug Administration (FDA), 10903 New Hampshire

the ASTM website. Ave., Silver Spring, MD 20993-0002, http://www.fda.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2402 − 11

4.4 The mass loss of three or more specimens (nominally 7.1.2 A temperature controller capable of executing a spe-

representing the maximum, midpoint and minimum of the cific temperature program by operating the furnace between

range of the test method) is measured at least in triplicate. A selected temperature limits at a rate of temperature change of

fourth blank specimen, containing no analyte, is also measured 5 to 25 °C⁄min to within 6 0.5 °C⁄min.

a

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2402–05 Designation:E2402–11

Standard Test Method for

Mass Loss and Residue Measurement Validation of

1

Thermogravimetric Analyzers

This standard is issued under the fixed designation E2402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thismethodprovidesproceduresforvalidatingmasslossandresiduemeasurementsbythermogravimetricanalyzers(TGA)

and analytical methods based upon the measurement of mass loss or residue content. Performance parameters determined include

mass loss and residue repeatability (precision), detection limit, quantitation limit, linearity and bias.

1.2 Validation of apparatus performance and analytical methods is requested or required for quality initiatives or where results

may be used for legal purposes.

1.3SI units are the standard.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 There is no ISO standard equivalent to this method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E473 Terminology Relating to Thermal Analysis and Rheology

E1142 Terminology Relating to Thermophysical Properties

E1582 Practice for Calibration of Temperature Scale for Thermogravimetry

E1970 Practice for Statistical Treatment of Thermoanalytical Data

E2040 Test Method for Mass Scale Calibration of Thermogravimetric Analyzers

E2161 Terminology Relating to Performance Validation in Thermal Analysis

2.2 Other Standard:

United States Food and Drug Administration, Q2B Validation of Analytical Procedures: Methodology, 62 FR 27464, May 19,

3

1997

3. Terminology

3.1 Technical terms used in this standard are defined in Practice E177 and in Terminologies E473, E1142, and E2161.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 highly volatile matter—materials (such as moisture, plasticizer, residual solvent, etc.) that boil at temperatures below

200 °C.

3.2.2 medium volatile matter—materials (such as oil and polymer degradation products) that boil in the temperature range

between 200 and 400 °C.

3.2.3 residue—material remaining (such as metal components, filler content or inert reinforcing materials) after more volatile

components are vaporized.

3.2.4 mass loss plateau—a region of a thermogravimetric curve with a relatively constant mass (that is, accompanied by a

minima in the first derivative of mass with respect to time).

1

This test method is under the jurisdiction ofASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

Current edition approved Jan. 1, 2005. Published February 2005. DOI: 10.1520/E2402-05.

CurrenteditionapprovedApril1,2011.PublishedMay2011.Originallyapprovedin2005.Lastpreviouseditionapprovedin2005asE2402 – 05.DOI:10.1520/E2402-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from FDA, 5600 Fishers Lane, Rockville, MD 20857.

3

Available from Food and Drug Administration (FDA), 10903 New Hampshire Ave., Silver Spring, MD 20993-0002, http://www.fda.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2402–11

4. Summary of Test Method

4.1 Mass is the primary dependent parameter and temperature is the primary independent parameter measured by TGA.

4.2 Mass loss and residue measurements are validated by their direct measurement using thermogravimetric apparatus over a

specified temperature range using reference materials of known volatiles content as an analyte.

4.3 Alternatively, validation of a TGA method based upon mass loss and residue measurements may be performed using a

specific test specimen as the analyte.

4.4 The mass loss

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.