ASTM B609/B609M-12(2016)

(Specification)Standard Specification for Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes

Standard Specification for Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes

ABSTRACT

This specification covers annealed and intermediate tempered round aluminum wires suitable for electrical purposes like stranding into conductors or for solid single conductors, either bare or insulated. The tempers covered here are 1350-O, 1350-H12 or 1350-H22, 1350-H14 or 1350-H24, 1350-H16 or 1350-H26, and 1350-H142 or 1350-H242. Materials shall be made from drawing stock in which the manufacturer shall have the option of producing the intermediate tempers by either strain-hardening only, by strain-hardening and partial annealing. The wires shall adhere to standard nominal diameters, cross-sectional areas, masses per unit length, and densities. Wires shall also be tested to evaluate their conformance to specified values of tensile strength and electrical resistivity.

SCOPE

1.1 This specification covers aluminum 1350-O (annealed), 1350-H12 or -H22 (1/4 hard), 1350-H14 or -H24 (1/2 hard), 1350-H16 or -H26 (3/4 hard) and 1350-H142 or -H242 (1/2 hard), suitable for stranding into conductors or for solid single conductors, either bare or insulated (see Table 1 or Table 2).

1.2 The values stated in inch-pound units or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

Note 1: Prior to 1975, aluminum 1350 was designated as EC-aluminum.

Note 2: The aluminum and temper designations conform to ANSI H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E527.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B609/B609M −12 (Reapproved 2016)

Standard Specification for

Aluminum 1350 Round Wire, Annealed and Intermediate

Tempers, for Electrical Purposes

This standard is issued under the fixed designation B609/B609M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B682 SpecificationforMetricSizesofElectricalConductors

B830 Specification for Uniform Test Methods and Fre-

1.1 This specification covers aluminum 1350-O (annealed),

quency

1 1

1350-H12 or -H22 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2 hard),

E29 Practice for Using Significant Digits in Test Data to

3 1

1350-H16 or -H26 ( ⁄4 hard) and 1350-H142 or -H242 ( ⁄2

Determine Conformance with Specifications

hard), suitable for stranding into conductors or for solid single

E527 Practice for Numbering Metals and Alloys in the

conductors, either bare or insulated (see Table 1 or Table 2).

Unified Numbering System (UNS)

1.2 The values stated in inch-pound units or SI units are to 3

2.3 ANSI Standard:

be regarded separately as standard. The values in each system

ANSI H35.1 American National Standard for Alloy and

are not exact equivalents; therefore, each system shall be used

Temper Designation Systems for Aluminum

independently of the other. Combining values from the two

ANSI H35.1[M] American National Standard for Alloy and

systems may result in nonconformance with the specification.

Temper Designation Systems for Aluminum

1.2.1 For density, resistivity, and temperature, the values

2.4 NIST Standards:

stated in SI units are to be regarded as standard.

NBS Handbook 100 —Copper Wire Tables of the National

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC- Bureau of Standards

aluminum.

NBS Handbook 109 —Aluminum Wire Tables of the Na-

NOTE 2—The aluminum and temper designations conform to ANSI

tional Bureau of Standards

H35.1. Aluminum 1350 corresponds to Unified Numbering System

A91350 in accordance with Practice E527.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.1.1 lot, n—a group of production units, up to 30 000 lb of

2.1 The following documents of the issue in effect on date

mass, of one type and size of wire, which was produced during

of material purchase form a part of this specification to the

the same time period, under similar production conditions, and

extent referenced herein.

is presented for acceptance at the same time (Explanatory Note

2.2 ASTM Standards:

5).

B193 Test Method for Resistivity of Electrical Conductor

3.1.2 production unit, n—a coil, reel, spool, or other pack-

Materials

age of wire that represents a single usable length.

B233 Specification for Aluminum 1350 Drawing Stock for

3.1.3 sample, n—the production unit or units from which a

Electrical Purposes

test specimen or specimens has been removed, and which is

B354 Terminology Relating to Uninsulated Metallic Electri-

considered to have properties representative of the lot.

cal Conductors

B557 Test Methods for Tension Testing Wrought and Cast

3.1.4 specimen, n—a length of wire removed for test pur-

Aluminum- and Magnesium-Alloy Products

poses.

4. Ordering Information

This specification is under the jurisdiction of ASTM Committee B01 on

4.1 Orders for material under this specification shall include

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

the following information:

Conductors of Light Metals.

4.1.1 Quantity of each size,

Current edition approved Oct. 1, 2016. Published October 2016. Originally

ɛ1

approved in 1977. Last previous edition approved in 2012 as B609/B609M – 12 .

DOI: 10.1520/B0609_B0609M-12R16.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B609/B609M−12 (2016)

TABLE 1 Standard Nominal Diameters, Cross-Sectional Areas, and Mass Per Unit Length of Solid Round Aluminum Wires and

Conductors at 20°C AWG or cmil Sizes

NOTE 1—Metric values listed as follows represent a soft conversion and as such they may not be the same as those metric mass per unit length which

are calculated from the basic metric density.

Conversion factors:

1 lb/1000 ft = 1.488 ft + 00 kg/km

1 in. = 25.4 mm

Diameter Cross-Sectional Area Mass Per Unit Length

Size cmil

2 2

or AWG

mils mm cmil in. mm lb/1000 ft kg/km

500 000 707.1 17.960 500 000 0.3927 253.3 459.4 683.7

450 000 670.8 17.040 450 000 0.3534 228.0 413.5 615.3

400 000 632.5 16.070 400 000 0.3142 202.7 367.6 547.0

350 000 591.6 15.030 350 000 0.2749 177.3 321.6 478.6

300 000 547.7 13.910 300 000 0.2356 152.0 275.7 410.2

250 000 500.0 12.700 250 000 0.1963 126.7 229.7 341.8

0000 460.0 11.680 211 600 0.1662 107.2 194.4 289.3

000 409.6 10.4000 167 800 0.1318 85.01 154.2 229.4

00 364.8 9.2660 133 100 0.1045 67.43 122.3 182.0

0 324.9 8.2520 105 600 0.08291 53.49 97.00 144.3

1 289.3 7.3480 83 690 0.06573 42.41 76.91 114.4

2 257.6 6.5430 66 360 0.05212 33.62 60.98 90.73

3 229.4 5.8270 52 620 0.04133 26.67 48.36 71.96

4 204.3 5.1890 41 740 0.03278 21.15 38.35 57.07

5 181.9 4.6200 33 090 0.02599 16.77 30.40 45.24

6 162.0 4.1150 26 240 0.02061 13.30 24.12 35.88

7 144.3 3.6650 20 820 0.01635 10.55 19.13 28.47

8 128.5 3.2640 16 510 0.01297 8.67 15.17 22.58

9 114.4 2.9060 13 090 0.01028 6.631 12.03 17.89

10 101.9 2.5880 10 380 0.008455 5.261 9.542 14.20

11 90.7 2.3040 8 226 0.006461 4.168 7.559 11.25

12 80.8 2.0520 6 529 0.005128 3.308 5.999 8.927

13 72.0 1.8290 5 184 0.004072 2.627 4.764 7.088

14 64.1 1.6280 4 109 0.003227 2.082 3.776 5.618

15 57.1 1.4500 3 260 0.002561 1.652 2.996 4.458

16 50.8 1.2900 2 581 0.002027 1.308 2.371 3.529

17 45.3 1.1510 2 052 0.001612 1.040 1.886 2.806

18 40.3 1.0240 1 624 0.001276 0.8229 1.492 2.221

19 35.9 0.9119 1 289 0.001012 0.6531 1.184 1.762

20 32.0 0.8128 1 024 0.0008042 0.5189 0.9410 1.400

21 28.5 0.7239 812.2 0.0006379 0.4116 0.7464 1.111

22 25.3 0.6426 640.1 0.0005027 0.3243 0.5882 0.8752

23 22.6 0.5740 510.8 0.0004011 0.2588 0.4693 0.6984

24 20.1 0.5105 404.0 0.0003173 0.2047 0.3713 0.5542

25 17.9 0.4547 320.4 0.0002516 0.1624 0.2944 0.4381

26 15.9 0.4039 252.8 0.0001986 0.1281 0.2323 0.3457

27 14.2 0.3607 201.6 0.0001589 0.1022 0.1853 0.2757

28 12.6 0.3200 158.8 0.0001247 0.08045 0.1459 0.2171

29 11.3 0.2870 127.7 0.0001003 0.06470 0.1173 0.1746

30 10.0 0.2540 100.0 0.00007854 0.05067 0.09189 0.1367

4.1.2 Wiresize;diameterininchesormillimetres(see11.1), strain-hardening only (H12, H14, H16, H142) or by strain-

4.1.3 Temper (Section 5), hardening and partial annealing (H22, H24, H26, H242)

4.1.4 Special tension test if required (see 7.2), (Explanatory Note 1 and ANSI H35.1 or ANSI H35.1[M]).

4.1.5 Special jointing procedures if permitted (see 12.2), 5.2.1 When the manufacturer is to be given the option in

4.1.6 Place of inspection (see 15.2), 5.2, the intermediate tempers should be specified as H12 or

4.1.7 Package size and type (see 16.1), and H22, H14 or H24, H16 or H26, or H142 or H242.

4.1.8 Special package marking, if required, (see 16.1). 5.2.2 When the manufacturer is not to be given the option in

5.2, the specific temper must be specified, for example, H12,

5. Materials and Manufacture

H22, and so forth.

5.1 The aluminum wire shall be made from drawing stock

meeting the requirements of Specification B233. 6. Workmanship, Finish, and Appearance

5.2 Unless otherwise specified, the manufacturer shall have 6.1 The wire shall be free of imperfections not consistent

the option of producing the intermediate tempers by either with good commercial practice.

B609/B609M−12 (2016)

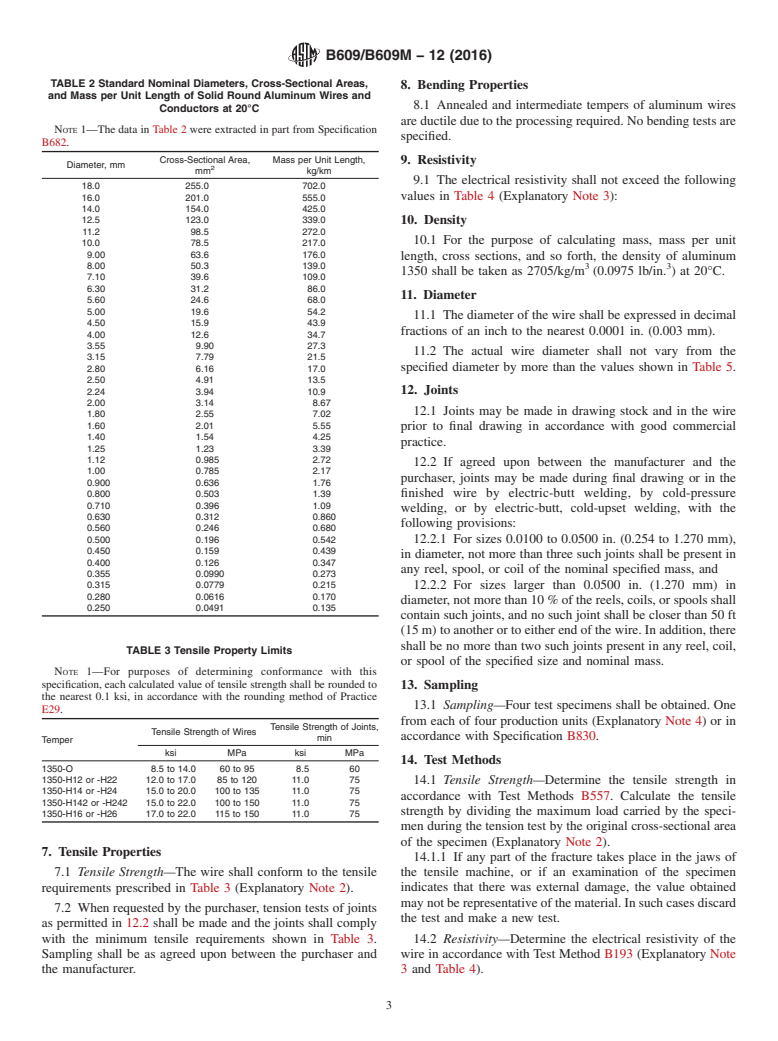

TABLE 2 Standard Nominal Diameters, Cross-Sectional Areas,

8. Bending Properties

and Mass per Unit Length of Solid Round Aluminum Wires and

8.1 Annealed and intermediate tempers of aluminum wires

Conductors at 20°C

are ductile due to the processing required. No bending tests are

NOTE 1—The data in Table 2 were extracted in part from Specification

specified.

B682.

Cross-Sectional Area, Mass per Unit Length,

9. Resistivity

Diameter, mm

mm kg/km

9.1 The electrical resistivity shall not exceed the following

18.0 255.0 702.0

16.0 201.0 555.0 values in Table 4 (Explanatory Note 3):

14.0 154.0 425.0

12.5 123.0 339.0

10. Density

11.2 98.5 272.0

10.1 For the purpose of calculating mass, mass per unit

10.0 78.5 217.0

9.00 63.6 176.0

length, cross sections, and so forth, the density of aluminum

8.00 50.3 139.0 3 3

1350 shall be taken as 2705/kg/m (0.0975 lb/in. ) at 20°C.

7.10 39.6 109.0

6.30 31.2 86.0

11. Diameter

5.60 24.6 68.0

5.00 19.6 54.2

11.1 The diameter of the wire shall be expressed in decimal

4.50 15.9 43.9

fractions of an inch to the nearest 0.0001 in. (0.003 mm).

4.00 12.6 34.7

3.55 9.90 27.3

11.2 The actual wire diameter shall not vary from the

3.15 7.79 21.5

specified diameter by more than the values shown in Table 5.

2.80 6.16 17.0

2.50 4.91 13.5

2.24 3.94 10.9 12. Joints

2.00 3.14 8.67

12.1 Joints may be made in drawing stock and in the wire

1.80 2.55 7.02

1.60 2.01 5.55

prior to final drawing in accordance with good commercial

1.40 1.54 4.25

practice.

1.25 1.23 3.39

1.12 0.985 2.72

12.2 If agreed upon between the manufacturer and the

1.00 0.785 2.17

purchaser, joints may be made during final drawing or in the

0.900 0.636 1.76

0.800 0.503 1.39 finished wire by electric-butt welding, by cold-pressure

0.710 0.396 1.09

welding, or by electric-butt, cold-upset welding, with the

0.630 0.312 0.860

following provisions:

0.560 0.246 0.680

0.500 0.196 0.542 12.2.1 For sizes 0.0100 to 0.0500 in. (0.254 to 1.270 mm),

0.450 0.159 0.439

in diameter, not more than three such joints shall be present in

0.400 0.126 0.347

any reel, spool, or coil of the nominal specified mass, and

0.355 0.0990 0.273

0.315 0.0779 0.215 12.2.2 For sizes larger than 0.0500 in. (1.270 mm) in

0.280 0.0616 0.170

diameter, not more than 10 % of the reels, coils, or spools shall

0.250 0.0491 0.135

contain such joints, and no such joint shall be closer than 50 ft

(15 m) to another or to either end of the wire. In addition, there

shall be no more than two such joints present in any reel, coil,

TABLE 3 Tensile Property Limits

or spool of the specified size and nominal mass.

NOTE 1—For purposes of determining conformance with this

specification, each calculated value of tensile strength shall be rounded to

13. Sampling

the nearest 0.1 ksi, in accordance with the rounding method of Practice

13.1 Sampling—Four test specimens shall be obtained. One

E29.

from each of four production units (Explanatory Note 4)orin

Tensile Strength of Joints,

Tensile Strength of Wires

accordance with Specification B830.

min

Temper

ksi MPa ksi MPa

14. Test Methods

1350-O 8.5 to 14.0 60 to 95 8.5 60

1350-H12 or -H22 12.0 to 17.0 85 to 120 11.0 75

14.1 Tensile Strength—Determine the tensile strength in

1350-H14 or -H24 15.0 to 20.0 100 to 135 11.0 75

accordance with Test Methods B557. Calculate the tensile

1350-H142 or -H242 15.0 to 22.0 100 to 150 11.0 75

strength by dividing the maximum load carried by the speci-

1350-H16 or -H26 17.0 to 22.0 115 to 150 11.0 75

men during the tension test by the original cross-sectional area

of the specimen (Explanatory Note 2).

7. Tensile Properties

14.1.1 If any part of the fracture takes place in the jaws of

7.1 Tensile Strength—The wire shall conform to the tensile the tensile machine, or if an examination of the specimen

requirements prescribed in Table 3 (Explanatory Note 2). indicates that there was external damage, the value obtained

may not be representative of the material. In such cases discard

7.2 When requested by the purchaser, tension tests of joints

the test and make a new test.

as permitted in 12.2 shall be made and the joints shall comply

with the minimum tensile requirements shown in Table 3. 14.2 Resistivity—Determine the electrical resistivity of the

Sampling shall be as agreed upon between the purchaser and wire in accordance with Test Method B193 (Explanatory Note

the manufacturer. 3 and Table 4).

B609/B609M−12 (2016)

A

TABLE 4 Equivalent Resistivity Requirements and Equivalent Copper Resistivity at 20°C

Resistivity Constants

Volume Conductivity,

Material Volume

% IACS

Ω·cmil/ft Ω·mm /m µΩ·in. µΩ·cm

Copper Equivalent 100 10.371 0.017241 0.67879 1.7241

1350 Aluminum H_2 through 61.0 17.002 0.028264 1.1128 2.8264

H_6

1350-O Temper Aluminum 61.8 16.782 0.027899 1.0984 2.7899

A 2

The equivalent resistivity values for 100 % IACS (soft copper) were each computed from the fundamental IEC value (1/58Ω·mm /m) using conversion factors each

accurate to at least seven significant figures. Corresponding values for other conductivities (aluminum) were derived from these by multiplying by the reciprocal of the

conductivity ratios accurate to at least seven significant figures.

TABLE 5 Diameter Tolerances

14.6.4 If the lot average results for one or more of the tested

Permissible Variations of Mean Diameter properties is not in conformance, but all the individual speci-

Specified Diameter, in. (mm)

from Specified Diameter, plus and minus

men results are in conformance, then additional test specimens

0.0100 to under 0.0360 0.0005 in. (0.013 mm)

and tests shall be required as follows:

(0.254 to under 0.914)

14.6.4.1 An additional six test specimens shall be obtained,

0.0360 to under 0.1000 0.0010 in. (0.025 mm)

(0.914 to under 2.540)

one each from six production units other than the four

0.1000 to 0.7071, incl 1%

originally sampled. Tests shall be run on the six additional

(2.540 to 17.960, incl)

specimens,andanumericalaverageofthetentestedspecimens

shall be calculated and considered the lot average.

14.6.4.2 If the ten specimen lot average results are in

conformance, and all ten of the individual specimen results are

in conformance, the lot shall be considered in conformance.

14.3 Diameter Measurements—Measurethediameterwitha

micrometer caliper graduated in 0.0001 in. (0.003 mm). Make 14.6.4.3 If the ten specimen lot average results for one or

more of the tested properties are not in conformance, or if one

measurements on each speci

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B609/B609M − 12 B609/B609M − 12 (Reapproved 2016)

Standard Specification for

Aluminum 1350 Round Wire, Annealed and Intermediate

Tempers, for Electrical Purposes

This standard is issued under the fixed designation B609/B609M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reference to Note 5 in 3.1.1 was editorially corrected in May 2015.

1. Scope

1 1

1.1 This specification covers aluminum 1350-O (annealed), 1350-H12 or -H22 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2 hard),

3 1

1350-H16 or -H26 ( ⁄4 hard) and 1350-H142 or -H242 ( ⁄2 hard), suitable for stranding into conductors or for solid single

conductors, either bare or insulated (see Table 1 or Table 2).

1.2 The values stated in inch-pound units or SI units are to be regarded separately as standard. The values in each system are

not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems

may result in nonconformance with the specification.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC-aluminum.

NOTE 2—The aluminum and temper designations conform to ANSI H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in

accordance with Practice E527.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B233 Specification for Aluminum 1350 Drawing Stock for Electrical Purposes

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B682 Specification for Metric Sizes of Electrical Conductors

B830 Specification for Uniform Test Methods and Frequency

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.3 ANSI Standard:

ANSI H35.1 American National Standard for Alloy and Temper Designation Systems for Aluminum

ANSI H35.1[M] American National Standard for Alloy and Temper Designation Systems for Aluminum

2.4 NIST Standards:

NBS Handbook 100 Handbook 100—Copper —Copper Wire Tables of the National Bureau of Standards

NBSNBS Handbook 109 Handbook 109—Aluminum —Aluminum Wire Tables of the National Bureau of Standards

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved April 1, 2012Oct. 1, 2016. Published May 2012October 2016. Originally approved in 1977. Last previous edition approved in 20102012 as

ɛ1

B609/B609M – 99 (2010).B609/B609M – 12 . DOI: 10.1520/B0609_B0609M-12E01.10.1520/B0609_B0609M-12R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from National Technical Information Service (NTIS), 5301 Shawnee Rd., Alexandria, VA 22312, http://www.ntis.gov.Institute of Standards and Technology

(NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B609/B609M − 12 (2016)

TABLE 1 Standard Nominal Diameters, Cross-Sectional Areas, and Mass Per Unit Length of Solid Round Aluminum Wires and

Conductors at 20°C AWG or cmil Sizes

NOTE 1—Metric values listed as follows represent a soft conversion and as such they may not be the same as those metric mass per unit length which

are calculated from the basic metric density.

Conversion factors:

1 lb/1000 ft = 1.488 ft + 00 kg/km

1 in. = 25.4 mm

Diameter Cross-Sectional Area Mass Per Unit Length

Size cmil

2 2

or AWG

mils mm cmil in. mm lb/1000 ft kg/km

500 000 707.1 17.960 500 000 0.3927 253.3 459.4 683.7

450 000 670.8 17.040 450 000 0.3534 228.0 413.5 615.3

400 000 632.5 16.070 400 000 0.3142 202.7 367.6 547.0

350 000 591.6 15.030 350 000 0.2749 177.3 321.6 478.6

300 000 547.7 13.910 300 000 0.2356 152.0 275.7 410.2

250 000 500.0 12.700 250 000 0.1963 126.7 229.7 341.8

0000 460.0 11.680 211 600 0.1662 107.2 194.4 289.3

000 409.6 10.4000 167 800 0.1318 85.01 154.2 229.4

00 364.8 9.2660 133 100 0.1045 67.43 122.3 182.0

0 324.9 8.2520 105 600 0.08291 53.49 97.00 144.3

1 289.3 7.3480 83 690 0.06573 42.41 76.91 114.4

2 257.6 6.5430 66 360 0.05212 33.62 60.98 90.73

3 229.4 5.8270 52 620 0.04133 26.67 48.36 71.96

4 204.3 5.1890 41 740 0.03278 21.15 38.35 57.07

5 181.9 4.6200 33 090 0.02599 16.77 30.40 45.24

6 162.0 4.1150 26 240 0.02061 13.30 24.12 35.88

7 144.3 3.6650 20 820 0.01635 10.55 19.13 28.47

8 128.5 3.2640 16 510 0.01297 8.67 15.17 22.58

9 114.4 2.9060 13 090 0.01028 6.631 12.03 17.89

10 101.9 2.5880 10 380 0.008455 5.261 9.542 14.20

11 90.7 2.3040 8 226 0.006461 4.168 7.559 11.25

12 80.8 2.0520 6 529 0.005128 3.308 5.999 8.927

13 72.0 1.8290 5 184 0.004072 2.627 4.764 7.088

14 64.1 1.6280 4 109 0.003227 2.082 3.776 5.618

15 57.1 1.4500 3 260 0.002561 1.652 2.996 4.458

16 50.8 1.2900 2 581 0.002027 1.308 2.371 3.529

17 45.3 1.1510 2 052 0.001612 1.040 1.886 2.806

18 40.3 1.0240 1 624 0.001276 0.8229 1.492 2.221

19 35.9 0.9119 1 289 0.001012 0.6531 1.184 1.762

20 32.0 0.8128 1 024 0.0008042 0.5189 0.9410 1.400

21 28.5 0.7239 812.2 0.0006379 0.4116 0.7464 1.111

22 25.3 0.6426 640.1 0.0005027 0.3243 0.5882 0.8752

23 22.6 0.5740 510.8 0.0004011 0.2588 0.4693 0.6984

24 20.1 0.5105 404.0 0.0003173 0.2047 0.3713 0.5542

25 17.9 0.4547 320.4 0.0002516 0.1624 0.2944 0.4381

26 15.9 0.4039 252.8 0.0001986 0.1281 0.2323 0.3457

27 14.2 0.3607 201.6 0.0001589 0.1022 0.1853 0.2757

28 12.6 0.3200 158.8 0.0001247 0.08045 0.1459 0.2171

29 11.3 0.2870 127.7 0.0001003 0.06470 0.1173 0.1746

30 10.0 0.2540 100.0 0.00007854 0.05067 0.09189 0.1367

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot, n—a group of production units, up to 30 000 lb of mass, of one type and size of wire, which was produced during the

same time period, under similar production conditions, and is presented for acceptance at the same time (Explanatory Note 5).

3.1.2 production unit, n—a coil, reel, spool, or other package of wire that represents a single usable length.

3.1.3 sample, n—the production unit or units from which a test specimen or specimens has been removed, and which is

considered to have properties representative of the lot.

3.1.4 specimen, n—a length of wire removed for test purposes.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

B609/B609M − 12 (2016)

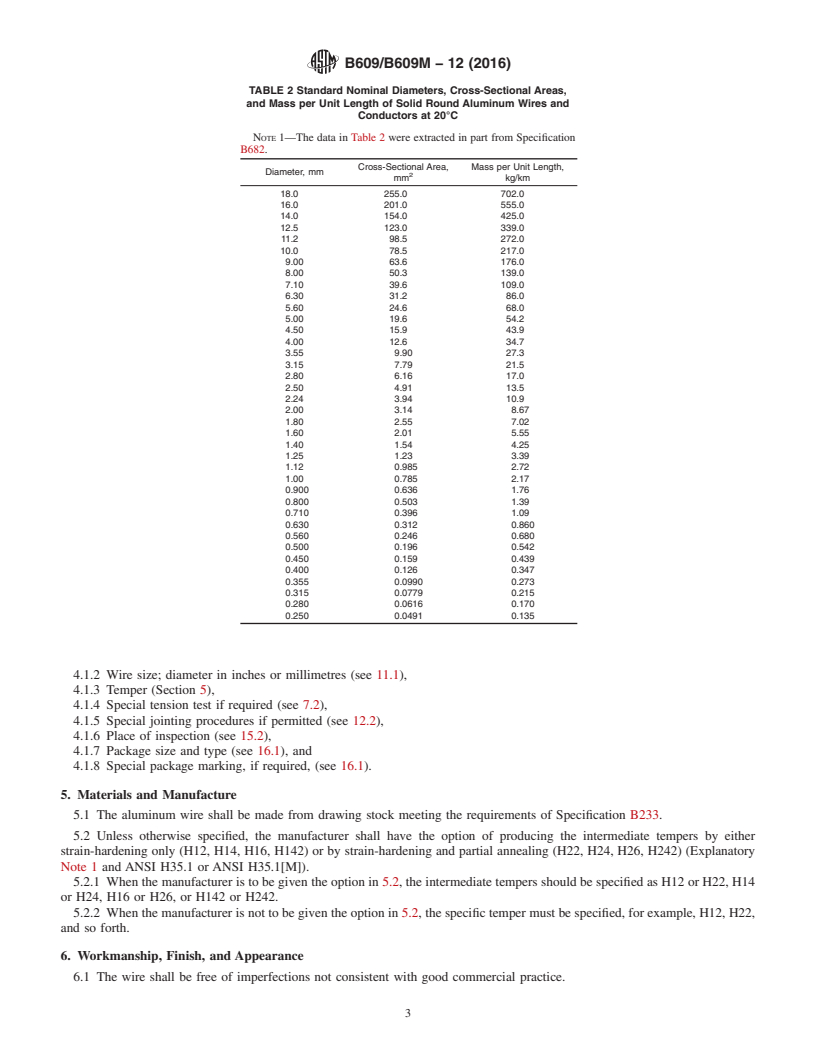

TABLE 2 Standard Nominal Diameters, Cross-Sectional Areas,

and Mass per Unit Length of Solid Round Aluminum Wires and

Conductors at 20°C

NOTE 1—The data in Table 2 were extracted in part from Specification

B682.

Cross-Sectional Area, Mass per Unit Length,

Diameter, mm

mm kg/km

18.0 255.0 702.0

16.0 201.0 555.0

14.0 154.0 425.0

12.5 123.0 339.0

11.2 98.5 272.0

10.0 78.5 217.0

9.00 63.6 176.0

8.00 50.3 139.0

7.10 39.6 109.0

6.30 31.2 86.0

5.60 24.6 68.0

5.00 19.6 54.2

4.50 15.9 43.9

4.00 12.6 34.7

3.55 9.90 27.3

3.15 7.79 21.5

2.80 6.16 17.0

2.50 4.91 13.5

2.24 3.94 10.9

2.00 3.14 8.67

1.80 2.55 7.02

1.60 2.01 5.55

1.40 1.54 4.25

1.25 1.23 3.39

1.12 0.985 2.72

1.00 0.785 2.17

0.900 0.636 1.76

0.800 0.503 1.39

0.710 0.396 1.09

0.630 0.312 0.860

0.560 0.246 0.680

0.500 0.196 0.542

0.450 0.159 0.439

0.400 0.126 0.347

0.355 0.0990 0.273

0.315 0.0779 0.215

0.280 0.0616 0.170

0.250 0.0491 0.135

4.1.2 Wire size; diameter in inches or millimetres (see 11.1),

4.1.3 Temper (Section 5),

4.1.4 Special tension test if required (see 7.2),

4.1.5 Special jointing procedures if permitted (see 12.2),

4.1.6 Place of inspection (see 15.2),

4.1.7 Package size and type (see 16.1), and

4.1.8 Special package marking, if required, (see 16.1).

5. Materials and Manufacture

5.1 The aluminum wire shall be made from drawing stock meeting the requirements of Specification B233.

5.2 Unless otherwise specified, the manufacturer shall have the option of producing the intermediate tempers by either

strain-hardening only (H12, H14, H16, H142) or by strain-hardening and partial annealing (H22, H24, H26, H242) (Explanatory

Note 1 and ANSI H35.1 or ANSI H35.1[M]).

5.2.1 When the manufacturer is to be given the option in 5.2, the intermediate tempers should be specified as H12 or H22, H14

or H24, H16 or H26, or H142 or H242.

5.2.2 When the manufacturer is not to be given the option in 5.2, the specific temper must be specified, for example, H12, H22,

and so forth.

6. Workmanship, Finish, and Appearance

6.1 The wire shall be free of imperfections not consistent with good commercial practice.

B609/B609M − 12 (2016)

TABLE 3 Tensile Property Limits

NOTE 1—For purposes of determining conformance with this

specification, each calculated value of tensile strength shall be rounded to

the nearest 0.1 ksi, in accordance with the rounding method of Practice

E29.

Tensile Strength of Joints,

Tensile Strength of Wires

min

Temper

ksi MPa ksi MPa

1350-O 8.5 to 14.0 60 to 95 8.5 60

1350-H12 or -H22 12.0 to 17.0 85 to 120 11.0 75

1350-H14 or -H24 15.0 to 20.0 100 to 135 11.0 75

1350-H142 or -H242 15.0 to 22.0 100 to 150 11.0 75

1350-H16 or -H26 17.0 to 22.0 115 to 150 11.0 75

7. Tensile Properties

7.1 Tensile Strength—The wire shall conform to the tensile requirements prescribed in Table 3 (Explanatory Note 2).

7.2 When requested by the purchaser, tension tests of joints as permitted in 12.2 shall be made and the joints shall comply with

the minimum tensile requirements shown in Table 3. Sampling shall be as agreed upon between the purchaser and the

manufacturer.

8. Bending Properties

8.1 Annealed and intermediate tempers of aluminum wires are ductile due to the processing required. No bending tests are

specified.

9. Resistivity

9.1 The electrical resistivity shall not exceed the following values in Table 4 (Explanatory Note 3):

10. Density

10.1 For the purpose of calculating mass, mass per unit length, cross sections, and so forth, the density of aluminum 1350 shall

3 3

be taken as 2705/kg/m (0.0975 lb/in. ) at 20°C.

11. Diameter

11.1 The diameter of the wire shall be expressed in decimal fractions of an inch to the nearest 0.0001 in. (0.003 mm).

11.2 The actual wire diameter shall not vary from the specified diameter by more than the values shown in Table 5.

12. Joints

12.1 Joints may be made in drawing stock and in the wire prior to final drawing in accordance with good commercial practice.

12.2 If agreed upon between the manufacturer and the purchaser, joints may be made during final drawing or in the finished

wire by electric-butt welding, by cold-pressure welding, or by electric-butt, cold-upset welding, with the following provisions:

12.2.1 For sizes 0.0100 to 0.0500 in. (0.254 to 1.270 mm), in diameter, not more than three such joints shall be present in any

reel, spool, or coil of the nominal specified mass, and

12.2.2 For sizes larger than 0.0500 in. (1.270 mm) in diameter, not more than 10 % of the reels, coils, or spools shall contain

such joints, and no such joint shall be closer than 50 ft (15 m) to another or to either end of the wire. In addition, there shall be

no more than two such joints present in any reel, coil, or spool of the specified size and nominal mass.

A

TABLE 4 Equivalent Resistivity Requirements and Equivalent Copper Resistivity at 20°C

Resistivity Constants

Volume Conductivity,

Material Volume

% IACS

Ω·cmil/ft Ω·mm /m μΩ·in. μΩ·cm

Copper Equivalent 100 10.371 0.017241 0.67879 1.7241

1350 Aluminum H_2 through 61.0 17.002 0.028264 1.1128 2.8264

H_6

1350-O Temper Aluminum 61.8 16.782 0.027899 1.0984 2.7899

A 2

The equivalent resistivity values for 100 % IACS (soft copper) were each computed from the fundamental IEC value (1/58Ω·mm /m) using conversion factors each

accurate to at least seven significant figures. Corresponding values for other conductivities (aluminum) were derived from these by multiplying by the reciprocal of the

conductivity ratios accurate to at least seven significant figures.

B609/B609M − 12 (2016)

TABLE 5 Diameter Tolerances

Permissible Variations of Mean Diameter

Specified Diameter, in. (mm)

from Specified Diameter, plus and minus

0.0100 to under 0.0360 0.0005 in. (0.013 mm)

(0.254 to under 0.914)

0.0360 to under 0.1000 0.0010 in. (0.025 mm)

(0.914 to under 2.540)

0.1000 to 0.7071, incl 1 %

(2.540 to 17.960, incl)

13. Sampling

13.1 Sampling—Four test specimens shall be obtained. One from each of four production units (Explanatory Note 4) or in

accordance with Specification B830.

14. Test Methods

14.1 Tensile Strength—Determine the tensile strength in accordance with Test Methods B557. Calculate the tensile strength by

dividing the maximum load carried by the specimen during the tension test by the original cross-sectional area of the specimen

(Explanatory Note 2).

14.1.1 If any part of the fracture takes place in the jaws of the tensile machine, or if an examination of the specimen indicates

that there was external damage, the value obtained may not be representative of the material. In such cases discard the test and

make a new test.

14.2 Resistivity—Determine the electrical resistivity of the wire in accordance with Test Method B193 (Explanatory Note 3 and

Table 4).

14.3 Diameter Measurements—Measure the diameter with a micrometer caliper graduated in 0.0001 in. (0.003 mm). Make

measurements on each specimen selected for this test. Measure the diameter of the wire at two points, spaced approximately 90°

apart, around the circumfe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.