ASTM D4294-21

(Test Method)Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

SIGNIFICANCE AND USE

5.1 This test method provides rapid and precise measurement of total sulfur in petroleum and petroleum products with a minimum of sample preparation. A typical analysis time is 1 min to 5 min per sample.

5.2 The quality of many petroleum products is related to the amount of sulfur present. Knowledge of sulfur concentration is necessary for processing purposes. There are also regulations promulgated in federal, state, and local agencies that restrict the amount of sulfur present in some fuels.

5.3 This test method provides a means of determining whether the sulfur content of petroleum or a petroleum product meets specification or regulatory limits.

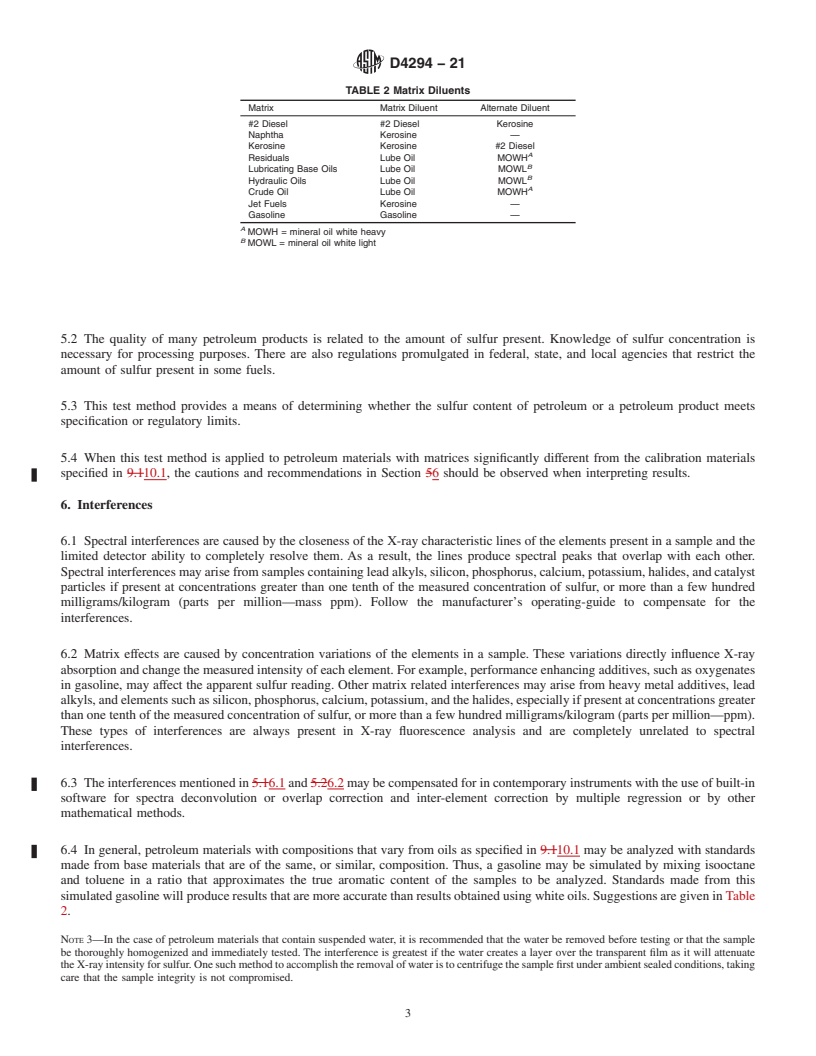

5.4 When this test method is applied to petroleum materials with matrices significantly different from the calibration materials specified in 10.1, the cautions and recommendations in Section 6 should be observed when interpreting results.

SCOPE

1.1 This test method covers the determination of total sulfur in petroleum and petroleum products that are single-phase and either liquid at ambient conditions, liquefiable with moderate heat, or soluble in hydrocarbon solvents. These materials can include diesel fuel, jet fuel, kerosine, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, gasoline-ethanol blends, biodiesel (see Note 2), and similar petroleum products.

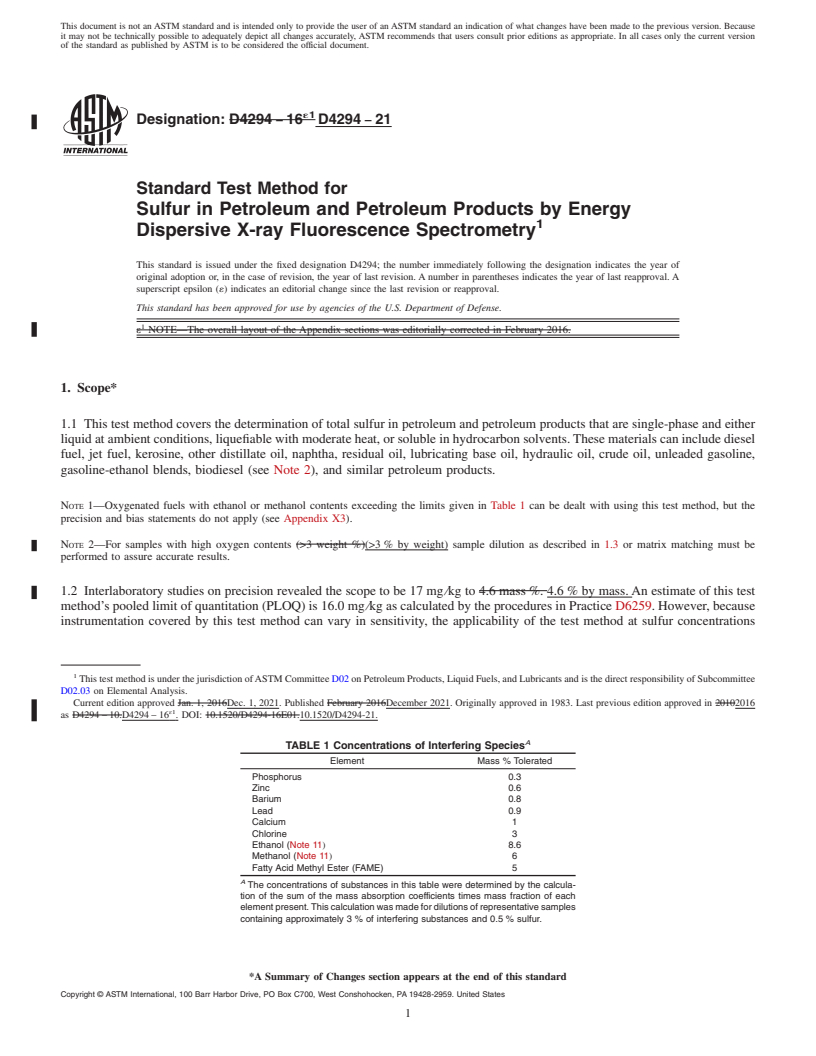

Note 1: Oxygenated fuels with ethanol or methanol contents exceeding the limits given in Table 1 can be dealt with using this test method, but the precision and bias statements do not apply (see Appendix X3).

Note 2: For samples with high oxygen contents (>3 % by weight) sample dilution as described in 1.3 or matrix matching must be performed to assure accurate results.

1.2 Interlaboratory studies on precision revealed the scope to be 17 mg/kg to 4.6 % by mass. An estimate of this test method’s pooled limit of quantitation (PLOQ) is 16.0 mg/kg as calculated by the procedures in Practice D6259. However, because instrumentation covered by this test method can vary in sensitivity, the applicability of the test method at sulfur concentrations below approximately 20 mg/kg must be determined on an individual basis. An estimate of the limit of detection is three times the reproducibility standard deviation, and an estimate of the limit of quantitation2 is ten times the reproducibility standard deviation.

1.3 Samples containing more than 4.6 % by mass sulfur can be diluted to bring the sulfur concentration of the diluted material within the scope of this test method. Samples that are diluted can have higher errors than indicated in Section 17 than non-diluted samples.

1.4 Volatile samples (such as high vapor pressure gasolines or light hydrocarbons) may not meet the stated precision because of selective loss of light materials during the analysis.

1.5 A fundamental assumption in this test method is that the standard and sample matrices are well matched, or that the matrix differences are accounted for (see 6.2). Matrix mismatch can be caused by C/H ratio differences between samples and standards (see Section 6) or by the presence of other heteroatoms.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4294 − 21

Standard Test Method for

Sulfur in Petroleum and Petroleum Products by Energy

1

Dispersive X-ray Fluorescence Spectrometry

This standard is issued under the fixed designation D4294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 Afundamental assumption in this test method is that the

standard and sample matrices are well matched, or that the

1.1 This test method covers the determination of total sulfur

matrix differences are accounted for (see 6.2). Matrix mis-

in petroleum and petroleum products that are single-phase and

match can be caused by C/H ratio differences between samples

either liquid at ambient conditions, liquefiable with moderate

and standards (see Section 6) or by the presence of other

heat, or soluble in hydrocarbon solvents. These materials can

heteroatoms.

include diesel fuel, jet fuel, kerosine, other distillate oil,

naphtha, residual oil, lubricating base oil, hydraulic oil, crude 1.6 The values stated in SI units are to be regarded as

oil, unleaded gasoline, gasoline-ethanol blends, biodiesel (see standard. No other units of measurement are included in this

Note 2), and similar petroleum products. standard.

1.7 This standard does not purport to address all of the

NOTE 1—Oxygenated fuels with ethanol or methanol contents exceed-

ingthelimitsgiveninTable1canbedealtwithusingthistestmethod,but safety concerns, if any, associated with its use. It is the

the precision and bias statements do not apply (see Appendix X3).

responsibility of the user of this standard to establish appro-

NOTE 2—For samples with high oxygen contents (>3 % by weight)

priate safety, health, and environmental practices and deter-

sample dilution as described in 1.3 or matrix matching must be performed

mine the applicability of regulatory limitations prior to use.

to assure accurate results.

1.8 This international standard was developed in accor-

1.2 Interlaboratory studies on precision revealed the scope

dance with internationally recognized principles on standard-

to be 17 mg⁄kg to 4.6 % by mass. An estimate of this test

ization established in the Decision on Principles for the

method’spooledlimitofquantitation(PLOQ)is16.0 mg⁄kgas

Development of International Standards, Guides and Recom-

calculated by the procedures in Practice D6259. However,

mendations issued by the World Trade Organization Technical

because instrumentation covered by this test method can vary

Barriers to Trade (TBT) Committee.

in sensitivity, the applicability of the test method at sulfur

concentrations below approximately 20 mg/kg must be deter-

2. Referenced Documents

mined on an individual basis. An estimate of the limit of

3

2.1 ASTM Standards:

detection is three times the reproducibility standard deviation,

2

D4057 Practice for Manual Sampling of Petroleum and

and an estimate of the limit of quantitation is ten times the

Petroleum Products

reproducibility standard deviation.

D4175 Terminology Relating to Petroleum Products, Liquid

1.3 Samples containing more than 4.6 % by mass sulfur can

Fuels, and Lubricants

be diluted to bring the sulfur concentration of the diluted

D4177 Practice for Automatic Sampling of Petroleum and

material within the scope of this test method. Samples that are

Petroleum Products

dilutedcanhavehighererrorsthanindicatedinSection17than

D6259 Practice for Determination of a Pooled Limit of

non-diluted samples.

Quantitation for a Test Method

1.4 Volatile samples (such as high vapor pressure gasolines

D6299 Practice for Applying Statistical Quality Assurance

or light hydrocarbons) may not meet the stated precision

and Control Charting Techniques to Evaluate Analytical

because of selective loss of light materials during the analysis.

Measurement System Performance

D7343 Practice for Optimization, Sample Handling,

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

3

Current edition approved Dec. 1, 2021. Published December 2021. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ɛ1

approved in 1983. Last previous edition approved in 2016 as D4294 – 16 . DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D4294-21. Standards volume

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4294 − 16 D4294 − 21

Standard Test Method for

Sulfur in Petroleum and Petroleum Products by Energy

1

Dispersive X-ray Fluorescence Spectrometry

This standard is issued under the fixed designation D4294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—The overall layout of the Appendix sections was editorially corrected in February 2016.

1. Scope*

1.1 This test method covers the determination of total sulfur in petroleum and petroleum products that are single-phase and either

liquid at ambient conditions, liquefiable with moderate heat, or soluble in hydrocarbon solvents. These materials can include diesel

fuel, jet fuel, kerosine, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline,

gasoline-ethanol blends, biodiesel (see Note 2), and similar petroleum products.

NOTE 1—Oxygenated fuels with ethanol or methanol contents exceeding the limits given in Table 1 can be dealt with using this test method, but the

precision and bias statements do not apply (see Appendix X3).

NOTE 2—For samples with high oxygen contents (>3 weight %)(>3 % by weight) sample dilution as described in 1.3 or matrix matching must be

performed to assure accurate results.

1.2 Interlaboratory studies on precision revealed the scope to be 17 mg ⁄kg to 4.6 mass %. 4.6 % by mass. An estimate of this test

method’s pooled limit of quantitation (PLOQ) is 16.0 mg ⁄kg as calculated by the procedures in Practice D6259. However, because

instrumentation covered by this test method can vary in sensitivity, the applicability of the test method at sulfur concentrations

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved Jan. 1, 2016Dec. 1, 2021. Published February 2016December 2021. Originally approved in 1983. Last previous edition approved in 20102016

ɛ1

as D4294 – 10.D4294 – 16 . DOI: 10.1520/D4294-16E01.10.1520/D4294-21.

A

TABLE 1 Concentrations of Interfering Species

Element Mass % Tolerated

Phosphorus 0.3

Zinc 0.6

Barium 0.8

Lead 0.9

Calcium 1

Chlorine 3

Ethanol (Note 11) 8.6

Methanol (Note 11) 6

Fatty Acid Methyl Ester (FAME) 5

A

The concentrations of substances in this table were determined by the calcula-

tion of the sum of the mass absorption coefficients times mass fraction of each

element present. This calculation was made for dilutions of representative samples

containing approximately 3 % of interfering substances and 0.5 % sulfur.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4294 − 21

below approximately 20 mg/kg must be determined on an individual basis. An estimate of the limit of detection is three times the

2

reproducibility standard deviation, and an estimate of the limit of quantitation is ten times the reproducibility standard deviation.

1.3 Samples containing more than 4.6 mass % 4.6 % by mass sulfur can be diluted to bring the sulfur concentration of the diluted

material within the scope of this test method. Samples that are diluted can have higher errors than indicated in Section 1617 than

non-diluted samples.

1.4 Volatile samples (such as high vapor pressure gasolines or light hydrocarbons) may not meet the stated precision because of

selective loss of light materials during the analysis.

1.5 A fundamental assumption in this test method is that the standard and sample matrices are well matched, or that the matrix

differences are accounted for (see 5.26.2). Matrix mismatch can be caused by C/H ratio differences between samples and standards

(see Section 56) or by the presence of other heteroatoms.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.