ASTM C297/C297M-04(2010)

(Test Method)Standard Test Method for Flatwise Tensile Strength of Sandwich Constructions

Standard Test Method for Flatwise Tensile Strength of Sandwich Constructions

SIGNIFICANCE AND USE

In a sandwich panel, core-to-facing bond integrity is necessary to maintain facing stability and permit load transfer between the facings and core. This test method can be used to provide information on the strength and quality of core-to-facing bonds. It can also be used to produce flatwise tensile strength data for the core material. While it is primarily used as a quality control test for bonded sandwich panels, it can also be used to produce flatwise tensile strength data for structural design properties, material specifications, and research and development applications.

Factors that influence the flatwise tensile strength and shall therefore be reported include the following: facing material, core material, adhesive material, methods of material fabrication, facing stacking sequence and overall thickness, core geometry (cell size), core density, adhesive thickness, specimen geometry, specimen preparation, specimen conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facing void content, adhesive void content, and facing volume percent reinforcement. Properties that may be derived from this test method include flatwise tensile strength.

SCOPE

1.1 This test method determines the flatwise tensile strength of the core, the core-to-facing bond, or the facing of an assembled sandwich panel. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C297/C297M − 04(Reapproved 2010)

Standard Test Method for

Flatwise Tensile Strength of Sandwich Constructions

This standard is issued under the fixed designation C297/C297M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D3878 Terminology for Composite Materials

D5229/D5229M TestMethodforMoistureAbsorptionProp-

1.1 This test method determines the flatwise tensile strength

erties and Equilibrium Conditioning of Polymer Matrix

of the core, the core-to-facing bond, or the facing of an

Composite Materials

assembled sandwich panel. Permissible core material forms

E4 Practices for Force Verification of Testing Machines

include those with continuous bonding surfaces (such as balsa

E6 Terminology Relating to Methods of Mechanical Testing

wood and foams) as well as those with discontinuous bonding

E122 Practice for Calculating Sample Size to Estimate,With

surfaces (such as honeycomb).

Specified Precision, the Average for a Characteristic of a

1.2 The values stated in either SI units or inch-pound units

Lot or Process

are to be regarded separately as standard. Within the text the

E177 Practice for Use of the Terms Precision and Bias in

inch-pound units are shown in brackets. The values stated in

ASTM Test Methods

each system are not exact equivalents; therefore, each system

E456 Terminology Relating to Quality and Statistics

must be used independently of the other. Combining values

E1309 Guide for Identification of Fiber-Reinforced

from the two systems may result in nonconformance with the

Polymer-Matrix Composite Materials in Databases

standard.

E1434 Guide for Recording Mechanical Test Data of Fiber-

1.3 This standard does not purport to address all of the Reinforced Composite Materials in Databases

safety concerns, if any, associated with its use. It is the

E1471 Guide for Identification of Fibers, Fillers, and Core

responsibility of the user of this standard to establish appro- Materials in Computerized Material Property Databases

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents 3.1 Definitions—Terminology D3878 defines terms relating

2 to high-modulus fibers and their composites. Terminology

2.1 ASTM Standards:

C274 defines terms relating to structural sandwich construc-

C274 Terminology of Structural Sandwich Constructions

tions. Terminology D883 defines terms relating to plastics.

D792 Test Methods for Density and Specific Gravity (Rela-

Terminology E6 defines terms relating to mechanical testing.

tive Density) of Plastics by Displacement

Terminology E456 and Practice E177 define terms relating to

D883 Terminology Relating to Plastics

statistics.Intheeventofaconflictbetweenterms,Terminology

D2584 Test Method for Ignition Loss of Cured Reinforced

D3878 shall have precedence over the other terminologies.

Resins

D2734 TestMethodsforVoidContentofReinforcedPlastics

3.2 Symbols:

D3039/D3039M Test Method for Tensile Properties of Poly-

A = cross-sectional area of a test specimen

mer Matrix Composite Materials

CV = coefficient of variation statistic of a sample population

D3171 Test Methods for Constituent Content of Composite

for a given property (in percent)

Materials

ftu

F = ultimate flatwise tensile strength

z

P = maximum force carried by test specimen before

max

This test method is under the jurisdiction of ASTM Committee D30 on

failure

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

S = standard deviation statistic of a sample population for

n-1

Current edition approved Oct. 1, 2010. Published December 2010. Originally

a given property

approved in 1952. Last previous edition approved in 2004 as C297/C297M – 04.

DOI: 10.1520/C0297_C0297M-04R10. x = test result for an individual specimen from the sample

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

population for a given property

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

x¯ = mean or average (estimate of mean) of a sample popu-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. lation for a given property

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C297/C297M − 04 (2010)

4. Summary of Test Method 6.3 Geometry—Specific geometric factors that affect sand-

wich flatwise tensile strength include core cell geometry, core

4.1 This test method consists of subjecting a sandwich

thickness, specimen shape (square or circular), adhesive

construction to a uniaxial tensile force normal to the plane of

thickness, facing thickness, and facing per-ply thickness.

the sandwich. The force is transmitted to the sandwich through

6.4 Environment—Resultsareaffectedbytheenvironmental

thickloadingblocks,whicharebondedtothesandwichfacings

conditions under which the tests are conducted. Specimens

or directly to the core.

tested in various environments can exhibit significant differ-

4.2 The only acceptable failure modes for flatwise tensile

ences in both strength behavior and failure mode. Critical

strength are those which are internal to the sandwich construc-

environments must be assessed independently for each facing,

tion. Failure of the loading block-to-sandwich bond is not an

adhesive and core material tested.

acceptable failure mode.

6.5 Conditioning—Asitisinappropriatetobondamoisture-

conditioned specimen to the bonding blocks, it is necessary to

5. Significance and Use

perform the bonding operation prior to such conditioning. The

5.1 In a sandwich panel, core-to-facing bond integrity is

presence of the bonding blocks will affect the degree of

necessary to maintain facing stability and permit load transfer

moisture intake into the specimen, in comparison to a non-

between the facings and core. This test method can be used to

bonded sample.

provide information on the strength and quality of core-to-

facing bonds. It can also be used to produce flatwise tensile

7. Apparatus

strength data for the core material.While it is primarily used as

7.1 Micrometers—Themicrometer(s)shallusea4-to5-mm

aqualitycontroltestforbondedsandwichpanels,itcanalsobe

[0.16- to 0.20-in.] nominal diameter ball-interface on irregular

used to produce flatwise tensile strength data for structural

surfaces such as the bag-side of a facing laminate, and a flat

design properties, material specifications, and research and

anvil interface on machined edges or very smooth-tooled

development applications.

surfaces.Theaccuracyoftheinstrument(s)shallbesuitablefor

reading to within 1 % of the sample length, width and

5.2 Factors that influence the flatwise tensile strength and

thickness. For typical specimen geometries, an instrument with

shall therefore be reported include the following: facing

anaccuracyof 625mm[60.001in.]isdesirableforthickness,

material, core material, adhesive material, methods of material

length and width measurement.

fabrication, facing stacking sequence and overall thickness,

core geometry (cell size), core density, adhesive thickness,

7.2 Loading Fixtures—The loading fixtures shall be self-

specimen geometry, specimen preparation, specimen

aligning and shall not apply eccentric loads.Asatisfactory type

conditioning, environment of testing, specimen alignment,

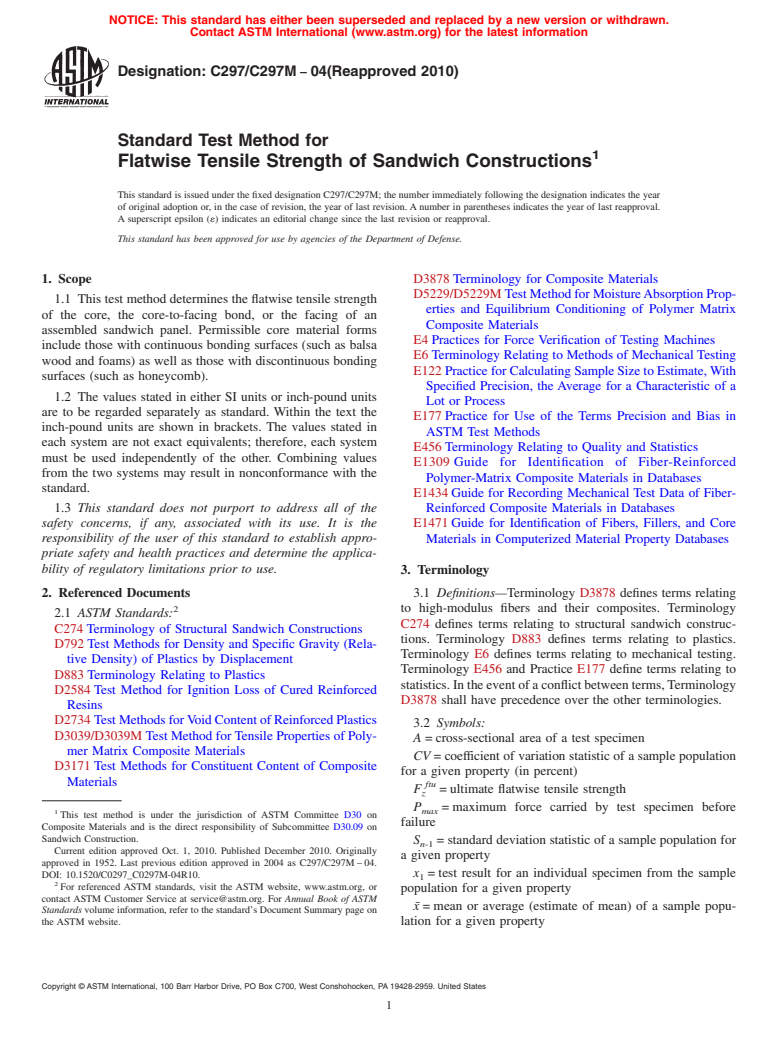

of apparatus is shown in Fig. 1. The loading blocks shall be

loading procedure, speed of testing, facing void content,

sufficiently stiff to keep the bonded core or facings essentially

adhesive void content, and facing volume percent reinforce-

flat under load. Loading blocks 40 to 50 mm [1.5 to 2.0 in.]

ment. Properties that may be derived from this test method

thick have been found to perform satisfactorily. Permissible

include flatwise tensile strength.

tolerances for the loading blocks (along with alignment re-

quirements) are provided in Fig. 2.

6. Interferences

7.3 Testing Machine—The testing machine shall be in ac-

6.1 Material and Specimen Preparation—Poormaterialfab-

cordance with Practices E4 and shall satisfy the following

rication practices, lack of control of fiber alignment, and

requirements:

damage induced by improper specimen machining are known

7.3.1 Testing Machine Configuration—The testing machine

causes of high data scatter in composites in general. Specific

shall have both an essentially stationary head and a movable

material factors that affect sandwich composites include vari-

head.

abilityincoredensityanddegreeofcureofresininbothfacing

7.3.2 Drive Mechanism—The testing machine drive mecha-

matrix material and core bonding adhesive. Important aspects

nism shall be capable of imparting to the movable head a

of sandwich panel specimen preparation that contribute to data

controlled velocity with respect to the stationary head. The

scatter are incomplete or nonuniform core bonding to facings,

velocity of the movable head shall be capable of being

misalignment of core and facing elements, the existence of

regulated in accordance with 11.6.

joints, voids or other core and facing discontinuities, out-of-

7.3.3 Load Indicator—The testing machine load-sensing

plane curvature, facing thickness variation, and surface rough-

device shall be capable of indicating the total force being

ness.

carried by the test specimen. This device shall be essentially

free from inertia lag at the specified rate of testing and shall

6.2 System Alignment—Excessive bending will cause pre-

indicate the force with an accuracy over the force range(s) of

maturefailure.Everyeffortshouldbemadetoeliminateexcess

interest of within 61 % of the indicated value.

bending from the test system. Bending may occur as a result of

misaligned grips, poor specimen preparation, or poor align- 7.4 Conditioning Chamber—When conditioning materials

ment of the bonding blocks and loading fixture. If there is any at non-laboratory environments, a temperature/vapor-level

doubt as to the alignment inherent in a given test machine, then controlledenvironmentalconditioningchamberisrequiredthat

the alignment should be checked as discussed in Test Method shall be capable of maintaining the required temperature to

D3039/D3039M. within 63°C [65°F] and the required relative humidity level

C297/C297M − 04 (2010)

specimen. The largest facing area listed in the table (5625

2 2

mm [9.0 in. ]) is a practical maximum for this test method.

Cores with cell sizes larger than 9 mm [0.375 in.] may require

a smaller number of cells to be tested in the specimen.

8.3 Specimen Preparation and Machining—Specimen

preparation is extremely important for this test method. Take

precautions when cutting specimens from large panels to avoid

notches, undercuts, rough or uneven surfaces, or delaminations

due to inappropriate machining methods. Obtain final dimen-

sions by water-lubricated precision sawing, milling, or grind-

ing. The use of diamond tooling has been found to be

extremely effective for many material systems. Edges should

be flat and parallel within the specified tolerances. Record and

report the specimen cutting preparation method.

8.4 Labeling—Label the test specimens so that they will be

distinct from each other and traceable back to the panel of

origin, and will neither influence the test nor be affected by it.

8.5 Loading Fixture Bonding—The loading blocks shall be

bonded to the core or facings of the test specimen using a

suitable adhesive. To minimize thermal exposure effects upon

the existing core-to-facing bonds, it is recommended that the

assembly bonding temperature be at room temperature, or at

least 28°C [50°F] lower than that at which the sandwich was

originally bonded. Similarly, the assembly bonding pressure

shall not be greater than the original facing-to-core bonding

pressure. Permissible tolerances for the bonded assembly

(along with alignment requirements) are provided in Fig. 2.

FIG. 1 Flatwise Tension Test Setup

9. Calibration

to within 63 %. Chamber conditions shall be monitored either

9.1 The accuracy of all measuring equipment shall have

on an automated continuous basis or on a manual basis at

certified calibrations that are current at the time of use of the

regular intervals.

equipment.

7.5 Environmental Test Chamber—An environmental test

chamber is required for test environments other than ambient

10. Conditioning

testing laboratory conditions. This chamber shall be capable of

10.1 Standard Conditioning Procedure—Unless a different

maintaining the gage section of the test specimen at the

environment is specified as part of the experiment, condition

required test environment during the mechanical test.

the test specimens in accordance with Procedure C of Test

Method D5229/D5229M, and store and test at standard labo-

8. Sampling and Test Specimens

ratoryatmosphere(23 63°C[73 65°F]and50 65 %relative

8.1 Sampling—Test at least five specimens per test condi-

humidity).

tion unless valid results can be gained through the use of fewer

specimens, as in the case of a designed experiment. For

11. Procedure

statistically significant data, consult the procedures outlined in

11.1 Parameters to Be Specified Before Test:

Practice E122. Report the method of sampling.

11.1.1 The specimen sampling method, specimen geometry,

8.2 Geometry—Test specimens shall have a square or cir-

and conditioning travelers (if required).

cular cross-section, and shall be equal in thickness to the

11.1.2 The properties and data reporting format desired.

sandwich panel thickness. Minimum specimen facing areas for

various types of core materials are as follows: NOTE 1—Determine specific material property, accuracy, and data

reporting requirements prior to test for proper selection of instrumentation

8.2.1 Continuous Bonding Surfaces (for example, balsa

and data recording equipment. Estimate the specimen strength to aid in

wood, foams)—Theminimumfacingareaofthespecimenshall

transducer selection, calibration of equipment, and determination of

2 2

be 625 mm [1.0 in. ].

equipment settings.

8.2.2 Discontinuous Cellular Bonding Surfaces (for

11.1.3 The environmental conditioning test parameters.

example, honeycomb)—The required facing area of the speci-

11.1.4 If performed, sampling method, specimen geometry,

men is dependent upon the cell size, to ensure a minimum

and test parameters used to determine facing density and

number of cells are tested. Minimum facing areas are recom-

reinforcement volume.

m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.