ASTM D7446-09(2017)

(Specification)Standard Specification for Structural Insulated Panel (SIP) Adhesives for Laminating Oriented Strand Board (OSB) to Rigid Cellular Polystryene Thermal Insulation Core Materials

Standard Specification for Structural Insulated Panel (SIP) Adhesives for Laminating Oriented Strand Board (OSB) to Rigid Cellular Polystryene Thermal Insulation Core Materials

ABSTRACT

This specification addresses the physical, chemical and test requirements for structural insulated panel (SIP) adhesives suitable for the bonding of oriented strand boards (OSB) to rigid cellular polystyrene thermal insulation core materials for general structural use. Douglas-fir to Douglas-fir assemblies shall pass the following qualification requirements when tested in accordance with referenced ASTM documents enumerated herein: block shear strength (dry shear, soak/re-dry, oxidation resistance, and mold resistance); tensile strength (dry tensile bond strength, soak/re-dry, and mold resistance); and creep resistance. OSB to core to OSB assemblies shall, alternatively, be tested and pass shear strength and tensile (flat wise) bond strength requirements as well.

SIGNIFICANCE AND USE

4.1 This specification addresses minimum performance criteria for adhesives used to laminate oriented strand board (OSB) structural panel facing material to expanded or extruded polystyrene core materials. Adhesive performance is based on tests that simulate exposure to moisture, temperature, seasonal weathering, and creep. Additionally, the adhesive is to demonstrate resistance to oxidation, mold, chemical reagents, and compatibility to the specific laminating materials.

4.2 The adhesive manufacturers can use this specification for new product development and quality control purposes.

4.3 Structural insulated panel manufacturers rely on an adhesive performance specification that determines its suitability before use.

4.4 Performance of the SIP adhesive when evaluated in accordance with this specification aids in determining the suitability of the adhesive for laminating OSB facings to rigid cellular polystyrene core materials in the manufacture of structural insulated panels.

SCOPE

1.1 This specification is designed to evaluate adhesives suitable for the bonding of oriented strand board (OSB) to rigid cellular polystyrene insulation core materials for general structure use.

1.2 The requirements of the structural insulated panel (SIP) adhesive are based on the performance of the adhesive as measured by:

1.2.1 Resistance to shear by compression loading in ambient conditions and after accelerated aging.

1.2.2 Resistance to tensile loading in ambient conditions and after accelerated aging.

1.2.3 Resistance to creep (deformation) under static load in ambient conditions and after accelerated aging.

1.2.4 Tensile and shear strength to polystyrene core materials.

1.3 The classification of the adhesive formulation is based on, but not limited to the adhesive’s industry accepted generic names, for example: phenol-resorcinol, emulsion polymer isocyanate, one and two-part urethane. The type of adhesive application and curing terminology are also usually included for classification purposes such as cold-setting phenol resorcinol, heat-cured phenol resorcinol, and hot melt one component urethane.

1.4 Evaluation of adhesive performance at high temperature conditions, such as during a fire exposure, is beyond the scope of this specification.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7446 −09 (Reapproved 2017)

Standard Specification for

Structural Insulated Panel (SIP) Adhesives for Laminating

Oriented Strand Board (OSB) to Rigid Cellular Polystryene

Thermal Insulation Core Materials

This standard is issued under the fixed designation D7446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This specification is designed to evaluate adhesives

1.7 This international standard was developed in accor-

suitableforthebondingoforientedstrandboard(OSB)torigid

dance with internationally recognized principles on standard-

cellular polystyrene insulation core materials for general struc-

ization established in the Decision on Principles for the

ture use.

Development of International Standards, Guides and Recom-

1.2 The requirements of the structural insulated panel (SIP)

mendations issued by the World Trade Organization Technical

adhesive are based on the performance of the adhesive as

Barriers to Trade (TBT) Committee.

measured by:

1.2.1 Resistance to shear by compression loading in ambi-

2. Referenced Documents

ent conditions and after accelerated aging.

1.2.2 Resistance to tensile loading in ambient conditions

2.1 ASTM Standards:

and after accelerated aging.

C273/C273M Test Method for Shear Properties of Sandwich

1.2.3 Resistance to creep (deformation) under static load in

Core Materials

ambient conditions and after accelerated aging.

C297/C297M Test Method for Flatwise Tensile Strength of

1.2.4 Tensile and shear strength to polystyrene core materi-

Sandwich Constructions

als.

C578 Specification for Rigid, Cellular Polystyrene Thermal

Insulation

1.3 The classification of the adhesive formulation is based

D572 Test Method for Rubber—Deterioration by Heat and

on, but not limited to the adhesive’s industry accepted generic

Oxygen

names, for example: phenol-resorcinol, emulsion polymer

D905 Test Method for Strength Properties of Adhesive

isocyanate, one and two-part urethane. The type of adhesive

Bonds in Shear by Compression Loading

application and curing terminology are also usually included

D907 Terminology of Adhesives

for classification purposes such as cold-setting phenol

D1183 Practices for Resistance of Adhesives to Cyclic

resorcinol, heat-cured phenol resorcinol, and hot melt one

Laboratory Aging Conditions

component urethane.

D1583 Test Method for Hydrogen Ion Concentration of Dry

1.4 Evaluation of adhesive performance at high temperature

Adhesive Films

conditions, such as during a fire exposure, is beyond the scope

D2294 Test Method for Creep Properties of Adhesives in

of this specification.

Shear by Tension Loading (Metal-to-Metal)

1.5 The values stated in SI units are to be regarded as the

D4300 Test Methods for Ability of Adhesive Films to

standard. The values given in parentheses are for information

Support or Resist the Growth of Fungi

only. D4442 Test Methods for Direct Moisture Content Measure-

ment of Wood and Wood-Based Materials

1.6 This standard does not purport to address all of the

D4444 Test Method for Laboratory Standardization and

safety concerns, if any, associated with its use. It is the

Calibration of Hand-Held Moisture Meters

responsibility of the user of this standard to establish appro-

E4 Practices for Force Verification of Testing Machines

This specification is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2017. Published May 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. Last previous edition approved in 2009 as D7446 – 09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7446-09R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7446−09 (2017)

2.2 Other Standards: suitability of the adhesive for laminating OSB facings to rigid

PS2 Performance Standard for Wood-Based Structural-Use cellular polystyrene core materials in the manufacture of

Panels structural insulated panels.

ISO 17025 General Requirements for the Competence of

5. Fillers and Extenders

Testing and Calibration Laboratories

5.1 If amylaceous or protein fillers and extenders are used,

3. Terminology

the adhesive shall not only pass requirements of this specifi-

3.1 Definitions—Many terms in this specification are de-

cation but, in addition, possess antifungal properties to inhibit

fined in Terminology D907.

the growth of selected fungal species when tested in accor-

dance with Test Method D4300. The adhesive manufacturer’s

3.2 Definitions of Terms Specific to This Standard:

literature shall indicate whether such materials are present.

3.2.1 core material, n—located between structural insulated

panel facings; for this specification, consists of rigid cellular

6. Apparatus

polystyrene thermal insulation, either expanded polystyrene

6.1 Testing Machine—shall conform to the requirements of

(EPS) or extruded polystyrene (XPS) that conforms to Speci-

fication C578. and have the capabilities of the machines prescribed in Test

Methods C297/C297M, C273/C273M, and D905 and have an

3.2.2 facings, n—the outer layers of a structural insulated

accuracy of 61 % when calibrated in accordance with Prac-

panel typically consisting of oriented strand board.

tices E4 requirements. The grips shall be capable of securely

3.2.3 oriented strand board (OSB), n—a mat formed panel

grabbingthespecimenthroughoutthetestwithoutallowingthe

product with oriented layers resulting in directional properties.

specimen to slip. The grips shall be self-aligning.

3.2.3.1 Discussion—Oriented strand board is comprised pri-

6.2 Temperature and RH-Controlling Equipment—The

marily of wood strands bonded with exterior adhesive formu-

equipment shall be capable of maintaining the test temperature

lations under heat and pressure. Design capacities are refer-

to 63ºC (65°F) and the relative humidity to 63%.

enced to the primary and secondary structural axis, which

typically correspond to the manufacturing machine and cross-

7. Chemical Requirements

machinedirections,respectively.Theprimarydirectionisoften

referred to as the strength direction. 7.1 The cured adhesive film shall develop a pH value of not

less than 2.5 when tested in accordance with Test Method

3.2.4 practical equilibrium, n—physical state in which the

D1583.

material weight does not change more than 0.5 % in 24 h.

3.2.5 standard conditions, n—consist of a controlled envi-

8. Physical Requirements

ronment set at 23 6 2°C (73 6 3°F) and 65 6 3 % relative

8.1 Adhesive manufacturer recommendations for

humidity (RH).

preparation, application, and handling of the SIPadhesive shall

3.2.6 structural insulated panel (SIP), n—factory manufac-

ensure proper usage and maintain product integrity. The

tured assembly consisting of a rigid polystyrene bonded with a

adhesive manufacturer shall furnish written instructions stating

structural adhesive between two rigid facings such as OSB.

the general chemical type of adhesive, its storage and mixing

procedure, the method of surface preparation with materials to

4. Significance and Use

be laminated, and any other data that is pertinent to the use of

4.1 This specification addresses minimum performance cri-

the adhesive in the manufacture of structural insulated panels.

teria for adhesives used to laminate oriented strand board

8.2 The adhesive shall pass the tests required by this

(OSB) structural panel facing material to expanded or extruded

specification. See Table 1, Table 2, and Section 10. The

polystyrene core materials. Adhesive performance is based on

adhesive manufacturer’s application specification sheet shall

tests that simulate exposure to moisture, temperature, seasonal

provide application instructions which include the limiting

weathering, and creep.Additionally, the adhesive is to demon-

conditions.

strate resistance to oxidation, mold, chemical reagents, and

8.2.1 The adhesive manufacturer is to provide specific

compatibility to the specific laminating materials.

application instructions for the test adhesive related to the

4.2 The adhesive manufacturers can use this specification

preparation of test assemblies required by this specification

for new product development and quality control purposes.

including both Douglas-fir to Douglas-fir and OSB to Core to

OSB.

4.3 Structural insulated panel manufacturers rely on an

adhesive performance specification that determines its suitabil-

8.3 Limiting conditions are conditions that must be con-

ity before use.

trolled within maximums, minimums, or ranges so that the

adhesive can function as designed. These conditions include,

4.4 Performance of the SIP adhesive when evaluated in

but are not limited to the following:

accordance with this specification aids in determining the

8.3.1 Maximum storage life of adhesive;

8.3.2 Assembly conditions including temperature and hu-

Available from National Institute of Standards and Technology (NIST), 100

midity;

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

8.3.3 Allowable moisture content and temperature for fac-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. ings and core materials;

D7446−09 (2017)

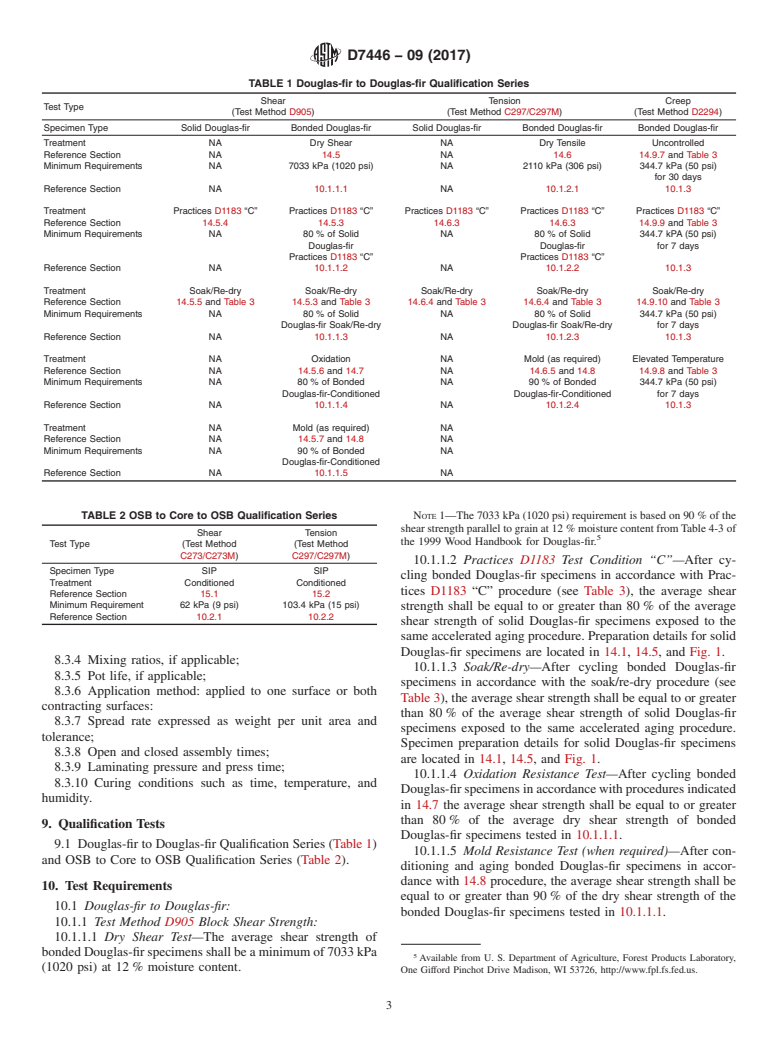

TABLE 1 Douglas-fir to Douglas-fir Qualification Series

Shear Tension Creep

Test Type

(Test Method D905) (Test Method C297/C297M) (Test Method D2294)

Specimen Type Solid Douglas-fir Bonded Douglas-fir Solid Douglas-fir Bonded Douglas-fir Bonded Douglas-fir

Treatment NA Dry Shear NA Dry Tensile Uncontrolled

Reference Section NA 14.5 NA 14.6 14.9.7 and Table 3

Minimum Requirements NA 7033 kPa (1020 psi) NA 2110 kPa (306 psi) 344.7 kPa (50 psi)

for 30 days

Reference Section NA 10.1.1.1 NA 10.1.2.1 10.1.3

Treatment Practices D1183 “C” Practices D1183 “C” Practices D1183 “C” Practices D1183 “C” Practices D1183 “C”

Reference Section 14.5.4 14.5.3 14.6.3 14.6.3 14.9.9 and Table 3

Minimum Requirements NA 80 % of Solid NA 80 % of Solid 344.7 kPA (50 psi)

Douglas-fir Douglas-fir for 7 days

Practices D1183 “C” Practices D1183 “C”

Reference Section NA 10.1.1.2 NA 10.1.2.2 10.1.3

Treatment Soak/Re-dry Soak/Re-dry Soak/Re-dry Soak/Re-dry Soak/Re-dry

Reference Section 14.5.5 and Table 3 14.5.3 and Table 3 14.6.4 and Table 3 14.6.4 and Table 3 14.9.10 and Table 3

Minimum Requirements NA 80 % of Solid NA 80 % of Solid 344.7 kPa (50 psi)

Douglas-fir Soak/Re-dry Douglas-fir Soak/Re-dry for 7 days

Reference Section NA 10.1.1.3 NA 10.1.2.3 10.1.3

Treatment NA Oxidation NA Mold (as required) Elevated Temperature

Reference Section NA 14.5.6 and 14.7 NA 14.6.5 and 14.8 14.9.8 and Table 3

Minimum Requirements NA 80 % of Bonded NA 90 % of Bonded 344.7 kPa (50 psi)

Douglas-fir-Conditioned Douglas-fir-Conditioned for 7 days

Reference Section NA 10.1.1.4 NA 10.1.2.4 10.1.3

Treatment NA Mold (as required) NA

Reference Section NA 14.5.7 and 14.8 NA

Minimum Requirements NA 90 % of Bonded NA

Douglas-fir-Conditioned

Reference Section NA 10.1.1.5 NA

TABLE 2 OSB to Core to OSB Qualification Series

NOTE 1—The 7033 kPa (1020 psi) requirement is based on 90 % of the

shear strength parallel to grain at 12 % moisture content fromTable 4-3 of

Shear Tension

the 1999 Wood Handbook for Douglas-fir.

Test Type (Test Method (Test Method

C273/C273M) C297/C297M)

10.1.1.2 Practices D1183 Test Condition “C”—After cy-

Specimen Type SIP SIP

cling bonded Douglas-fir specimens in accordance with Prac-

Treatment Conditioned Conditioned

tices D1183 “C” procedure (see Table 3), the average shear

Reference Section 15.1 15.2

Minimum Requirement 62 kPa (9 psi) 103.4 kPa (15 psi)

strength shall be equal to or greater than 80 % of the average

Reference Section 10.2.1 10.2.2

shear strength of solid Douglas-fir specimens exposed to the

same accelerated aging procedure. Preparation details for solid

Douglas-fir specimens are located in 14.1, 14.5, and Fig. 1.

8.3.4 Mixing ratios, if applicable;

10.1.1.3 Soak/Re-dry—After cycling bonded Douglas-fir

8.3.5 Pot life, if applicable;

specimens in accordance with the soak/re-dry procedure (see

8.3.6 Application method: applied to one surface or both

Table 3), the average shear strength shall be equal to or greater

contracting surfaces:

than 80 % of the average shear strength of solid Douglas-fir

8.3.7 Spread rate expressed as weight per unit area and

specimens exposed to the same accelerated aging procedure.

tolerance;

Specimen preparation details for solid Douglas-fir specimens

8.3.8 Open and closed assembly times;

are located in 14.1, 14.5, and Fig. 1.

8.3.9 Laminating pressure and press time;

10.1.1.4 Oxidation Resistance Test—After cycling bonded

8.3.10 Curing conditions such as time, temperature, and

Douglas-firspecimensinaccordancewithproceduresindicated

humidity.

in 14.7 the average shear strength shall be equal to or greater

than 80 % of the average dry shear strength of bonded

9. Qualification Tests

Douglas-fir specimens tested in 10.1.1.1.

9.1 Douglas-fir to Douglas-fir Qualification Series (Table 1)

10.1.1.5 Mold Resistance Test (when required)—After con-

and OSB to Core to OSB Qualification Series (Table 2).

ditioning and aging bonded Douglas-fir specimens in accor-

dance with 14.8 procedure, the average shear strength shall be

10. Test Requirements

equal to or greater than 90 % of the dry shear strength of the

10.1 Douglas-fir to Douglas-fir:

bonded Douglas-fir specimens tested in 10.1.1.1.

10.1.1 Test Method D905 Block Shear Strength:

10.1.1.1 Dry Shear Test—The average shear strength of

bondedDouglas-firspecimensshallbeaminimumof7033kPa

Available from U. S. Department of Agriculture, Forest Products Laboratory,

(1020 psi) at 12 % moisture content.

One Gifford Pinchot Drive Madison, WI 53726, http://www.fpl.fs.fed.us.

D7446−09 (2017)

TABLE 3 Douglas-fir Procedures

Practices D1183

Soak/Re-dry Creep Resistance

Procedure C

48 h at 71 ± 2°C (170 ± 3°F) <10 % RH 48 h submerged in 18 to 23°C (65 to 75°F) Set 1: Control Test for 30 days in uncontrolled

tap water t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.