ASTM F2617-08

(Test Method)Standard Test Method for Identification and Quantification of Chromium, Bromine, Cadmium, Mercury, and Lead in Polymeric Material Using Energy Dispersive X-ray Spectrometry

Standard Test Method for Identification and Quantification of Chromium, Bromine, Cadmium, Mercury, and Lead in Polymeric Material Using Energy Dispersive X-ray Spectrometry

SIGNIFICANCE AND USE

This test method is intended for the determination of chromium, bromine, cadmium, mercury, and lead, in homogeneous polymeric materials. The test method may be used to ascertain the conformance of the product under test to manufacturing specifications. Typical time for a measurement is 5 to 10 min per specimen, depending on the specimen matrix and the capabilities of the EDXRF spectrometer.

SCOPE

1.1 This test method describes an energy dispersive X-ray fluorescence (EDXRF) spectrometric procedure for identification and quantification of chromium, bromine, cadmium, mercury, and lead in polymeric materials.

1.2 This test method is not applicable to determine total concentrations of polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE) or hexavalent chromium. This test method cannot be used to determine the valence states of atoms or ions.

1.3 This test method is applicable for a range from 20 mg/kg to approximately 1 wt % for chromium, bromine, cadmium, mercury, and lead in polymeric materials.

1.4 This test method is applicable for homogeneous polymeric material.

1.5 The values stated in SI units are to be regarded as the standard. Values given in parentheses are for information only.

1.6 This test method is not applicable to quantitative determinations for specimens with one or more surface coatings present on the analyzed surface; however, qualitative information may be obtained. In addition, specimens less than infinitely thick for the measured X rays, must not be coated on the reverse side or mounted on a substrate.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2617 – 08

Standard Test Method for

Identification and Quantification of Chromium, Bromine,

Cadmium, Mercury, and Lead in Polymeric Material Using

Energy Dispersive X-ray Spectrometry

This standard is issued under the fixed designation F 2617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D 3641 Practice for Injection Molding Test Specimens of

Thermoplastic Molding and Extrusion Materials

1.1 This test method describes an energy dispersive X-ray

D 4703 Practice for Compression Molding Thermoplastic

fluorescence (EDXRF) spectrometric procedure for identifica-

Materials into Test Specimens, Plaques, or Sheets

tion and quantification of chromium, bromine, cadmium,

D 6299 Practice for Applying Statistical Quality Assurance

mercury, and lead in polymeric materials.

and Control Charting Techniques to Evaluate Analytical

1.2 This test method is not applicable to determine total

Measurement System Performance

concentrations of polybrominated biphenyls (PBB), polybro-

E29 Practice for Using Significant Digits in Test Data to

minateddiphenylethers(PBDE)orhexavalentchromium.This

Determine Conformance with Specifications

test method cannot be used to determine the valence states of

E 135 Terminology Relating to Analytical Chemistry for

atoms or ions.

Metals, Ores, and Related Materials

1.3 Thistestmethodisapplicableforarangefrom20mg/kg

E 1361 Guide for Correction of Interelement Effects in

to approximately 1 wt % for chromium, bromine, cadmium,

X-Ray Spectrometric Analysis

mercury, and lead in polymeric materials.

F 2576 Terminology Relating to Declarable Substances in

1.4 This test method is applicable for homogeneous poly-

Materials

meric material.

1.5 The values stated in SI units are to be regarded as the

3. Terminology

standard. Values given in parentheses are for information only.

3.1 Definitions—DefinitionsoftermsapplyingtoXRF,plas-

1.6 This test method is not applicable to quantitative deter-

tics and declarable substances appear in Terminology E 135,

minations for specimens with one or more surface coatings

Terminology D 883 and Terminology F 2576, respectively.

present on the analyzed surface; however, qualitative informa-

3.1.1 Compton scatter—the inelastic scattering of an X-ray

tion may be obtained. In addition, specimens less than infi-

photon through its interaction with the bound electrons of an

nitely thick for the measured X rays, must not be coated on the

atom; this process is also referred to as incoherent scatter.

reverse side or mounted on a substrate.

3.1.2 Rayleigh scatter—the elastic scattering of an X-ray

1.7 This standard does not purport to address all of the

photon through its interaction with the bound electrons of an

safety concerns, if any, associated with its use. It is the

atom; this process is also referred to as coherent scatter.

responsibility of the user of this standard to establish appro-

3.1.2.1 Discussion—The measured count rate of Compton

priate safety and health practices and determine the applica-

and Rayleigh scattered radiation varies depending upon speci-

bility of regulatory limitations prior to use.

men composition and may thus be used to compensate for

2. Referenced Documents matrix effects. One option is to use the measured count rate of

the Compton scatter in the same manner as the measured count

2.1 ASTM Standards:

rate of an internal standard element. Alternatively, the mea-

D 883 Terminology Relating to Plastics

sured count rate of the Compton scatter or the Compton/

Rayleigh scatter ratio may be used indirectly for estimating the

This test method is under the jurisdiction of ASTM Committee F40 on

effective mass absorption coefficient of the specimen, which is

Declarable Substances in Materials and is the direct responsibility of Subcommittee

used to compensate for matrix effects. The concept of correc-

F40.01 on Test Methods.

Current edition approved Aug. 15, 2008. Published September 2008. tions based on the Compton scatter effect is discussed as an

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

optional part of several calibration choices in this standard.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2617–08

3.1.3 fundamental parameters (FP) model—a model for with one another. Peaks from Cd may overlap with peaks from

calibration of X-ray fluorescence response, including the cor- Ca,Sn,orotherelements.Interactionsofphotonsandelectrons

rection of matrix effects, based on the theory describing the inside the detector give rise to additional peaks in a spectrum

physical processes of the interactions of X rays with matter. known as escape peaks and sum peaks. Fundamental Param-

3.1.4 homogeneous polymeric material—polymeric mate- etersequationsrequirethatthemeasurednetcountratesbefree

rial is considered homogeneous for XRF when the elemental from line overlap effects. Some empirical approaches incorpo-

composition is independent with respect to the measured rate line overlap corrections in their equations. Manufacturers’

location on the specimen and among separate specimens software may provide tools to compensate for overlapped

prepared from the same polymeric material. peaks, escape peaks, and sum peaks in spectra. The degree of

3.1.5 infinite thickness (or critical thickness)—the thickness line overlap and the best method to account or correct for it

of specimen which, if increased, yields no increase in intensity must be ascertained on an individual basis and must be

of secondary X rays, due to absorption by the polymer matrix. considered when calibrating the instrument.

3.1.5.1 Discussion—This thickness varies with secondary 6.2 Interelement Effects—Interelement effects, also called

X-ray energy, or wavelength. matrix effects, exist among all elements as the result of

3.2 Abbreviations: absorption of fluorescent X rays (secondary X rays) by atoms

3.2.1 EDXRF—energy dispersive X-ray fluorescence in the specimen. Absorption reduces the apparent sensitivity

3.2.2 FP—fundamental parameters for the element. In contrast, the atom that absorbs the X rays

3.2.3 PBB—polybrominated biphenyl may in turn emit a fluorescent X ray, increasing the apparent

3.2.4 PBDE—polybrominated diphenyl ether sensitivity for the second element. Mathematical methods may

be used to compensate for matrix effects. A number of

4. Summary of Test Method mathematical correction procedures are commonly utilized

includingfullFPtreatmentsandmathematicalmodelsbasedon

4.1 The optimum test sample is a smooth plaque or disk

influencecoefficientalgorithms.Theinfluencecoefficientsmay

large enough to cover the viewed area of the spectrometer.

be calculated either from first principles or from the empirical

Suitable specimens may be die-cut from extruded sheets, or

data, or some combination of the two approaches. See Guide

molded from resin pellets, from powders or from granules.

E 1361 for examples of these approaches. Also, consult the

4.2 The specimen is placed in the X-ray beam, and the

software manual for the spectrometer for information on the

appropriateregionofitsspectrumismeasuredtogivethecount

approaches provided with the spectrometer. Any of these that

rates or fluorescent intensities of lead, mercury, cadmium,

will achieve the necessary analytical accuracy is acceptable.

chromium and bromine.

Examples of common interelement effects are listed inTable 1.

4.3 TheEDXRFspectrometeriscalibratedbyoneofseveral

approaches including fundamental parameters and empirical,

7. Apparatus

classical curve construction, with either empirical or theoreti-

7.1 EDXRF Spectrometer—Designed for X-ray fluores-

cal influence coefficients, from measured polymer reference

cence analysis with energy dispersive selection of radiation.

materials. The calibration may be performed by the manufac-

The spectrometer is equipped with specimen holders and a

turer or by the user.

specimen chamber. Any EDXRF spectrometer may be used if

4.4 Choices of appropriate characteristic X-ray lines and

its design incorporates the following features.

spectrometer test conditions may vary according to each

element and with factors such as detector response, concentra-

tion range and other elements present in the polymer matrix.

TABLE 1 Common Interelement Effects in Formulated Plastics

Cause Effect

5. Significance and Use

Absorption by Cl in PVC Reduced sensitivity for all analytes as

5.1 This test method is intended for the determination of compared to when they are occurring

at the same concentration level in

chromium, bromine, cadmium, mercury, and lead, in homoge-

polyolefins

neous polymeric materials. The test method may be used to

Polymers of similar composition but Differences in C/H among calibrants

ascertain the conformance of the product under test to manu-

differences in the relative and samples may result in biases of a

facturing specifications.Typical time for a measurement is 5 to

concentrations of H and C few percent (relative).

10 min per specimen, depending on the specimen matrix and

Unmeasured elements B, N, O, and F If concentrations differ from the

the capabilities of the EDXRF spectrometer.

present in the matrix of the polymer, calibrants, substantial concentrations

for example, amide, fluorinated, and of these elements may cause

6. Interferences

terephthalate compounds. significant changes in both apparent

sensitivity and background count rates.

6.1 Spectral Interferences—Spectral interferences result

from the behavior of the detector subsystem of the spectrom-

Absorption by elements present in Reduction of apparent sensitivity for

flame-retardant compounds such as most analytes

eter and from scattering of X rays by the specimen, by a

PBBs, PBDEs, and Sb O

2 3

secondary target or by a monochromator, if the spectrometer is

so equipped. Overlaps among the X-ray lines from elements in Absorption by Na, P, S, Ca, Ti, Zn, Reduction of apparent sensitivity for

Mo, Sn, Ba, and other elements most analytes

the specimen are caused by the limited resolution of the

included in a formulation as fillers or

detection subsystem. Depending upon the resolution of the

performance additives

detectorsystem,thepeaksfromZn,Br,HgandPbmayoverlap

F2617–08

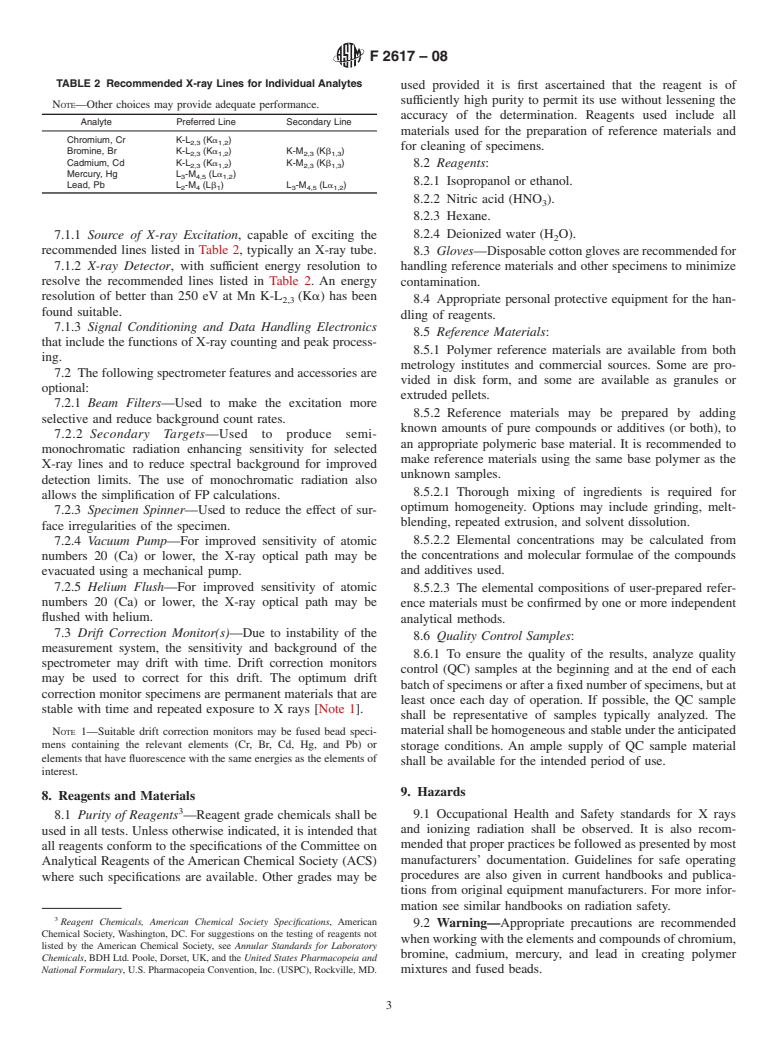

TABLE 2 Recommended X-ray Lines for Individual Analytes

used provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

NOTE—Other choices may provide adequate performance.

accuracy of the determination. Reagents used include all

Analyte Preferred Line Secondary Line

materials used for the preparation of reference materials and

Chromium, Cr K-L (Ka )

2,3 1,2

for cleaning of specimens.

Bromine, Br K-L (Ka)K-M (Kb )

2,3 1,2 2,3 1,3

Cadmium, Cd K-L (Ka)K-M (Kb )

2,3 1,2 2,3 1,3 8.2 Reagents:

Mercury, Hg L -M (La )

3 4,5 1,2

8.2.1 Isopropanol or ethanol.

Lead, Pb L -M (Lb)L -M (La )

2 4 1 3 4,5 1,2

8.2.2 Nitric acid (HNO ).

8.2.3 Hexane.

8.2.4 Deionized water (H O).

7.1.1 Source of X-ray Excitation, capable of exciting the

recommended lines listed in Table 2, typically an X-ray tube. 8.3 Gloves—Disposablecottonglovesarerecommendedfor

7.1.2 X-ray Detector, with sufficient energy resolution to

handling reference materials and other specimens to minimize

resolve the recommended lines listed in Table 2. An energy contamination.

resolution of better than 250 eV at Mn K-L (Ka) has been

2,3 8.4 Appropriate personal protective equipment for the han-

found suitable.

dling of reagents.

7.1.3 Signal Conditioning and Data Handling Electronics

8.5 Reference Materials:

that include the functions of X-ray counting and peak process-

8.5.1 Polymer reference materials are available from both

ing.

metrology institutes and commercial sources. Some are pro-

7.2 The following spectrometer features and accessories are

vided in disk form, and some are available as granules or

optional:

extruded pellets.

7.2.1 Beam Filters—Used to make the excitation more

8.5.2 Reference materials may be prepared by adding

selective and reduce background count rates.

known amounts of pure compounds or additives (or both), to

7.2.2 Secondary Targets—Used to produce semi-

an appropriate polymeric base material. It is recommended to

monochromatic radiation enhancing sensitivity for selected

make reference materials using the same base polymer as the

X-ray lines and to reduce spectral background for improved

unknown samples.

detection limits. The use of monochromatic radiation also

8.5.2.1 Thorough mixing of ingredients is required for

allows the simplification of FP calculations.

optimum homogeneity. Options may include grinding, melt-

7.2.3 Specimen Spinner—Used to reduce the effect of sur-

blending, repeated extrusion, and solvent dissolution.

face irregularities of the specimen.

8.5.2.2 Elemental concentrations may be calculated from

7.2.4 Vacuum Pump—For improved sensitivity of atomic

the concentrations and molecular formulae of the compounds

numbers 20 (Ca) or lower, the X-ray optical path may be

and additives used.

evacuated using a mechanical pump.

7.2.5 Helium Flush—For improved sensitivity of atomic

8.5.2.3 The elemental compositions of user-prepared refer-

numbers 20 (Ca) or lower, the X-ray optical path may be

ence materials must be confirmed by one or more independent

flushed with helium.

analytical methods.

7.3 Drift Correction Monitor(s)—Due to instability of the

8.6 Quality Control Samples:

measurement system, the sensitivity and background of the

8.6.1 To ensure the quality of the results, analyze quality

spectrometer may drift with time. Drift correction monitors

control (QC) samples at the beginning and at the end of each

may be used to correct for this drift. The optimum drift

batchofspecimensorafterafixednumberofspecimens,butat

correction monitor specimens are permanent materials that are

least once each day of operation. If possible, the QC sample

stable with time and repeated exposure to X rays [Note 1].

shall be representative of samples typically analyzed. The

NOTE 1—Suitable drift correction monitors may be fused bead speci- materialshallbehomogeneousandstableundertheanticipated

mens containing the relevant elements (Cr, Br, Cd, Hg, and Pb) or

storage conditions. An ample supply of QC sample material

elements that have fluorescence with the same energies as the eleme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.