ASTM D3806-19

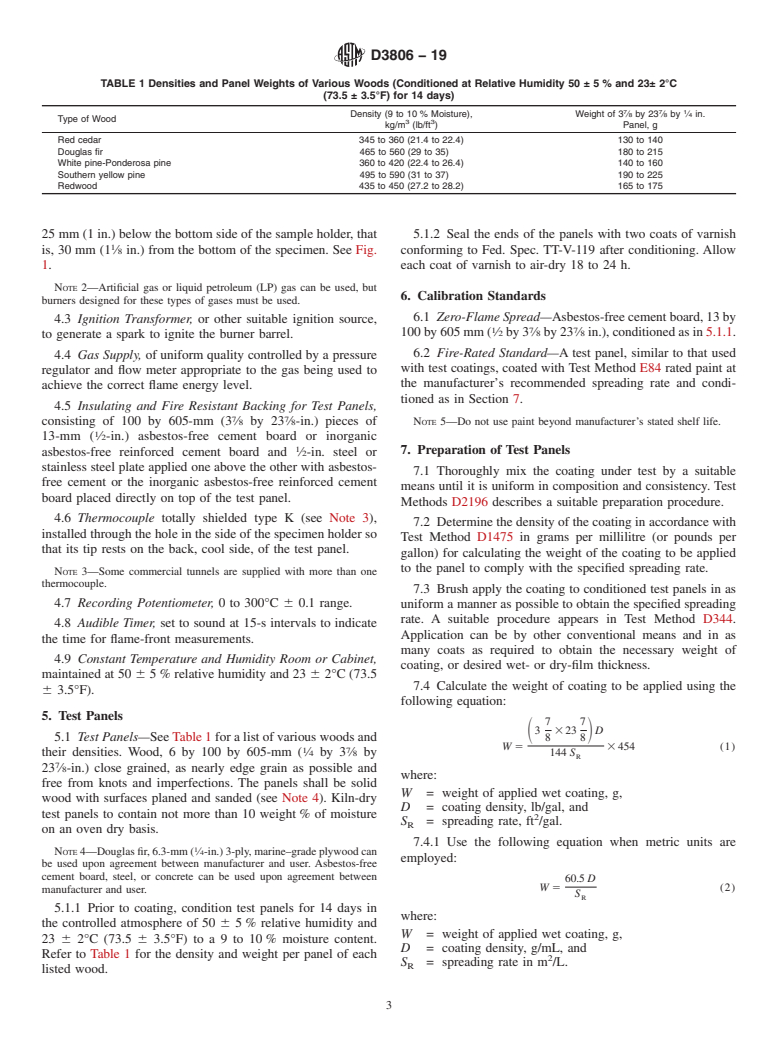

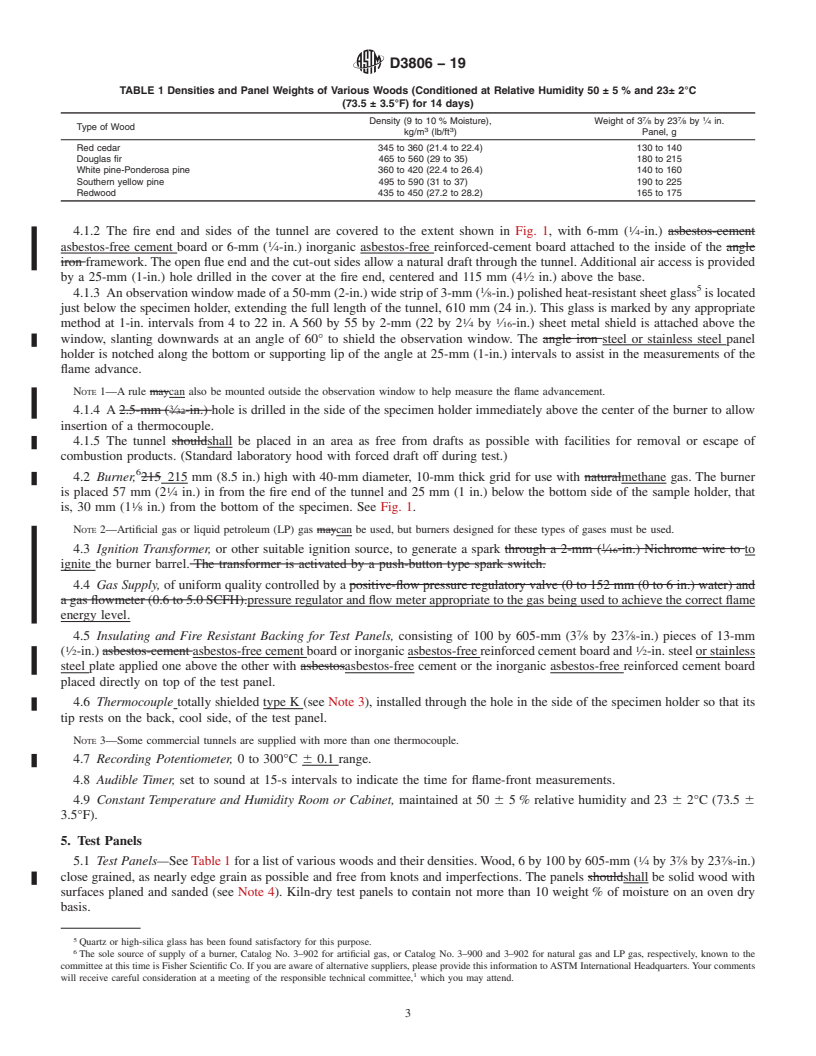

(Test Method)Standard Test Method of Small-Scale Evaluation of Fire-Retardant Paints (2-Foot Tunnel Method)

Standard Test Method of Small-Scale Evaluation of Fire-Retardant Paints (2-Foot Tunnel Method)

SIGNIFICANCE AND USE

3.1 A number of laboratory procedures are used to evaluate the effectiveness of fire-retardant and fire-resistant treatments and coatings. In general, these methods measure the three stages of fire development: (1) ignition; (2) flame spread (rate of growth of the fire); and (3) conflagration extent. While all three are of extreme importance, flame spread has been recognized as the main factor associated with testing fire-retardant coatings.

3.2 Flame spread ratings based upon Test Method E84 have acquired common acceptance by regulatory agencies, but such large-scale tests are seldom practical during the development or modification of a fire-retardant coating.

3.3 This test method provides the relative flame spread of experimental coatings using small test specimens under the conditions established in the 2-foot tunnel. By experimentally calibrating the 2-foot tunnel with similar Test Method E84-rated fire-retardant paint, results obtained by this test method can be used to screen coatings for suitability for testing in the Test Method E84 tunnel.

3.3.1 This test method is intended as an experimental tool in evaluating experimental coatings for further development. No direct correlation of results from this test method and the Test Method E84 tunnel have been made or are implied.

3.3.2 The results obtained by this test method do not in themselves act as an accurate predictor of performance in Test Method E84.

SCOPE

1.1 This test method determines the protection a coating affords its substrate, and the comparative burning characteristics of coatings by evaluating the flame spread over the surface when ignited under controlled conditions in a small tunnel. This establishes a basis for comparing surface-burning characteristics of different coatings without specific consideration of all the end-use parameters that might affect surface-burning characteristics under actual fire conditions.

1.2 In addition to the experimental flame spread rate, the weight of panel consumed, time of afterflaming and afterglow, char dimensions and index, and height of intumescence can be measured in this test. However, a relationship should not be presumed among these measurements.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3806 − 19

Standard Test Method of

Small-Scale Evaluation of Fire-Retardant Paints (2-Foot

1

Tunnel Method)

This standard is issued under the fixed designation D3806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method determines the protection a coating

affords its substrate, and the comparative burning characteris-

2. Referenced Documents

ticsofcoatingsbyevaluatingtheflamespreadoverthesurface

2

2.1 ASTM Standards:

when ignited under controlled conditions in a small tunnel.

D344Test Method for Relative Hiding Power of Paints by

This establishes a basis for comparing surface-burning charac-

3

the Visual Evaluation of Brushouts (Withdrawn 2018)

teristics of different coatings without specific consideration of

D1475Test Method for Density of Liquid Coatings, Inks,

all the end-use parameters that might affect surface-burning

and Related Products

characteristics under actual fire conditions.

D2196Test Methods for Rheological Properties of Non-

1.2 In addition to the experimental flame spread rate, the

Newtonian Materials by Rotational Viscometer

weight of panel consumed, time of afterflaming and afterglow,

E84Test Method for Surface Burning Characteristics of

char dimensions and index, and height of intumescence can be

Building Materials

measured in this test. However, a relationship should not be

2.2 Federal Standard:

presumed among these measurements.

4

Fed. Spec. TT-V-119Varnish, Spar, Phenolic Resin

1.3 The values stated in SI units are to be regarded as the

3. Significance and Use

standard. The values given in parentheses are for information

only.

3.1 Anumber of laboratory procedures are used to evaluate

the effectiveness of fire-retardant and fire-resistant treatments

1.4 This standard is used to measure and describe the

and coatings. In general, these methods measure the three

response of materials, products, or assemblies to heat and

stages of fire development: (1) ignition; (2) flame spread (rate

flame under controlled conditions, but does not by itself

incorporate all factors required for fire hazard or fire risk of growth of the fire); and (3) conflagration extent. While all

three are of extreme importance, flame spread has been

assessment of the materials, products, or assemblies under

actual fire conditions. recognized as the main factor associated with testing fire-

retardant coatings.

1.5 Fire testing is inherently hazardous. Adequate safe-

guards for personnel and property shall be employed in

3.2 Flame spread ratings based uponTest Method E84 have

conducting these tests.

acquired common acceptance by regulatory agencies, but such

1.6 This standard does not purport to address all of the

large-scale tests are seldom practical during the development

safety concerns, if any, associated with its use. It is the

or modification of a fire-retardant coating.

responsibility of the user of this standard to establish appro-

3.3 This test method provides the relative flame spread of

priate safety, health, and environmental practices and deter-

experimental coatings using small test specimens under the

mine the applicability of regulatory limitations prior to use.

conditions established in the 2-foot tunnel. By experimentally

1.7 This international standard was developed in accor-

calibrating the 2-foot tunnel with similar Test Method E84-

dance with internationally recognized principles on standard-

rated fire-retardant paint, results obtained by this test method

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint Standards volume information, refer to the standard’s Document Summary page on

and Related Coatings, Materials, andApplications and is the direct responsibility of the ASTM website.

3

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. The last approved version of this historical standard is referenced on

Current edition approved Oct. 1, 2019. Published October 2019. Originally www.astm.org.

4

approved in 1979. Last previous edition approved in 2016 as D3806–98(2016). Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

DOI: 10.1520/D3806-19. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C7

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3806 − 98 (Reapproved 2016) D3806 − 19

Standard Test Method of

Small-Scale Evaluation of Fire-Retardant Paints (2-Foot

1

Tunnel Method)

This standard is issued under the fixed designation D3806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method determines the protection a coating affords its substrate, and the comparative burning characteristics of

coatings by evaluating the flame spread over the surface when ignited under controlled conditions in a small tunnel. This

establishes a basis for comparing surface-burning characteristics of different coatings without specific consideration of all the

end-use parameters that might affect surface-burning characteristics under actual fire conditions.

1.2 In addition to the experimental flame spread rate, the weight of panel consumed, time of afterflaming and afterglow, char

dimensions and index, and height of intumescence maycan be measured in this test. However, a relationship should not be

presumed among these measurements.

1.3 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat

and flame under controlled laboratory conditions, and should not be used to describe or appraise the fire hazard or fire risk of

materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk

assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end

use.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.5 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C220 Specification for Flat Asbestos-Cement Sheets

3

D344 Test Method for Relative Hiding Power of Paints by the Visual Evaluation of Brushouts (Withdrawn 2018)

D1475 Test Method for Density of Liquid Coatings, Inks, and Related Products

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer

E84 Test Method for Surface Burning Characteristics of Building Materials

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Dec. 1, 2016Oct. 1, 2019. Published December 2016October 2019. Originally approved in 1979. Last previous edition approved in 20112016

as D3806 – 98 (2011).(2016). DOI: 10.1520/D3806-98R16.10.1520/D3806-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3806 − 19

2.2 Federal Standard:

4

Fed. Spec. TT-V-119 Varnish, Spar, Phenolic Resin

3. Significance and Use

3.1 A numbe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.