ASTM B603-90(2001)

(Specification)Standard Specification for Drawn or Rolled Iron-Chromium-Aluminum Alloys for Electrical Heating Elements

Standard Specification for Drawn or Rolled Iron-Chromium-Aluminum Alloys for Electrical Heating Elements

SCOPE

1.1 This specification covers annealed, drawn, or rolled shapes for electrical heating and resistance purposes of alloys consisting mainly of iron, chromium, and aluminum as detailed in Table 1.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 603 – 90 (Reapproved 2001)

Standard Specification for

Drawn or Rolled Iron-Chromium-Aluminum Alloys for

Electrical Heating Elements

This standard is issued under the fixed designation B 603; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

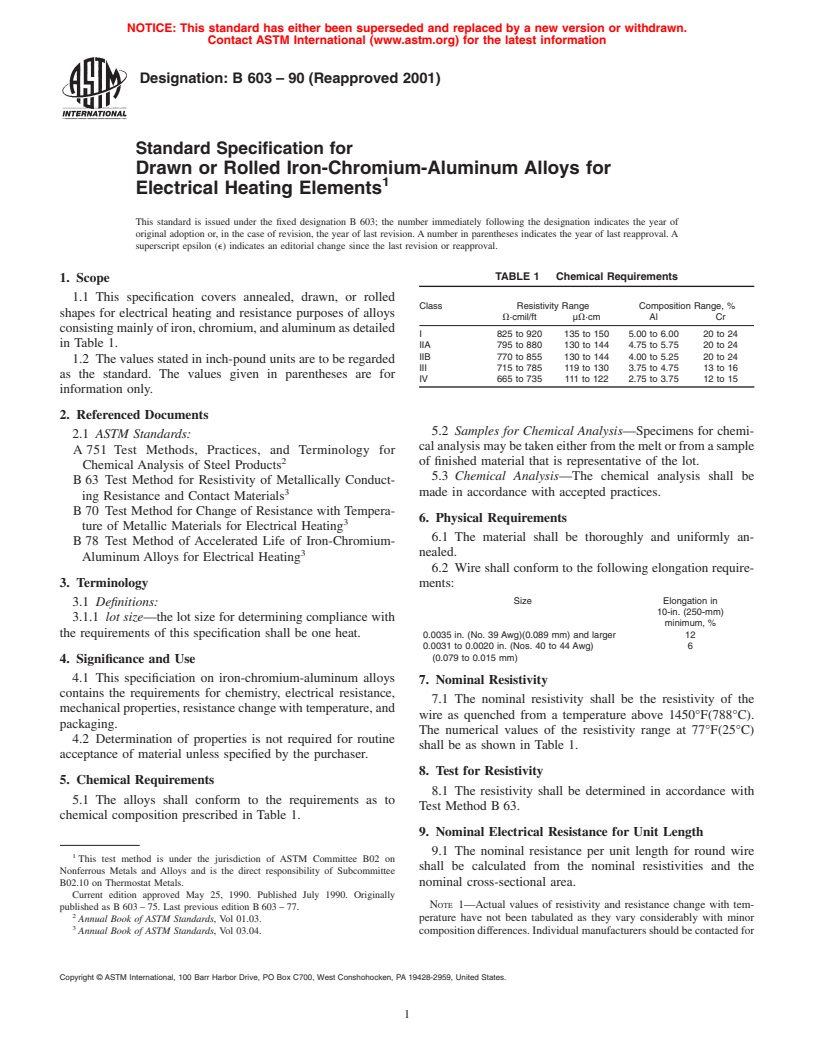

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers annealed, drawn, or rolled

Class Resistivity Range Composition Range, %

shapes for electrical heating and resistance purposes of alloys

V·cmil/ft µV·cm Al Cr

consistingmainlyofiron,chromium,andaluminumasdetailed

I 825 to 920 135 to 150 5.00 to 6.00 20 to 24

in Table 1.

IIA 795 to 880 130 to 144 4.75 to 5.75 20 to 24

IIB 770 to 855 130 to 144 4.00 to 5.25 20 to 24

1.2 The values stated in inch-pound units are to be regarded

III 715 to 785 119 to 130 3.75 to 4.75 13 to 16

as the standard. The values given in parentheses are for

IV 665 to 735 111 to 122 2.75 to 3.75 12 to 15

information only.

2. Referenced Documents

5.2 Samples for Chemical Analysis—Specimens for chemi-

2.1 ASTM Standards:

calanalysismaybetakeneitherfromthemeltorfromasample

A 751 Test Methods, Practices, and Terminology for

2 of finished material that is representative of the lot.

Chemical Analysis of Steel Products

5.3 Chemical Analysis—The chemical analysis shall be

B 63 Test Method for Resistivity of Metallically Conduct-

made in accordance with accepted practices.

ing Resistance and Contact Materials

B 70 Test Method for Change of Resistance with Tempera-

6. Physical Requirements

ture of Metallic Materials for Electrical Heating

6.1 The material shall be thoroughly and uniformly an-

B 78 Test Method of Accelerated Life of Iron-Chromium-

nealed.

Aluminum Alloys for Electrical Heating

6.2 Wire shall conform to the following elongation require-

3. Terminology ments:

Size Elongation in

3.1 Definitions:

10-in. (250-mm)

3.1.1 lot size—the lot size for determining compliance with

minimum, %

the requirements of this specification shall be one heat.

0.0035 in. (No. 39 Awg)(0.089 mm) and larger 12

0.0031 to 0.0020 in. (Nos. 40 to 44 Awg) 6

(0.079 to 0.015 mm)

4. Significance and Use

4.1 This specificiation on iron-chromium-aluminum alloys

7. Nominal Resistivity

contains the requirements for chemistry, electrical resistance,

7.1 The nominal resistivity shall be the resistivity of the

mechanicalproperties,resistancechangewithtemperature,and

wire as quenched from a temperature above 1450°F(788°C).

packaging.

The numerical values of the resistivity range at 77°F(25°C)

4.2 Determination of properties is not required for routine

shall be as shown in Table 1.

acceptance of material unless specified by the purchaser.

8. Test for Resistivity

5. Chemical Requirements

8.1 The resistivity shall be determined in accordance with

5.1 The alloys shall conform to the requirements as to

Test Method B 63.

chemical composition prescribed in Table 1.

9. Nominal Electrical Resistance for Unit Length

9.1 The nominal resistance per unit length for round wire

This test method is under the jurisdiction of ASTM Committee B02 on

shall be calculated from the nominal resistivities and the

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.10 on Thermostat Metals. nominal cross-sectional area.

Current edition approved May 25, 1990. Published July 1990. Originally

NOTE 1—Actual values of resistivity and resistance change with tem-

published as B 603 – 75. Last previous edition B 603 – 77.

perature have not been tabulated as they vary considerably with minor

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 03.04. composition differences. Individual manufacturers should be contacted for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 603

detailed information regarding their properties.

11. Resist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.