ASTM A627-95

(Specification)Standard Specification for Homogeneous Tool-Resisting Steel Bars for Security Applications

Standard Specification for Homogeneous Tool-Resisting Steel Bars for Security Applications

SCOPE

1.1 This specification covers requirements for the performance characteristics including conventional mechanical tests, simulated service tests and testing equipment for determining the characteristics of homogeneous tool-resisting steel bars and does not preclude the possibility of severing or penetrating this material by cutting means other than those described herein. This material can be severed with tungsten/carbide coated or tipped saws.

1.2 Three tests, describing minimum performance characteristics required for bars of different diameters covered by this specification are: (1) drop-weight test, (2) cutting test, and (3) deflection test.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 627 – 95

Standard Specification for

Homogeneous Tool-Resisting Steel Bars for Security

1

Applications

This standard is issued under the fixed designation A 627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2 cutting test—a simulated service test in which the rating

is based on the calculated theoretical number of a specific type

1.1 This specification covers requirements for the perfor-

of ordinary hacksaw blades required to cut through the bar.

mance characteristics including conventional mechanical tests,

3.3 equipment manufacturer—a manufacturer who fabri-

simulated service tests and testing equipment for determining

cates and assembles security products, including tool-resisting

the characteristics of homogeneous tool-resisting steel bars and

steel enclosures, for installation in areas requiring security

does not preclude the possibility of severing or penetrating this

against ingress and egress. This manufacturer processes the

material by cutting means other than those described herein.

semifinished bar to produce a finished bar suitable for fabrica-

This material can be severed with tungsten/carbide coated or

tion into components and is responsible for all heat-treating

tipped saws.

and other fabricating processes to obtain the performance

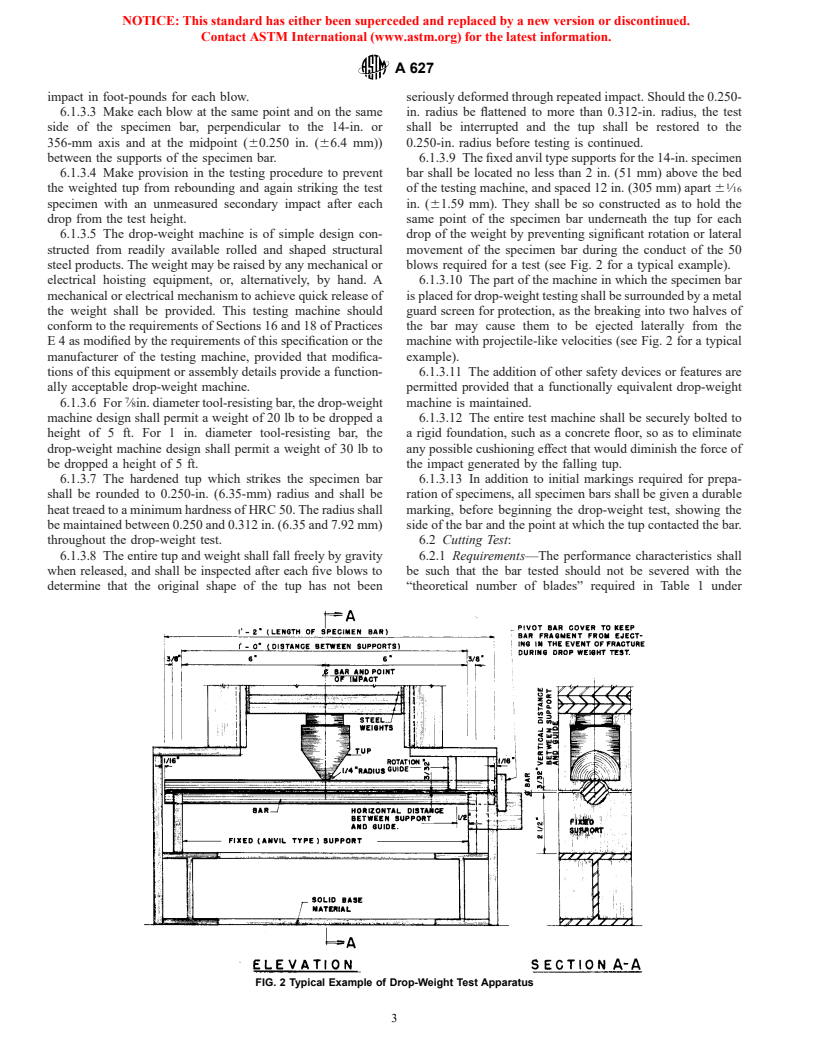

1.2 Three tests, describing minimum performance charac-

characteristics specified herein. This manufacturer is also

teristics required for bars of different diameters covered by this

responsible for fabricating and assembling all ancillary items

specification are: (1) drop-weight test, (2) cutting test, and (3)

so as not to impair the performance characteristics of the bar.

deflection test.

3.4 homogeneous bar—a bar that is nominally of uniform

1.3 The values stated in inch-pound units are to be regarded

chemistry throughout.

as the standard.

3.5 lot—all bars of the same nominal diameter from the

2. Referenced Documents same mill heat.

3.6 performance characteristic—the response to any one

2.1 ASTM Standards:

test (drop-weight, cutting, or deflection) shown in Table 1.

C 39 Test Method for Compressive Strength of Cylindrical

2

3.7 test completion—conduct of one test sequence for each

Concrete Specimens

3

lot of bars.

E 4 Practices for Force Verification of Testing Machines

3.8 testing laboratory—a recognized testing laboratory, ca-

E 329 Specification for Agencies Engaged in the Testing

4

pable of complying with Practice E 329, selected by the

and/or Inspection of Materials Used in Construction

equipment manufacturer.

2.2 Other Documents:

3.9 test sequence—conduct of drop-weight test and cutting

U. S. Federal Specification GGG-B-451c, dated April 11,

test on one specimen bar, and conduct of deflection test on one

1960, and Amendments 1, 2, and 3: Blade, Hand Hacksaw

5

additional specimen bar.

and Blade, Power Hacksaw

4. Ordering Information

3. Terminology

4.1 Orders for material under this specification shall include

3.1 bars—round, ribbed, hexagonal, or other shaped bars

7 the following information:

that can readily be reduced to a round cross-sectional shape, ⁄8

4.1.1 Name of material (homogeneous tool-resisting steel),

to 1 in. (22.2 to 25.4 mm) in diameter (see Fig. 1).

4.1.2 Dimensions (nominal diameter),

4.1.3 Cross section (double-ribbed round, hexagon, other

1

This specification is under the jurisdiction of ASTM Committee F-33 on

shapes),

Detention and Correctional Facilities and is the direct responsibility of Subcommit-

4.1.4 ASTM designation (A 627),

tee F33.02 on Physical Barriers.

4.1.5 Test reports (if required),

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as A 627 – 68. Last previous edition A 627 – 88.

4.1.6 Certification (if required), and

2

Annual Book of ASTM Standards, Vol 04.02.

4.1.7 Special requirements (if any).

3

Annual Book of ASTM Standards, Vol 03.01.

4

4.2 Bars of different nominal diameters may be specified or

Annual Book of ASTM Standards, Vol 14.02.

5

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 shown on drawings. Each bar of the nominal diameter tested

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 627

FI

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.