ASTM D5420-98a

(Test Method)Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)

Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)

SCOPE

1.1 This test method covers the determination of the relative ranking of materials according to the energy required to crack or break flat, rigid plastic specimens under various specified conditions of impact of a striker impacted by a falling weight.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: D 5420 – 98a

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimen by Means

of a Striker Impacted by a Falling Weight (Gardner Impact)

This standard is issued under the fixed designation D5420; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* (Vinyl Chloride) (PVC) Building Products

D5628 Test Method for Impact Resistance of Flat, Rigid

1.1 Thistestmethodcoversthedeterminationoftherelative

Plastic Specimens by Means of a Falling Dart (Tup or

ranking of materials according to the energy required to crack

Falling Weight)

or break flat, rigid plastic specimens under various specified

E171 Specification for Standard Atmospheres for Condi-

conditions of impact of a striker impacted by a falling weight.

tioning and Testing Flexible Barrier Materials

1.2 The values stated in SI units are to be regarded as the

E691 Practice for Conducting an Interlaboratory Study to

standard. The values given in parentheses are for information

Determine the Precision of a Test Method

only.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions—For definitions of plastics terms used in

responsibility of the user of this standard to establish appro-

this test method, see Terminologies D 883 and

priate safety and health practices and determine the applica-

D1600D883D1600.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—There is no similar or equivalent ISO standard.

3.2.1 failure (of test specimen)—the presence of any crack

or split created by the impact of the falling weight that can be

2. Referenced Documents

seen by the naked eye under normal laboratory lighting

2.1 ASTM Standards:

conditions.

D374 Test Methods for Thickness of Solid Electrical Insu-

3.2.1.1 Discussion—Failure shall include the following:

lation

(1) complete shattering of the plaque; (2) any crack radiating

D618 Practice for Conditioning Plastics and Electrical

out toward the edges of the plaque on either surface of the

Insulating Materials for Testing

plaque; (3) any radial crack within or just outside the impact

D883 Terminology Relating to Plastics

area of the striker; (4) any hole in the plaque, whether due to

D1600 Terminology for Abbreviated Terms Relating to

brittle or ductile puncture, where unobstructed light or water

Plastics

could pass through; (5) any brittle splitting of the bottom

D1898 Practice for Sampling of Plastics

surface of the plaque; and (6) any glassy-type chip dislodged

D2794 Test Method for Resistance of Organic Coatings to

from or loosened from the plaque.

the Effects of Rapid Deformation (Impact)

3.2.1.2 Discussion—Since the interpretation of failure may

D3763 Test Method for High-Speed Puncture Properties of

be slightly different between material types, refer to the

Plastics Using Load and Displacement Sensors

appropriate material specification for guidance.

D4066 Specification for Nylon Injection and Extrusion

3.2.1.3 Discussion—Cracks usually start at the surface op-

Materials

posite the one that is struck. Occasionally incipient cracking in

D4226 Test Methods for Impact Resistance of Rigid Poly-

glass-reinforced polymers, for example, may be difficult to

differentiate from the reinforcing fibers. In such cases, a

penetrating dye may be used to confirm the onset of crack

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics formation.

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Jan. and May 10, 1998. Published February 1999.

Originally published as D5420–93. Last previous edition D5420–96.

2 6

Annual Book of ASTM Standards, Vols 10.01. Annual Book of ASTM Standards, Vol 08.04.

3 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

4 8

Annual Book of ASTM Standards, Vol 06.01. Annual Book of ASTM Standards, Vol 15.09.

5 9

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 5420 – 98a

3.2.2 mean-failure energy (mean impact resistance)—the 5. Significance and Use

energy required to produce 50% failures, equal to the product

5.1 Plastics are viscoelastic and therefore may be sensitive

of the constant mass and mean failure height.

to changes in velocity of weights falling on their surfaces.

3.2.3 mean-failure height (impact-failure height)—the

However, the velocity of a free-falling object is a function of

height at which a standard mass, when dropped on test

the square root of the drop height.Achange of a factor of two

specimens, will cause 50% failures.

in the drop height will cause a change of only 1.4 in velocity.

Hagan, et al (2) found that the mean-failure energy of sheeting

wasconstantatdropheightsbetween0.30and1.4m.Different

materials respond differently to changes in the velocity of

impact.

5.2 The test conditions used in Geometry GA are the same

as those used in Geometry FA of Test Method D5628D5628

(see Table 1).

5.3 The test conditions of Geometry GB are equivalent to

thegeometryusedfortheGardnerVariableHeightImpactTest

(3).

5.4 The test conditions of Geometry GC cause a punch-

shear type of failure because the support-plate hole is close to

the diameter of the striker.

5.5 The test conditions of Geometry GD are the same as

those in Test Method D3763D3763.

5.6 The test conditions of Geometry GE are the same as

those in Test Method D4226D4226, impactor head configu-

ration H.25.

5.7 Because of the nature of impact testing, the selection of

a test method and striker must be somewhat arbitrary. While

any one of the striker geometries may be selected, knowledge

of the final or intended end-use application should be consid-

ered.

6. Interferences

6.1 Falling-weight-impact test results are dependent on the

geometry of the falling weight, striker, and the support. Thus,

impact tests should be used only to obtain relative rankings of

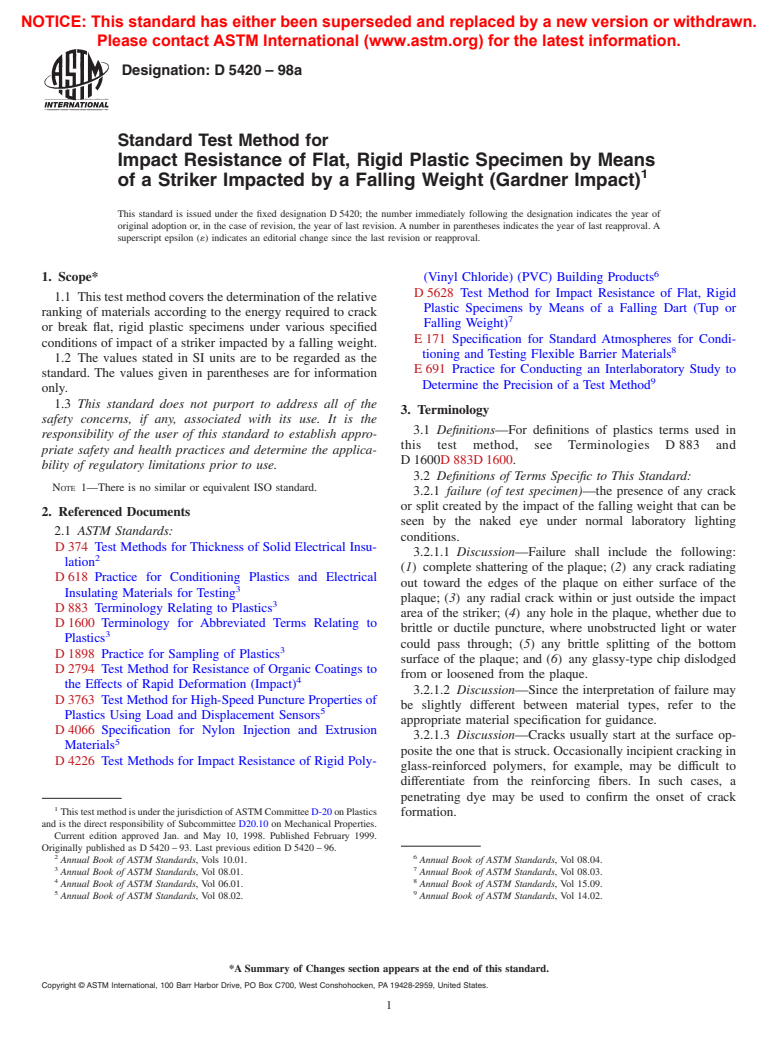

FIG. 1 Impact Tester

materials. Impact values cannot be considered absolute unless

the geometry of the test equipment and specimen conform to

the end-use requirement. Data obtained with different geom-

4. Summary of Test Method

etries,cannot,ingeneral,becompareddirectlywitheachother.

4.1 In this test method, a weight falls through a guide tube

6.1.1 Falling-weight-impact types of tests are not suitable

and impacts a striker resting on top of a supported specimen.

for predicting the relative ranking of materials at impact

The fixed weight is dropped from various heights (see Fig. 1).

velocities differing greatly from those imposed by these test

4.2 The procedure determines the energy

methods.

(mass 3gravity 3height) that will cause 50% of the speci-

6.2 As cracks usually start at the surface opposite the one

mens tested to fail (mean-failure energy).

that is struck, the results obtained can be greatly influenced by

4.3 The technique used to determine mean-failure energy is

thequalityofthetestspecimens.Therefore,thecompositionof

commonly called the Bruceton Staircase Method, or the

this surface layer and the degree of orientation introduced

Up-and-Down Method (1). Testing is concentrated near the

mean, reducing the number of specimens required to obtain a

TABLE 1 Striker and Specimen-Support-Plate Dimensions

reasonably precise estimate of the impact resistance.

Striker Diameter, Support Plate Inside Diameter, mm

Geometry

4.4 This test method permits the use of different striker

mm (in.) (in.)

diameters and specimen support plate geometries to obtain

GA 15.86 6 0.10 76.06 3.0

different modes of failure, permit easier sampling, or test

(0.625 6 0.004) (3.00 6 0.12)

GB 15.86 6 0.10 31.756 0.025

limited amounts of material. There is no known means for

(0.625 6 0.004) (1.25 6 0.001)

correlating the results of tests made by different methods or

GC 15.86 6 0.10 16.26 6 0.025

procedures.

(0.625 6 0.004) (0.640 6 0.001)

GD 12.70 6 0.10 76.0 6 3.0

(0.500 6 0.004) (3.00 6 0.12)

GE 12.70 6 0.10 16.26 6 0.025

Theboldfacenumbersinparenthesesrefertothelistofreferencesfoundatthe (0.500 6 0.004) (0.640 6 0.001)

end of this test method.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 5420 – 98a

during the formation of the specimen (such as may occur

during injection molding, if substandard conditions are used)

are very important variables. Flaws in this surface will also

affect results.

6.3 Impact properties of plastic materials can be very

sensitive to temperature. This test can be carried out at any

reasonable temperature and humidity, thus representing actual-

use environments. However, this test method is intended

primarily for rating materials under specific impact conditions.

6.4 The apparatus used in this test method may not have

sufficient energy available to cause failure of some specimens

under the conditions of this procedure.

7. Apparatus

7.1 Testing Mechanism—The apparatus is shown in Fig. 1.

This apparatus can either be adapted from Test Method

D2794D2794 or obtained commercially and shall consist of

the following: suitable base to withstand the impact shock;

steel-rod impact mass, weighing 0.9 kg (2 lb), 1.8 kg (4 lb), or

3.6 kg (8 lb); a hardened steel striker having a round nose with

diameter described in 7.1.1 and 7.1.2 and Table 1; a slotted

guide tube 1.0 m (40 in.) in length, in which the impact mass

slides, having graduations in newton-metres (inch-pound in-

crements) or multiples thereof. A bracket is used to hold the

tube in a vertical position by attaching it to the base and also

to hold the hand knob, which is a pivot arm alignment for the

striker, about 50 mm (2 in.) under the tube. This instrument

shall be mounted firmly to a rigid table or bench.The top edge

of the opening in each specimen-support plate should be

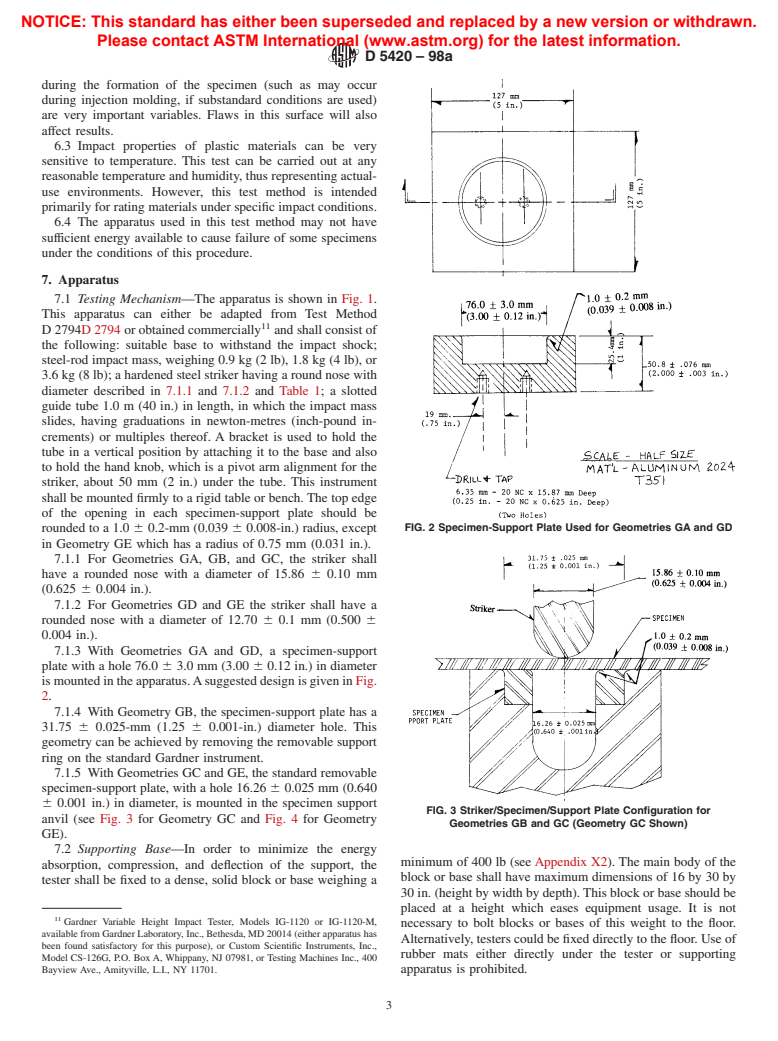

rounded to a 1.0 6 0.2-mm (0.039 6 0.008-in.) radius, except FIG. 2 Specimen-Support Plate Used for Geometries GA and GD

in Geometry GE which has a radius of 0.75 mm (0.031 in.).

7.1.1 For Geometries GA, GB, and GC, the striker shall

have a rounded nose with a diameter of 15.86 6 0.10 mm

(0.625 6 0.004 in.).

7.1.2 For Geometries GD and GE the striker shall have a

rounded nose with a diameter of 12.70 6 0.1 mm (0.500 6

0.004 in.).

7.1.3 With Geometries GA and GD, a specimen-support

plate with a hole 76.0 6 3.0 mm (3.00 6 0.12 in.) in diameter

ismountedintheapparatus.AsuggesteddesignisgiveninFig.

2.

7.1.4 With Geometry GB, the specimen-support plate has a

31.75 6 0.025-mm (1.25 6 0.001-in.) diameter hole. This

geometry can be achieved by removing the removable support

ring on the standard Gardner instrument.

7.1.5 With Geometries GC and GE, the standard removable

specimen-support plate, with a hole 16.26 6 0.025 mm (0.640

6 0.001 in.) in diameter, is mounted in the specimen support

FIG. 3 Striker/Specimen/Support Plate Configuration for

anvil (see Fig. 3 for Geometry GC and Fig. 4 for Geometry

Geometries GB and GC (Geometry GC Shown)

GE).

7.2 Supporting Base—In order to minimize the energy

minimum of 400 lb (seeAppendix X2). The main body of the

absorption, compression, and deflection of the support, the

block or base shall have maximum dimensions of 16 by 30 by

tester shall be fixed to a dense, solid block or base weighing a

30in.(heightbywidthbydepth).Thisblockorbaseshouldbe

placed at a height which eases equipment usage. It is not

Gardner Variable Height Impact Tester, Models IG-1120 or IG-1120-M,

necessary to bolt blocks or bases of this weight to the floor.

available from Gardner Laboratory, Inc., Bethesda, MD 20014 (either apparatus has

Alternatively,testerscouldbefixeddirectlytothefloor.Useof

been found satisfactory for this purpose), or Custom Scientific Instruments, Inc.,

rubber mats either directly under the tester or supporting

Model CS-126G, P.O. BoxA, Whippany, NJ 07981, or Testing Machines Inc., 400

Bayview Ave., Amityville, L.I., NY 11701. apparatus is prohibited.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 5420 – 98a

parts, however, should be tested in the as-received condition to

determine conformance to specified standards.

9.5 Select a suitable method for making the specimen that

will minimize the effect of specimen preparation on the impact

resistance of the material. Refer to the appropriate material

specification for requirements for specimen preparation.

NOTE 3—As few as ten specimens often yield sufficiently reliable

estimatesofthemean-failureheight.However,insuchcasestheestimated

standard deviation will be relatively large (1).

10. Conditioning

10.1 Unless otherwise specified, condition the test speci-

NOTE 1—Depth of penetration when fully seated shall be 12.2 6 0.1

mm (0.48 6 0.04 in.). mens at 23 6 2°C (73.4 6 3.6°F) and 50 6 5% relative

FIG. 4 Striker/Specimen/Support Plate Configuration for

humidityfornotlessthan40hpriortotest,inaccordancewith

Geometry GE

Procedure A of Practice D 618D 618 and Specification

E171E171, for those tests where conditioning is required. In

cases of disagreement, the tolerances shall be 61°C (61.8°F)

7.2.1 Supporting bases or tables lighter than 400 lb should

and 62% relative humidity.

be bolted to a concrete floor. For each different material tested,

10.1.1 Note that for some hygroscopic materials, such as

comparisons between MFE data generated using this support

nylons, the material specifications (for example, Specification

and one where the tester is fixed directly to the concrete floor

D4066D4066) call for testing “dry as-molded specimens.”

should be made. If MFE differences between two types of

Such requirements take precedence over the above routine

supports are found to be statistically nonsignificant, use of the

preconditioning to 50% relative humidity and require sealing

lighter support shall be allowed.

the specimens in water vapor-impermeable containers as soon

as molded and not removing them until ready for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.