ASTM D924-99e1

(Test Method)Standard Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical Insulating Liquids

Standard Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical Insulating Liquids

SCOPE

1.1 This test method covers new electrical insulating liquids as well as liquids in service or subsequent to service in cables, transformers, oil circuit breakers, and other electrical apparatus.

1.2 This test method provides a procedure for making referee tests at a commercial frequency of approximately 60 Hz.

1.3 Where it is desired to make routine determinations requiring less accuracy, certain modifications to this test method are permitted as described in Sections 17 to 25.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. Specific precautions are given in 14.4.2.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 924 – 99

Standard Test Method for

Dissipation Factor (or Power Factor) and Relative

Permittivity (Dielectric Constant) of Electrical Insulating

Liquids

This standard is issued under the fixed designation D 924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial corrections were made in December 1999.

1. Scope electric Dissipation Factor (Tan 8) and DC Resistivity of

Insulating Liquids

1.1 This test method covers new electrical insulating liquids

as well as liquids in service or subsequent to service in cables,

3. Terminology

transformers, oil circuit breakers, and other electrical appara-

3.1 Definitions—Definitions of terms used in this test

tus.

method are given in Terminology D 2864.

1.2 This test method provides a procedure for making

referee tests at a commercial frequency of between 45 and 65

4. Significance and Use

Hz.

4.1 Dissipation Factor (or Power Factor)—This is a mea-

1.3 Where it is desired to make routine determinations

sure of the dielectric losses in an electrical insulating liquid

requiring less accuracy, certain modifications to this test

when used in an alternating electric field and of the energy

method are permitted as described in Sections 19 to 27.

dissipated as heat. A low dissipation factor or power factor

1.4 This standard does not purport to address all of the

indicates low a-c dielectric losses. Dissipation factor or power

safety concerns, if any, associated with its use. It is the

factor may be useful as a means of quality control, and as an

responsibility of the user of this standard to establish appro-

indication of changes in quality resulting from contamination

priate safety and health practices and to determine the

and deterioration in service or as a result of handling.

applicability of regulatory limitations prior to use. Specific

4.1.1 The loss characteristic is commonly measured in

precautions are given in 14.4.2.

terms of dissipation factor (tangent of the loss angle) or of

2. Referenced Documents power factor (sine of the loss angle) and may be expressed as

a decimal value or as a percentage. For decimal values up to

2.1 ASTM Standards:

0.05, dissipation factor and power factor values are equal to

D 150 Test Methods for AC Loss Characteristics and Per-

each other within about one part in one thousand. In general,

mittivity (Dielectric Constant) of Solid Electrical Insulat-

since the dissipation factor or power factor of insulating oils in

ing Materials

good condition have decimal values below 0.005, the two

D 923 Test Method for Sampling Electrical Insulating Liq-

3 measurements (terms) may be considered interchangeable.

uids

4.1.2 The exact relationship between dissipation factor (D)

D 2864 Terminology Relating to Electrical Insulating Liq-

3 and power factor (PF) is given by the following equations:

uids and Gases

E 145 Specification for Gravity-Convection and Forced- D PF

PF 5 D 5 (1)

2 2

Ventilation Ovens

=1 1 D =12~PF!

2.2 Other Standard:

The reported value of D or PF may be expressed as a

IEC 247–1978 Measurement of Relative Permittivity, Di-

decimal value or as a percentage. For example:

D or PF at 25°C 5 0.002 or 0.2% (2)

4.2 Relative Permittivity (Dielectric Constant)—Insulating

This test method is under the jurisdiction of ASTM Committee D-27 on

liquids are used in general either to insulate components of an

Electrical Insulating Liquids and Gasesand is the direct responsibility of Subcom-

mittee D27.05 on Electrical Test.

electrical network from each other and from ground, alone or

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as D 924 – 47 T. Last previous edition D 924 – 92.

Annual Book of ASTM Standards, Vol 10.01.

3 5

Annual Book of ASTM Standards, Vol 10.03. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 14.02. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 924

in combination with solid insulating materials, or to function as requirements given in the Annex are considered suitable for use

the dielectric of a capacitor. For the first use, a low value of in making these tests.

relative permittivity is often desirable in order to have the

9.2 Automatic Thermo-Regulator Cell:

capacitance be as small as possible, consistent with acceptable 9.2.1 When tests are to be made above room temperature

chemical and heat transfer properties. However, an intermedi-

but below the flash point, an automatic thermo-regulator cell

ate value of relative permittivity may sometimes be advanta- can be used as long as it provides uniform heating of the test

geous in achieving a better voltage distribution of a-c electric

cell.

fields between the liquid and solid insulating materials with 9.2.2 The automatic thermo-regulator cell must be able to

which the liquid may be in series. When used as the dielectric

provide rapid, controlled rate of temperature rise, and be able

in a capacitor, it is desirable to have a higher value of relative to maintain a liquid temperature constant to within 6 1°C.

permittivity so the physical size of the capacitor may be as

small as possible. 10. Apparatus

10.1 Forced-Draft Oven:

NOTE 1—See Terminology D 2864 for further definitions.

10.1.1 When the tests are to be made above room tempera-

5. General Considerations

ture, a suitable forced-draft, thermostatically controlled oven

5.1 Measuring equipment used in these procedures shall be

shall be used as the test chamber. The oven must be capable of

in accordance with Test Methods D 150.

meeting the temperature requirements set out in Section 14.

5.2 Theory relating to dielectric measurement techniques

For tests at room temperature the unheated oven can be

and to the sources of dielectric loss is given in Test Methods

conveniently used as the test chamber.

D 150.

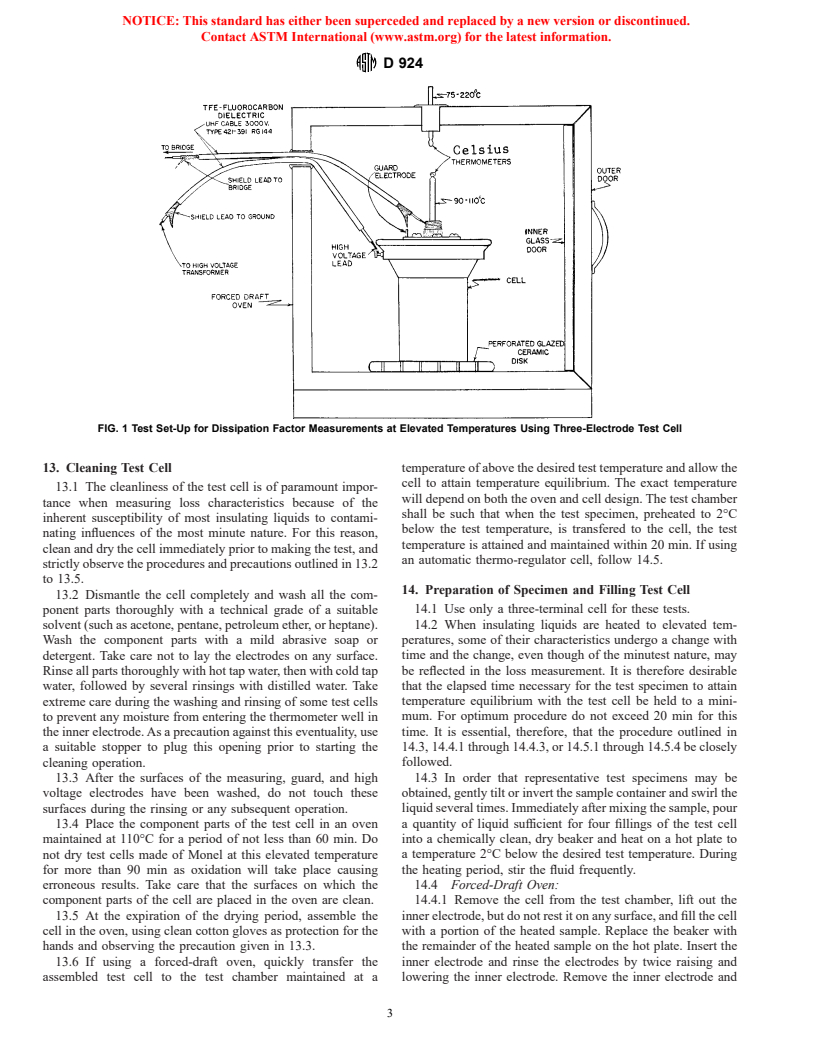

10.1.2 Provide the test chamber with an opening in the wall

through which two lengths of TFE-fluorocarbon-insulated (or

6. Sampling

similar) shielded cable pass to make electrical connection from

6.1 Sample electrical insulating liquids in accordance with

the measuring equipment and high-voltage transformer, respec-

Test Methods D 923. Samples to be subjected to this test

tively, to the test cell. Use a perforated ceramic plate or disk to

should preferably be obtained through a closed system. If

insulate the test cell from the metal flooring of the oven if the

exposed to atmospheric conditions, it is preferable to take the

flooring is not insulated from the oven. Provide a safety

sample when the relative humidity is 50 % or less. If it is not

interlock on the door of the oven so that the electrical circuit

feasible, the length of time the sample is exposed to atmo-

supplying voltage to the test cell will be broken when the oven

spheric conditions must be kept to a minimum.

door is opened.

6.2 Some liquids, in certain applications, require special

10.1.3 A cross-sectional view of the test chamber with a

handling and processes in the sampling, and these will be

three-electrode test cell in place and with test cables connected

found in the governing procedures. Consult such procedures

is shown in Fig. 1.

before samples are taken. The relative humidity should be

taken at the time of sampling and recorded with the sample

11. Test Temperature

identification.

11.1 The temperature at which a referee test is made shall be

6.3 The quantity of sample taken for this test shall be

mutually agreed upon between the purchaser and the seller.

sufficient for at least three separate determinations of loss

Measurements are made at many different temperatures. For

characteristics and relative permittivity.

acceptance tests, it is generally made at a temperature of

6.4 The loss characteristic measurement (dissipation factor

100°C, while for routine testing it is usually made at room

or power factor) may be affected by contamination introduced

temperature, 85 or 100°C. In some research investigations,

during sampling and subsequent handling.

tests may be made at considerably higher temperatures while in

7. Conditioning and Storing Sample

other cases, particularly for tests on cable oils in service, tests

7.1 Store the sample in its original sealed container,

may be made over a range of temperatures.

shielded from either natural or artificial light. Some liquids,

such as oils of petroleum origin, undergo changes when

12. Test Voltage

exposed to sunlight. Allow the sealed container to stand

12.1 The average stress to which the specimen is subjected

undisturbed in the room in which the test is to be made for a

shall not be less than 200 V/mm (5 V/mil) (rms). Tests at higher

sufficient period of time to permit the sample to attain room

stresses are desirable but shall not reach such values that

temperature before it is opened.

electrical discharges across the cell insulating surfaces occur or

8. Storing Test Cell

that internal ionization of the specimen may be expected.

Stress ranges in normal usage for referee tests are 200 to 1200

8.1 When not in use, clean and dry the test cell in accor-

V/mm (5 to 30 V/mil) (rms).

dance with Section 13 and store in a dust-free cabinet until

ready for use, at which time clean and dry the cell again in 12.2 Because the ac loss characteristics can vary with

voltage stress, for reference purposes it is desirable to make the

accordance with Section 13.

measurements at a specific value of voltage stress within the

PROCEDURE FOR MAKING REFEREE TESTS

limits in 12.1.

9. Test Cells

12.3 Referee tests should be carried out in the frequency

9.1 The design of test cells that conform to the general range 45–65 H2.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 924

FIG. 1 Test Set-Up for Dissipation Factor Measurements at Elevated Temperatures Using Three-Electrode Test Cell

13. Cleaning Test Cell temperature of above the desired test temperature and allow the

cell to attain temperature equilibrium. The exact temperature

13.1 The cleanliness of the test cell is of paramount impor-

will depend on both the oven and cell design. The test chamber

tance when measuring loss characteristics because of the

shall be such that when the test specimen, preheated to 2°C

inherent susceptibility of most insulating liquids to contami-

below the test temperature, is transfered to the cell, the test

nating influences of the most minute nature. For this reason,

temperature is attained and maintained within 20 min. If using

clean and dry the cell immediately prior to making the test, and

an automatic thermo-regulator cell, follow 14.5.

strictly observe the procedures and precautions outlined in 13.2

to 13.5.

14. Preparation of Specimen and Filling Test Cell

13.2 Dismantle the cell completely and wash all the com-

14.1 Use only a three-terminal cell for these tests.

ponent parts thoroughly with a technical grade of a suitable

solvent (such as acetone, pentane, petroleum ether, or heptane). 14.2 When insulating liquids are heated to elevated tem-

peratures, some of their characteristics undergo a change with

Wash the component parts with a mild abrasive soap or

detergent. Take care not to lay the electrodes on any surface. time and the change, even though of the minutest nature, may

be reflected in the loss measurement. It is therefore desirable

Rinse all parts thoroughly with hot tap water, then with cold tap

water, followed by several rinsings with distilled water. Take that the elapsed time necessary for the test specimen to attain

temperature equilibrium with the test cell be held to a mini-

extreme care during the washing and rinsing of some test cells

to prevent any moisture from entering the thermometer well in mum. For optimum procedure do not exceed 20 min for this

time. It is essential, therefore, that the procedure outlined in

the inner electrode. As a precaution against this eventuality, use

a suitable stopper to plug this opening prior to starting the 14.3, 14.4.1 through 14.4.3, or 14.5.1 through 14.5.4 be closely

followed.

cleaning operation.

13.3 After the surfaces of the measuring, guard, and high 14.3 In order that representative test specimens may be

obtained, gently tilt or invert the sample container and swirl the

voltage electrodes have been washed, do not touch these

surfaces during the rinsing or any subsequent operation. liquid several times. Immediately after mixing the sample, pour

13.4 Place the component parts of the test cell in an oven a quantity of liquid sufficient for four fillings of the test cell

maintained at 110°C for a period of not less than 60 min. Do into a chemically clean, dry beaker and heat on a hot plate to

not dry test cells made of Monel at this elevated temperature a temperature 2°C below the desired test temperature. During

for more than 90 min as oxidation will take place causing the heating period, stir the fluid frequently.

erroneous results. Take care that the surfaces on which the 14.4 Forced-Draft Oven:

component parts of the cell are placed in the oven are clean. 14.4.1 Remove the cell from the test chamber, lift out the

13.5 At the expiration of the drying period, assemble the inner electrode, but do not rest it on any surface, and fill the cell

cell in the oven, using clean cotton gloves as protection for the with a portion of the heated sample. Replace the beaker with

hands and observing the precaution given in 13.3. the remainder of the heated sample on the hot plate. Insert the

13.6 If using a forced-draft oven, quickly transfer the inner electrode and rinse the electrodes by twice raising and

assembled test cell to the test chamber maintained at a lowering the inner electrode. Remove the inner electrode and

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 924

hold it suspended in air; then decant the rinsing liquid and measurements in calculating the relative permittivity from the

immediately fill the cell from the remainder of the heate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.