ASTM D2300-08(2017)

(Test Method)Standard Test Method for Gassing of Electrical Insulating Liquids Under Electrical Stress and Ionization (Modified Pirelli Method)

Standard Test Method for Gassing of Electrical Insulating Liquids Under Electrical Stress and Ionization (Modified Pirelli Method)

SIGNIFICANCE AND USE

4.1 For certain applications when insulating liquid is stressed at high voltage gradients, it is desirable to be able to determine the rate of gas evolution or gas absorption under specified test conditions. At present time correlation of such test results with equipment performance is limited.

4.2 In this test method, hydrogen (along with low molecular weight hydrocarbons) is generated by ionic bombardment of some insulating liquid molecules and absorbed by chemical reaction with other insulating liquid molecules. The value reported is the net effect of these two competing reactions. The aromatic molecules or unsaturated portions of molecules present in insulating liquids are largely responsible for the hydrogen-absorbing reactions. Both molecule type, as well as concentration, affects the gassing tendency result. Saturated molecules tend to be gas evolving. The relation between aromaticity and quantity of unsaturates of the insulating liquid and gassing tendency is an indirect one and cannot be used for a quantitative assessment of either in the insulating liquid.

4.3 This test method measures the tendency of insulating liquids to absorb or evolve gas under conditions of electrical stress and ionization based on the reaction with hydrogen, the predominant gas in the partial discharge. For the test conditions, the activating gas hydrogen, in contrast to other gases, for example, nitrogen, enhances the discrimination of differences in the absorption-evolution patterns exhibited by the insulating liquids. Insulating liquids shown to have gas-absorbing (H2) characteristics in the test have been used to advantage in reducing equipment failures, particularly cables and capacitors. However, the advantage of such insulating liquids in transformers is not well defined and there has been no quantitative relationship established between the gassing tendency as indicated by this test method and the operating performance of the equipment. This test method is not concerne...

SCOPE

1.1 This test method measures the rate at which gas is evolved or absorbed by insulating liquids when subjected to electrical stress of sufficient intensity to cause ionization in cells having specific geometries.

1.2 This test method is not concerned with bubbles arising from supersaturation of the insulating liquid.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions see 5.1.4 and 8.4.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D2300 −08 (Reapproved 2017)

Standard Test Method for

Gassing of Electrical Insulating Liquids Under Electrical

Stress and Ionization (Modified Pirelli Method)

This standard is issued under the fixed designation D2300; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope volume per unit of time from changes in pressure with time

from two specimens run on the same sample.

1.1 This test method measures the rate at which gas is

evolved or absorbed by insulating liquids when subjected to 3.2 Thistestmethodindicateswhetherinsulatingliquidsare

electrical stress of sufficient intensity to cause ionization in gas absorbing or gas evolving under the test conditions.

cells having specific geometries.

4. Significance and Use

1.2 This test method is not concerned with bubbles arising

4.1 For certain applications when insulating liquid is

from supersaturation of the insulating liquid.

stressed at high voltage gradients, it is desirable to be able to

1.3 This standard does not purport to address all of the

determine the rate of gas evolution or gas absorption under

safety concerns, if any, associated with its use. It is the

specified test conditions. At present time correlation of such

responsibility of whoever uses this standard to consult and

test results with equipment performance is limited.

establish appropriate safety and health practices and deter-

4.2 Inthistestmethod,hydrogen(alongwithlowmolecular

mine the applicability of regulatory limitations prior to use.

weight hydrocarbons) is generated by ionic bombardment of

For specific precautions see 5.1.4 and 8.4.

some insulating liquid molecules and absorbed by chemical

reaction with other insulating liquid molecules. The value

2. Referenced Documents

reportedistheneteffectofthesetwocompetingreactions.The

2.1 ASTM Standards:

aromatic molecules or unsaturated portions of molecules pres-

D924Test Method for Dissipation Factor (or Power Factor)

ent in insulating liquids are largely responsible for the

and Relative Permittivity (Dielectric Constant) of Electri-

hydrogen-absorbing reactions. Both molecule type, as well as

cal Insulating Liquids

concentration, affects the gassing tendency result. Saturated

molecules tend to be gas evolving. The relation between

3. Summary of Test Method

aromaticity and quantity of unsaturates of the insulating liquid

and gassing tendency is an indirect one and cannot be used for

3.1 After being saturated with a gas (usually hydrogen), the

a quantitative assessment of either in the insulating liquid.

insulating liquid is subjected to a radial electrical stress. The

gas space above the insulating liquid film is ionized due to the

4.3 This test method measures the tendency of insulating

electrical stresses and therefore the insulating liquid surface at

liquids to absorb or evolve gas under conditions of electrical

the insulating liquid-gas interface is subjected to ionic bom-

stress and ionization based on the reaction with hydrogen, the

bardment. The evolving or absorbing of gas is calculated in

predominant gas in the partial discharge. For the test

conditions, the activating gas hydrogen, in contrast to other

gases, for example, nitrogen, enhances the discrimination of

This test method is under the jurisdiction of ASTM Committee D27 on differences in the absorption-evolution patterns exhibited by

Electrical Insulating Liquids and Gasesand is the direct responsibility of Subcom-

the insulating liquids. Insulating liquids shown to have gas-

mittee D27.05 on Electrical Test.

absorbing (H ) characteristics in the test have been used to

Current edition approved Jan. 1, 2017. Published February 2017. Originally

advantage in reducing equipment failures, particularly cables

approved in 1968. Last previous edition approved in 2008 as D2300-08. DOI:

10.1520/D2300-08R17.

and capacitors. However, the advantage of such insulating

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

liquids in transformers is not well defined and there has been

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

no quantitative relationship established between the gassing

Standards volume information, refer to the standard’s Document Summary page on

tendency as indicated by this test method and the operating

the ASTM website.

The original Pirelli method is described by Guiseppe Palandri and Ugo

performance of the equipment. This test method is not con-

Pellagatti in the paper. “Gli Oli Isolanti per Cavi Elettrici” (Insulating Oils for

cerned with bubble evolution, which may arise from physical

Electric Cables), Elettrotecnica (Milan) Jan. 8, 1955. Translation of this paper is

processes associated with super-saturation of gases in oil or

containedin“MinutesoftheMeetingoftheInsulatedConductorsCommitteeofthe

American Institute of Electrical Engineers,” Nov. 15 and 16, 1955. water vapor bubbles evolving from wet insulation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2300−08 (2017)

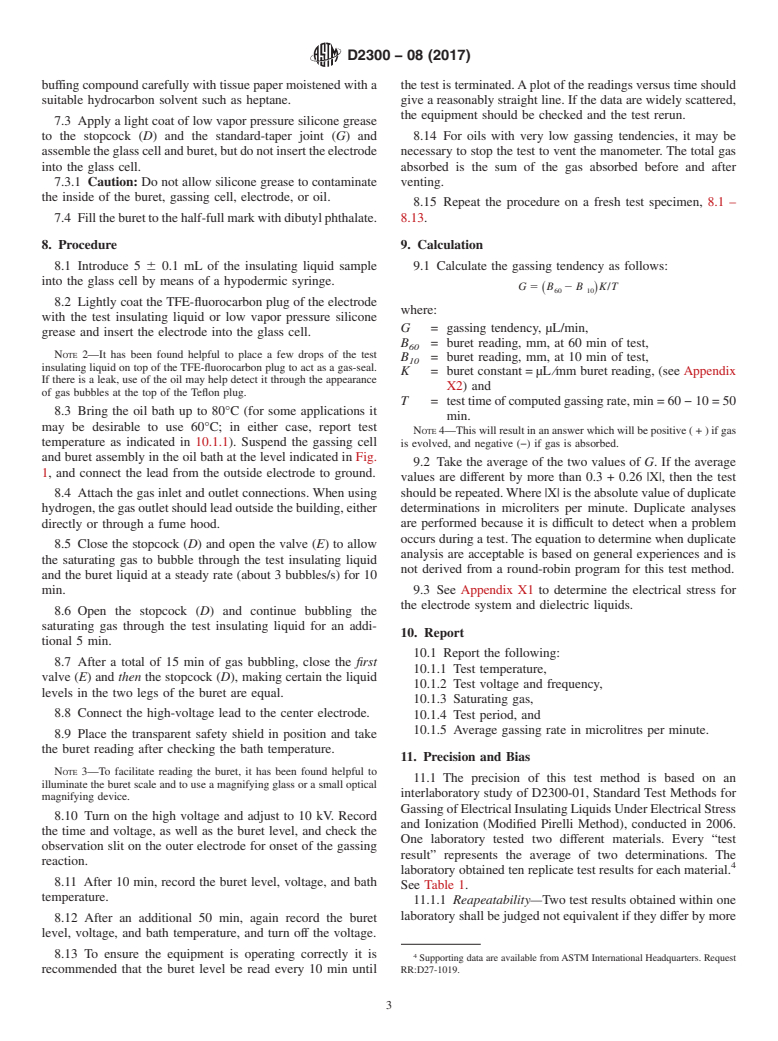

5. Apparatus

5.1 The apparatus for making gassing tests where the

insulating liquid is saturated in the same cell that is used

thereafter to electrically stress the insulating liquid is shown in

Fig. 1. The apparatus consists of the following:

5.1.1 Gassing Cell and Buret Assembly ,asshowninFig.1,

withdimensionsasgiveninFig.2.Thegassingcellconsistsof

the following two components:

5.1.1.1 Cell made of borosilicate glass with the part under

stressconstructedof16mminsidediameterand18mmoutside

diameter truebore tubing. This cell has an outer (ground)

electrode of painted or plated silver with a vertical slit for

observing the insulating liquid level, and a metal conductor

band for ground connection.

5.1.1.2 Hollow High-Voltage Electrode made of 10 6

0.1-mm outside diameter center-less-ground and polished No.

304 stainless steel seamless tubing and containing an 18-gage

stainless steel capillary tubing as a gas passage. The electrode

FIG. 2 Detailed Dimensions of the Glass Cell and the Inner

(High-Voltage) Electrode

shallbesupportedandcenteredbyaprecision-machined24/40

recessedTFE-fluorocarbonplug.A ⁄8-in.needlevalve(E)with

gas inlet is on top of the electrode.

transformer and its controlling equipment shall be of such size

5.1.2 Gas Buret (Fig. 1) made of 7-mm outside diameter

anddesignthatwiththetestspecimeninthecircuit,thevoltage

borosilicate glass tubing with an etched scale, tapered glass

wave shape shall approximate a sinoid with both half cycles

joint (G) for connecting to the gassing cell, a bypass stopcock

closely alike. The ratio of peak-to-rms values should be equal

(D), and three glass bulbs, (A, B, and C).

to the square root of two within 65 % while maintaining 10

5.1.3 OilBathwiththermostaticcontroltomaintainthebath

RV 62%.

at test temperature 60.5°C. The bath shall be equipped with a

stirrer, a heating arrangement capable of maintaining the

6. Reagents and Materials

necessary temperature control, a suitable support for the

6.1 Hydrogen, oxygen-free. See Note 1.

gassing test cell assembly, and a thermometer graduated in

6.2 Dibutyl Phthalate, reagent grade.

0.1°C divisions. As the test is temperature sensitive, it is

importantthatthecalibrationistraceabletoastandard,suchas

6.3 2-Propanol, reagent grade.

NIST.

6.4 Low vapor pressure grease, such as high vacuum

5.1.4 Transparent Safety Shield to protect the operator from

silicone grease.

contact with high voltage.

6.5 Unless otherwise indicated, it is intended that all re-

5.1.5 High-Voltage Transformer, providing a test voltage

agents shall conform to the Committee onAnalytical Reagents

having a frequency in the range of 45 to 65 Hz. The

of the American Chemical Society.

NOTE 1—Hydrogen normally is the saturating gas but other gases, such

as nitrogen, carbon dioxide, argon, or air may be used.

7. Preparation of Apparatus

7.1 Clean the glass cell by first rinsing it inside and outside

with a suitable hydrocarbon solvent such as heptane or other

solventsuitableforthedielectricliquidtesttested.Thenfillthe

cell with the hydrocarbon solvent and scrub to remove waxy

deposits from previous tests. Clean the tapered joint, taking

care that none of the grease enters the cell. Again rinse with

hydrocarbon solvent and blow dry with clean compressed air.

Check the silver electrode and repair if necessary.

7.2 Clean the hollow electrode by blowing a suitable hy-

drocarbon solvent through the capillary tube with compressed

air, rinsing the insulating liquid off the entire electrode with a

suitable hydrocarbon solvent, such as heptane, and wiping off

any waxy deposit with tissue paper. Polish the surface with a

2-propanol soaked towel. If there are visible marks on the

stainless steel shaft of the electrode, they should be polished

FIG. 1 Schematic Diagram of Cell and Manometer Assembly with a suitable device, such as a buffing wheel, wiping off the

D2300−08 (2017)

buffingcompoundcarefullywithtissuepapermoistenedwitha thetestisterminated.Aplotofthereadingsversustimeshould

suitable hydrocarbon solvent such as heptane. give a reasonably straight line. If the data are widely scattered,

the equipment should be checked and the test rerun.

7.3 Apply a light coat of low vapor pressure silicone grease

to the stopcock (D) and the standard-taper joint (G) and 8.14 For oils with very low gassing tendencies, it may be

assembletheglasscellandburet,butdonotinserttheelectrode necessary to stop the test to vent the manometer. The total gas

into the glass cell. absorbed is the sum of the gas absorbed before and after

7.3.1 Caution: Do not allow silicone grease to conta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.