ASTM F914-03

(Test Method)Standard Test Method for Acoustic Emission for Insulated and Non-Insulated Aerial Personnel Devices Without Supplemental Load Handling Attachments

Standard Test Method for Acoustic Emission for Insulated and Non-Insulated Aerial Personnel Devices Without Supplemental Load Handling Attachments

SIGNIFICANCE AND USE

This test method provides a means of evaluating acoustic emissions generated by the rapid release of energy from localized sources within an aerial personnel device under controlled loading. The resultant energy releases occur during intentional application of a controlled predetermined load. These energy releases can be monitored and interpreted by qualified individuals.

This test method permits testing of the major components of an aerial personnel device under controlled loading. This test method utilizes objective criteria for evaluation and may be discontinued at any time to investigate a particular area of concern or prevent a fault from continuing to ultimate failure.

This test method provides a means of detecting acoustic emission sources that may be defects or irregularities, or both, affecting the structural integrity or intended use of the aerial personnel device.

Sources of acoustic emission found with this test method shall be evaluated by either more refined acoustic emission test methods or other nondestructive techniques (visual, liquid penetrant, radiography, ultrasonics, magnetic particle, etc.). Other nondestructive tests may be required to locate defects present in aerial personnel devices.

Defective areas found in aerial personnel devices by this test method should be repaired and retested as appropriate. Repair procedure recommendations are outside the scope of this test method.

SCOPE

1.1 This test method describes a procedure for non-destructive testing using acoustic emission (AE) testing for insulated and non-insulated aerial personnel devices which do not have a supplemental load handling attachment.

1.1.1 Equipment Covered—This test method covers the following types of vehicle-mounted insulated aerial personnel devices:

1.1.1.1 Extensible boom aerial personnel devices,

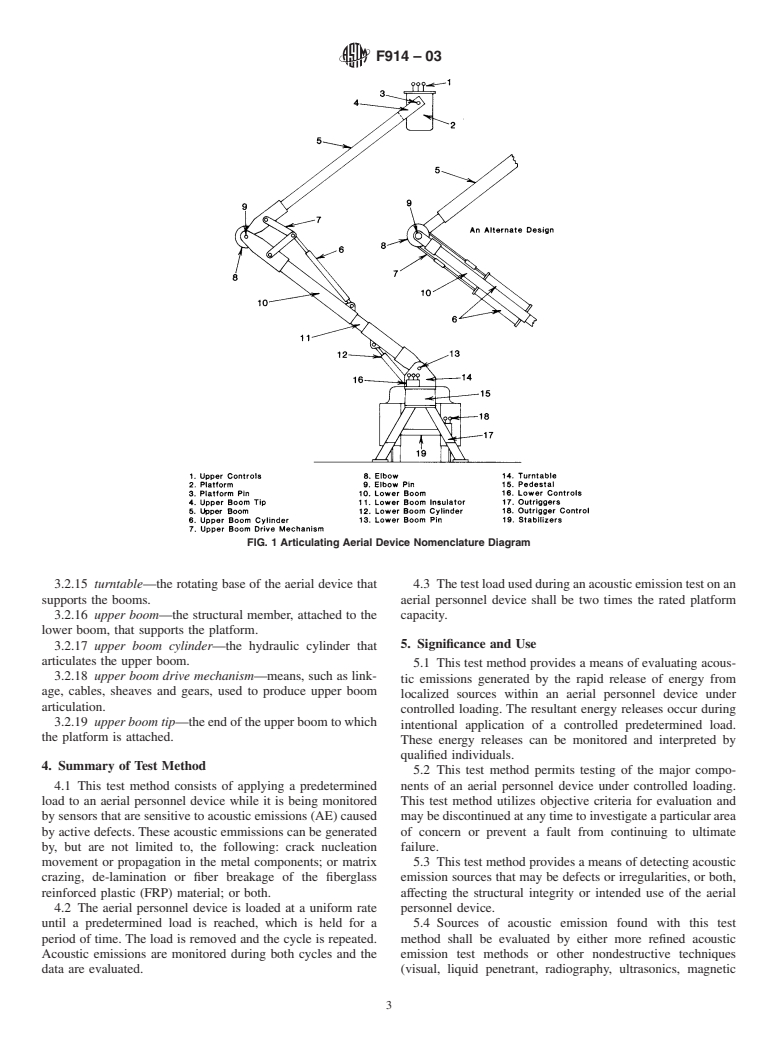

1.1.1.2 Articulating boom aerial personnel devices, and

1.1.1.3 Any combination of 1.1.1.1 and 1.1.1.2.

1.1.2 Equipment Not Covered—This test method does not cover any of the following equipment:

Material-handling aerial devices,

Digger-derricks with platform, and

Cranes with platform.

1.2 The AE test method is used to detect and area-locate emission sources. Verification of emission sources may require the use of other nondestructive test (NDT) methods, such as radiography, ultrasonics, magnetic particle, liquid penetrant, and visual inspection. Warning—This test method requires that external loads be applied to the superstructure of the vehicle under test. During the test, caution must be taken to safeguard personnel and equipment against unexpected failure or instability of the vehicle or components.

Note 1—This test method is not intended to be a stand alone NDT method for the verification of the structural integrity of an aerial device. Other NDT methods should be used to supplement the results.

1.3 The values given in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F914–03

Standard Test Method for

Acoustic Emission for Insulated and Non-Insulated Aerial

Personnel Devices Without Supplemental Load Handling

1

Attachments

ThisstandardisissuedunderthefixeddesignationF914;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method describes a procedure for non-

destructive testing using acoustic emission (AE) testing for

2. Referenced Documents

insulated and non-insulated aerial personnel devices which do

2

2.1 ASTM Standards:

not have a supplemental load handling attachment.

E569 Practice for Acoustic Emission Monitoring of Struc-

1.1.1 Equipment Covered—This test method covers the

tures During Controlled Stimulation

following types of vehicle-mounted insulated aerial personnel

E610 Terminology Relating to Acoustic Emission

devices:

E650 Guide for Mounting Piezoelectric Acoustic Emission

1.1.1.1 Extensible boom aerial personnel devices,

Sensors

1.1.1.2 Articulating boom aerial personnel devices, and

E750 Practice for CharacterizingAcoustic Emission Instru-

1.1.1.3 Any combination of 1.1.1.1 and 1.1.1.2.

mentation

1.1.2 Equipment Not Covered—This test method does not

E976 Guide for Determining the Reproducibility ofAcous-

cover any of the following equipment:

tic Emission Sensor Response

1.1.2.1 Material-handling aerial devices,

F2174 Practice for Verifying Acoustic Emission Sensor

1.1.2.2 Digger-derricks with platform, and

Response

1.1.2.3 Cranes with platform.

2.2 ANSI Standard:

1.2 The AE test method is used to detect and area-locate

ANSI A92.2 Standard for Vehicle-Mounted Elevating and

emissionsources.Verificationofemissionsourcesmayrequire

3

Rotating Aerial Devices

the use of other nondestructive test (NDT) methods, such as

2.3 ASNT Standard:

radiography, ultrasonics, magnetic particle, liquid penetrant,

4

ASNT Recommended Practice SNT-TC-1A

and visual inspection. Warning—This test method requires

2.4 CARP/SPI Standard:

that external loads be applied to the superstructure of the

Recommended Practice for Acoustic Emission Testing of

vehicle under test. During the test, caution must be taken to

5

Fiberglass Tanks-Vessels

safeguard personnel and equipment against unexpected failure

or instability of the vehicle or components.

3. Terminology

NOTE 1—This test method is not intended to be a stand alone NDT

3.1 Definitions:

method for the verification of the structural integrity of an aerial device.

3.1.1 acoustic emission (AE)—the class of phenomena

Other NDT methods should be used to supplement the results.

whereby elastic waves are generated by the rapid release of

1.3 The values given in inch-pound units are to be regarded

energy from a localized source or sources within a material, or

as the standard. The SI units given in parentheses are for

thetransientelasticwave(s)sogenerated.Acousticemissionis

information only.

the recommended term for general use. Other terms that have

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee F18 on the ASTM website.

3

Electrical Protective Equipment for Workers and is the direct responsibility of Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Subcommittee F18.55 on Inspection and Non-Destructive Test Methods for Aerial 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Devices. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Current edition approved Sept. 10, 2003. Published November 2003. Originally 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

5

approved in 1985. Last previous edition approved in 1998 as F914–98. DOI: AvailablefromtheSocietyofPlasticsIndustry,355LexingtonAve.,NewYork,

10.1520/F0914-03. NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F914–03

been used in AE literature include stress wave emission, structure, made of a material having a high dielectric strength,

microseismic activity, and emission or acoustic emission with usually FRP or the equivalent.

other qualifying modifiers.

3.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.