ASTM F2683-11(2017)

(Guide)Standard Guide for Selection of Booms for Oil-Spill Response

Standard Guide for Selection of Booms for Oil-Spill Response

SIGNIFICANCE AND USE

3.1 This guide is intended to aid in the selection of oil spill containment boom for various response conditions. It is not intended to define rigid sets of boom selection standards.

3.2 This guide is intended to be used by persons generally familiar with the practical aspects of oil spill cleanup operations including on-scene response coordinators, planners, oil spill management teams, oil spill removal organizations, and plan evaluators.

3.3 Minimum requirements for boom dimensions, buoyancy, and tensile strength are specified in Guide F1523/F1523M. This guide provides additional qualitative information to aid in boom selection.

3.4 Seven general types of boom systems are described in this standard. Each description includes a summary of the operating principle and a list of selection considerations.

3.5 Definitions relating to boom design, boom types, boom components, boom characteristics, and boom performance can be found in Terminology F818.

3.6 Selection considerations are included to help the user on the selection of a particular boom type or category. Users are cautioned that within each category there may be a wide variation in performance among the various booms.

SCOPE

1.1 This guide covers the selection of boom for the containment and recovery of marine oil spills.

1.2 This guide does not address the compatibility of spill-control equipment with spill products. It is the user’s responsibility to ensure that any equipment selected is compatible with anticipated products and conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2683 − 11(Reapproved 2017)

Standard Guide for

Selection of Booms for Oil-Spill Response

This standard is issued under the fixed designation F2683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This guide covers the selection of boom for the contain- 3.1 This guide is intended to aid in the selection of oil spill

ment and recovery of marine oil spills. containment boom for various response conditions. It is not

intended to define rigid sets of boom selection standards.

1.2 This guide does not address the compatibility of spill-

control equipment with spill products. It is the user’s respon- 3.2 This guide is intended to be used by persons generally

sibility to ensure that any equipment selected is compatible

familiar with the practical aspects of oil spill cleanup opera-

with anticipated products and conditions. tions including on-scene response coordinators, planners, oil

spill management teams, oil spill removal organizations, and

1.3 The values stated in inch-pound units are to be regarded

plan evaluators.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.3 Minimum requirements for boom dimensions,

and are not considered standard. buoyancy, and tensile strength are specified in Guide F1523/

F1523M. This guide provides additional qualitative informa-

1.4 This standard does not purport to address all of the

tion to aid in boom selection.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.4 Seven general types of boom systems are described in

priate safety and health practices and determine the applica-

this standard. Each description includes a summary of the

bility of regulatory limitations prior to use.

operating principle and a list of selection considerations.

1.5 This international standard was developed in accor-

3.5 Definitions relating to boom design, boom types, boom

dance with internationally recognized principles on standard-

components, boom characteristics, and boom performance can

ization established in the Decision on Principles for the

be found in Terminology F818.

Development of International Standards, Guides and Recom-

3.6 Selection considerations are included to help the user on

mendations issued by the World Trade Organization Technical

the selection of a particular boom type or category. Users are

Barriers to Trade (TBT) Committee.

cautioned that within each category there may be a wide

2. Referenced Documents

variation in performance among the various booms.

2.1 ASTM Standards:

4. Boom Selection Considerations

F818 Terminology Relating to Spill Response Booms and

Barriers

4.1 Selecting a boom for a particular application involves

F1093 Test Methods for Tensile Strength Characteristics of

examining the boom’s likely performance with regards to a

Oil Spill Response Boom

range of operational requirements. The following recommen-

F1523/F1523M Guide for Selection of Booms in Accor-

dations are a guide to this process with the requirements

dance With Water Body Classifications

grouped together according to the operating environment, the

F2152/F2152M Guide for In-Situ Burning of Spilled Oil:

slick conditions, and boom performance criteria. Comments on

Fire-Resistant Boom

each of these operational requirements, specific to each boom

type, are given in Section 6.

4.2 The general statements below describe likely boom

This guide is under the jurisdiction of ASTM Committee F20 on Hazardous

performance with regards to individual design elements, and

Substances and Oil Spill Response and is the direct responsibility of Subcommittee

F20.11 on Control.

shouldbeusedwiththeunderstandingthatoverallperformance

Current edition approved May 1, 2017. Published May 2017. Originally

is affected by a combination of design elements. For example,

approved in 2011. Last previous edition approved in 2011 as F2683-11. DOI:

lower than typical buoyancy may be counteracted by providing

10.1520/F2683–11R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or increased longitudinal flexibility.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3 Wave and Current Conditions—In general, booms work

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. best in calm conditions or in a long, gentle swell with no

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2683 − 11(2017)

current. Performance is degraded in high waves, in short, the depth of the water or the acceleration of the water in the

choppy or breaking waves, and in strong currents. restricted area between the bottom of the skirt and the stream

bed may cause entrainment losses.

4.4 Roll Response in Currents—Good roll response is im-

portant to effective containment in high currents and waves. 4.7 Forces on a Boom:

Roll response is improved with: sufficient ballast; ballast 4.7.1 Straight-line drag force is tension on a boom caused

located low on the skirt; flotation located away from the boom by towing it from one end. This may limit transit speed of

centerline; and tension members located low on the skirt. vessels en route to a spill. Tow speed should be adjusted to

account for the strength of the towline, strength of the boom

4.5 Heave Response in Waves—Good heave response will

tension members, strength of end connectors where the towline

reduce losses due to splashover. Heave response is a function

is attached, and stability of the boom under tow.

of the buoyancy, boom mass, and the float water plane area.

4.7.2 Towing a boom in a catenary configuration (U or J)

Heave response is improved with increased waterplane area

will generate much higher drag forces than towing in a straight

and buoyancy-to-weight ratio.

line. Booms are towed in this way at very low speeds, typically

4.5.1 Heave response is also a function of the longitudinal

(0.5 to 0.75 knots). Tow forces are easily estimated as a

flexibility of a boom as a wave moves along its length. Boom

function of boom draft, length, gap ratio, and tow or current

freeboard and draft are reduced if a boom is too rigid to move

4,5

speed.

with the wave pattern.Water plane area and buoyancy are good

measures of heave response if a boom has the flexibility to 4.8 Boom Strength Criteria—Tensile strength is an impor-

move with the wave pattern. Good flexibility helps a boom tant boom criterion and also one of the most difficult to

follow the surface of a moving wave. Boom flexibility is measure accurately and to understand. There are several

generally enhanced by shorter float sections and closer float problems. If a boom is stressed to failure, tension members

spacing, providing flex between floats is allowed by the fabric. may not all fail together. This means that the strength of a

Good flexibility is also provided by a continuous, but limber boom is not necessarily equal to the aggregate strength of its

flotation material, such as a continuously inflated flotation assembled components.Although all tension members contrib-

chamber. ute to overall strength, boom strength may be determined by its

4.5.2 Calm Water booms should have a gross buoyancy-to- weakest component. For example, boom connectors may fail

weight (BW) ratio of at least 3:1, Protected Water booms 4:1, long before the tension members, so boom strength would be

and Open Water booms 8:1. (See “Recommendations for limited to the strength of the weakest component. The only

Selection of Spill Containment Booms,” Guide F1523/ way to accurately determine boom strength is to test a sample

F1523M.) to failure. (See Test Methods F1093.)

4.5.3 In general, booms with buoyancy-to-weight ratios

5. Boom Selection Checklist

lower than those specified in Guide F1523/F1523M may not be

as effective in other than benign conditions (that is, no wind, 5.1 The primary selection criteria are generally draft and

freeboard dimensions, strength, and buoyancy-to-weight ratio.

waves, or currents). Exceptions to the specified minimum BW

Buoyancy-to-weight ratios greater than those listed may result

ratios include booms designed for special applications, such as

boom designed for static containment (that is, not towed), in improved boom performance under certain conditions;

however, further research is required before minimum values

fire-resistant boom, and permanent boom. The latter two types

of boom typically have low buoyancy-to-weight ratios as a greater than those shown can be established. As a result, users

should be alert to special requirements that would demand

result of their use of heavy, durable materials for fire-resistance

and long-term deployment, respectively. These booms may higher buoyancy-to-weight ratios than those listed in the guide.

The user should be particularly alert when selecting heavy,

have BW ratios lower than the minimums listed in Guide

F1523/F1523M. permanent boom. Many of these products have size and

strength appropriate for Protected Water or Open Water, but

4.6 Freeboard Height and Skirt Depth—Adequate freeboard

some have very low buoyancy-to-weight ratios and therefore

is desirable to prevent splashover losses. Excessive freeboard

may not be as effective except in Calm Water.

can lead to problems in high winds, with the wind depressing

the freeboard and raising the skirt if the appropriate relation- 5.2 Boomflexibilityisimportantforapplicationsinmedium

swells and short-period waves. Shorter flotation elements

ships between freeboard, draft, and ballast are not maintained.

4.6.1 Skirt depth is typically half to two-thirds of the total generally provide better flexibility. Further, the distance be-

tween flotation sections should be less than one half the

boom height.Adeeper skirt does not contain more oil and may

be detrimental in high current conditions. In a fast current, average wave length to prevent out of phase motions being set

up. Good flexibility is also provided by a continuous but

wateracceleratestomovearoundthebottomoftheskirt,which

is likely to cause entrainment losses. Generally a skirt should flexible flotation material or an inflated flotation chamber.

not be deeper than 6 in. (150 mm) in a current greater than 1.5

5.3 Externalflotation,rigginglines,orothersurfacefeatures

knots and 3 in. (75 mm) for speeds greater than 3 knots. In

may interrupt the fluid flow along the boom. A boom that has

1 1

shallow water, the skirt should be no greater than ⁄3 rd to ⁄5 th

World Catalog of Oil Spill Response Products, 9th Edition, 2008.

Schulze, R. and Potter, S. “Estimating Forces on Oil Spill Containment

Hansen, K. and Coe, T., Oil Spill Response in Fast Currents: A Field Guide, Booms,” Spill Technology Newsletter, Vol 27, Jan-Dec 2002, Environment Canada,

U.S. Coast Guard Report CG-D-01-02, 2001 . Ottawa, Ontario.

F2683 − 11(2017)

TABLE 1 Boom Selection Criteria

Boom Type Typical General Buoyancy Roll Heave

Applications Comments Response Response

Fence Permanent or long-term Easy to deploy, Generally low, Generally low; Generally low;

deployment; resistant to varies with may be improved may be improved

fueling areas, damage, but design. by ballast and by increasing water

around ships, relatively bulky off-center float plane area and

power plant for storage. area. B:W ratio.

outfalls, and other

calm and protected

water applications.

Curtain, internal Various calm and Fairly easy B:W ratios Good; helped by Good; improved

foam flotation protected water to store. generally in the flexibility and by short float

applications. range of 2 to 8. bottom tension sections to increase

member. flexibility.

Curtain, external Industrial, permanent, Durable. Easy to B:W ratios Good; helped by Fair to good;

foam flotation and other calm store and deploy; generally in the flexible fabric and helped by B:W

and protected water generally more range of 2 to 8. ballast. ratio and flexibility.

applications. expensive than

curtain boom

with internal

foam.

Self-inflatable Calm, protected, Rapid deployment. B:W ratios Good; good Good resulting

curtain and open water Low storage generally >10. flexibility and from high B:W

applications. volume. Typically Buoyancy could bottom tension and flexibility.

Generally not used stored be lost from puncture help roll.

for industrial on reels. or leaking valve.

applications or

long-term

deployment.

Pressure-inflatable Calm, protected, Deployment B:W ratios Good due to Good due to high

curtain and open water somewhat slower generally >10. bottom tension B:W ratio and

applications. than self-inflatable Buoyancy could and flexibility. flexibility.

Generally not curtain. Typically be lost from puncture

used for industrial stored on reels. or leaking valve.

applications or

long-term

deployment.

Fire resistant Used to contain Generally designed B:W ratios Generally poor Generally poor

an oil slick for for one burn generally in the range due to weight and due to weight and

in situ burning. application; some of2to5; low B:W; low B:W;

Conventional can be stored generally low depends on boom depends on

booms may be used and reused. due to use of type. boom type.

to direct oil into relatively heavy

burn pocket of fire-resistant

fire-resistant materials.

boom.

Tidal seal Used in the Used to bridge Only enough Generally good; Poor due to low

intertidal zone, the gap between to rise with tide; controlled by B:W (note: generally

perpendicular or land and water. controlled by buoyancy and not an issue in

parallel to shore, water ballast. ballast. intertidal applications).

to prevent oil

from moving

along shoreline

or into intertidal

areas.

a consistent profile along its length, and that is free of surface 5.8 Handles located along the top of the boom aid in

irregularities will promote laminar fluid flow along the boom

deployment and handling.

and reduce losses related to eddy currents.Aconsistent profile

5.9 Booms can deteriorate in storage, particularly when

is also less prone to collecting debris.

exposed to the elements, to extreme temperatures, to extreme

5.4 Materials should be strong enough to resist puncture by

humidity, and when handled in extreme temperatures. Selec-

debris. With air flotation booms, puncture resistance is a prime

tion of appropriate f

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2683 − 11(Reapproved 2017)

Standard Guide for

Selection of Booms for Oil-Spill Response

This standard is issued under the fixed designation F2683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This guide covers the selection of boom for the contain- 3.1 This guide is intended to aid in the selection of oil spill

ment and recovery of marine oil spills.

containment boom for various response conditions. It is not

intended to define rigid sets of boom selection standards.

1.2 This guide does not address the compatibility of spill-

control equipment with spill products. It is the user’s respon-

3.2 This guide is intended to be used by persons generally

sibility to ensure that any equipment selected is compatible familiar with the practical aspects of oil spill cleanup opera-

with anticipated products and conditions.

tions including on-scene response coordinators, planners, oil

spill management teams, oil spill removal organizations, and

1.3 The values stated in inch-pound units are to be regarded

plan evaluators.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.3 Minimum requirements for boom dimensions,

and are not considered standard.

buoyancy, and tensile strength are specified in Guide F1523/

F1523M. This guide provides additional qualitative informa-

1.4 This standard does not purport to address all of the

tion to aid in boom selection.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.4 Seven general types of boom systems are described in

priate safety and health practices and determine the applica-

this standard. Each description includes a summary of the

bility of regulatory limitations prior to use.

operating principle and a list of selection considerations.

1.5 This international standard was developed in accor-

3.5 Definitions relating to boom design, boom types, boom

dance with internationally recognized principles on standard-

components, boom characteristics, and boom performance can

ization established in the Decision on Principles for the

be found in Terminology F818.

Development of International Standards, Guides and Recom-

3.6 Selection considerations are included to help the user on

mendations issued by the World Trade Organization Technical

the selection of a particular boom type or category. Users are

Barriers to Trade (TBT) Committee.

cautioned that within each category there may be a wide

2. Referenced Documents variation in performance among the various booms.

2.1 ASTM Standards:

4. Boom Selection Considerations

F818 Terminology Relating to Spill Response Booms and

Barriers

4.1 Selecting a boom for a particular application involves

F1093 Test Methods for Tensile Strength Characteristics of

examining the boom’s likely performance with regards to a

Oil Spill Response Boom

range of operational requirements. The following recommen-

F1523/F1523M Guide for Selection of Booms in Accor-

dations are a guide to this process with the requirements

dance With Water Body Classifications

grouped together according to the operating environment, the

F2152/F2152M Guide for In-Situ Burning of Spilled Oil:

slick conditions, and boom performance criteria. Comments on

Fire-Resistant Boom

each of these operational requirements, specific to each boom

type, are given in Section 6.

4.2 The general statements below describe likely boom

This guide is under the jurisdiction of ASTM Committee F20 on Hazardous

performance with regards to individual design elements, and

Substances and Oil Spill Response and is the direct responsibility of Subcommittee

F20.11 on Control.

should be used with the understanding that overall performance

Current edition approved May 1, 2017. Published May 2017. Originally

is affected by a combination of design elements. For example,

approved in 2011. Last previous edition approved in 2011 as F2683-11. DOI:

lower than typical buoyancy may be counteracted by providing

10.1520/F2683–11R17.

increased longitudinal flexibility.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3 Wave and Current Conditions—In general, booms work

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. best in calm conditions or in a long, gentle swell with no

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2683 − 11(2017)

current. Performance is degraded in high waves, in short, the depth of the water or the acceleration of the water in the

choppy or breaking waves, and in strong currents. restricted area between the bottom of the skirt and the stream

bed may cause entrainment losses.

4.4 Roll Response in Currents—Good roll response is im-

portant to effective containment in high currents and waves. 4.7 Forces on a Boom:

Roll response is improved with: sufficient ballast; ballast 4.7.1 Straight-line drag force is tension on a boom caused

located low on the skirt; flotation located away from the boom by towing it from one end. This may limit transit speed of

centerline; and tension members located low on the skirt. vessels en route to a spill. Tow speed should be adjusted to

account for the strength of the towline, strength of the boom

4.5 Heave Response in Waves—Good heave response will

tension members, strength of end connectors where the towline

reduce losses due to splashover. Heave response is a function

is attached, and stability of the boom under tow.

of the buoyancy, boom mass, and the float water plane area.

4.7.2 Towing a boom in a catenary configuration (U or J)

Heave response is improved with increased waterplane area

will generate much higher drag forces than towing in a straight

and buoyancy-to-weight ratio.

line. Booms are towed in this way at very low speeds, typically

4.5.1 Heave response is also a function of the longitudinal

(0.5 to 0.75 knots). Tow forces are easily estimated as a

flexibility of a boom as a wave moves along its length. Boom

function of boom draft, length, gap ratio, and tow or current

freeboard and draft are reduced if a boom is too rigid to move

4,5

speed.

with the wave pattern. Water plane area and buoyancy are good

measures of heave response if a boom has the flexibility to 4.8 Boom Strength Criteria—Tensile strength is an impor-

move with the wave pattern. Good flexibility helps a boom tant boom criterion and also one of the most difficult to

follow the surface of a moving wave. Boom flexibility is measure accurately and to understand. There are several

generally enhanced by shorter float sections and closer float problems. If a boom is stressed to failure, tension members

spacing, providing flex between floats is allowed by the fabric. may not all fail together. This means that the strength of a

Good flexibility is also provided by a continuous, but limber boom is not necessarily equal to the aggregate strength of its

flotation material, such as a continuously inflated flotation assembled components. Although all tension members contrib-

chamber. ute to overall strength, boom strength may be determined by its

4.5.2 Calm Water booms should have a gross buoyancy-to- weakest component. For example, boom connectors may fail

weight (BW) ratio of at least 3:1, Protected Water booms 4:1, long before the tension members, so boom strength would be

and Open Water booms 8:1. (See “Recommendations for limited to the strength of the weakest component. The only

Selection of Spill Containment Booms,” Guide F1523/ way to accurately determine boom strength is to test a sample

F1523M.) to failure. (See Test Methods F1093.)

4.5.3 In general, booms with buoyancy-to-weight ratios

5. Boom Selection Checklist

lower than those specified in Guide F1523/F1523M may not be

5.1 The primary selection criteria are generally draft and

as effective in other than benign conditions (that is, no wind,

waves, or currents). Exceptions to the specified minimum BW freeboard dimensions, strength, and buoyancy-to-weight ratio.

ratios include booms designed for special applications, such as Buoyancy-to-weight ratios greater than those listed may result

in improved boom performance under certain conditions;

boom designed for static containment (that is, not towed),

fire-resistant boom, and permanent boom. The latter two types however, further research is required before minimum values

greater than those shown can be established. As a result, users

of boom typically have low buoyancy-to-weight ratios as a

result of their use of heavy, durable materials for fire-resistance should be alert to special requirements that would demand

higher buoyancy-to-weight ratios than those listed in the guide.

and long-term deployment, respectively. These booms may

have BW ratios lower than the minimums listed in Guide The user should be particularly alert when selecting heavy,

permanent boom. Many of these products have size and

F1523/F1523M.

strength appropriate for Protected Water or Open Water, but

4.6 Freeboard Height and Skirt Depth—Adequate freeboard

some have very low buoyancy-to-weight ratios and therefore

is desirable to prevent splashover losses. Excessive freeboard

may not be as effective except in Calm Water.

can lead to problems in high winds, with the wind depressing

5.2 Boom flexibility is important for applications in medium

the freeboard and raising the skirt if the appropriate relation-

ships between freeboard, draft, and ballast are not maintained. swells and short-period waves. Shorter flotation elements

generally provide better flexibility. Further, the distance be-

4.6.1 Skirt depth is typically half to two-thirds of the total

boom height. A deeper skirt does not contain more oil and may tween flotation sections should be less than one half the

average wave length to prevent out of phase motions being set

be detrimental in high current conditions. In a fast current,

water accelerates to move around the bottom of the skirt, which up. Good flexibility is also provided by a continuous but

flexible flotation material or an inflated flotation chamber.

is likely to cause entrainment losses. Generally a skirt should

not be deeper than 6 in. (150 mm) in a current greater than 1.5

5.3 External flotation, rigging lines, or other surface features

knots and 3 in. (75 mm) for speeds greater than 3 knots. In

may interrupt the fluid flow along the boom. A boom that has

1 1

shallow water, the skirt should be no greater than ⁄3 rd to ⁄5 th

World Catalog of Oil Spill Response Products, 9th Edition, 2008.

Schulze, R. and Potter, S. “Estimating Forces on Oil Spill Containment

Hansen, K. and Coe, T., Oil Spill Response in Fast Currents: A Field Guide, Booms,” Spill Technology Newsletter, Vol 27, Jan-Dec 2002, Environment Canada,

U.S. Coast Guard Report CG-D-01-02, 2001 . Ottawa, Ontario.

F2683 − 11(2017)

TABLE 1 Boom Selection Criteria

Boom Type Typical General Buoyancy Roll Heave

Applications Comments Response Response

Fence Permanent or long-term Easy to deploy, Generally low, Generally low; Generally low;

deployment; resistant to varies with may be improved may be improved

fueling areas, damage, but design. by ballast and by increasing water

around ships, relatively bulky off-center float plane area and

power plant for storage. area. B:W ratio.

outfalls, and other

calm and protected

water applications.

Curtain, internal Various calm and Fairly easy B:W ratios Good; helped by Good; improved

foam flotation protected water to store. generally in the flexibility and by short float

applications. range of 2 to 8. bottom tension sections to increase

member. flexibility.

Curtain, external Industrial, permanent, Durable. Easy to B:W ratios Good; helped by Fair to good;

foam flotation and other calm store and deploy; generally in the flexible fabric and helped by B:W

and protected water generally more range of 2 to 8. ballast. ratio and flexibility.

applications. expensive than

curtain boom

with internal

foam.

Self-inflatable Calm, protected, Rapid deployment. B:W ratios Good; good Good resulting

curtain and open water Low storage generally >10. flexibility and from high B:W

applications. volume. Typically Buoyancy could bottom tension and flexibility.

Generally not used stored be lost from puncture help roll.

for industrial on reels. or leaking valve.

applications or

long-term

deployment.

Pressure-inflatable Calm, protected, Deployment B:W ratios Good due to Good due to high

curtain and open water somewhat slower generally >10. bottom tension B:W ratio and

applications. than self-inflatable Buoyancy could and flexibility. flexibility.

Generally not curtain. Typically be lost from puncture

used for industrial stored on reels. or leaking valve.

applications or

long-term

deployment.

Fire resistant Used to contain Generally designed B:W ratios Generally poor Generally poor

an oil slick for for one burn generally in the range due to weight and due to weight and

in situ burning. application; some of 2 to 5; low B:W; low B:W;

Conventional can be stored generally low depends on boom depends on

booms may be used and reused. due to use of type. boom type.

to direct oil into relatively heavy

burn pocket of fire-resistant

fire-resistant materials.

boom.

Tidal seal Used in the Used to bridge Only enough Generally good; Poor due to low

intertidal zone, the gap between to rise with tide; controlled by B:W (note: generally

perpendicular or land and water. controlled by buoyancy and not an issue in

parallel to shore, water ballast. ballast. intertidal applications).

to prevent oil

from moving

along shoreline

or into intertidal

areas.

a consistent profile along its length, and that is free of surface 5.8 Handles located along the top of the boom aid in

irregularities will promote laminar fluid flow along the boom deployment and handling.

and reduce losses related to eddy currents. A consistent profile

5.9 Booms can deteriorate in storage, particularly when

is also less prone to collecting debris.

exposed to the elements, to extreme temperatures, to extreme

5.4 Materials should be strong enough to resist puncture by

humidity, and when handled in extreme temperatures. Selec-

debris. With air flotation booms, puncture resistance is a prime

tion of appropriate fabrics and good storage practices are

consideration.

im

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2683 − 11 F2683 − 11(Reapproved 2017)

Standard Guide for

Selection of Booms for Oil-Spill Response

This standard is issued under the fixed designation F2683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers the selection of boom for the containment and recovery of marine oil spills.

1.2 This guide does not address the compatibility of spill-control equipment with spill products. It is the user’s responsibility

to ensure that any equipment selected is compatible with anticipated products and conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

F818 Terminology Relating to Spill Response Booms and Barriers

F1093 Test Methods for Tensile Strength Characteristics of Oil Spill Response Boom

F1523F1523/F1523M Guide for Selection of Booms in Accordance With Water Body Classifications

F2152F2152/F2152M Guide for In-Situ Burning of Spilled Oil: Fire-Resistant Boom

3. Significance and Use

3.1 This guide is intended to aid in the selection of oil spill containment boom for various response conditions. It is not intended

to define rigid sets of boom selection standards.

3.2 This guide is intended to be used by persons generally familiar with the practical aspects of oil spill cleanup operations

including on-scene response coordinators, planners, oil spill management teams, oil spill removal organizations, and plan

evaluators.

3.3 Minimum requirements for boom dimensions, buoyancy, and tensile strength are specified in Guide F1523F1523/F1523M.

This guide provides additional qualitative information to aid in boom selection.

3.4 Seven general types of boom systems are described in this standard. Each description includes a summary of the operating

principle and a list of selection considerations.

3.5 Definitions relating to boom design, boom types, boom components, boom characteristics, and boom performance can be

found in Terminology F818.

3.6 Selection considerations are included to help the user on the selection of a particular boom type or category. Users are

cautioned that within each category there may be a wide variation in performance among the various booms.

This guide is under the jurisdiction of ASTM Committee F20 on Hazardous Substances and Oil Spill Response and is the direct responsibility of Subcommittee F20.11

on Control.

Current edition approved April 1, 2011May 1, 2017. Published April 2011May 2017. Originally approved in 2011. Last previous edition approved in 2011 as F2683-11.

DOI: 10.1520/F2683–11.10.1520/F2683–11R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2683 − 11(2017)

4. Boom Selection Considerations

4.1 Selecting a boom for a particular application involves examining the boom’s likely performance with regards to a range of

operational requirements. The following recommendations are a guide to this process with the requirements grouped together

according to the operating environment, the slick conditions, and boom performance criteria. Comments on each of these

operational requirements, specific to each boom type, are given in Section 6.

4.2 The general statements below describe likely boom performance with regards to individual design elements, and should be

used with the understanding that overall performance is affected by a combination of design elements. For example, lower than

typical buoyancy may be counteracted by providing increased longitudinal flexibility.

4.3 Wave and Current Conditions—In general, booms work best in calm conditions or in a long, gentle swell with no current.

Performance is degraded in high waves, in short, choppy or breaking waves, and in strong currents.

4.4 Roll Response in Currents—Good roll response is important to effective containment in high currents and waves. Roll

response is improved with: sufficient ballast; ballast located low on the skirt; flotation located away from the boom centerline; and

tension members located low on the skirt.

4.5 Heave Response in Waves—Good heave response will reduce losses due to splashover. Heave response is a function of the

buoyancy, boom mass, and the float water plane area. Heave response is improved with increased waterplane area and

buoyancy-to-weight ratio.

4.5.1 Heave response is also a function of the longitudinal flexibility of a boom as a wave moves along its length. Boom

freeboard and draft are reduced if a boom is too rigid to move with the wave pattern. Water plane area and buoyancy are good

measures of heave response if a boom has the flexibility to move with the wave pattern. Good flexibility helps a boom follow the

surface of a moving wave. Boom flexibility is generally enhanced by shorter float sections and closer float spacing, providing flex

between floats is allowed by the fabric. Good flexibility is also provided by a continuous, but limber flotation material, such as

a continuously inflated flotation chamber.

4.5.2 Calm Water booms should have a gross buoyancy-to-weight (BW) ratio of at least 3:1, Protected Water booms 4:1, and

Open Water booms 8:1. (See “Recommendations for Selection of Spill Containment Booms,” Guide F1523F1523/F1523M.)

4.5.3 In general, booms with buoyancy-to-weight ratios lower than those specified in Guide F1523F1523/F1523M may not be

as effective in other than benign conditions (that is, no wind, waves, or currents). Exceptions to the specified minimum BW ratios

include booms designed for special applications, such as boom designed for static containment (that is, not towed), fire-resistant

boom, and permanent boom. The latter two types of boom typically have low buoyancy-to-weight ratios as a result of their use

of heavy, durable materials for fire-resistance and long-term deployment, respectively. These booms may have BW ratios lower

than the minimums listed in Guide F1523F1523/F1523M.

4.6 Freeboard Height and Skirt Depth—Adequate freeboard is desirable to prevent splashover losses. Excessive freeboard can

lead to problems in high winds, with the wind depressing the freeboard and raising the skirt if the appropriate relationships between

freeboard, draft, and ballast are not maintained.

4.6.1 Skirt depth is typically half to two-thirds of the total boom height. A deeper skirt does not contain more oil and may be

detrimental in high current conditions. In a fast current, water accelerates to move around the bottom of the skirt, which is likely

to cause entrainment losses. Generally a skirt should not be deeper than 6 in. (150 mm) in a current greater than 1.5 knots and 3

1 1

In shallow water, the skirt should be no greater than ⁄3 rd to ⁄5 th the depth of the

in. (75 mm) for speeds greater than 3 knots.

water or the acceleration of the water in the restricted area between the bottom of the skirt and the stream bed may cause

entrainment losses.

4.7 Forces on a Boom:

4.7.1 Straight-line drag force is tension on a boom caused by towing it from one end. This may limit transit speed of vessels

en route to a spill. Tow speed should be adjusted to account for the strength of the towline, strength of the boom tension members,

strength of end connectors where the towline is attached, and stability of the boom under tow.

4.7.2 Towing a boom in a catenary configuration (U or J) will generate much higher drag forces than towing in a straight line.

Booms are towed in this way at very low speeds, typically (0.5 to 0.75 knots). Tow forces are easily estimated as a function of

4,5

boom draft, length, gap ratio, and tow or current speed.

4.8 Boom Strength Criteria—Tensile strength is an important boom criterion and also one of the most difficult to measure

accurately and to understand. There are several problems. If a boom is stressed to failure, tension members may not all fail together.

This means that the strength of a boom is not necessarily equal to the aggregate strength of its assembled components. Although

all tension members contribute to overall strength, boom strength may be determined by its weakest component. For example,

Hansen, K. and Coe, T., Oil Spill Response in Fast Currents: A Field Guide, U.S. Coast Guard Report CG-D-01-02, 2001 .

World Catalog of Oil Spill Response Products, 9th Edition, 2008.

Schulze, R. and Potter, S. “Estimating Forces on Oil Spill Containment Booms,” Spill Technology Newsletter, Vol 27, Jan-Dec 2002, Environment Canada, Ottawa,

Ontario.

F2683 − 11(2017)

boom connectors may fail long before the tension members, so boom strength would be limited to the strength of the weakest

component. The only way to accurately determine boom strength is to test a sample to failure. (See Test Methods F1093.)

5. Boom Selection Checklist

5.1 The primary selection criteria are generally draft and freeboard dimensions, strength, and buoyancy-to-weight ratio.

Buoyancy-to-weight ratios greater than those listed may result in improved boom performance under certain conditions; however,

further research is required before minimum values greater than those shown can be established. As a result, users should be alert

to special requirements that would demand higher buoyancy-to-weight ratios than those listed in the guide. The user should be

particularly alert when selecting heavy, permanent boom. Many of these products have size and strength appropriate for Protected

Water or Open Water, but some have very low buoyancy-to-weight ratios and therefore may not be as effective except in Calm

Water.

5.2 Boom flexibility is important for applications in medium swells and short-period waves. Shorter flotation elements generally

provide better flexibility. Further, the distance between flotation sections should be less than one half the average wave length to

prevent out of phase motions being set up. Good flexibility is also provided by a continuous but flexible flotation material or an

inflated flotation chamber.

5.3 External flotation, rigging lines, or other surface features may interrupt the fluid flow along the boom. A boom that has a

consistent profile along its length, and that is free of surface irregularities will promote laminar fluid flow along the boom and

reduce losses related to eddy currents. A consistent profile is also less prone to collecting debris.

5.4 Materials should be strong enough to resist puncture by debris. With air flotation booms, puncture resistance is a prime

consideration.

5.5 Anchor points are recommended at about 50 ft (15 m) intervals.

5.6 Booms should be packaged for ease in transportation. Storage volume is important for storage and handling.

5.7 Booms should be easy to assemble, deploy, and retrieve.

5.8 Handles located along the top of the boom aid in deployment and handling.

5.9 Booms can deteriorate in storage, particularly when exposed to the elements, to extreme temperatures, to extreme humidity,

and when handled in extreme temperatures. Selection of appropriate fabrics and good storage practices are important to slow

deterioration and extend the life of the boom.

6. Description of Boom Types

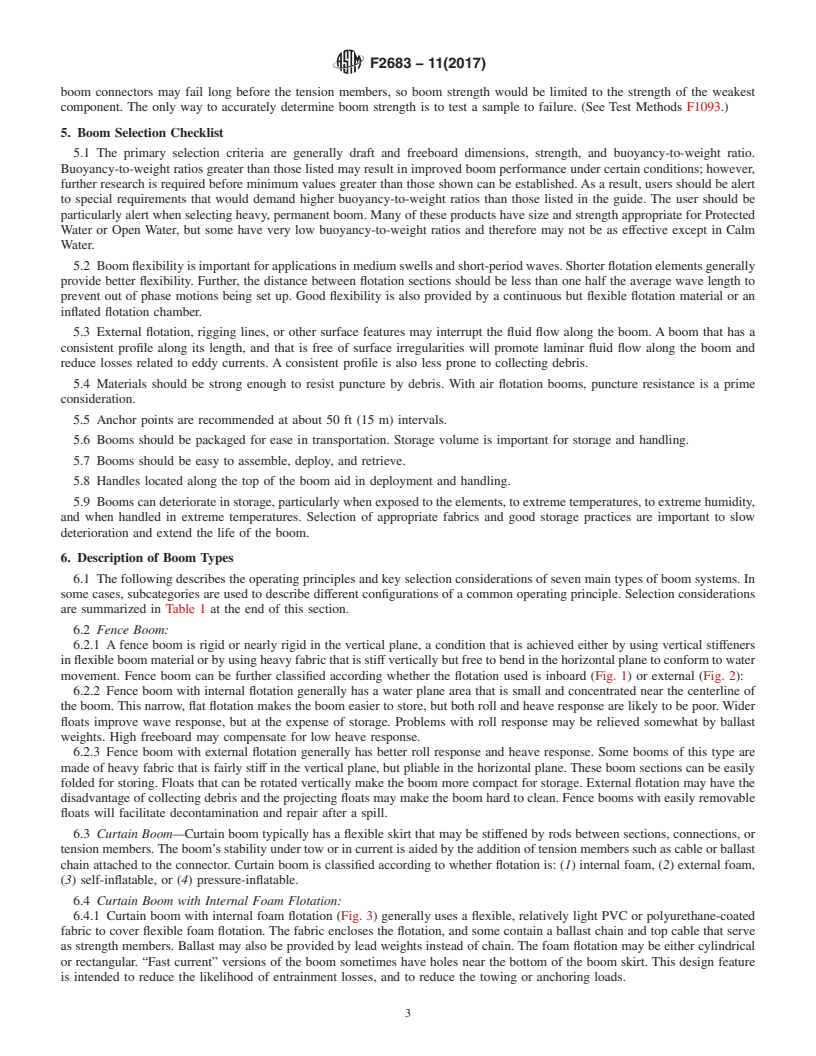

6.1 The following describes the operating principles and key selection considerations of seven main types of boom systems. In

some cases, subcategories are used to describe different configurations of a common operating principle. Selection considerations

are summarized in Table 1 at the end of this section.

6.2 Fence Boom:

6.2.1 A fence boom is rigid or nearly rigid in the vertical plane, a condition that is achieved either by using vertical stiffeners

in flexible boom material or by using heavy fabric that is stiff vertically but free to bend in the horizontal plane to conform to water

movement. Fence boom can be further classified according whether the flotation used is inboard (Fig. 1) or external (Fig. 2):

6.2.2 Fence boom with internal flotation generally has a water plane area that is small and concentrated near the centerline of

the boom. This narrow, flat flotation makes the boom easier to store, but both roll and heave response are likely to be poor. Wider

floats improve wave response, but at the expense of storage. Problems with roll response may be relieved somewhat by ballast

weights. High freeboard may compensate for low heave response.

6.2.3 Fence boom with external flotation generally has better roll response and heave response. Some booms of this type are

made of heavy fabric that is fairly stiff in the vertical plane, but pliable in the horizontal plane. These boom sections can be easily

folded for storing. Floats that can be rotated vertically make the boom more compact for storage. External flotation may have the

disadvantage of collecting debris and the projecting floats may make the boom hard to clean. Fence booms with easily removable

floats will facilitate decontamination and repair after a spill.

6.3 Curtain Boom—Curtain boom typically has a flexible skirt that may be stiffened by rods between sections, connections, or

tension members. The boom’s stability under tow or in current is aided by the addition of tension members such as cable or ballast

chain attached to the connector. Curtain boom is classified according to whether flotation is: (1) internal foam, (2) external foam,

(3) self-inflatable, or (4) p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.