ASTM E1868-02

(Test Method)Standard Test Method for Loss-On-Drying by Thermogravimetry

Standard Test Method for Loss-On-Drying by Thermogravimetry

SCOPE

1.1 This test method covers a procedure for determining the amount of volatile matter of any kind that is driven off from a test specimen under a specific set of temperature and time conditions. This test method determines only the mass of material lost, not its identity.

1.2 This test method is applicable to a wide variety of solid or liquid materials, mixtures or blends where the major component is stable at the test temperature.

1.3 The applicable temperature range for this test method is generally between ambient temperature and 1000°C.

1.4 Electronic instrumentation or automated data analysis and data reduction systems or treatments equivalent to this method may be used.

Note 1—Users are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine the necessary equivalency prior to use.

1.5 SI units are the standard.

1.6 There is no ISO standard equivalent to this test method.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1868 – 02

Standard Test Method for

1

Loss-On-Drying by Thermogravimetry

This standard is issued under the fixed designation E 1868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2595 Test Method for Evaporation Loss of Lubricating

6

Greases Over Wide-Temperature Range

1.1 This test method covers a procedure for determining the

D 2832 Guide for Determining Volatile and Nonvolatile

amount of volatile matter of any kind that is driven off from a

7

Content of Paint and Related Coatings

test specimen under a specific set of temperature and time

D 3175 Test Method for Moisture in the Analysis Sample of

conditions. This test method determines only the mass of

8

Coal and Coke

material lost, not its identity.

9

D 4893 Test Method for Determination of Pitch Volatility

1.2 This test method is applicable to a wide variety of solid

E 359 Test Method for Chemical Analysis of Soda Ash

or liquid materials, mixtures or blends where the major

10

(Sodium Carbonate)

component is stable at the test temperature.

11

E 473 Terminology Relating to Thermal Analysis

1.3 The applicable temperature range for this test method is

E 897 Test Method for Volatile Matter in the Analysis

generally between ambient temperature and 1000°C.

12

Sample of Refuse-Derived Fuel

1.4 Electronic instrumentation or automated data analysis

E 1131 Test Method for Compositional Analysis by Ther-

and data reduction systems or treatments equivalent to this

11

mogravimetry

method may be used.

E 1142 Terminology Relating to Thermophysical Proper-

11

NOTE 1—Users are expressly advised that all such instruments or

ties

techniques may not be equivalent. It is the responsibility of the user to

E 1582 Practice for Calibration of Temperature Scale for

determine the necessary equivalency prior to use.

11

Thermogravimetry

1.5 SI units are the standard.

E 1860 Test Method for Elapsed Time Calibration of Ther-

11

1.6 There is no ISO standard equivalent to this test method.

mal Analyzers

1.7 This standard does not purport to address all of the

E 2040 Test Method for Mass Scale Calibration of Thermo-

11

safety concerns, if any, associated with its use. It is the

gravimetric Analyzers

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1 Definitions:

3.1.1 Specific technical terms used in this test method are

2. Referenced Documents

defined in Terminology E 473 and Terminology E 1142.

2.1 ASTM Standards:

4. Summary of Test Method

D 6 Test Method for Loss on Heating of Oil and Asphaltic

2

Compounds

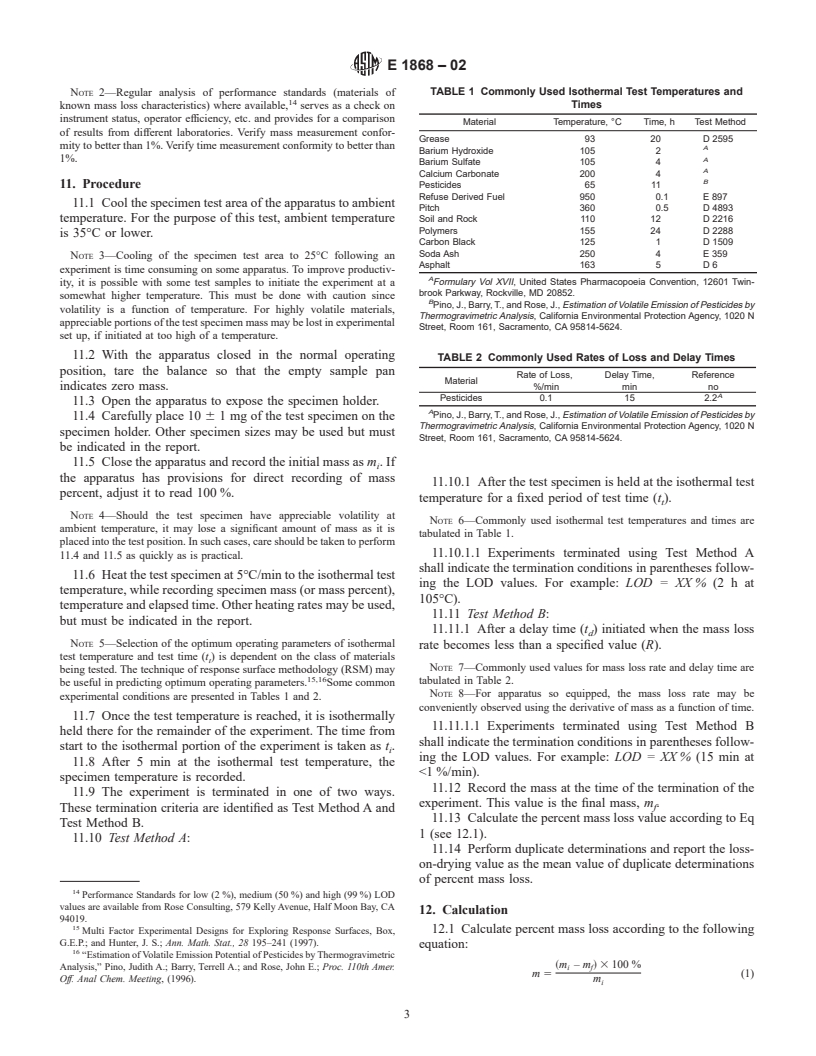

4.1 A specimen of known mass is heated at a constant

3

D 1509 Test Method for Carbon Black—Heating Loss

temperature while its mass is continuously measured as a

D 2216 Test Method for Laboratory Determination of Water

function of time. At the end of a pre-determined time interval,

4

(Moisture) Content of Soil and Rock

or when the loss reaches a pre-determined rate, the mass loss of

D 2288 Test Method for Weight Loss of Plasticizers on

the specimen is recorded as a percent of the original mass. This

5

Heating

value is identified as the loss-on-drying (LOD) value. The

LOD value is a function of both temperature and time.

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

6

Methods. Annual Book of ASTM Standards, Vol 05.01.

7

Current edition approved August 10, 2002. Published October 2002. Originally Annual Book of ASTM Standards, Vol 06.01.

8

published as E 1868–97. Last previous edition E 1868–97. Annual Book of ASTM Standards, Vol 05.06

2 9

Annual Book of ASTM Standards, Vol 04.04. Annual Book of ASTM Standards, Vol 05.02

3 10

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 15.05.

4 11

Annual Book of ASTM Standards, Vol 04.08. Annual Book of ASTM Standards, Vol 14.02.

5 12

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 11.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1868–02

Therefore these values must be identified and reported. A 7.1.5 Measurement System, to continuously record speci-

typical LOD value is reported as LOD = XX % (60 min at men temperature to within 60.1°C over the range from 25 to

120°C). 1000°C.

7.1.6 Timer, capable of continuously recording elapsed time

5. Significance and Use up to 20 h to within 60.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.