ASTM A518/A518M-99(2018)

(Specification)Standard Specification for Corrosion-Resistant High-Silicon Iron Castings

Standard Specification for Corrosion-Resistant High-Silicon Iron Castings

ABSTRACT

This specification covers standards for high-silicon iron castings of Grades 1, 2, and 3 intended for severe environment corrosion-resistant services. The alloy shall be produced by any melting and casting process, or combination of processes that will be capable of meeting the specified contents of carbon, manganese, silicon, chromium, molybdenum, and copper. Reference analysis methods are given for each chemical component. Transverse bend test and hydrostatic test shall be performed. Material shall conform to minimum load at center and minimum deflection at center requirements.

SCOPE

1.1 This specification covers high-silicon cast iron castings intended for corrosion-resistant service.

1.2 This specification covers three grades as shown in Table 1. Selection of grade depends on the corrosive service to be experienced by the casting. All three grades are suited for application in severe corrosive environments. However, Grade 2 is particularly suited for application in strong chloride environments, and Grade 3 is recommended for impressed current anodes.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A518/A518M −99 (Reapproved 2018)

Standard Specification for

1

Corrosion-Resistant High-Silicon Iron Castings

This standard is issued under the fixed designationA518/A518M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A438 Test Method for Transverse Testing of Gray Cast Iron

3

(Withdrawn 2003)

1.1 This specification covers high-silicon cast iron castings

E350 Test Methods for Chemical Analysis of Carbon Steel,

intended for corrosion-resistant service.

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

1.2 This specification covers three grades as shown in Table

Wrought Iron

1. Selection of grade depends on the corrosive service to be

E351 Test Methods for ChemicalAnalysis of Cast Iron—All

experienced by the casting. All three grades are suited for

Types

application in severe corrosive environments. However, Grade

2 is particularly suited for application in strong chloride

3. Ordering Information

environments, and Grade 3 is recommended for impressed

3.1 Orders for material under this specification shall include

current anodes.

the following information:

1.3 The values stated in either SI units or inch-pound units

3.1.1 ASTM designation and year of issue.

are to be regarded separately as standard. The values stated in

3.1.2 Grade of high-silicon cast iron (see Section 5).

each system may not be exact equivalents; therefore, each

3.1.3 Number of castings.

system shall be used independently of the other. Combining

3.1.4 Approximate weight of the casting.

values from the two systems may result in nonconformance

3.1.5 Drawing showing the size, shape, dimensions, and

with the standard.

finishing details. The drawing should indicate any critical

dimensions and should give the allowable tolerances on all

1.4 The following safety hazards caveat pertains only to the

dimensions and on the accumulation of dimensions. If the

test method portion, Section 9, of this specification: This

purchaser supplies the pattern, the dimensions of the casting

standarddoesnotpurporttoaddressallofthesafetyconcerns,

shall conform to those predicted by the pattern.

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

3.1.6 Options in this specification, including:

of this standard to establish appropriate safety, health, and

3.1.6.1 The status of the heat treatment of the castings when

environmental practices and determine the applicability of

shipped by the manufacturer (see Section 7).

regulatory limitations prior to use.

3.1.6.2 If the chemical analysis and mechanical test results

1.5 This international standard was developed in accor-

are to be reported to the purchaser (see Section 14).

dance with internationally recognized principles on standard-

3.1.6.3 If a transverse test is required (see 8.1).

ization established in the Decision on Principles for the

3.1.6.4 If hydraulic testing is required, and, if required, the

Development of International Standards, Guides and Recom-

test pressure and the leakage permitted (see 8.2).

mendations issued by the World Trade Organization Technical

3.1.6.5 Any special packing, markings, etc.

Barriers to Trade (TBT) Committee.

4. Method of Manufacture

2. Referenced Documents

2

4.1 The alloy may be produced by any melting and casting

2.1 ASTM Standards:

process, or combination of processes, capable of meeting the

chemical composition and mechanical properties specified.

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGreyandWhite

5. Chemical Composition

Iron Castings.

Current edition approved Dec. 15, 2018. Published December 2018. Originally

5.1 High-silicon iron castings are produced in one of three

approved in 1964. Last previous edition approved in 2012 as A518/A518M – 99

grades, as given in Table 1 of this specification.

(2012). DOI: 10.1520/A0518_A0518M-99R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A518/A518M − 99 (2018)

TABLE 1 Chemical Composition

6.4.3 Carbon—Determine carbon in accordance with sec-

Composition, Weight % tio

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A518/A518M − 99 (Reapproved 2012) A518/A518M − 99 (Reapproved 2018)

Standard Specification for

1

Corrosion-Resistant High-Silicon Iron Castings

This standard is issued under the fixed designation A518/A518M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers high-silicon cast iron castings intended for corrosion-resistant service.

1.2 This specification covers three grades as shown in Table 1. Selection of grade depends on the corrosive service to be

experienced by the casting. All three grades are suited for application in severe corrosive environments. However, Grade 2 is

particularly suited for application in strong chloride environments, and Grade 3 is recommended for impressed current anodes.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

A438 Test Method for Transverse Testing of Gray Cast Iron (Withdrawn 2003)

E350 Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought

Iron

E351 Test Methods for Chemical Analysis of Cast Iron—All Types

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 ASTM designation and year of issue.

3.1.2 Grade of high-silicon cast iron (see Section 5).

3.1.3 Number of castings.

3.1.4 Approximate weight of the casting.

3.1.5 Drawing showing the size, shape, dimensions, and finishing details. The drawing should indicate any critical dimensions

and should give the allowable tolerances on all dimensions and on the accumulation of dimensions. If the purchaser supplies the

pattern, the dimensions of the casting shall conform to those predicted by the pattern.

3.1.6 Options in this specification, including:

3.1.6.1 The status of the heat treatment of the castings when shipped by the manufacturer (see Section 7).

3.1.6.2 If the chemical analysis and mechanical test results are to be reported to the purchaser (see Section 14).

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.01 on Grey and White Iron

Castings.

Current edition approved Oct. 1, 2012Dec. 15, 2018. Published November 2012December 2018. Originally approved in 1964. Last previous edition approved in 20082012

as A518/A518M – 99 (2008).(2012). DOI: 10.1520/A0518_A0518M-99R12.10.1520/A0518_A0518M-99R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

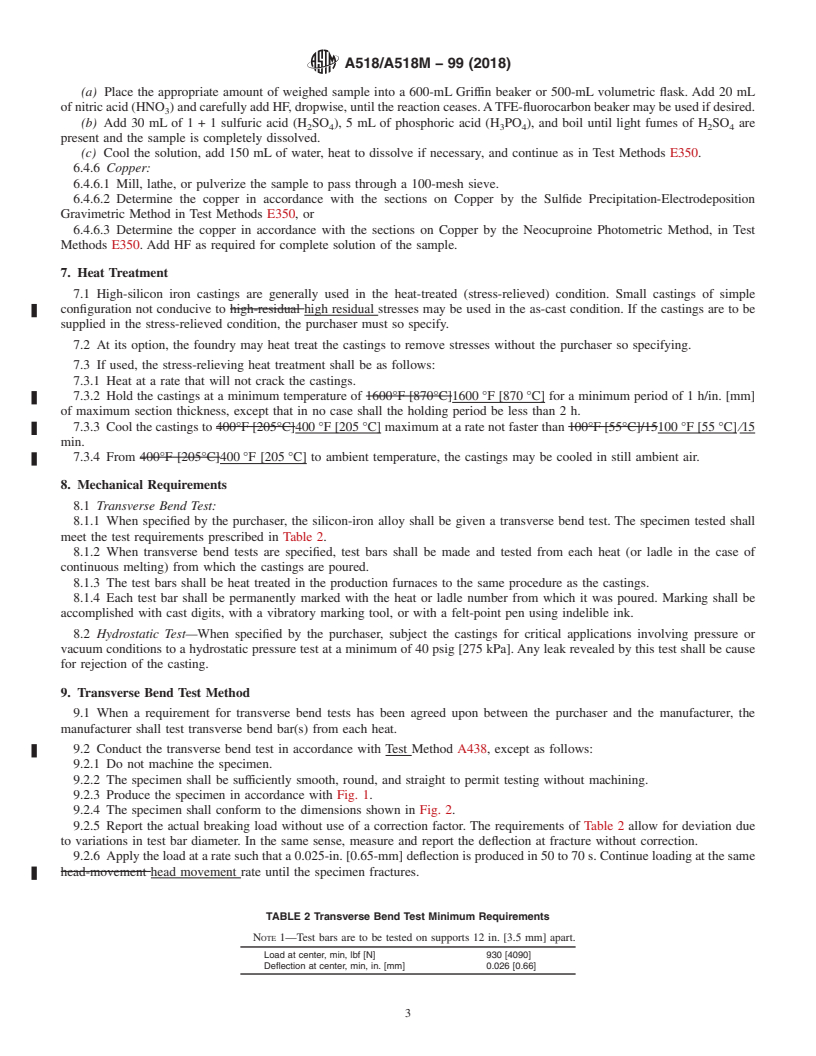

A518/A518M − 99 (2018)

TABLE 1 Chemical Composition

Composition, Weight %

Element

Grade 1 Grade 2 Grade 3

Carbon 0.65–1.10 0.75–1.15 0.70–1.10

Manganese 1.50, max 1.50, max 1.50, max

Silicon 14.20–14.75 14.20–14.75 14.20–14.75

Chromium 0.50,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.