ASTM D7397-10(2016)

(Test Method)Standard Test Method for Cloud Point of Petroleum Products (Miniaturized Optical Method)

Standard Test Method for Cloud Point of Petroleum Products (Miniaturized Optical Method)

SIGNIFICANCE AND USE

5.1 The cloud point of petroleum products and biodiesel fuels is an index of the lowest temperature of their utility for certain applications. Wax crystals of sufficient quantity can plug filters used in some fuel systems.

5.2 Petroleum blending operations require a precise measurement of the cloud point.

5.3 This test method can determine the temperature of the test specimen at which wax crystals have formed sufficiently to be observed as a cloud with a resolution of 0.1°C.

5.4 This test method provides results that are equivalent to Test Method D5773/IP 446. The temperature results of this test method have been found to be warmer than those of Test Method D2500/IP 219 by an average of 0.49 °C; however, no sample specific bias was observed.

5.5 Similar to Test Method D5773/IP 446, this test method determines cloud point in a shorter period of time than Test Method D2500/IP 219.

Note 1: In cases of samples with cloud points near ambient temperatures, time savings may not be realized.

Note 2: This test method eliminates most of the operator time required of Test Method D2500/IP 219.

Note 3: The only utility required by the apparatus described in this test method is electricity with power consumption of approximately 20 W. The electric power can come from an alternating current source (wall receptacle) or direct current source such as a battery or a cigarette lighter plug in a vehicle.

Note 4: The apparatus described by this test method can be made much smaller and lighter than that of Test Methods D5773/IP 446 and D2500/IP 219, allowing full portability.

Note 5: The apparatus used in the 2006 interlaboratory study weighed approximately 1 kg and occupied the space of a small lunch box. See Section 13.

SCOPE

1.1 This test method covers the determination of the cloud point of petroleum products and biodiesel fuels that are transparent in layers 40 mm in thickness by an automatic instrument.

1.2 This test method covers the range of temperatures from –60 °C to +20 °C with temperature resolution of 0.1 °C; however, the range of temperatures included in the 2006 interlaboratory cooperative test program only covered the temperature range of –35 °C to +12 °C. See Section 13.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7397 − 10 (Reapproved 2016)

Standard Test Method for

Cloud Point of Petroleum Products (Miniaturized Optical

Method)

This standard is issued under the fixed designation D7397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the cloud 3.1 Definitions:

point of petroleum products and biodiesel fuels that are

3.1.1 biodiesel, n—fuel comprising mono-alkyl esters of

transparent in layers 40 mm in thickness by an automatic

long-chain fatty acids derived from vegetable oils or animal

instrument.

fats, designated B100.

3.1.1.1 Discussion—Biodiesel is typically produced by a

1.2 This test method covers the range of temperatures from

reaction of vegetable oil or animal fat with an alcohol such as

–60 °C to +20 °C with temperature resolution of 0.1 °C;

methanol or ethanol in the presence of a catalyst to yield

however, the range of temperatures included in the 2006

mono-esters and glycerin.The fuel typically may contain up to

interlaboratory cooperative test program only covered the

14differenttypesoffattyacidsthatarechemicallytransformed

temperature range of –35 °C to +12 °C. See Section 13.

into fatty acid methyl esters (FAME).

1.3 The values stated in SI units are to be regarded as

3.1.2 biodiesel blend (BXX), n—blend of biodiesel fuel with

standard. No other units of measurement are included in this

petroleum-based diesel fuel designated BXX, where XX is the

standard.

volume percentage (as a whole number without the percentage

1.4 This standard does not purport to address all of the

sign) of biodiesel.

safety concerns, if any, associated with its use. It is the

3.1.3 cloud point, n—in petroleum products and biodiesel

responsibility of the user of this standard to establish appro-

fuels, the temperature of a liquid specimen when the smallest

priate safety and health practices and determine the applica-

observable cluster of hydrocarbon crystals first occurs upon

bility of regulatory limitations prior to use.

cooling under prescribed conditions.

2. Referenced Documents

3.1.3.1 Discussion—The cloud point occurs when the tem-

perature of the specimen is low enough to cause hydrocarbon

2.1 ASTM Standards:

D2500 Test Method for Cloud Point of Petroleum Products crystals to precipitate. In a homogeneous liquid, the cloud is

always noted first at the location in the specimen where the

D4057 Practice for Manual Sampling of Petroleum and

specimen temperature is the lowest. The cloud point is the

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and temperature at which the crystals first occur, regardless of their

location in the specimen, and not after extensive crystallization

Petroleum Products

D5773 Test Method for Cloud Point of Petroleum Products has taken place. The hydrocarbon crystals that precipitate at

lower temperatures are typically, but not excluded to, straight

(Constant Cooling Rate Method)

2.2 Energy Institute Standards: chain hydrocarbons commonly called “wax crystals.”

IP 219 Test Method for Cloud Point of Petroleum Products

3.2 Definitions of Terms Specific to This Standard:

IP 446 Test Method for Cloud Point of Petroleum Products

3.2.1 D2500/IP 219 equivalent cloud point, n—temperature

of a specimen, in integers, calculated by applying a bias and

This test method is under the jurisdiction of ASTM Committee D02 on

rounding the result to the next lower integer (see 12.2).

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

3.2.1.1 Discussion—This test method produces results with

Subcommittee D02.07 on Flow Properties.

0.1 °C resolution. Should the user wish to provide results with

Current edition approved April 1, 2016. Published May 2016. Originally

approved in 2007. Last previous edition approved in 2010 as D7397 – 10. DOI:

a similar format to Test Method D2500, then this calculation

10.1520/D7397-10R16.

can be performed (see 12.2). Some apparatus can perform this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

calculation automatically.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.2.2 automatic cloud point, n—temperature of a specimen,

the ASTM website.

3 when the appearance of the cloud is determined under the

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

U.K., http://www.energyinst.org.uk. conditions of this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7397 − 10 (2016)

3.2.2.1 Discussion—The cloud point in this test method is 5.5 Similar to Test Method D5773/IP 446, this test method

determined by an automatic instrument using a miniaturized determines cloud point in a shorter period of time than Test

test receptacle equipped with two optical fibers, one to bring Method D2500/IP 219.

light into the test receptacle and the other to receive light

NOTE 1—In cases of samples with cloud points near ambient

scattered from the specimen.

temperatures, time savings may not be realized.

NOTE2—Thistestmethodeliminatesmostoftheoperatortimerequired

3.2.3 miniaturized optical method, n— in cloud point test

of Test Method D2500/IP 219.

methods, test procedure using prescribed cooling rate, speci-

NOTE3—Theonlyutilityrequiredbytheapparatusdescribedinthistest

men receptacle, and optical system for detection of crystal

methodiselectricitywithpowerconsumptionofapproximately20 W.The

formation.

electric power can come from an alternating current source (wall recep-

tacle) or direct current source such as a battery or a cigarette lighter plug

3.2.3.1 Discussion—The prescribed cooling rate is de-

in a vehicle.

scribed in 4.1, the specimen receptacle is described in Annex

NOTE 4—The apparatus described by this test method can be made

A1, and the optical system for the detection of crystal forma-

much smaller and lighter than that of Test Methods D5773/IP 446 and

tion is described in Annex A1.

D2500/IP 219, allowing full portability.

NOTE 5—The apparatus used in the 2006 interlaboratory study weighed

3.2.4 Peltier device, n—solid state thermoelectric device

approximately 1 kg and occupied the space of a small lunch box. See

constructed with dissimilar semiconductor materials and con-

Section 13.

figured in such a way that it will transfer heat to or away from

a test specimen dependent on the direction of electric current 6. Apparatus

4, 5

applied to the device.

6.1 Automatic Apparatus —The automatic cloud point

apparatus described in this test method consists of a test

4. Summary of Test Method

chamber controlled by a microprocessor that is capable of

controlling the heating and cooling of the test specimen,

4.1 A specimen is cooled by a Peltier device in a miniatur-

optically observing the first appearance of a cloud of wax

ized specimen receptacle (A1.1.1) at a rate of 30 °C 6

crystals and recording the temperature of the specimen de-

5 °C⁄min, while continuously being illuminated by a light

scribed in detail in Annex A1.

source (A1.1.4). The specimen is continuously monitored by

an optical detector (A1.1.5) for the first appearance of a cloud

6.2 The apparatus shall be equipped with a specimen

of wax crystals. Once crystals are first detected, as manifested

receptacle, optical detector, light source, optical fibers, digital

by an increase in scattered light level received by the optical

display, Peltier device, and a specimen temperature measuring

detector, the specimen is warmed at a rate of 15 °C 6

device.

5 °C⁄min.As soon as all the crystals have re-dissolved into the

6.3 The Peltier device shall be capable of heating or cooling

liquid specimen, warming is halted and the specimen is cooled

the test specimen at a rate of 3 °C to 35 °C⁄min.

again; but this time at a slower rate of 6 °C 6 3 °C⁄min.When

6.4 The temperature measuring device in the specimen

crystals first appear under this slower cooling rate, the tem-

receptacle shall be capable of measuring the temperature of the

perature of the specimen is recorded to 0.1 °C resolution as

test specimen from –60 °C to +20 °C at a resolution of 0.1 °C.

cloud point.

NOTE 6—The apparatus described above is covered by patents. If you

5. Significance and Use

are aware of an alternative(s) to the patented items, please attach to your

ballot return a description of the alternative(s). All suggestions will be

5.1 The cloud point of petroleum products and biodiesel

considered by the committee.

fuels is an index of the lowest temperature of their utility for

certain applications. Wax crystals of sufficient quantity can 7. Reagents and Materials

plug filters used in some fuel systems.

7.1 Disposable syringe that is capable of dispensing at least

10 mL 60.5 mLperfulldischargeofsampleintothespecimen

5.2 Petroleum blending operations require a precise mea-

receptacle.

surement of the cloud point.

NOTE 7—The apparatus can also be connected to a sample supply line

5.3 This test method can determine the temperature of the

to receive new sample. The amount of sample required per analysis is the

test specimen at which wax crystals have formed sufficiently to

same as that for the syringe injection procedure (that is, 20 mL 6 1.0 mL

be observed as a cloud with a resolution of 0.1°C.

per analysis). In such cases, a disposable syringe would not be needed.

5.4 This test method provides results that are equivalent to

8. Sampling

Test Method D5773/IP446.The temperature results of this test

method have been found to be warmer than those of Test

8.1 Obtain a sample in accordance with Practices D4057 or

Method D2500/IP 219 by an average of 0.49 °C; however, no D4177.

sample specific bias was observed.

The sole source of supply of the apparatus known to the committee at this time

is Phase Technology Miniature Cloud Point Analyzer available from Phase

ThePeltierdeviceiscoveredbyapatent.Interestedpartiesareinvitedtosubmit Technology, 11168 Hammersmith Gate, Richmond, B.C., Canada V7A-5H8. If you

information regarding the identification of an alternative(s) to this patented item to are aware of alternative suppliers, please provide this information to ASTM

the ASTM International Headquarters. Your comments will receive careful consid- I

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7397 − 10 D7397 − 10 (Reapproved 2016)

Standard Test Method for

Cloud Point of Petroleum Products (Miniaturized Optical

Method)

This standard is issued under the fixed designation D7397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This test method covers the determination of the cloud point of petroleum products and biodiesel fuels that are transparent

in layers 40 mm 40 mm in thickness by an automatic instrument.

1.2 This test method covers the range of temperatures from –60–60 °C to +20°C+20 °C with temperature resolution of

0.1°C;0.1 °C; however, the range of temperatures included in the 2006 interlaboratory cooperative test program only covered the

temperature range of –35–35 °C to +12°C.+12 °C. See Section 13.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2500 Test Method for Cloud Point of Petroleum Products

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D5773 Test Method for Cloud Point of Petroleum Products (Constant Cooling Rate Method)

2.2 Energy Institute Standards:

IP 219 Test Method for Cloud Point of Petroleum Products

IP 446 Test Method for Cloud Point of Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 biodiesel, n—fuel comprising mono-alkyl esters of long-chain fatty acids derived from vegetable oils or animal fats,

designated B100.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

Current edition approved May 1, 2010April 1, 2016. Published August 2010May 2016. Originally approved in 2007. Last previous edition approved in 20082010 as

D7397D7397 – 10.–08. DOI: 10.1520/D7397-10.10.1520/D7397-10R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

3.1.1.1 Discussion—

Biodiesel is typically produced by a reaction of vegetable oil or animal fat with an alcohol such as methanol or ethanol in the

presence of a catalyst to yield mono-esters and glycerin. The fuel typically may contain up to 14 different types of fatty acids that

are chemically transformed into fatty acid methyl esters (FAME).

3.1.2 biodiesel blend (BXX), n—blend of biodiesel fuel with petroleum-based diesel fuel designated BXX, where XX is the

volume percentage (as a whole number without the percentage sign) of biodiesel.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7397 − 10 (2016)

3.1.3 cloud point, n—in petroleum products and biodiesel fuels, the temperature of a liquid specimen when the smallest

observable cluster of hydrocarbon crystals first occurs upon cooling under prescribed conditions.

3.1.3.1 Discussion—

The cloud point occurs when the temperature of the specimen is low enough to cause hydrocarbon crystals to precipitate. In a

homogeneous liquid, the cloud is always noted first at the location in the specimen where the specimen temperature is the lowest.

The cloud point is the temperature at which the crystals first occur, regardless of their location in the specimen, and not after

extensive crystallization has taken place. The hydrocarbon crystals that precipitate at lower temperatures are typically, but not

excluded to, straight chain hydrocarbons commonly called “wax crystals.”

3.2 Definitions of Terms Specific to This Standard:

3.2.1 D2500/IP 219 equivalent cloud point, n—temperature of a specimen, in integers, calculated by applying a bias and

rounding the result to the next lower integer (see 12.2).

3.2.1.1 Discussion—

This test method produces results with 0.1°C0.1 °C resolution. Should the user wish to provide results with a similar format to Test

Method D2500, then this calculation can be performed (see 12.2). Some apparatus can perform this calculation automatically.

3.2.2 automatic cloud point, n—temperature of a specimen, when the appearance of the cloud is determined under the conditions

of this test method.

3.2.2.1 Discussion—

The cloud point in this test method is determined by an automatic instrument using a miniaturized test receptacle equipped with

two optical fibers, one to bring light into the test receptacle and the other to receive light scattered from the specimen.

3.2.3 miniaturized optical method, n— in cloud point test methods, test procedure using prescribed cooling rate, specimen

receptacle, and optical system for detection of crystal formation.

3.2.3.1 Discussion—

The prescribed cooling rate is described in 4.1, the specimen receptacle is described in Annex A1, and the optical system for the

detection of crystal formation is described in Annex A1.

3.2.4 Peltier device, n—solid state thermoelectric device constructed with dissimilar semiconductor materials and configured in

such a way that it will transfer heat to or away from a test specimen dependent on the direction of electric current applied to the

device.

4. Summary of Test Method

4.1 A specimen is cooled by a Peltier device in a miniaturized specimen receptacle (A1.1.1) at a rate of 3030 °C 6

5°C/min,5 °C ⁄min, while continuously being illuminated by a light source (A1.1.4). The specimen is continuously monitored by

an optical detector (A1.1.5) for the first appearance of a cloud of wax crystals. Once crystals are first detected, as manifested by

an increase in scattered light level received by the optical detector, the specimen is warmed at a rate of 1515 °C 6

5°C/min.5 °C ⁄min. As soon as all the crystals have re-dissolved into the liquid specimen, warming is halted and the specimen is

cooled again; but this time at a slower rate of 66 °C 6 3°C/min.3 °C ⁄min. When crystals first appear under this slower cooling

rate, the temperature of the specimen is recorded to 0.1°C0.1 °C resolution as cloud point.

5. Significance and Use

5.1 The cloud point of petroleum products and biodiesel fuels is an index of the lowest temperature of their utility for certain

applications. Wax crystals of sufficient quantity can plug filters used in some fuel systems.

5.2 Petroleum blending operations require a precise measurement of the cloud point.

5.3 This test method can determine the temperature of the test specimen at which wax crystals have formed sufficiently to be

observed as a cloud with a resolution of 0.1°C.

The Peltier device is covered by a patent. Interested parties are invited to submit information regarding the identification of an alternative(s) to this patented item to the

ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee.

D7397 − 10 (2016)

5.4 This test method provides results that are equivalent to Test Method D5773/IP 446. The temperature results of this test

method have been found to be warmer than those of Test Method D2500/IP 219 by an average of 0.49°C;0.49 °C; however, no

sample specific bias was observed.

5.5 Similar to Test Method D5773/IP 446, this test method determines cloud point in a shorter period of time than Test Method

D2500/IP 219.

NOTE 1—In cases of samples with cloud points near ambient temperatures, time savings may not be realized.

NOTE 2—This test method eliminates most of the operator time required of Test Method D2500/IP 219.

NOTE 3—The only utility required by the apparatus described in this test method is electricity with power consumption of approximately 20 watts.

20 W. The electric power can come from an alternating current source (wall receptacle) or direct current source such as a battery or a cigarette lighter

plug in a vehicle.

NOTE 4—The apparatus described by this test method can be made much smaller and lighter than that of Test Methods D5773/IP 446 and D2500/IP

219, allowing full portability.

NOTE 5—The apparatus used in the 2006 interlaboratory study weighed approximately 1 kg 1 kg and occupied the space of a small lunch box. See

Section 13.

6. Apparatus

4, 5

6.1 Automatic Apparatus —The automatic cloud point apparatus described in this test method consists of a test chamber

controlled by a microprocessor that is capable of controlling the heating and cooling of the test specimen, optically observing the

first appearance of a cloud of wax crystals and recording the temperature of the specimen described in detail in Annex A1.

6.2 The apparatus shall be equipped with a specimen receptacle, optical detector, light source, optical fibers, digital display,

Peltier device, and a specimen temperature measuring device.

6.3 The Peltier device shall be capable of heating or cooling the test specimen at a rate of 33 °C to 35°C/min.35 °C ⁄min.

6.4 The temperature measuring device in the specimen receptacle shall be capable of measuring the temperature of the test

specimen from –60–60 °C to +20°C+20 °C at a resolution of 0.1°C.0.1 °C.

NOTE 6—The apparatus described above is covered by patents. If you are aware of an alternative(s) to the patented items, please attach to your ballot

return a description of the alternative(s). All suggestions will be considered by the committee.

7. Reagents and Materials

7.1 Disposable syringe that is capable of dispensing at least 1010 mL 6 0.5 mL 0.5 mL per full discharge of sample into the

specimen receptacle.

NOTE 7—The apparatus can also be connected to a sample supply line to receive new sample. The amount of sample required per analysis is the same

as that for the syringe injection procedure (that is, 2020 mL 6 1.0 mL 1.0 mL per analysis). In such cases, a disposable syringe would not be needed.

8. Sampling

8.1 Obtain a sample in accordance with Practices D4057 or D4177.

8.2 Samples of very viscous materials may be warmed until they are reasonably fluid before they are tested. However, no sample

should be heated more than absolutely necessary.

8.3 The sample shall not be heated above 70°C.70 °C. When the sample is heated above 70 °C, allow the sample to cool below

70°C70 °C before filtering or inserting into the apparatus.

8.4 When moisture is present in the sample, remove the moisture by a method, such as filtration through dry lint-free filter paper,

until the specimen is perfectly clear, but make such filtration at a temperature at least 14°C14 °C above the expected cloud point.

NOTE 8—Moisture will be noticed in the sample as a separate phase or as a haze throughout the entire sample. Generally, a slight haze will not interfere

with the detection of the wax cloud.

9. Preparation of Apparatus

9.1 Prepare the instrument for operation in accordance with the manufacturer’s instructions.

9.2 Turn on the main power switch of the analyzer.

10. Calibration and Standardization

10.1 Ensure that all of the manufacturer’s instructions for calibrating, checking, and operating the apparatus are followed.

10.2 A sample with a mutually agreed upon cloud point can be used to verify performance of the apparatus.

The sole source of supply of the apparatus known to the committee at this time is Phase Technology Miniature Cloud Point Analyzer available from Phase Technology,

11168 Hammersmith Gate, Richmond, B.C., Canada V7A-5H8. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters.

Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

D7397 − 10 (2016)

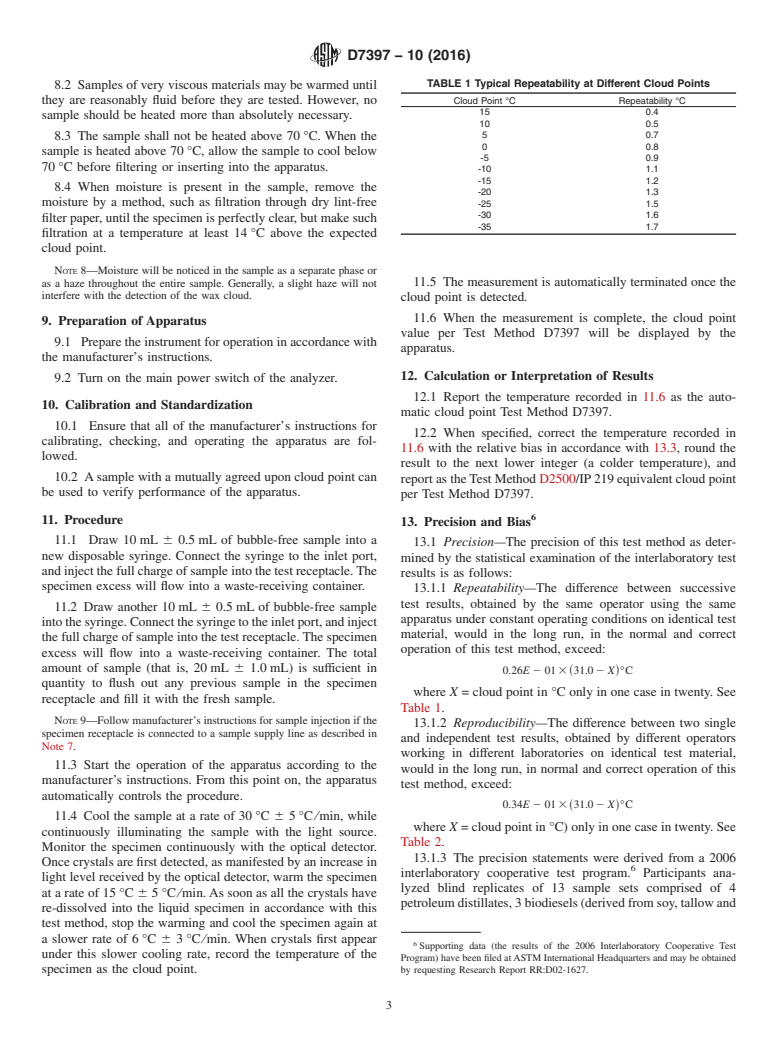

TABLE 1 Typical Repeatability at Different Cloud Points

Cloud Point °C Repeatability °C

15 0.4

10 0.5

5 0.7

0 0.8

-5 0.9

-10 1.1

-15 1.2

-20 1.3

-25 1.5

-30 1.6

-35 1.7

11. Procedure

11.1 Draw 1010 mL 6 0.5 mL 0.5 mL of bubble-free sample into a new disposable syringe. Connect the syringe to the inlet

port, and inject the full charge of sample into the test receptacle. The specimen excess will flow into a waste-receiving container.

11.2 Draw another 1010 mL 6 0.5 mL 0.5 mL of bubble-free sample into the syringe. Connect the syringe to the inlet port, and

inject the full charge of sample into the test receptacle. The specimen excess will flow into a waste-receiving container. The total

amount of sample (that is, 2020 mL 6 1.0 mL) 1.0 mL) is sufficient in quantity to flush out any previous sample in the specimen

receptacle and fill it with the fresh sample.

NOTE 9—Follow manufacturer’s instructions for sample injection if the specimen receptacle is connected to a sample supply line as described in Note

7.

11.3 Start the operation of the apparatus according to the manufacturer’s instructions. From this point on, the apparatus

automatically controls the procedure.

11.4 Cool the sample at a rate of 3030 °C 6 5°C/min,5 °C ⁄min, while continuously illuminating the sample with the light

source. Monitor the specimen continuously with the optical detector. Once crystals are first detected, as manifested by an increase

in light level received by the optical detector, warm the specimen at a rate of 1515 °C 6 5°C/min.5 °C ⁄min. As soon as all the

crystals have re-dissolved into the liquid specimen in accordance with this test method, stop the warming and cool the specimen

again at a slower rate of 66 °C 6 3°C/min.3 °C ⁄min. When crystals first appear under this slower cooling rate, record the

temperature of the specimen as the cloud point.

11.5 The measurement is automatically terminated once the cloud point is detected.

11.6 When the measurement is complete, the cloud point value

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.