ASTM E1157-87(1996)

(Specification)Standard Specification for Sampling and Testing of Reusable Laboratory Glassware

Standard Specification for Sampling and Testing of Reusable Laboratory Glassware

SCOPE

1.1 This specification covers laboratory items for use until they are no longer considered functional for the intended purpose. It is written specifically for reusable items and is not to be confused with disposable (single use) items that are described in other standards.

1.2 This specification covers the sampling inspection and basic testing criteria for the following four types of laboratory glassware: blown and pressed glassware, nongraduated ; blown and pressed glassware, graduated ; tubular glassware, nongraduated; and tubular glassware, graduated.

1.3 This specification is intended to be used in conjunction with a standard specification for a specific laboratory glassware product.

1.4 The following precautionary statement pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1157 – 87 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Sampling and Testing of Reusable Laboratory Glassware

This standard is issued under the fixed designation E 1157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 lot—items of the same respective type, class, style,

and size offered for acceptance at one time that have been

1.1 This specification covers laboratory items for use until

produced by one manufacturer under essentially the same

they are no longer considered functional for the intended

manufacturing conditions.

purpose. It is written specifically for reusable items and is not

3.1.2 inspection—as both “examination” (such as visual

to be confused with disposable (single use) items that are

investigation without the use of special laboratory appliances

described in other standards.

or procedure) and “testing” (determination by technical means

1.2 This specification covers the sampling inspection and

of physical and chemical properties) of the item.

basic testing criteria for the following four types of laboratory

glassware: blown and pressed glassware, nongraduated ;

4. Performance Requirements

blown and pressed glassware, graduated ; tubular glassware,

4.1 The product shall be designed to meet test performance

nongraduated; and tubular glassware, graduated.

requirements specified in Section 6. Testing of individual lots

1.3 This specification is intended to be used in conjunction

may be obviated when process controls are employed and

with a standard specification for a specific laboratory glassware

monitored. Deviation from or changes to established manufac-

product.

turing procedures that could adversely affect performance of a

1.4 The following precautionary statement pertains only to

product shall be cause for performing applicable testing

the test method portion, Section 6, of this specification. This

requirements on a specific lot to verify quality acceptance.

standard does not purport to address all of the safety concerns,

4.2 Alternate testing methods, inspection levels, and sample

if any, associated with its use. It is the responsibility of the user

sizes may also be implemented. Any deviation shall not negate

of this standard to establish appropriate safety and health

responsibility of product from complying with the applicable

practices and determine the applicability of regulatory limita-

test performance standards.

tions prior to use.

4.3 Unless otherwise specified in the contract or purchase

2. Referenced Documents order, the supplier shall be responsible for the performance of

all designated inspection requirements. Except as otherwise

2.1 ASTM Standards:

specified in the contract or purchase order, the supplier may use

C 162 Terminology of Glass and Glass Products

his own or any other facilities suitable for the performance of

E 542 Practice for Calibration of Laboratory Volumetric

the inspection requirements. The purchaser has the right to

Apparatus

perform any of the inspections set forth in the specification

E 671 Specification for Maximum Permissible Thermal Re-

where such inspections are deemed necessary to ensure sup-

sidual Stress in Annealed Glass Laboratory Apparatus

plies conform to prescribed requirements.

2.2 Military Standard:

MIL-STD-105 Sampling Procedures and Tables for Inspec-

5. Sampling and Inspection

tion by Attributes

5.1 Sampling shall be conducted in accordance with MIL-

3. Terminology STD-105 with the levels of inspection and examination and

acceptable quality levels as noted in Tables 1-13 unless

3.1 Definitions of Terms Specific to This Standard:

otherwise agreed upon by purchaser and vendor. Where appli-

cable, distilled water and reagent grade chemicals shall be used

This specification is under the jurisdiction of ASTM Committee E-41 on

throughout the tests. Inspection shall be conducted in accor-

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

dance with applicable section and individual specifications.

Glass Apparatus.

Current edition approved March 27, 1987. Published July 1987.

As defined in Terminology C 162. 6. Test Methods

Annual Book of ASTM Standards, Vol 15.02.

6.1 Leakage Test—The item shall be filled to nominal

Annual Book of ASTM Standards, Vol 14.02.

capacity with distilled water at 25 6 5°C, normally capped or

Available from Specification Sales (3FRSBS) Bldg. 197, Washington Navy

Yard, GSA, Washington, DC 20407.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1157

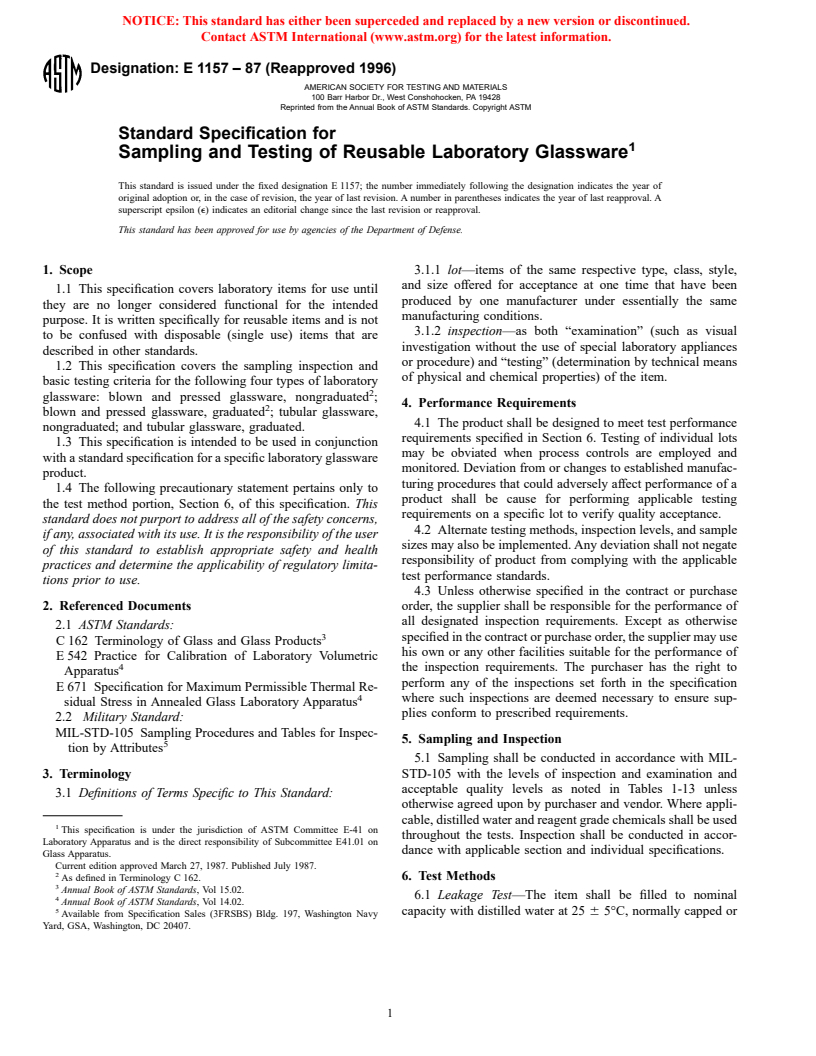

TABLE 1 Examination TABLE 3 Classification of Defects (Graduated)

Visual Inspection Acceptance Major:

Examination Level Quality Level

101—Not free of cracks, unhealed chips, breaks or sharp edges.

102—Not free of checks and open blisters.

Major defects 2 2.5

103—Required components missing.

Minor defects 2 4.0

104—Not free of protruding stones.

Dimensional Examination S-3 2.5

105—Not free of stones (buried) or knots which exceed dimensions in Table 7.

106—Required glass joints, rubber stoppers, stopcock plugs or closures not as

specified.

TABLE 2 BLOWN OR PRESSED ITEMS (GRADUATED AND

107—Capacity or graduation lines of wrong width, missing or not straight.

NONGRADUATED) 1

108—Not free of skips in graduation lines that exceed ⁄4 of the line length.

Classification of Defects (Nongraduated) 109—On Class“ A” items, the “A” or serial number (where specified) is missing.

110—Not free of blemishes in meniscus reading area that interfere with setting

Major:

the meniscus.

101—Not free of cracks, unhealed chips, breaks or sharp edges.

111—Not within stress limits as defined in Specification E 671.

102—Not free of checks and open blisters.

Minor:

103—Required components missing.

201—Identification marking not complete, correct, legible or permanent (See

104—Not free of protruding stones.

A

6.2).

105—Not free of stones (buried) or knots that exceed dimensions in Table 7.

202—Not free of skips in the graduation lines less than ⁄4 of the line length.

106—Required glass joints, rubber stoppers, stopcock plugs or closures not as

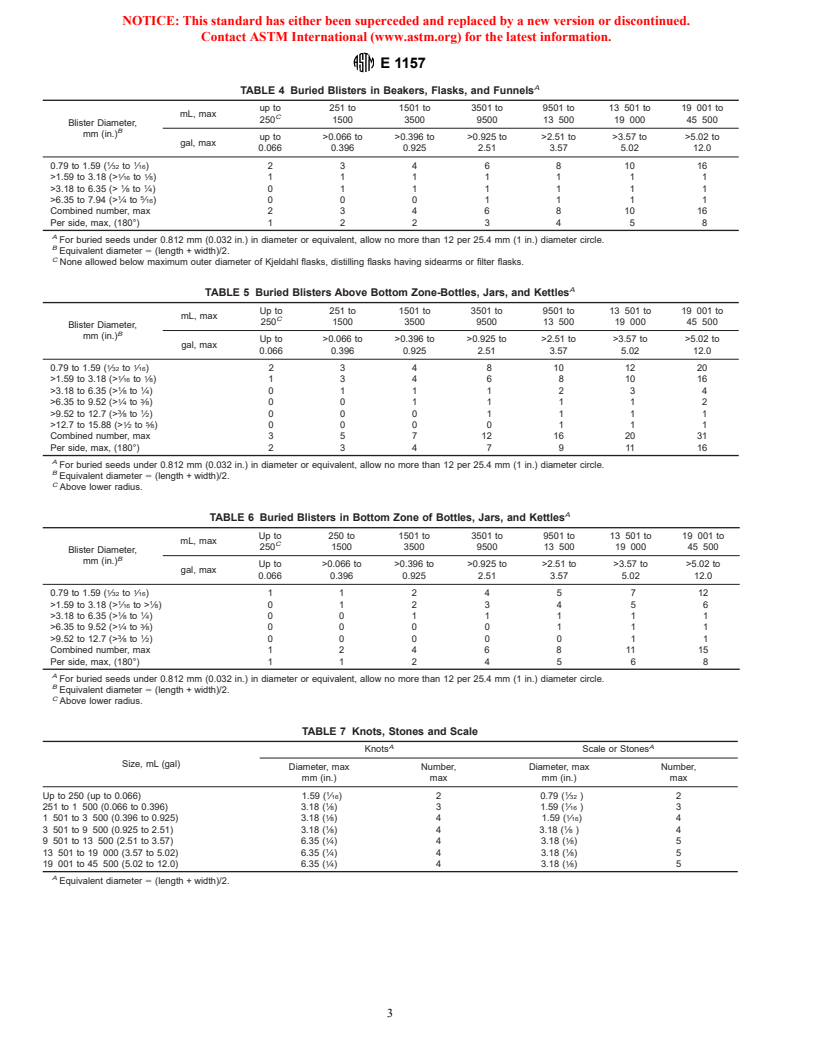

203—Not free of blisters (buried) which exceed dimensions in Table 4, Table 5,

specified.

and Table 6.

107—Not within stress limits as defined in Specification E 671.

204—Not free of wiry cord or deformation that affects intended use or

Minor:

serviceability.

201—Identification marking not complete, correct, legible, and permanent, (see

205—Not free of scale that exceeds dimensions in Table 7.

6.2).

A

202—Not free of blisters (buried) that exceed dimensions in Table 4, Table 5,

Disregard minor smears, smudges or skips in letters or numbers that do not

and Table 6. destroy legibility.

203—Not free of wiry cord or deformation that affects intended use or

standard for the item. The test shall be conducted at room

serviceability.

204—Not free of scale that exceeds dimensions in Table 5.

temperature (25 6 5°C).

6.3.2 Blown or Pressed Items (Graduated) and Tubular

Glassware (Graduated)—Accuracy shall be as defined in

stoppered and laid on side for 60 s. No leakage shall result. appropriate item standard. Testing shall be conducted in

6.2 Permanency of Marking: accordance with procedures in Practice E 542.

6.2.1 Alkali Test—A representative piece of each sample 6.4 Autoclaving—Items with respective cap or cover se-

shall be completely immersed in 1 N sodium hydroxide cured shall be subject to three consecutive autoclaving cycles

solution at room temperature, covered, boiled for 30 min, and at 15 psi for 30 min. Capped items shall be removed after each

allowed to stand in the alkali for an additional hour. The piece autoclaving cycle and allowed to cool for 30 min before

shall then be removed, thoroughly rinsed with distilled water, repeating the heating cycle. Autoclaved items with cap or cover

and dried by rubbing vigorously with a cloth. No appreciable shall be subjected to leakage test. Temperature shall be 121°C.

change in decoration appearance shall result. Loss of gloss 6.5 Pour Test—Fill the item to normal capacity with dis-

shall not be considered a defect. tilled water. Tilt at an angle of 45° and pour approximately one

6.2.2 Acid Test—A representative piece of each sample shall

fourth of the water from the item at such a rate that the water

be completely immersed in concentrated sulfuric acid at room flows in a continuous stream and falls freely from the spout.

temperature and allowed to stand 1 h. The piece shall then be Stream of water should not cling to the outside of the item and

removed, thoroughly rinsed with distilled water, and dried by flow off the bottom.

rubbing vigorously with a cloth. No appreciable change in 6.6 Centrifuge Test—The centrifuge may be any type or

decoration appearance shall result. Loss of gloss shall not be model commercially available or normally employed in labo-

considered a defect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.